Preparation method for non-equal convergent-point high-elasticity composite yarn

A technology of composite yarn and converging point, which is applied in the direction of yarn, textile and papermaking, etc., can solve the problems of fabric elastic loss, unstable structure, unsatisfactory, etc., and achieve the effect of improved elasticity, simple method, and enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

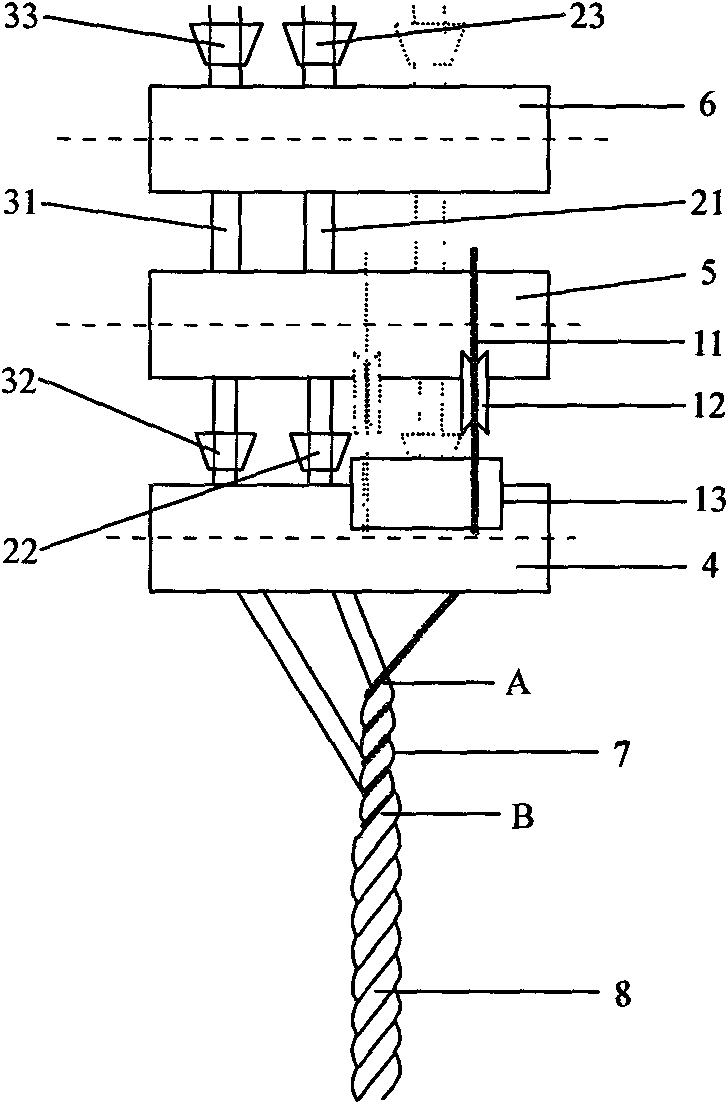

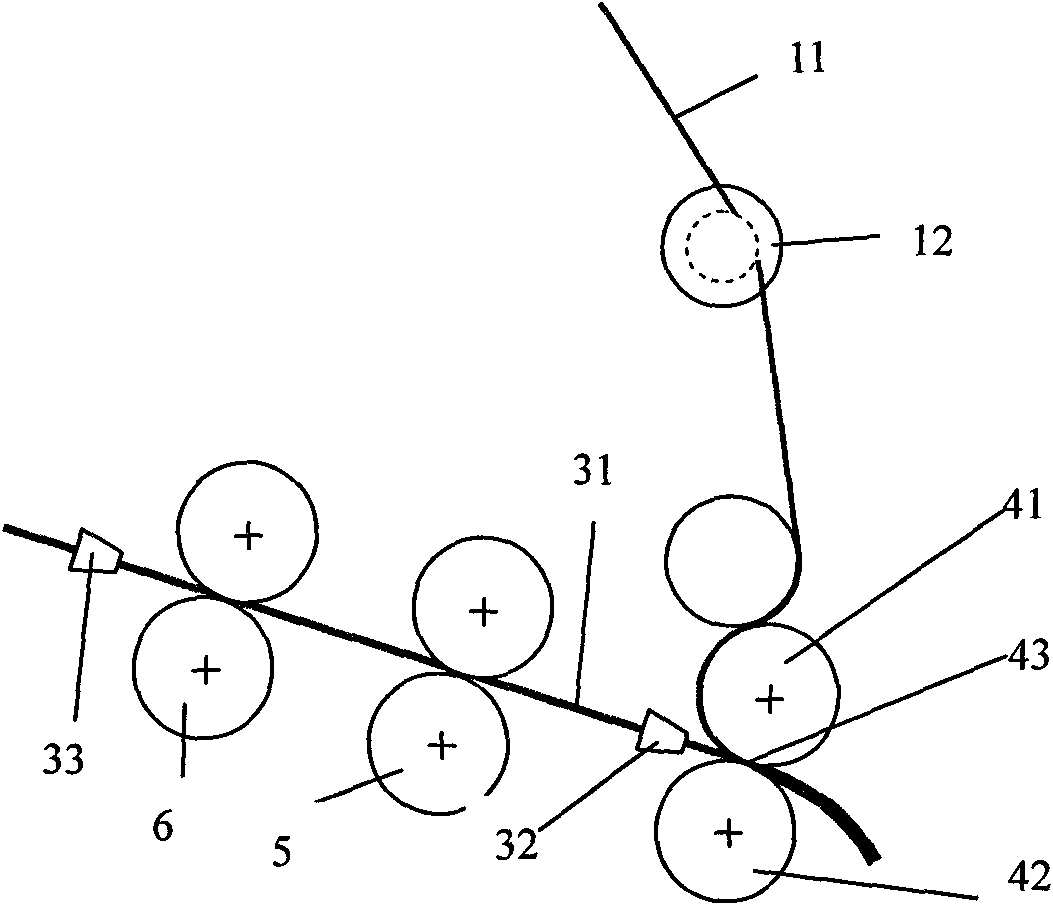

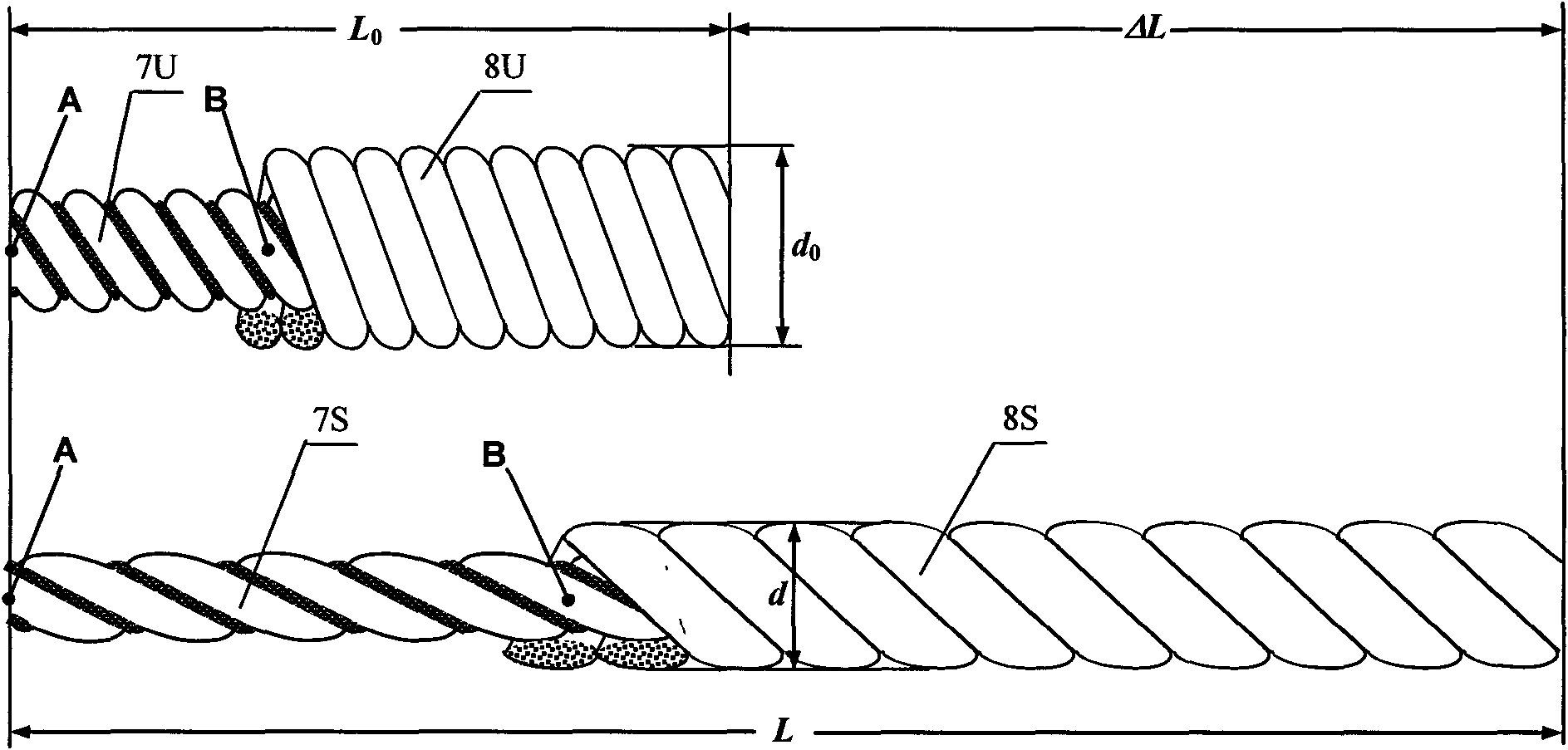

[0040] A method for preparing high-elastic composite yarns with non-equal convergence points, which adopts adding a positioning tension disc for controlling the position and tension of elastic filaments (elastic yarns) on an ordinary ring spinning frame, and adding a feeding tension disc in an equal tension mode. The holding rod for the elastic yarn and two strand positioners used to control the position of the staple strands respectively; and the feeding of the two staple strands and the elastic strands in a three-axis system and the addition of non-equal collection points are implemented. Twist composite, and finally spun into a high-elastic yarn core with a double-helix structure as the core layer; the outer layer is a high-elastic composite yarn 8 that is covered with short fiber strands and has a freely stretchable pitch, such as figure 1 , figure 2 , image 3 shown.

[0041] The preparation method of the non-equal convergence point high elastic composite yarn, the spe...

Embodiment 1

[0048] Example 1: Spinning cotton+spandex filament non-equal convergence point high elastic composite yarn

[0049] Select two tubes of cotton roving and one tube of spandex filament to carry out non-equal convergence point composite spinning of triaxial system; triaxial raw material: the composite mass ratio of cotton / cotton / spandex yarn is 40 / 40 / 20, and the above-mentioned composite spinning Yarn method, the spandex yarn is fed from one shaft with a tension of 8cN, and the enveloping angle with the holding rod is 120°+0° plus the number of turns is zero; two bundles of cotton staple fibers are fed from the other two shafts and Spandex yarns are fed in with an interaxial distance of 8mm and 4mm; the twist of spinning is 120 twists / 10cm; the spandex yarns and one of the cotton staple strands that exit the nip of the front roller are first compounded at point A to form a double-helix yarn segment, and then This yarn segment is compounded at point B with another cotton staple fi...

Embodiment 2

[0050] Example 2: Spinning spun silk + Lycra non-equal convergence point high elastic composite yarn

[0051] Select two cylinders of spun silk roving and one cylinder of Lycra filaments to carry out three-axis non-equal convergence point composite spinning; three-axis raw materials: composite mass ratio of spun silk staple fiber / spun silk staple fiber / spandex yarn is 35 / 35 / 30, using the above-mentioned composite spinning method, the Lycra silk is fed from one axis with a tension of 8cN, and the enveloping angle with the holding stick is 100°+0° plus the number of turns is zero; the spun silk staple fiber is spun The natural tension of the yarn drafting is fed from the other two shafts with a distance of 8mm and 4mm from the Lycra yarn; the twist of the spinning yarn is 120 twists / 10cm, and the Lycra yarn coming out of the nip of the front roller and one of the spun silk staple fibers First compound at point A to form a yarn segment with a double helix structure, and then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com