Current-loaded linear friction welding device

A linear friction welding and current-carrying technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of complexity, high cost, low efficiency, etc., to reduce requirements, improve welding efficiency, reduce complexity and The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below.

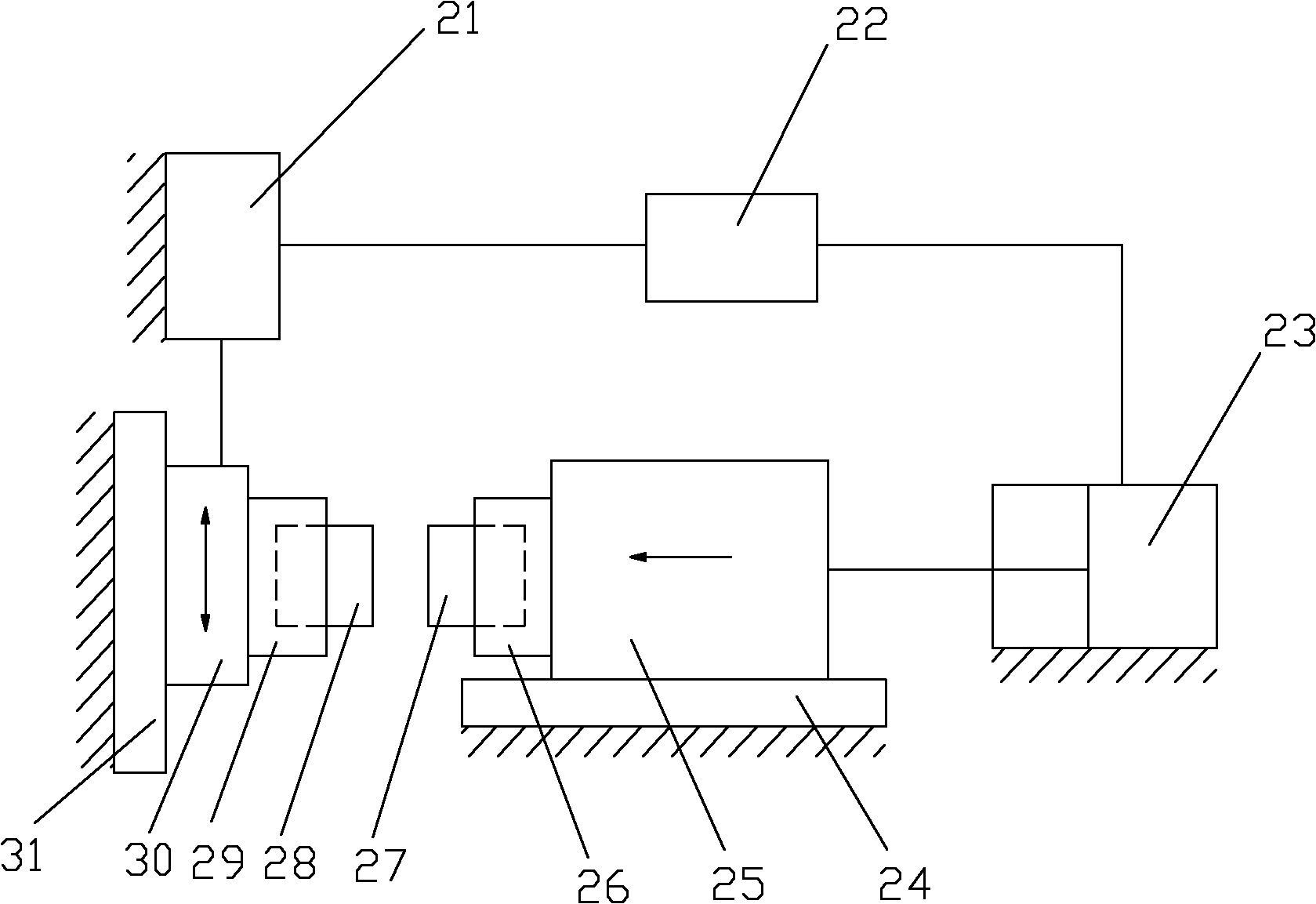

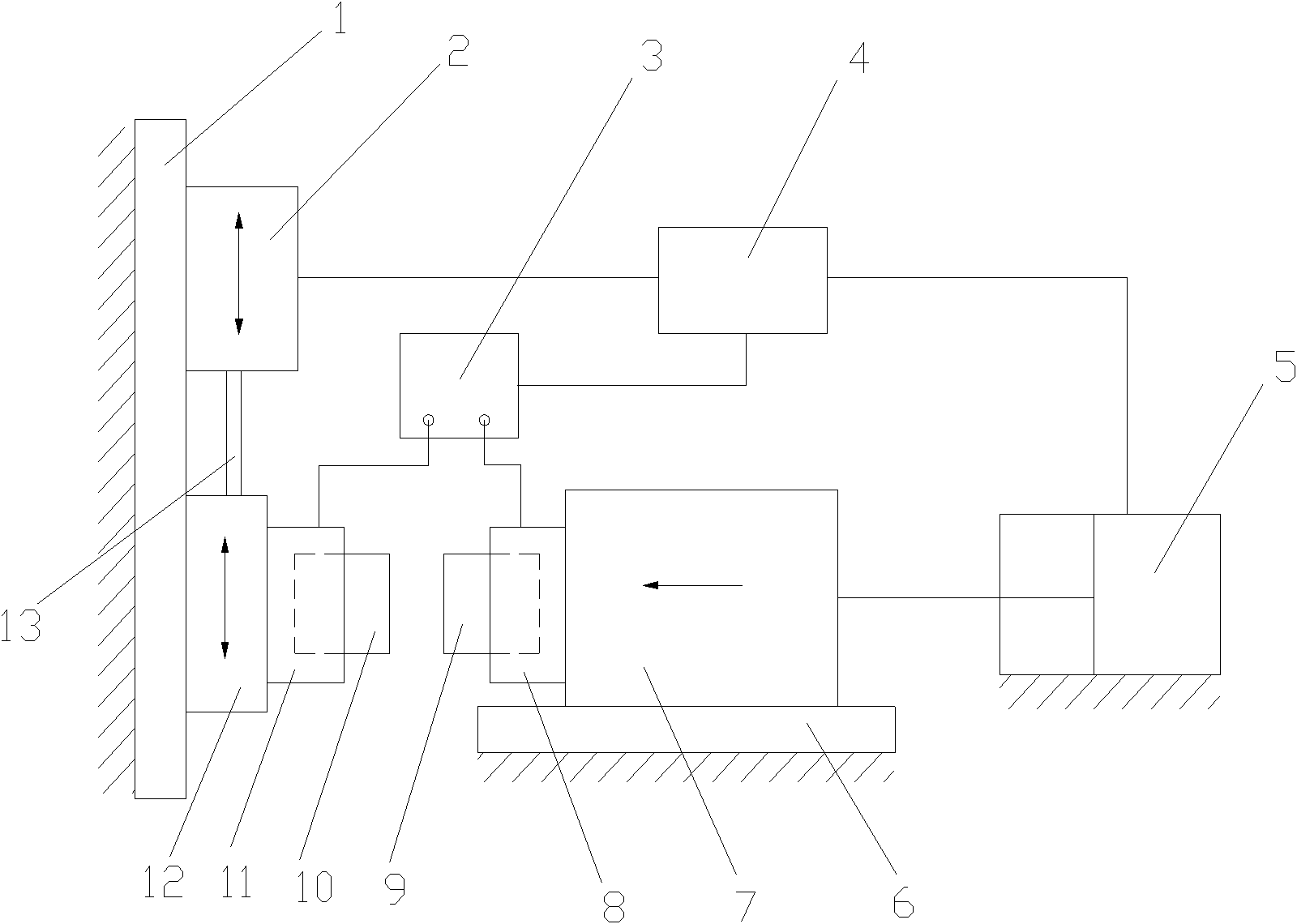

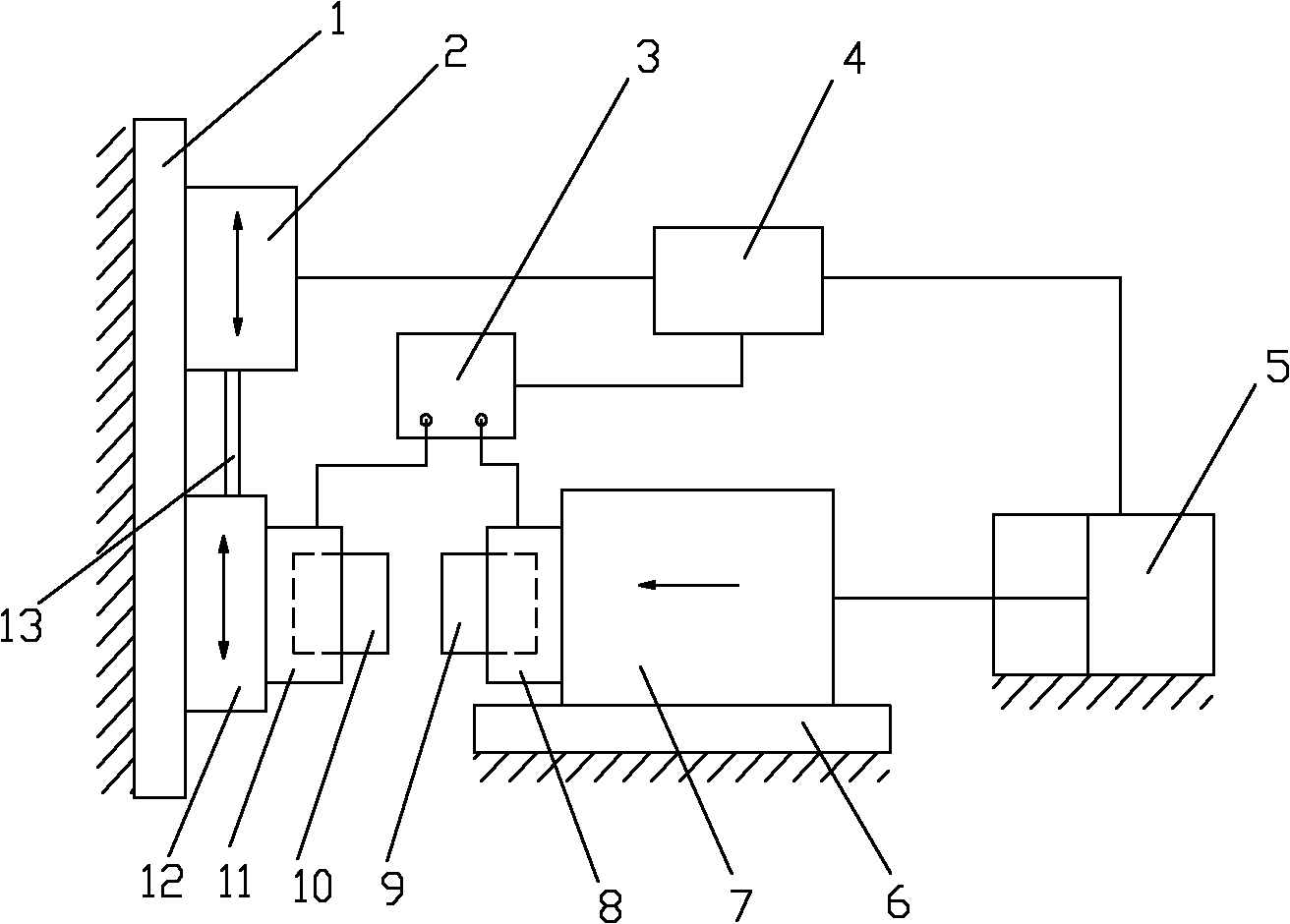

[0023] see figure 1 , the current-carrying linear friction welding device of this embodiment includes a control system 2, an upset end system and a vibration end system.

[0024] The upsetting end system includes an upsetting end fixture 8, an upsetting hydraulic system 5, an upsetting slide 7 and an upsetting bed 6, the upsetting slide 7 is slidably fitted on the upsetting bed 6, and the upsetting The piston rod of the hydraulic system 5 is connected to the upsetting slide 7 to drive the upsetting slide 7 to slide on the upsetting bed 6, the upsetting end fixture 8 is set on the upsetting slide 7, and the upsetting hydraulic pressure The control terminal of the system 5 is electrically connected with the control output terminal of the control system 2 .

[0025] The vibrating end system also includes a vibrating end fixture 11, a vibrating guide rail 1, a vibrating slide table 12 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com