Piston valve, especially for a pneumatic brake system in a vehicle

A technology of pneumatic braking and piston valve, applied in the direction of brakes, brake components, vehicle parts, etc., can solve the problems of high manufacturing cost and limited function of piston valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

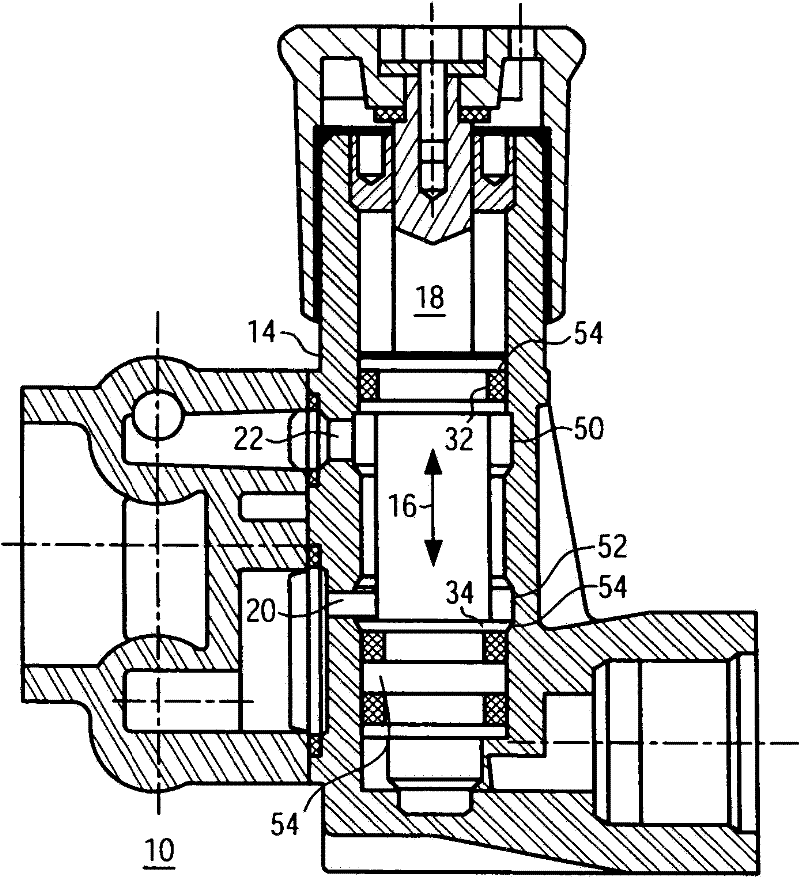

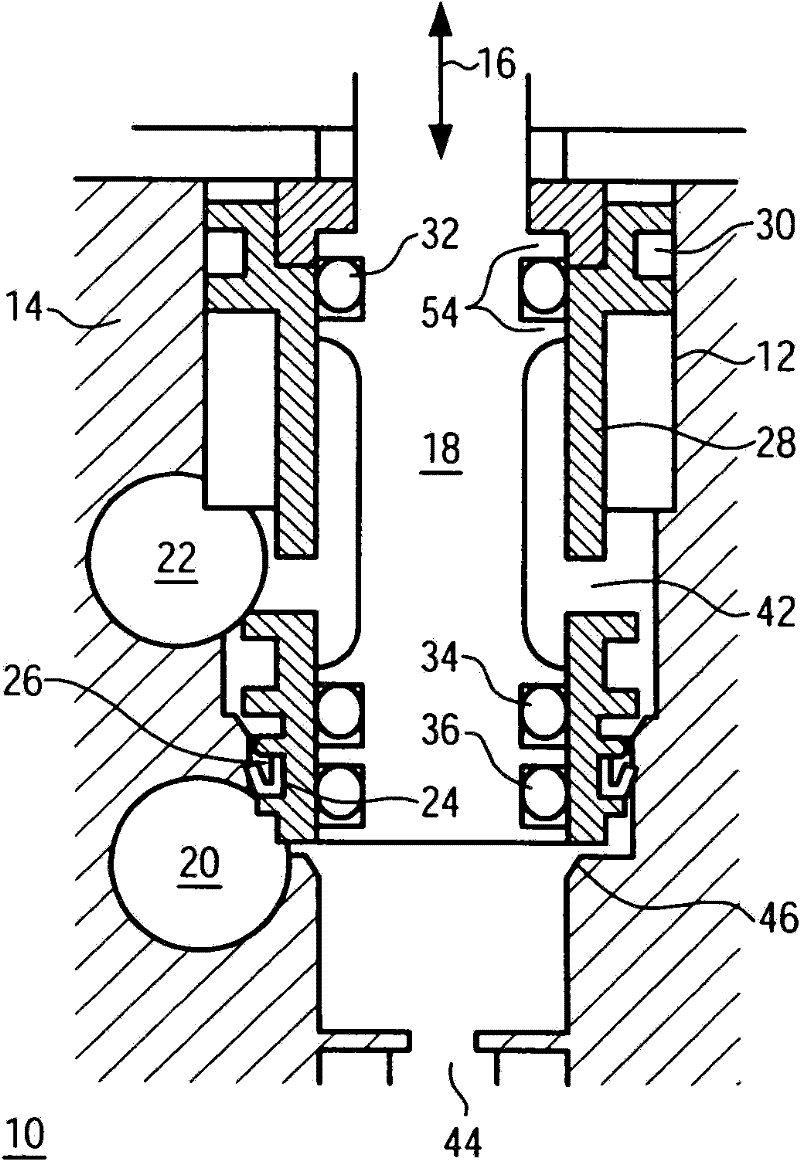

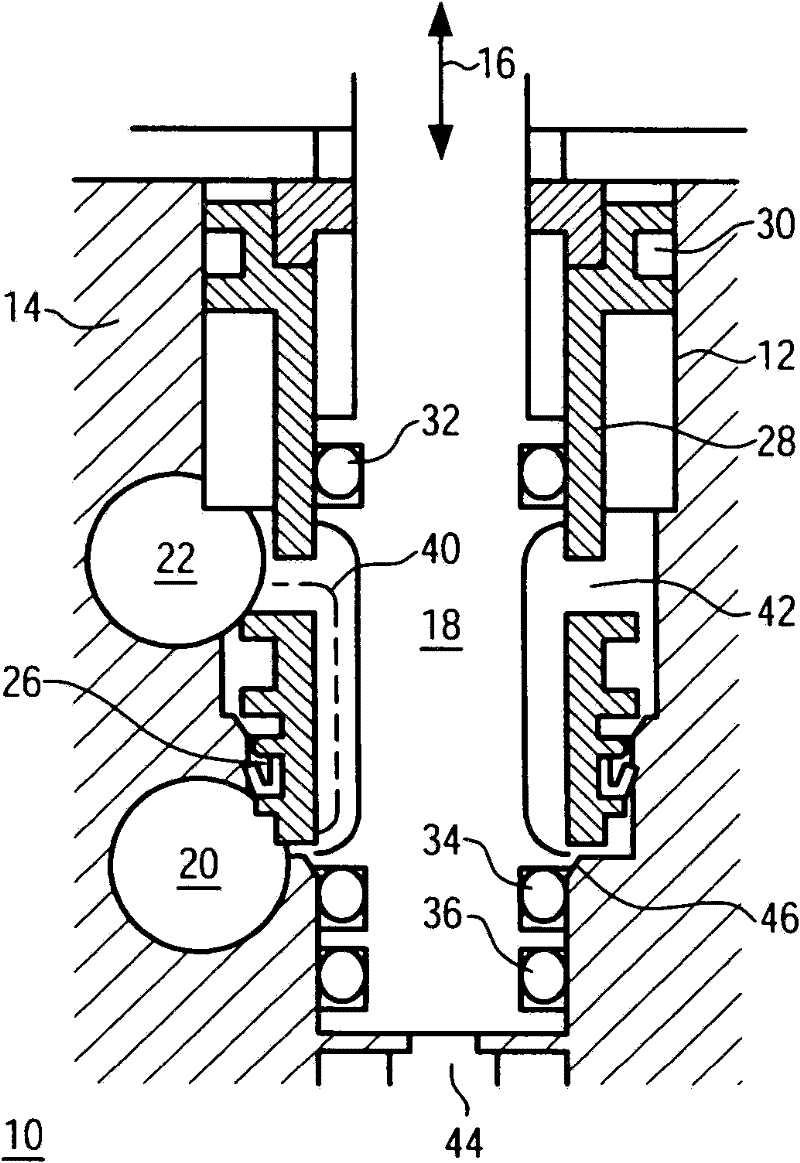

[0018] Figure 1 shows a piston valve according to the prior art. The piston valve 10 shown has a switching piston 18 that is movable in an axial direction 16 within a housing 14 . Arranged on the switching piston 18 are sealing rings 32 , 34 which are supported by a shoulder 54 . A further sealing ring 36 can be designed for secure sealing at all piston positions. The housing 14 includes a first port 20 and a second port 22 , which open into the region inside the housing 14 in which the movable switching piston 18 is arranged. During the movement of the switching piston 18 in the axial direction 16 , the sealing rings 34 , 36 are moved past the port 20 so that the compressed air passage between the first port 20 and the second port 22 is opened or closed. In that piston position in which the connection between ports 20 and 22 is closed, a further compressed air passage between first port 20 and third port 44 can be opened. In order to avoid damage to the sealing rings 32 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com