Expandable casing with enhanced collapse resistance and sealing capabilit

An expansion tube, depth technology, used in casing, drill pipe, wellbore/well components, etc., can solve problems such as difficult sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It should be understood that the various embodiments described herein can take various orientations, such as oblique, inverted, horizontal, upright, etc., and can take various configurations without departing from the principles of the present disclosure. The embodiments are described merely as useful examples of applications of the principles of the disclosure, which are not limited to any specific details of these embodiments.

[0016] In the following description of representative embodiments of the disclosure, directional terms, such as "above," "below," "upper," "lower," etc., are used for convenience when referring to the drawings. In general, "above", "upper", "upward" and similar terms refer to the direction along the borehole toward the Earth's surface, while "below", "lower", "downward" and similar terms refer to Along the direction of the borehole away from the Earth's surface.

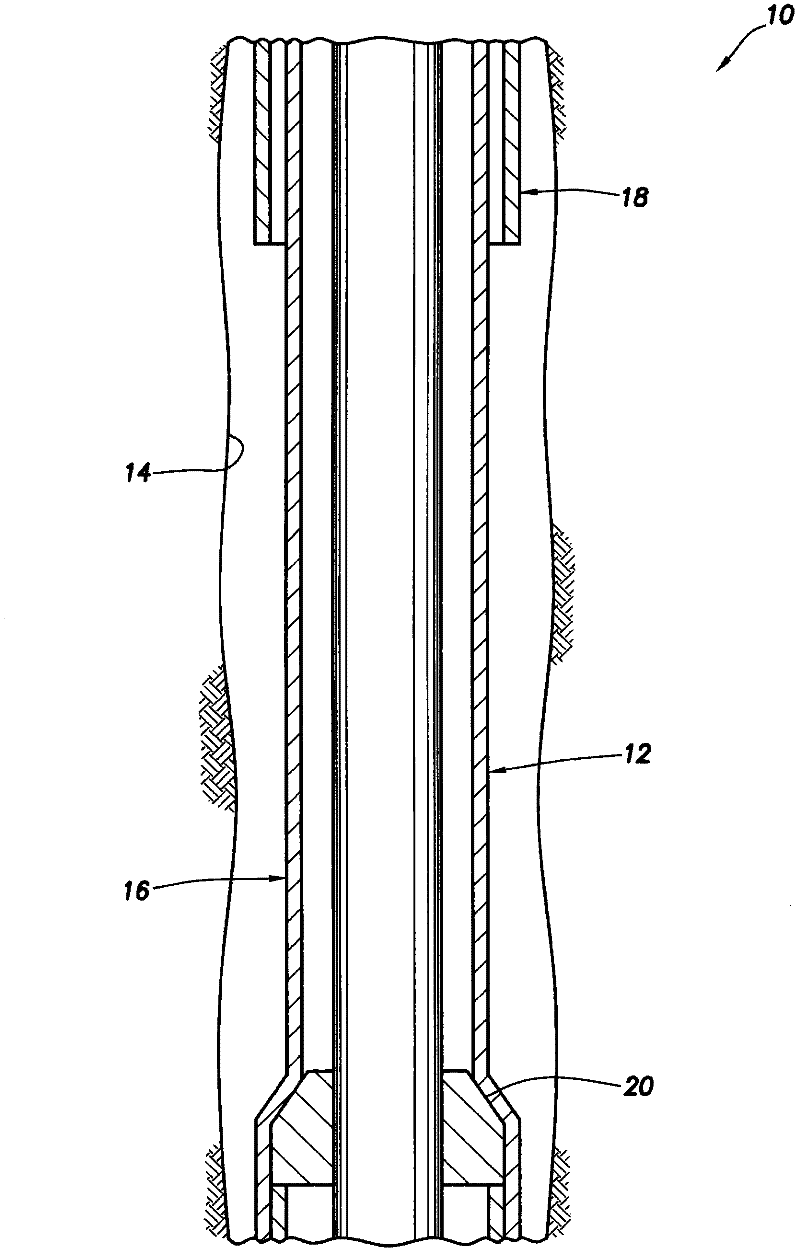

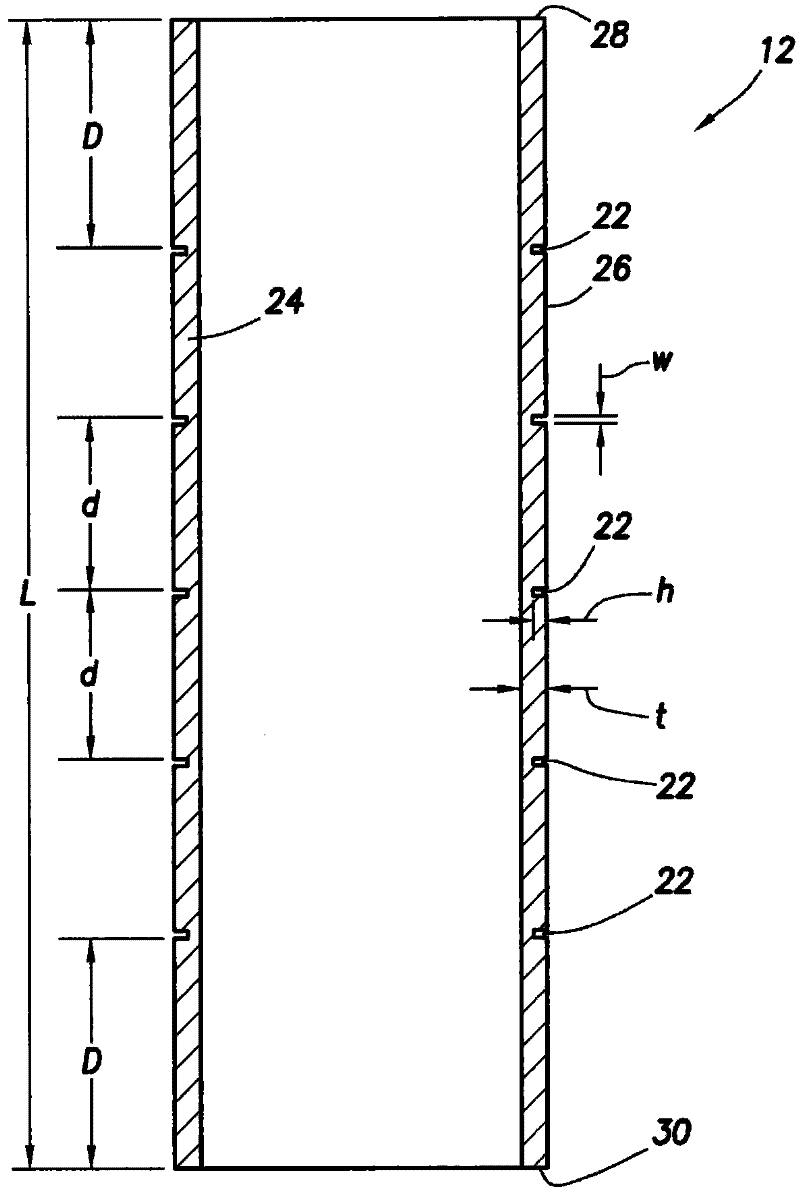

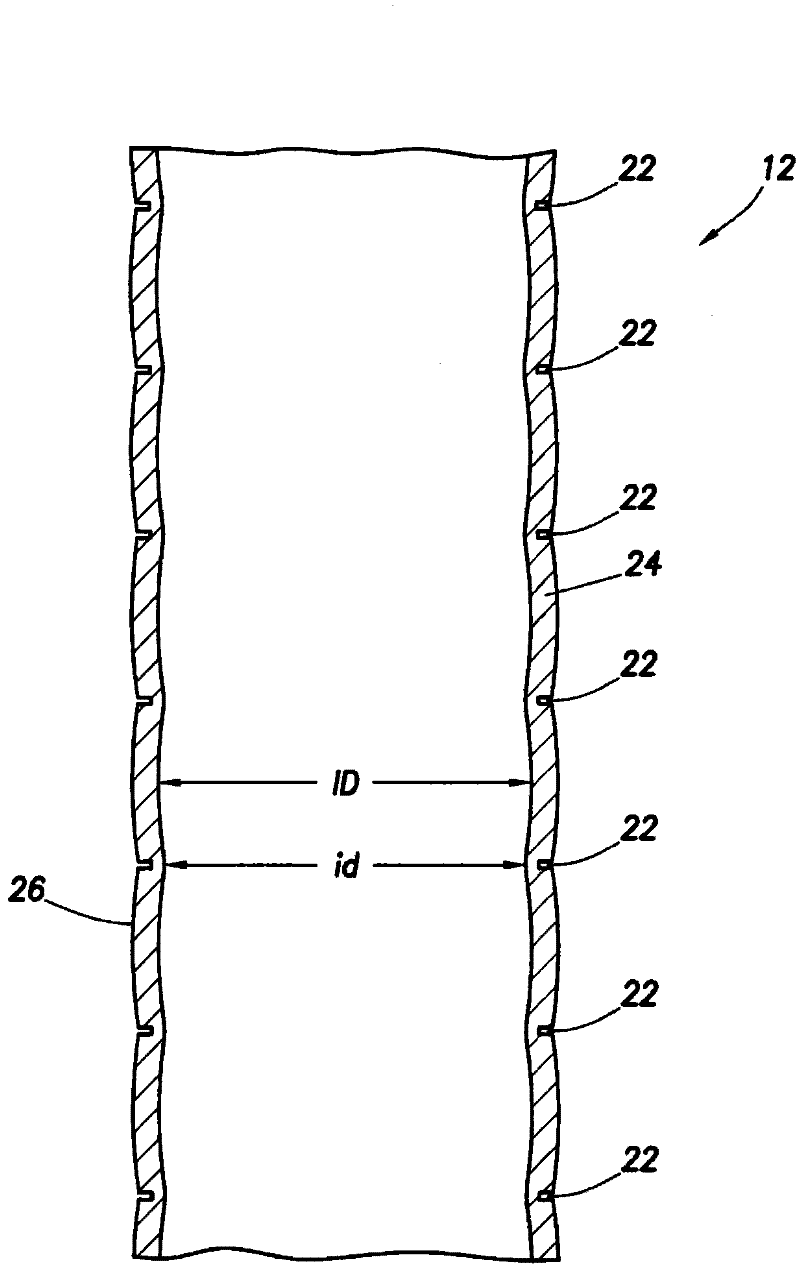

[0017] figure 1 Representatively illustrated in is a well system 10 embodying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com