Sealed connection of power lithium battery top cover electrode column and its manufacturing and assembling method

An electrode column and lithium battery technology, which is applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high defect rate, poor sealing performance of electrode columns, and complicated manufacturing and assembly processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

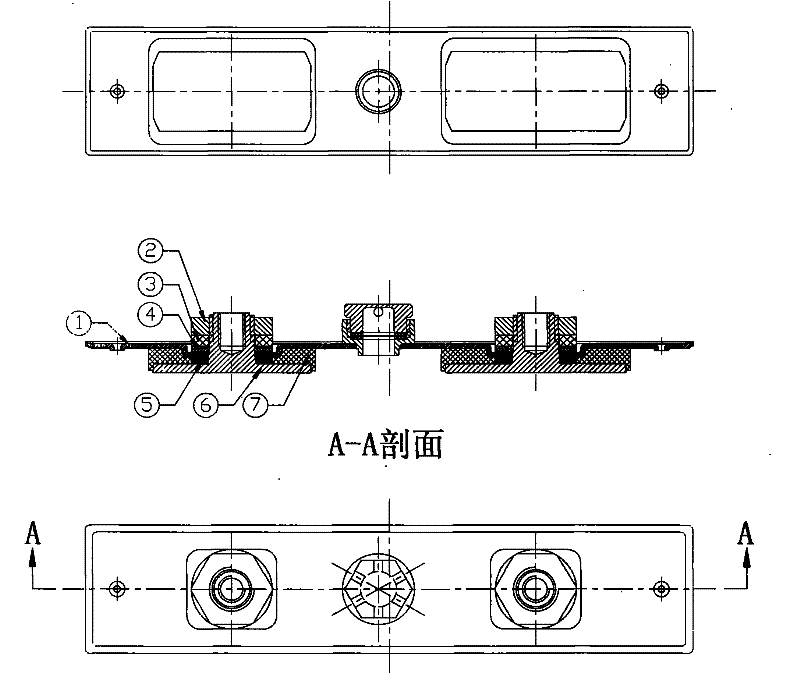

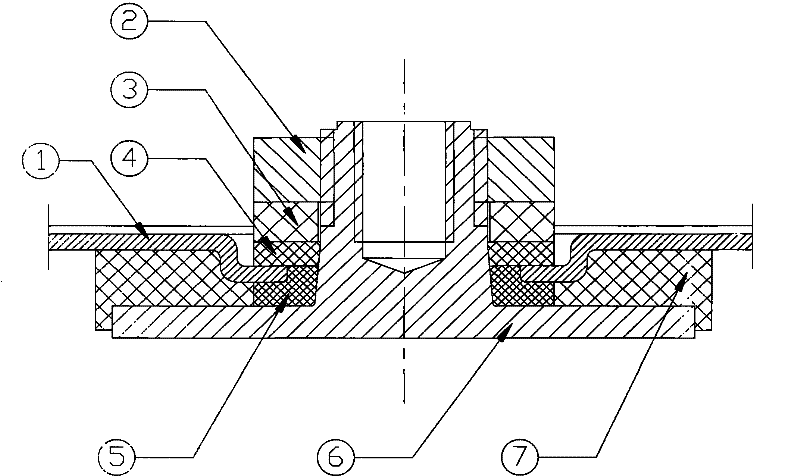

[0013] The manufacturing and assembly method of the sealed connection of the electrode column of the top cover of the power lithium battery:

[0014] Each part is made separately.

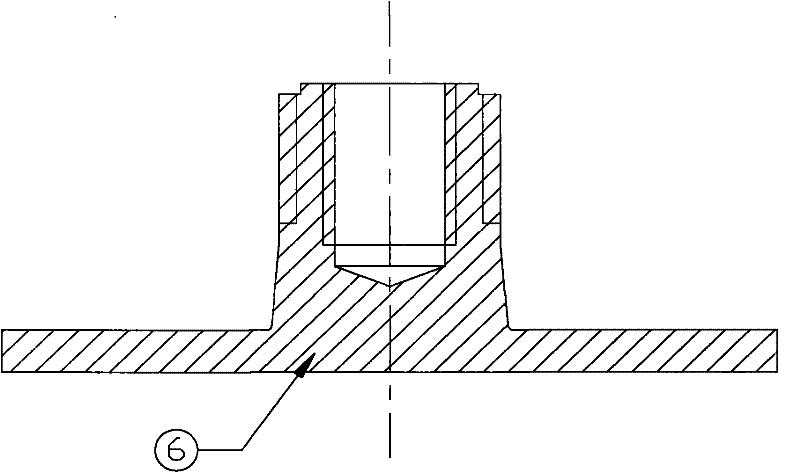

[0015] Install the tapered Teflon (Teflon) sealing ring 5 on the top cover stamping part 1, the tapered electrode column 6 passes through the tapered Teflon (Teflon) sealing ring 5, and then sequentially place the tapered The Teflon (Teflon) sealing gasket 4 and the plastic gasket 3 are installed on the electrode column 6 with a tapered surface, and then locked with the lock nut 2 coated with thread lock, and passed through the electrode column 6 with a tapered surface. The taper surface acts, and the Teflon (Teflon) sealing ring 5 and the Teflon (Teflon) sealing gasket 4 with the tapered surface are tightly sealed on the plane and the hole of the top cover stamping part 1 . Assemble the other electrode column in the same way. Finally, the injection molding part 7 is injected with an injection mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com