System for quickly changing chassis battery for electric passenger vehicle based on cartesian robot

A technology of rectangular coordinates and battery quick replacement, which is applied in the direction of electric power devices, power devices, vehicle components, etc., can solve problems such as insufficient lifting, failure to realize automatic battery replacement, and over-lifting of the lifting battery box to achieve safety The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

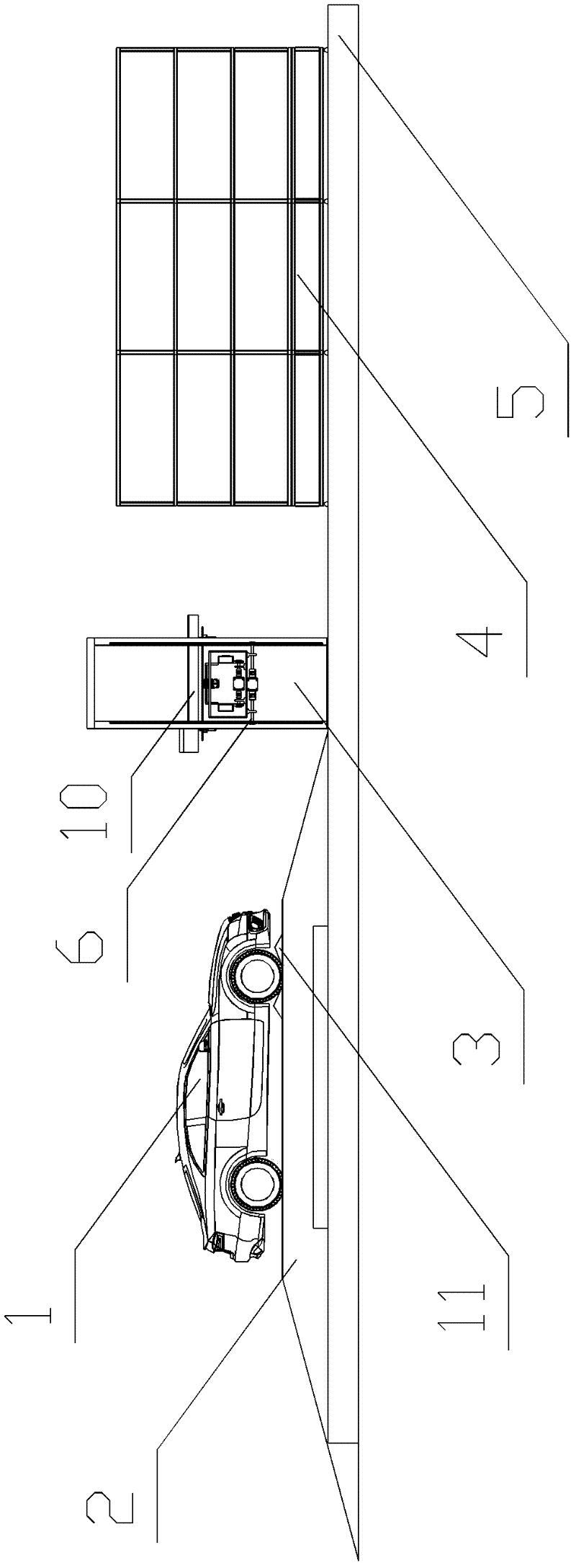

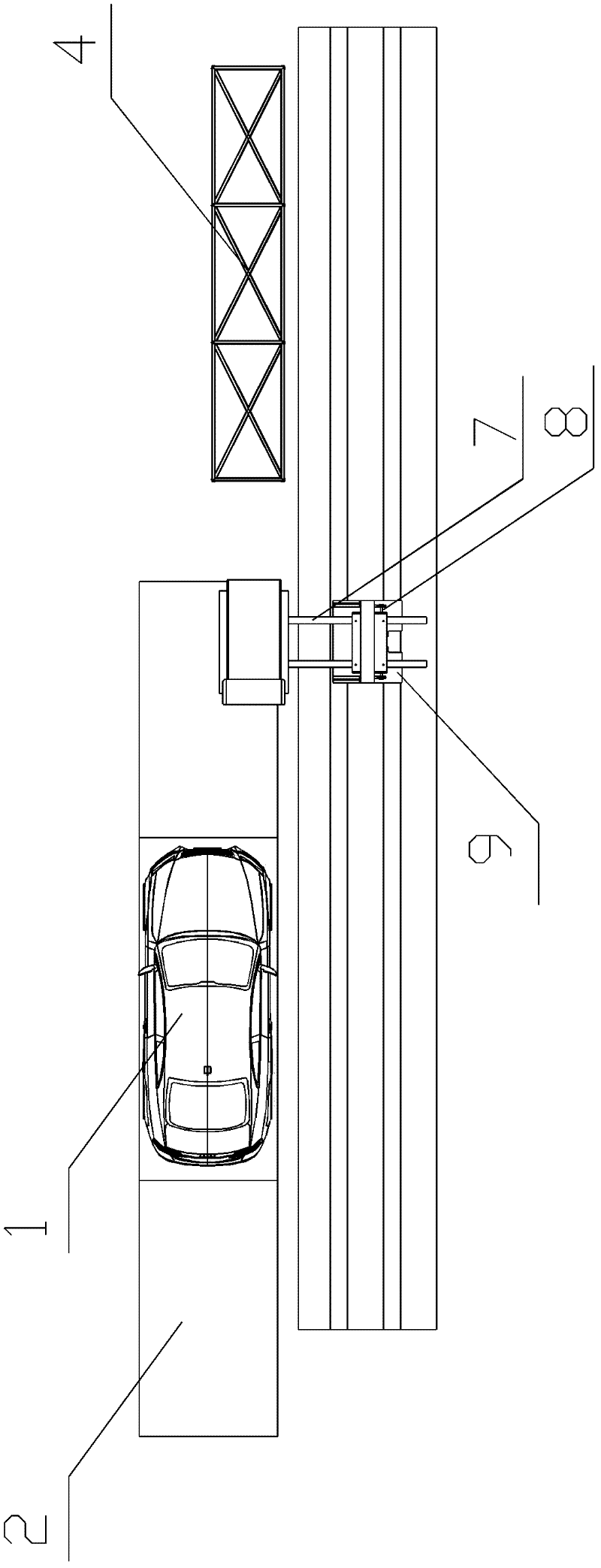

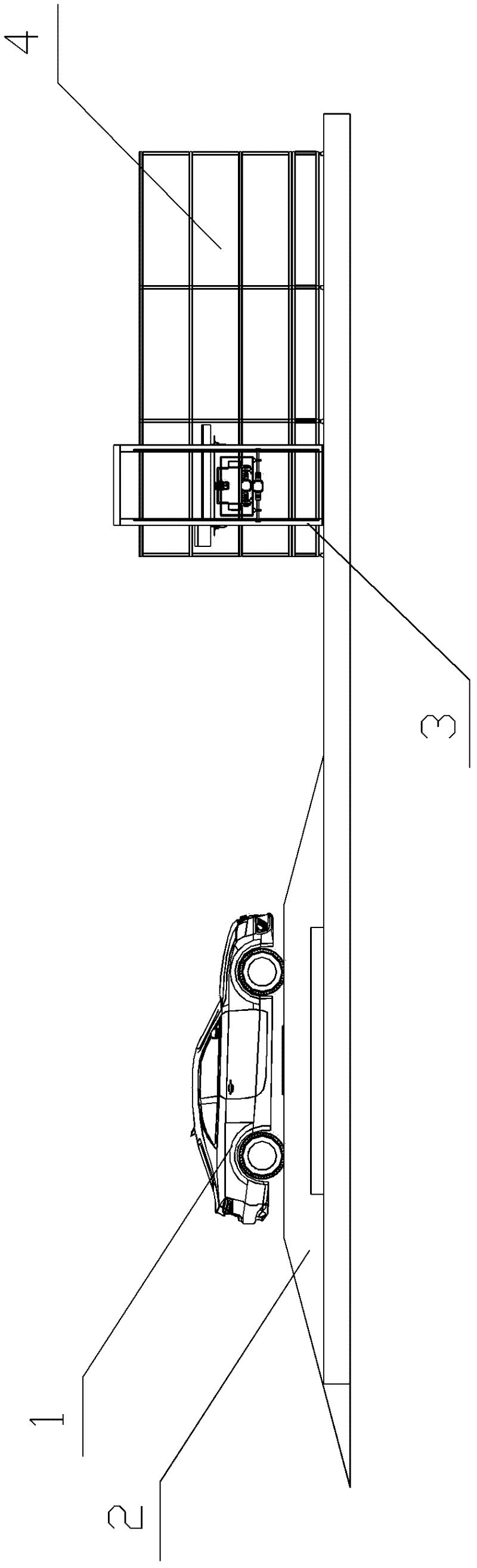

[0062] Figure 1-Figure 9 Among them, an electric passenger car chassis battery quick-change system based on a Cartesian robot, which includes a power-changing platform 2, and the power-changing platform 2 is on the same straight line as the quick-changing robot 3 and the charging rack 4; the quick-changing robot 3 Including a battery tray 9 and a Cartesian robot with four degrees of freedom, the Cartesian robot includes an X-axis linear positioning system 5, a Z-axis lifting platform 6, a Y-axis telescopic platform 7, an R-axis angle correction system 8, and an X-axis linear positioning system 5 includes X-axis double-rail rack 12, Z-axis lifting platform 6 includes Y-axis double-rail rack 20, R-axis angle correction system 8 includes R-axis drive motor 15; both ends of X-axis double-rail rack 12 respectively extend to power exchange platform 2 and ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com