Method for manufacturing flower-shaped nickel-carbon nanotube composite material

A technology of carbon nanotubes and composite materials, applied in the field of nanocomposites, can solve problems such as application limitations, achieve low cost, easy industrial application and promotion, and unique formation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

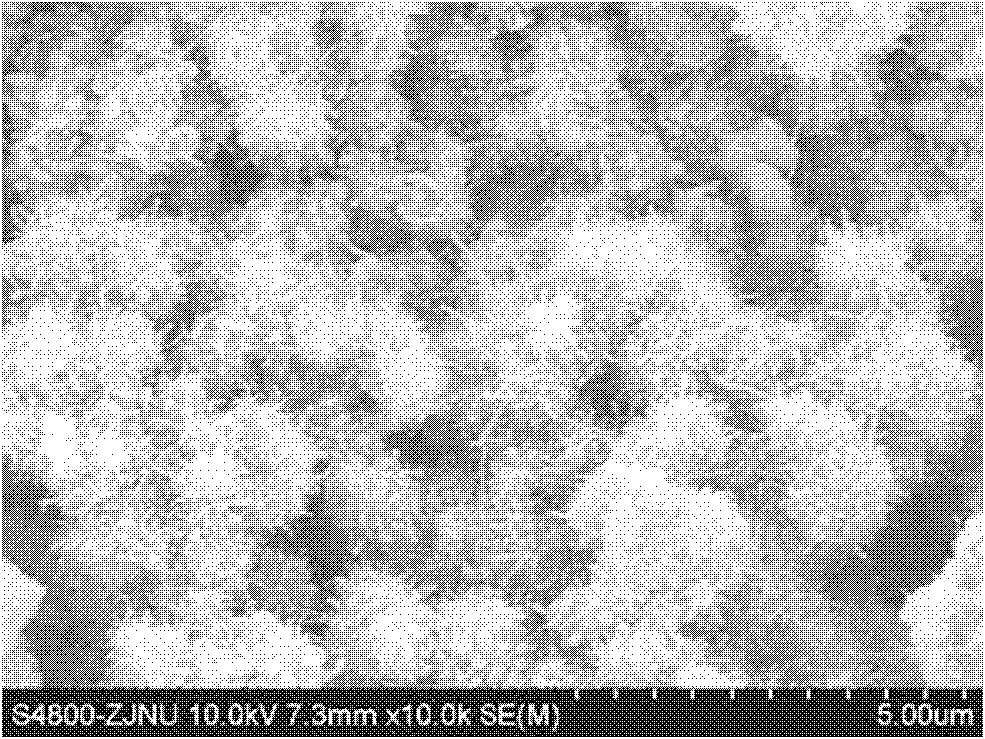

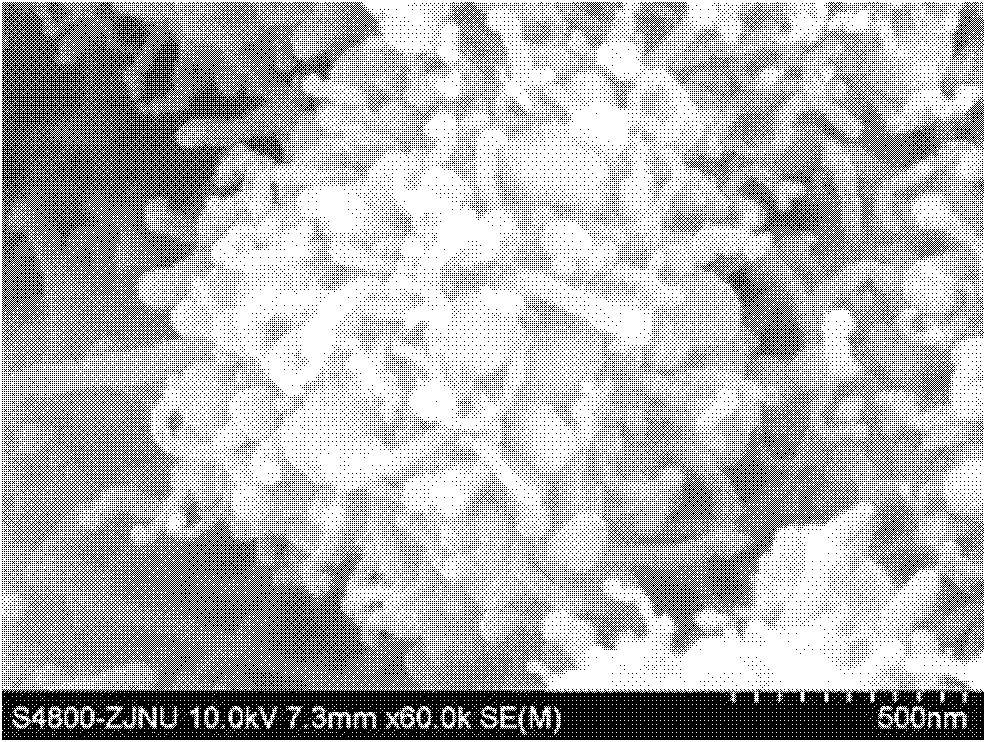

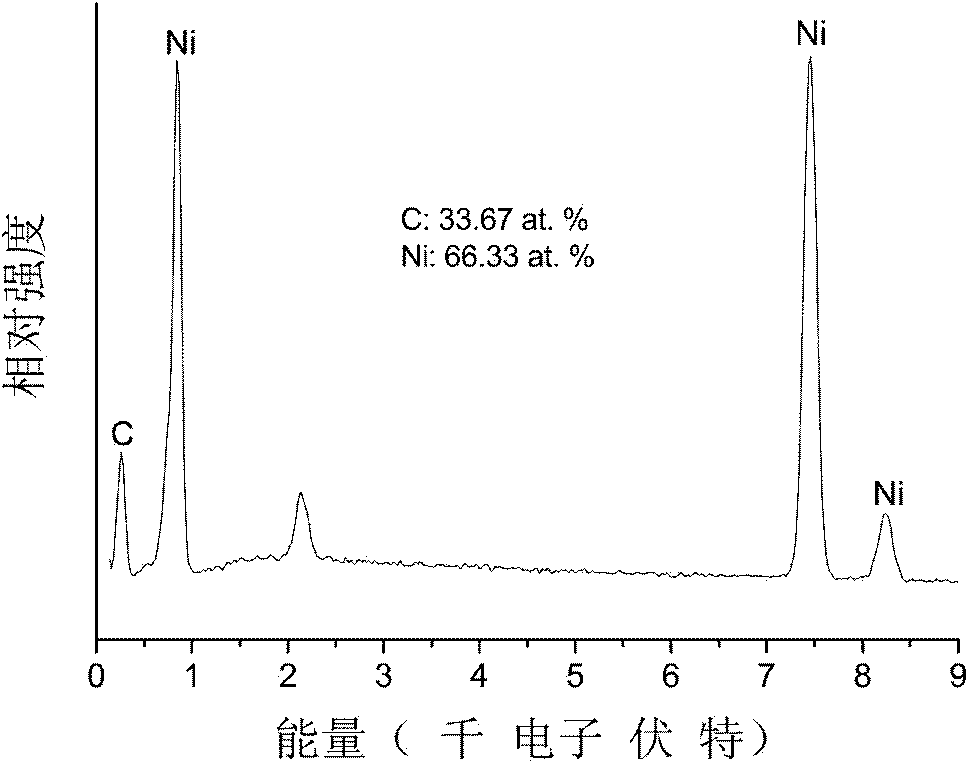

Embodiment 1

[0044] Disperse 0.2 g of octahedral nickel oxide particles into 1.5 g of polyethylene glycol 20000, load it with a 6 cm x 3 cm x 1.5 cm ceramic ark, place it in a tube furnace, and react at 750 °C for 2 hours under nitrogen protection. After the reaction was completed, it was cooled to room temperature with the furnace under the protection of nitrogen, and the morphology of the resulting product was as follows: figure 1 and figure 2 Shown are flower-shaped nickel-carbon nanotube composite particles. image 3 The EDS spectrum of the product shows that the mass percentages of carbon and nickel are 33.67% and 66.33%, respectively. Figure 4 It is the XRD spectrum of a typical product. It can be seen that the diffraction peaks at 2θ=26.1° are the characteristic peaks of carbon, and the diffraction peaks at 2θ=44.5°, 51.8°, 76.4° etc. are respectively the (111 ), (200), (220) characteristic peaks of the crystal plane. Low-power and high-power TEM images of the product observed ...

Embodiment 2

[0046]Adopt the technology in embodiment 1, difference is: when reaction temperature is 600 ℃, and reaction time is 2 hours, the appearance of gained product is as follows Figure 7 Shown are flower-shaped nickel-carbon nanotube composite particles. This indicates that the flower-shaped nickel-carbon nanotube composite particles can also be obtained by lowering the reaction temperature (600°C).

Embodiment 3

[0048] Adopt the technology in embodiment 1, difference is: when thermal decomposition temperature is 850 ℃, and reaction time is 2 hours, the appearance of gained product is as follows Figure 8 Shown are flower-shaped nickel-carbon nanotube composite particles. This shows that raising the reaction temperature (850°C) can also obtain flower-shaped nickel-carbon nanotube composite particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com