Device and method for friction fuzzing and pilling of yarn

A technology of pilling and yarn, applied in the direction of adopting mechanical devices, measuring devices, instruments, etc., can solve problems such as differences, achieve less interference, excellent repeatability and reproducibility, and save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

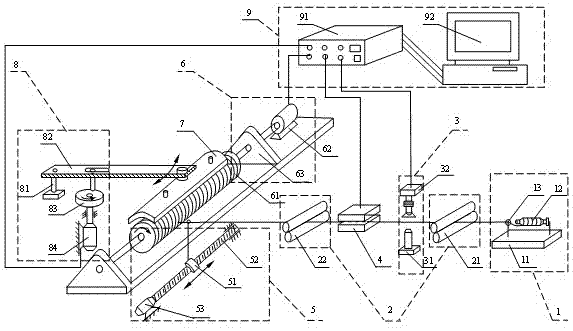

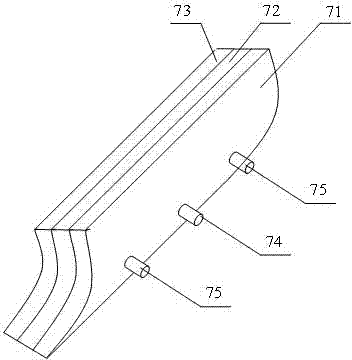

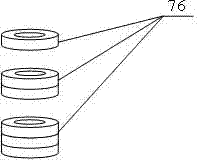

[0029] Such as figure 1 As shown, it is a schematic structural diagram of a device for friction and pilling of yarn, and the device for friction and pilling of yarn consists of bobbin support 1, guide roller 2, camera system 3, capacitor plate 4, It consists of a moving yarn guiding mechanism 5, a winding mechanism 6, a friction cover 7, a moving friction mechanism and a data processing system 9.

[0030] The bobbin support 1 is composed of a platform 11, a support rod 12 and a fixed yarn guiding hook 13. There are support rods 12 and fixed yarn guide hooks 13 on the platform 11, both of which have the same height, and their transverse distance is slightly larger than the length of the bobbin, the center of the hole of the fixed yarn guide hooks 13 is coaxial with the support rod 12, and the yarn bobbins are sleeved on the support At the horizontal end of the bar 12, the yarn is drawn out through a fixed guide hook 13, which facilitates the unwinding of the yarn.

[0031] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com