An orange red automatic extrusion molding machine

An automatic extrusion and forming machine technology, which is applied in the field of orange red processing, can solve problems such as low work efficiency, low output, and insufficient extrusion, and achieve the effects of improving work efficiency, improving product appearance, and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

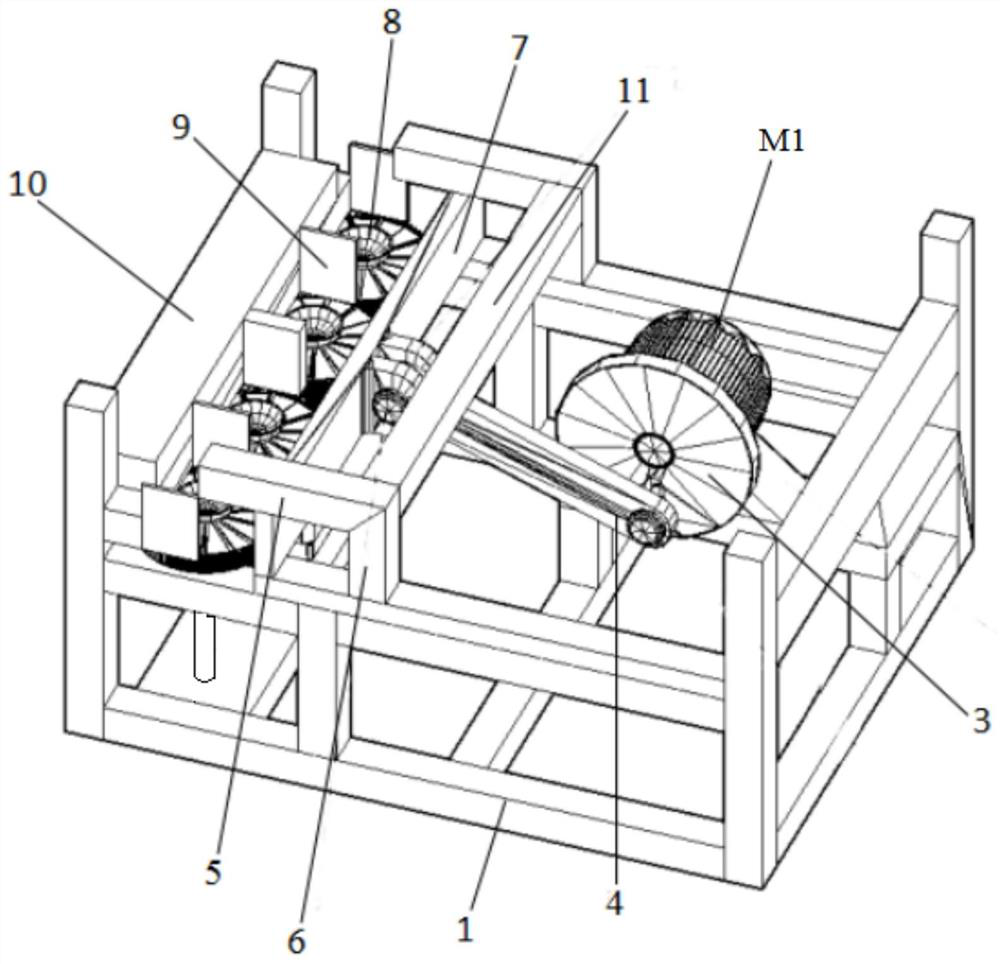

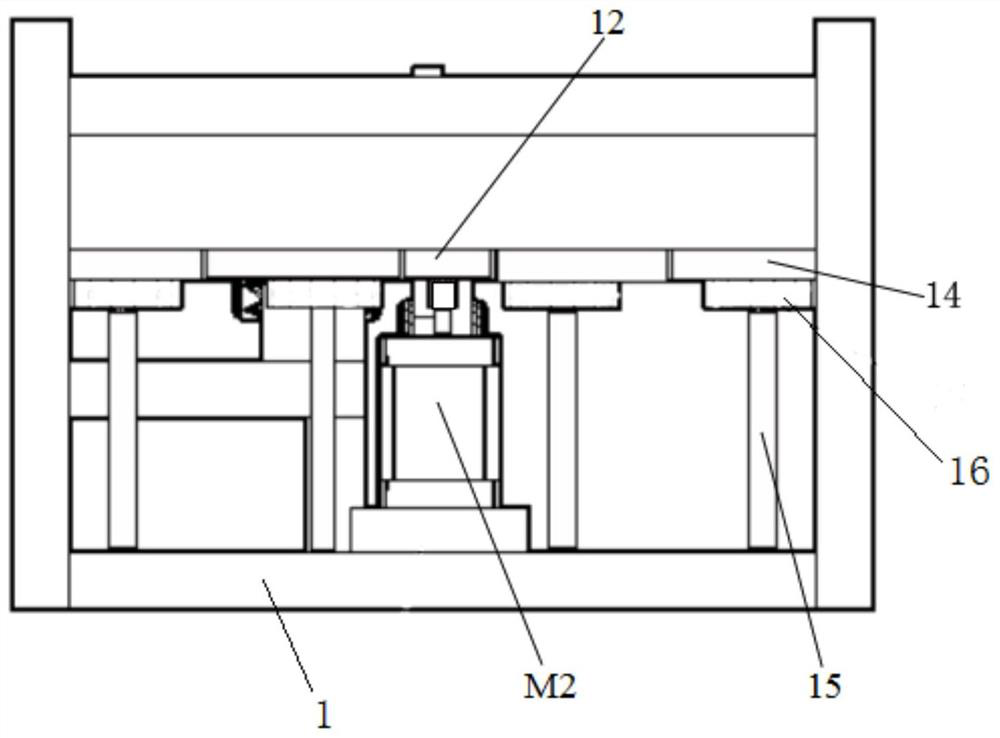

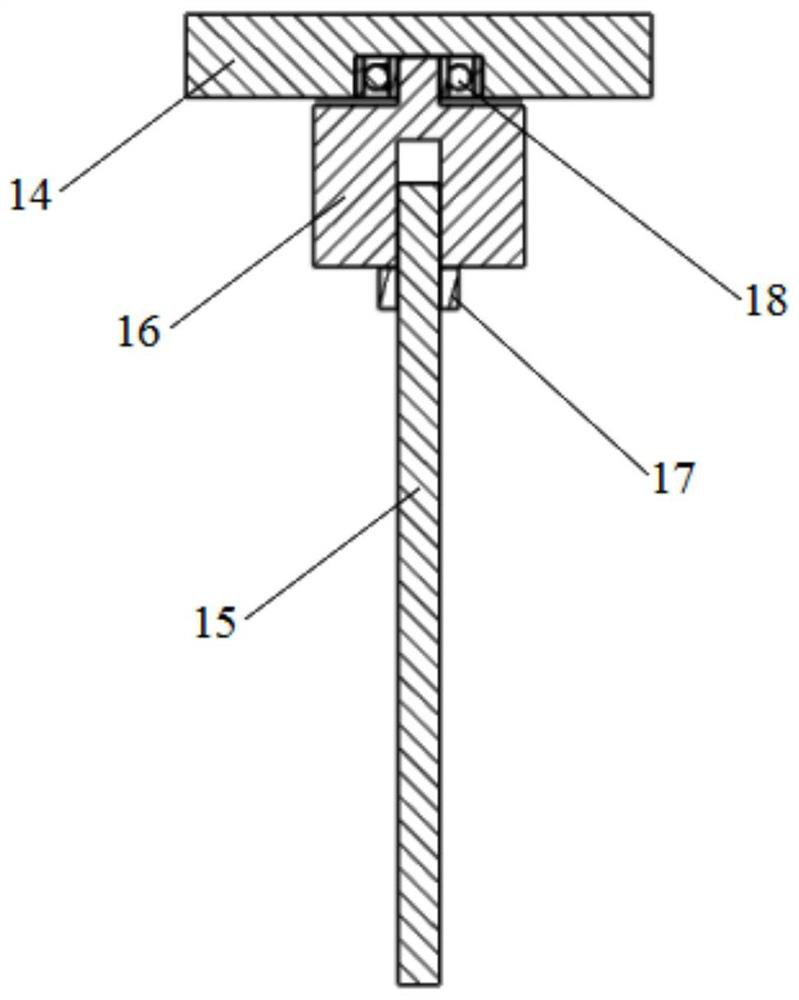

[0023] refer to Figure 1-Figure 4 , a kind of tangerine automatic extrusion molding machine of the present invention, comprises support 1, is provided with at least one fruit groove 8 for placing tangerine on the support 1, preferably, this fruit groove 8 is four, can extrude four at a time Juhong greatly improves the processing efficiency; the fruit trough 8 is a conical disk, which can stably place the orange fruit on it, which is convenient for placing the orange. Fruit trough 8 periphery is provided with the locating component that is used for positioning orange red; Fruit trough 8 one side is provided with the extruding mechanism that can reciprocate, is used to ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com