Loose piece misplacing and underflow locking device

A technology of locking device and loose block, which is applied in the direction of casting and molding equipment, etc., can solve the problems of difficult detection of live blocks, restrictions on the use of the environment, and the inability to prevent loose blocks from being out of position and installation, etc., to achieve automatic operation and a wide range of device applications , construction and operation costs are low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

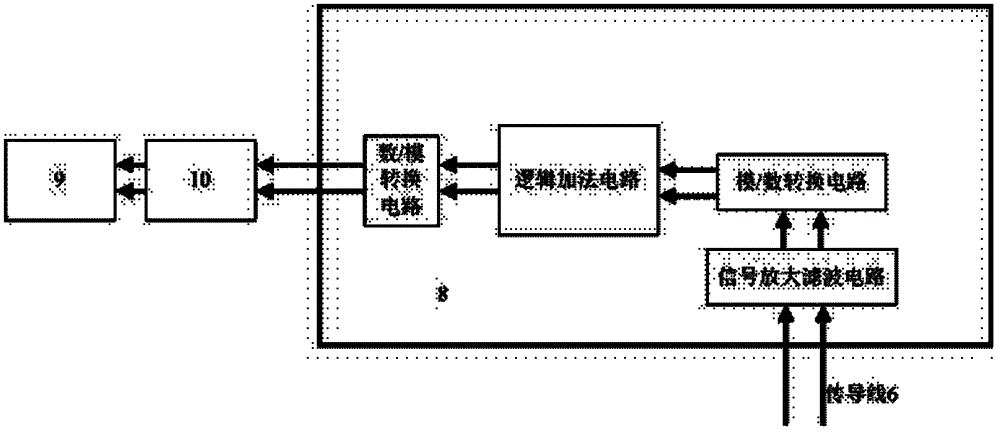

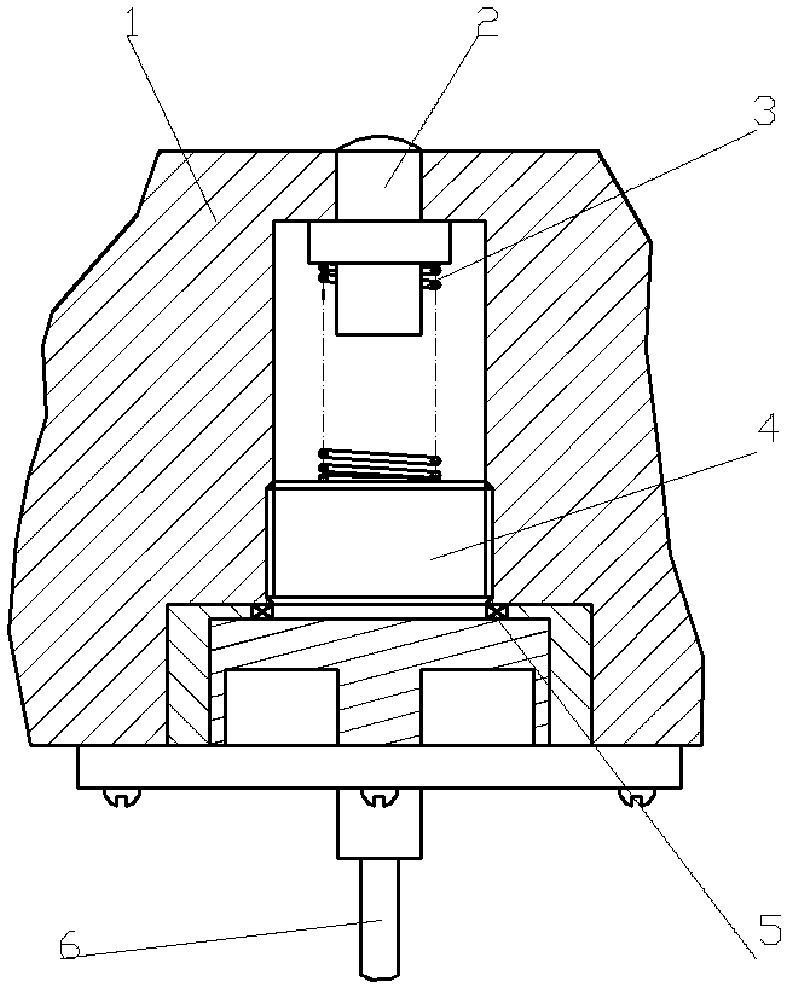

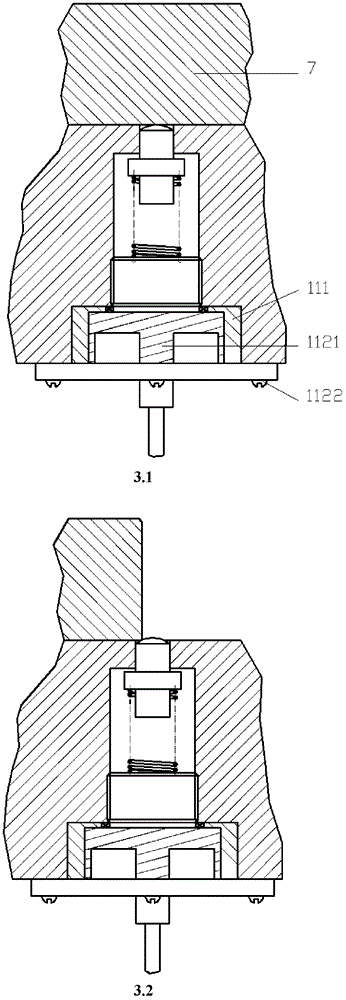

[0055]The locking device for loose block out of position and under position according to the present invention includes a loose block out of position and under position detection part and a loose block out of position under position control part, specifically including the mold substrate 1, the positive position thimble 2, and the return spring 3 , pressure sensor 4, sealing gasket 5, analog signal conduction line 6, loose block 7, control circuit 8, mold clamping main circuit 9, relay 10 and support 11.

[0056] The detection part of the missing position of the movable block is composed of the positive position ejector pin 2, the return spring 3, the pressure sensor 4 and the support member 11 located in the mold base plate. Among them, the sealing requirements and the safety and reliability of pressure transmission are considered when installing the positive thimble 2 and the return spring 3 . Through the cooperation of the positive thimble 2 and the return spring 3, the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com