Braking energy recovery system for vehicles and vehicles equipped with the system

一种能量回收、制动系统的技术,应用在高效的车辆充电、通用动力装置的多个不同原动机的布置、制动器等方向,能够解决限制、使用复杂等问题,达到构造简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention relates to a braking energy recovery system which can be installed as standard equipment on new vehicles or as a retrofit to existing vehicles. Through the use of variable displacement hydraulic pumps and motors, the recovered energy can be adjusted according to braking demand and the stored energy can be adjusted according to the power demand from auxiliary systems. Furthermore, in one embodiment of the invention, the brake energy recovery system can also be used to boost the vehicle during acceleration.

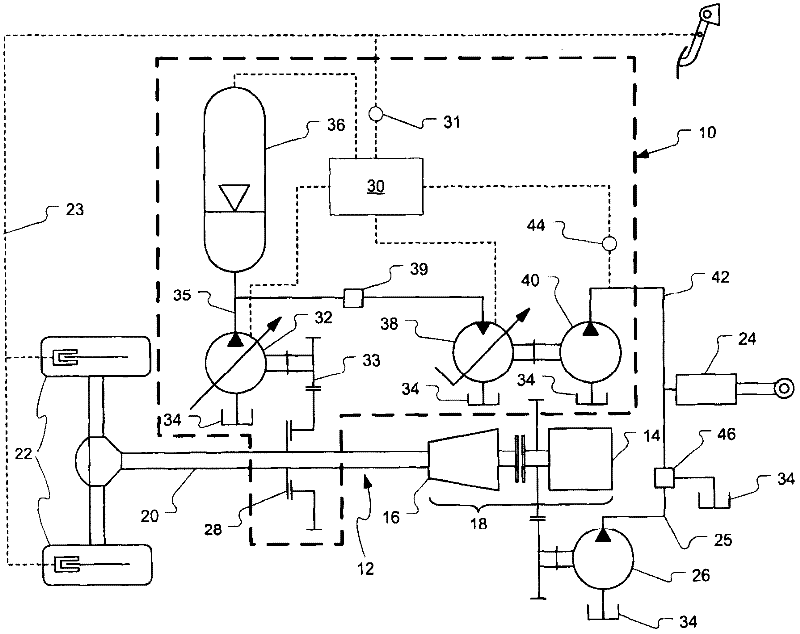

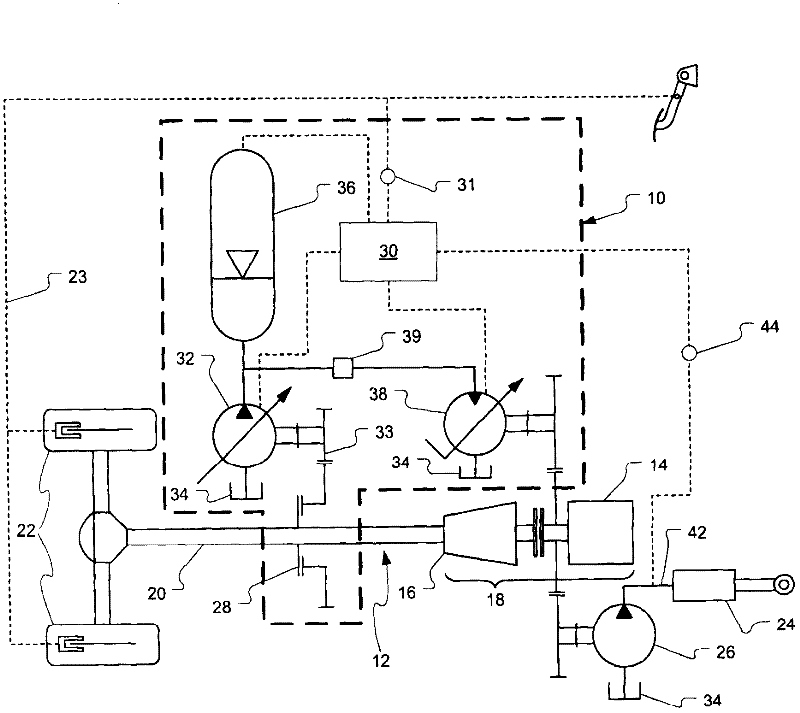

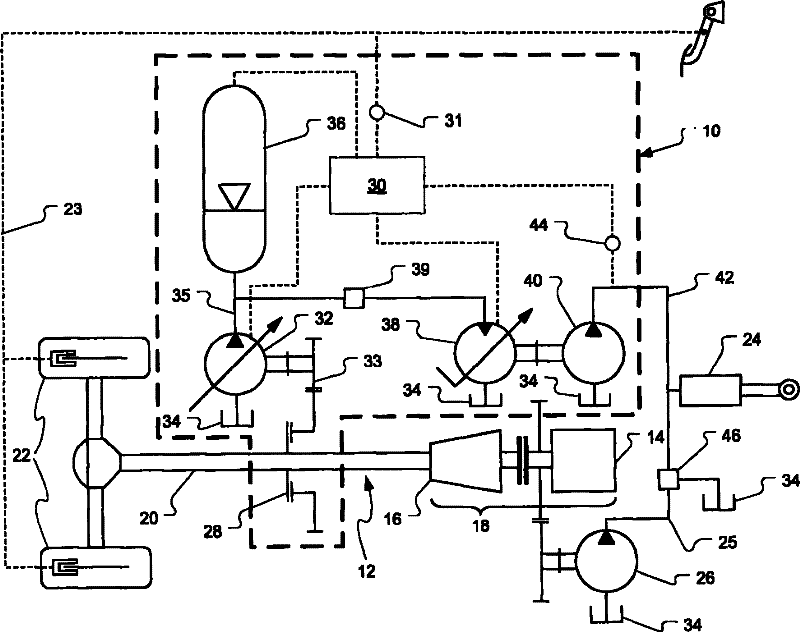

[0019] see now figure 1 , which schematically depicts the braking energy recovery system 10 of the present invention. For better understanding, the brake energy recovery system 10 is shown mounted on a powertrain 12 of a vehicle. figure 1 The components of powertrain 12 shown in are: internal combustion engine 14 and transmission 16 , which together form an engine-transmission assembly 18 ; and propshaft 20 , which connects a wheel set 22 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com