Duct piece transporter for small-diameter shield machine and operating method of duct piece transporter

A technology of shield machine and conveyor, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problem of small space for segment transportation and pickup, low segment handling efficiency, and inability to accommodate secondary segment cranes. or feeder and other problems, to achieve the effect of improving assembly efficiency, compact structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

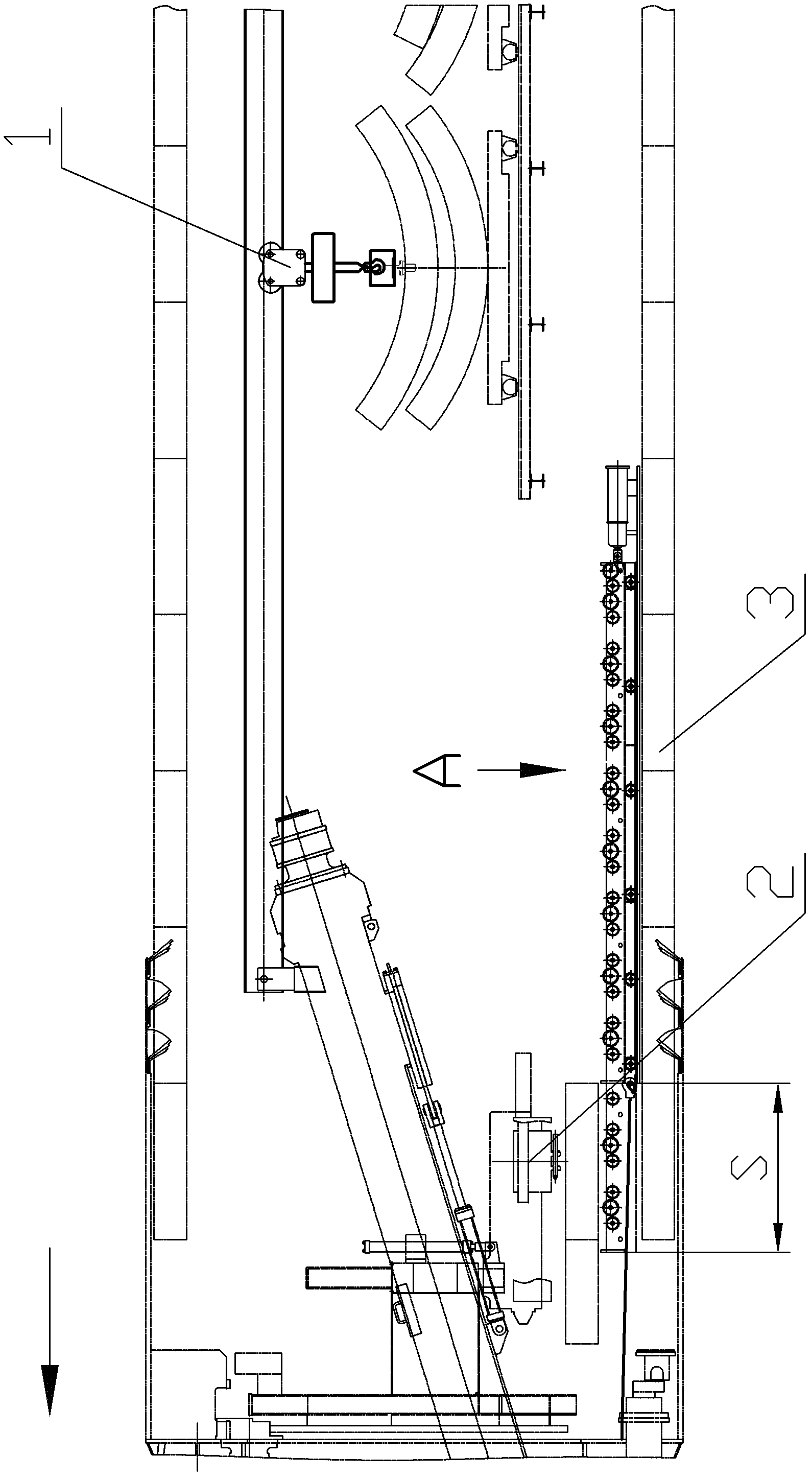

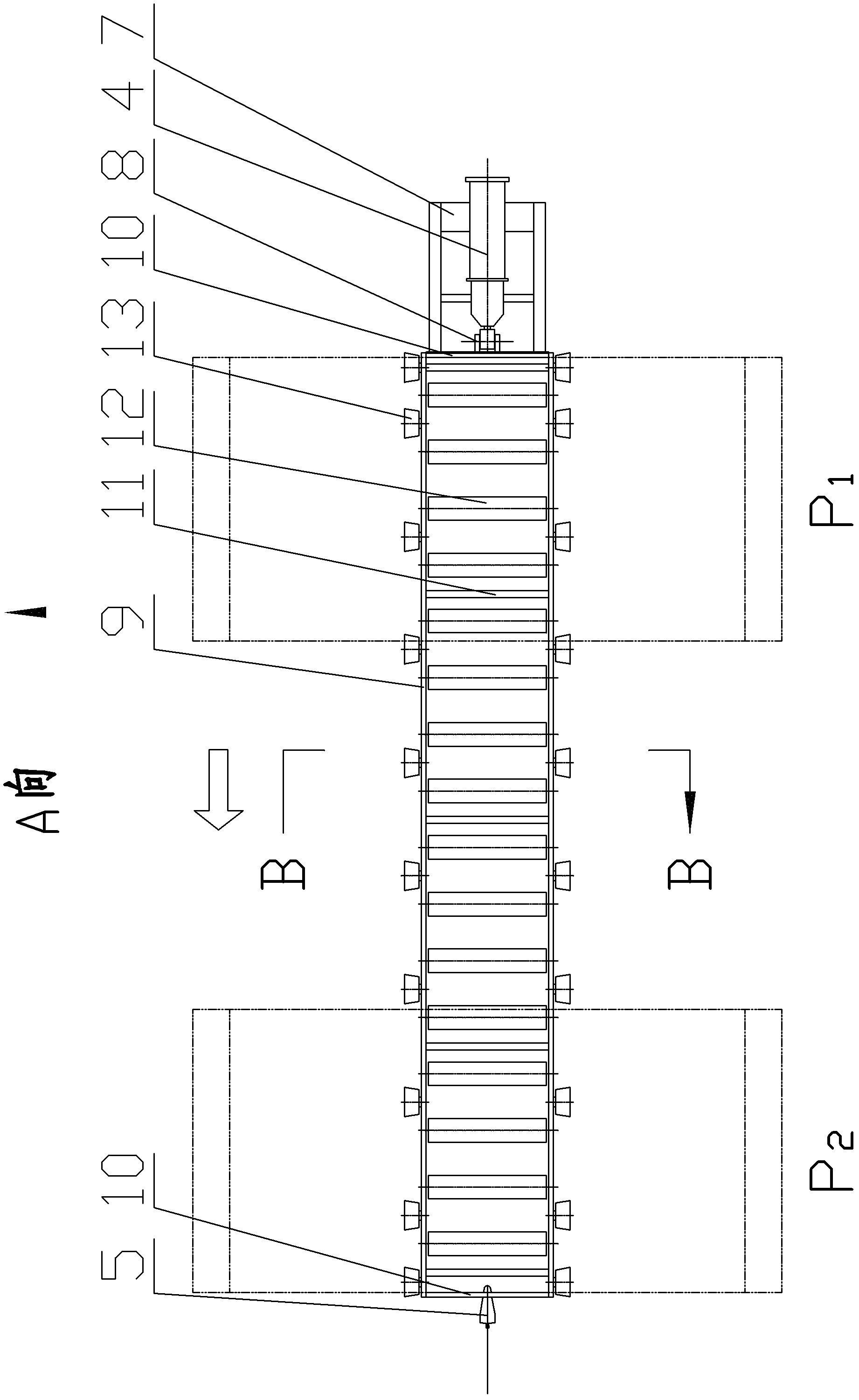

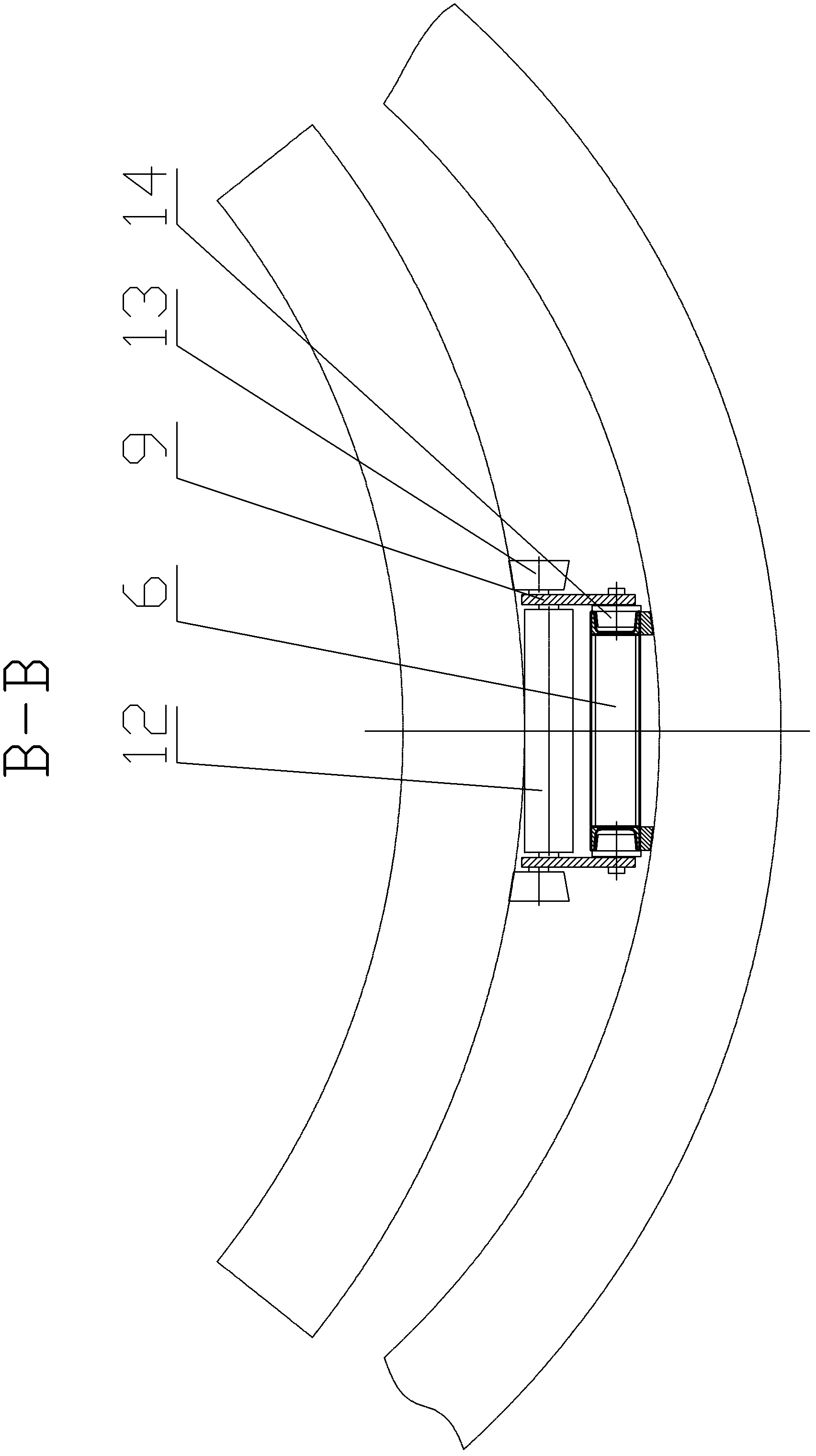

[0028] figure 1 , 2 Shown in , 3 is the specific embodiment of the present invention, and it is the small-diameter shield machine segment conveyer that is installed on the small-sized shield machine of φ 4.16 meters of the underground power pipeline of certain city; The machine is characterized in that: a segment conveyer driven by an electro-hydraulic push rod is installed on the inner bottom surface of the combined segment 3 between the segment crane 1 and the segment assembly machine 2, and the electro-hydraulic push rod drives The segment conveyor is mainly composed of an electro-hydraulic push rod 4, a moving roller table, a roller table track 6 and a traction shackle 5, and the roller table track 6 is a double track with a support 7 at the rear end composed of two parallel single rails; The electro-hydraulic push rod 4 is connected to the bracket 7 at the tail end of the double track, and the extended rod end of the electro-hydraulic push rod 4 is hinged on the hinge se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com