Rock triaxial compression acoustic emission test system

A test system and triaxial compression technology, applied in the field of test systems, can solve problems such as inability to perform triaxial compression tests on rocks, and achieve reliable results for mine disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

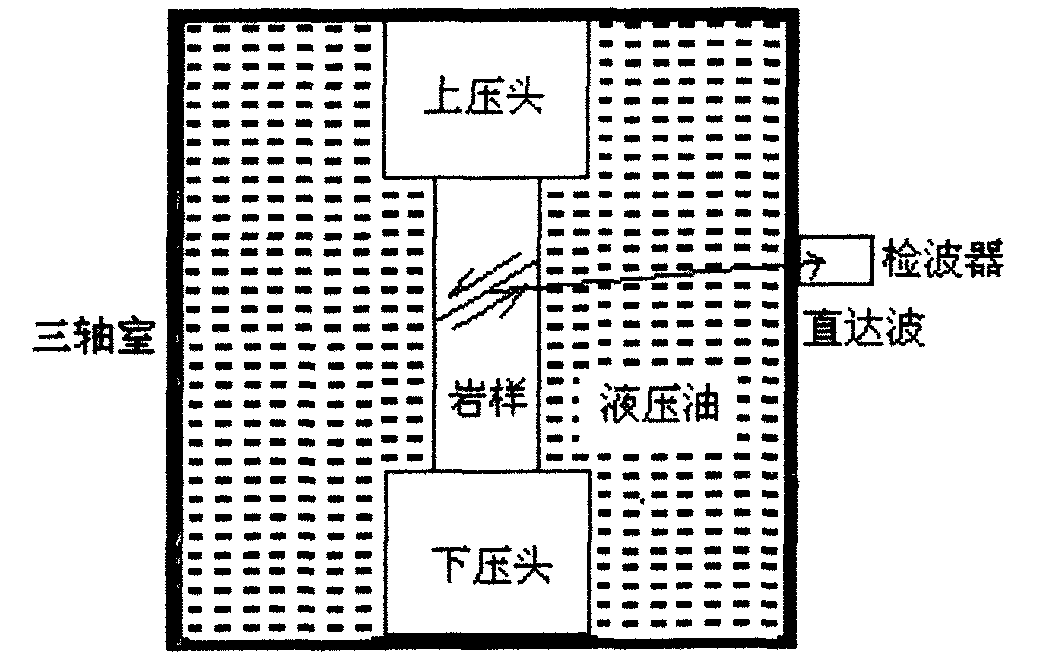

[0025] figure 1 It is a schematic diagram of the arrangement of the existing rock triaxial compression acoustic emission experiment. It can be seen from the figure that since the acoustic emission detector cannot be placed on the base, the acoustic emission detector can only be placed on the outer wall of the triaxial chamber.

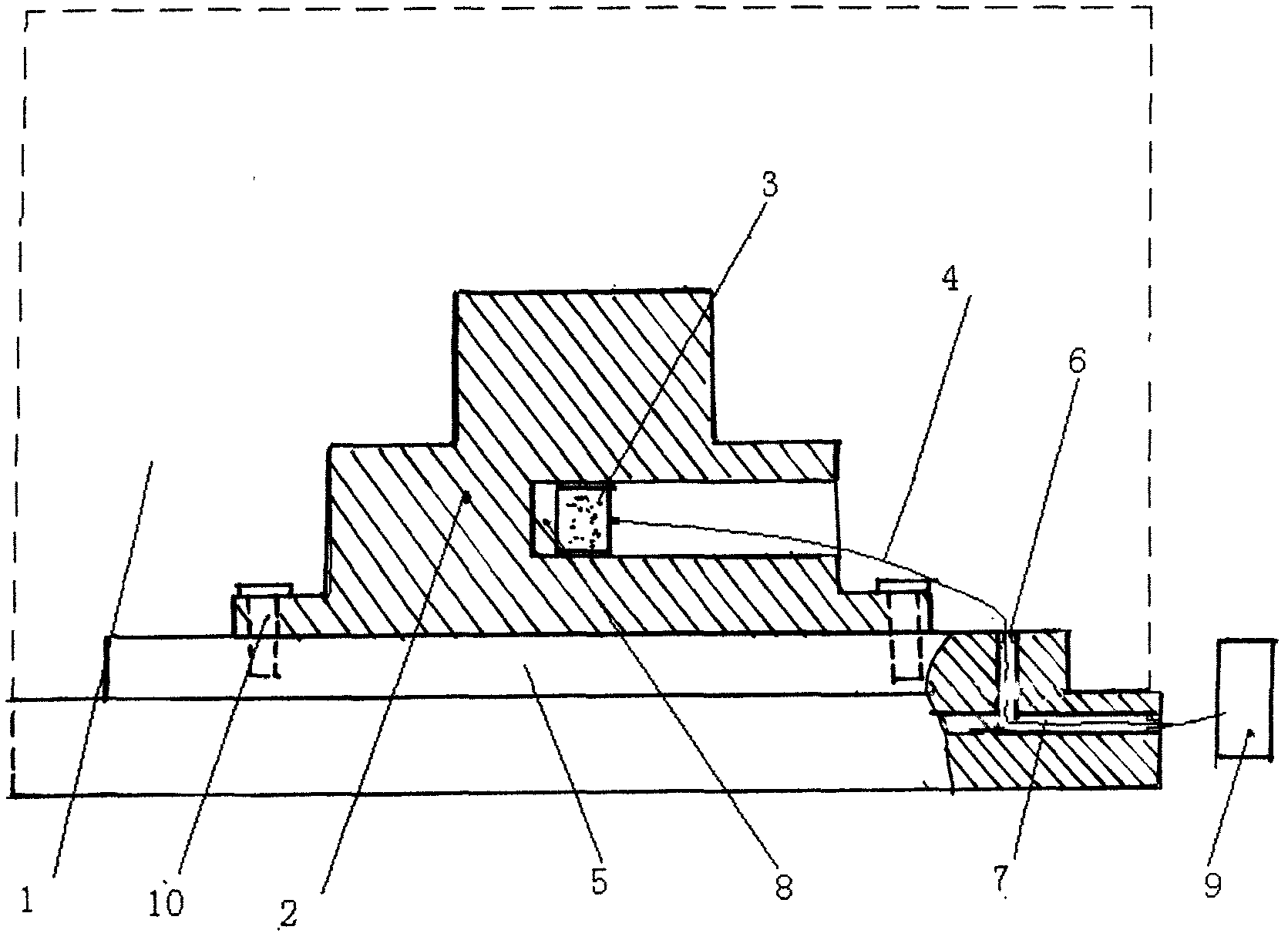

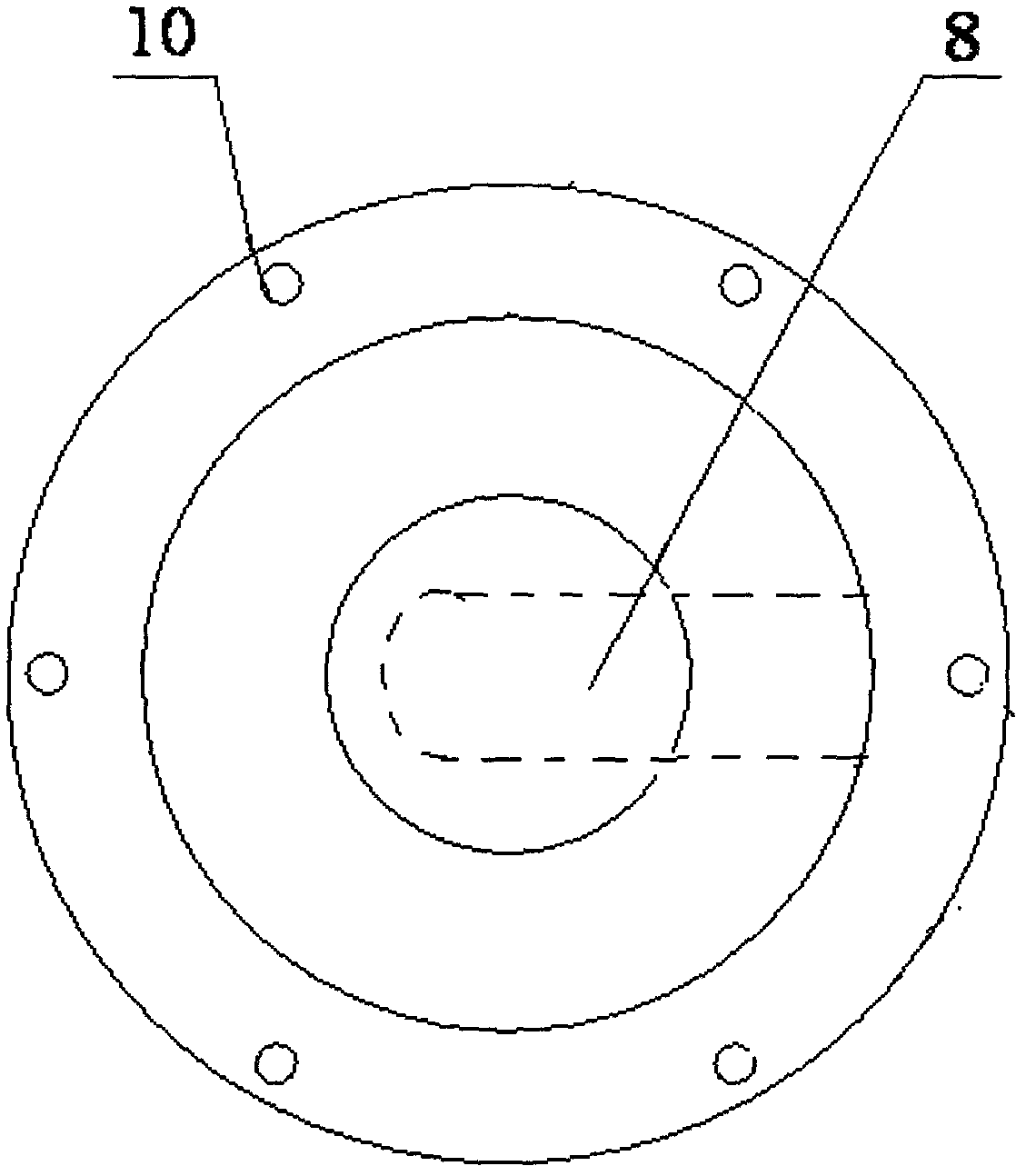

[0026] like figure 2 and image 3 As shown, the rock triaxial compression acoustic emission test system of the present invention is provided with an upper indenter (not shown in the figure) and a boss-shaped bottom indenter 2 in the triaxial chamber 1 of the existing MTS815 rock servo test system A cavity 8 opening to one side is processed on the thick diameter part of the bottom indenter 2. The cavity 8 is located on the indentation axis directly below the rock sample. The bottom of the bottom indenter 2 is also provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com