Method for preparing antifouling material with surface of ridged microstructure

A microstructure and ridge-like technology, applied in the field of bionic antifouling material preparation, can solve the problems of reducing the effective attachment area of fouling organisms on the shark skin, reducing the number of fouling organisms' attachment points, and being unsuitable for large-scale production. Small effective contact area, improved diatom adhesion rate, and biofouling inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: surface adsorption tetrabutyl titanate (Ti(OB u ) 4 ) prepared from polydimethylsiloxane (PDMS) elastomer

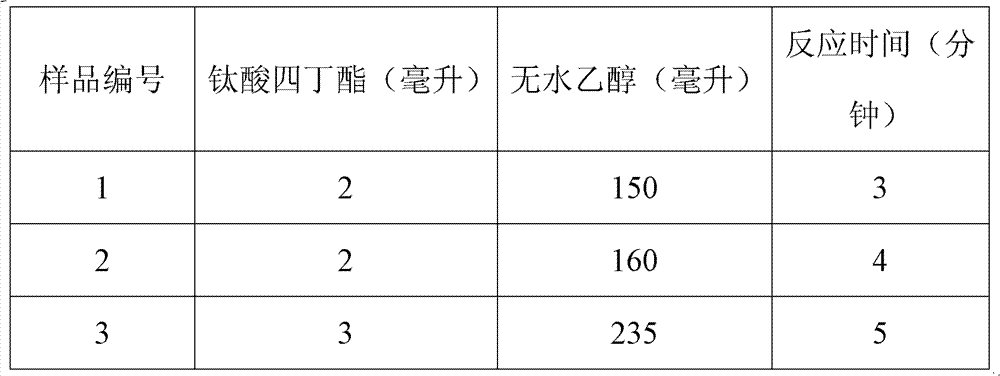

[0009] In this embodiment, tetrabutyl titanate (Ti(OB u ) 4 ) and absolute ethanol according to the volume ratio of 1:75~80 to make tetrabutyl titanate (Ti(OB u ) 4 ) in ethanol solution; then, place the polydimethylsiloxane (PDMS, 1cm×1cm) elastomer sample with hydroxyl-rich surface after the hydroxylation treatment in the solution for 3 to 5 minutes and take it out after immersion reaction. Rinse the surface with water and ethanol to obtain surface-adsorbed tetrabutyl titanate (Ti(OB u ) 4 ) polydimethylsiloxane (PDMS) elastomer; experimental control parameters are as shown in table 1:

[0010] Table 1 Surface adsorption of tetrabutyl titanate (Ti(OB u ) 4 ) Experimental control parameters for the preparation of polydimethylsiloxane (PDMS) elastomer

[0011]

Embodiment 2

[0012] Embodiment 2: the surface has TiO 2 Preparation of Polydimethylsiloxane (PDMS) Elastomer for Gel Film Layer

[0013] In this embodiment, the surface prepared in Example 1 is adsorbed with tetrabutyl titanate (Ti(OB u ) 4 ) polydimethylsiloxane (PDMS) elastomer samples 1, 2, and 3 were immersed in water for 4 minutes, 5 minutes, and 3 minutes, respectively, and the tetrabutyl titanate (Ti(OB) adsorbed on the surface u ) 4 ) can be hydrolyzed on the surface of polydimethylsiloxane (PDMS) elastomer to form TiO 2 gel film layer.

Embodiment 3

[0014] Example 3: Preparation of antifouling material with ridge microstructure on the surface

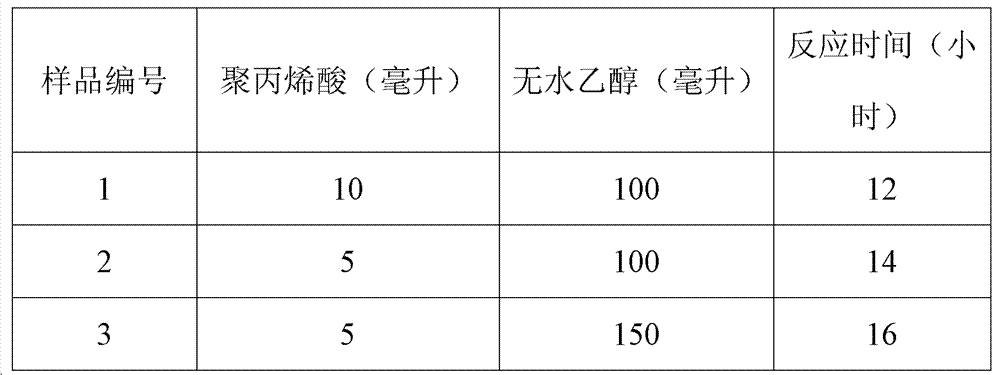

[0015] In this embodiment, polyacrylic acid (PAA) and absolute ethanol are prepared into an ethanol solution of polyacrylic acid (PAA) at a volume ratio of 1:10 to 30; then, the surfaces prepared in Example 2 with TiO 2 The polydimethylsiloxane (PDMS) elastomer samples 1, 2, and 3 of the gel film layer were put into the solution, respectively immersed in the reaction for 12 to 16 hours, then taken out, washed with absolute ethanol, and dried to obtain the surface Antifouling material with ridge microstructure; experimental control parameters are shown in Table 2:

[0016] Table 2 Control parameters of the preparation experiment of antifouling materials with ridge microstructure on the surface

[0017]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap