Metal support and manufacturing method thereof

A technology of metal stents and inner stents, applied in the field of metal stents of drug-eluting stents and their preparation, can solve the problems of high drug concentration, catching up of vascular restenosis, delayed vascular endothelialization, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

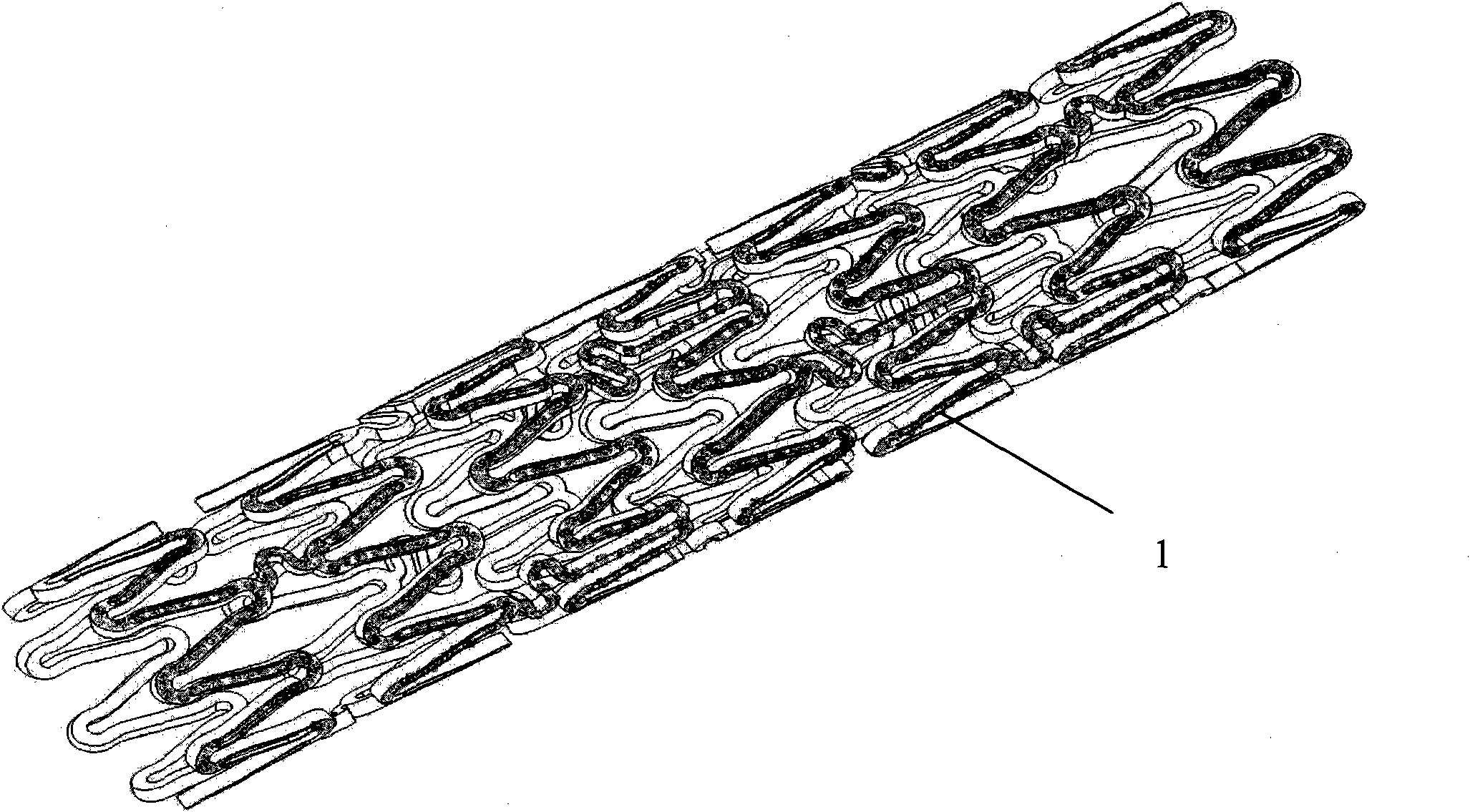

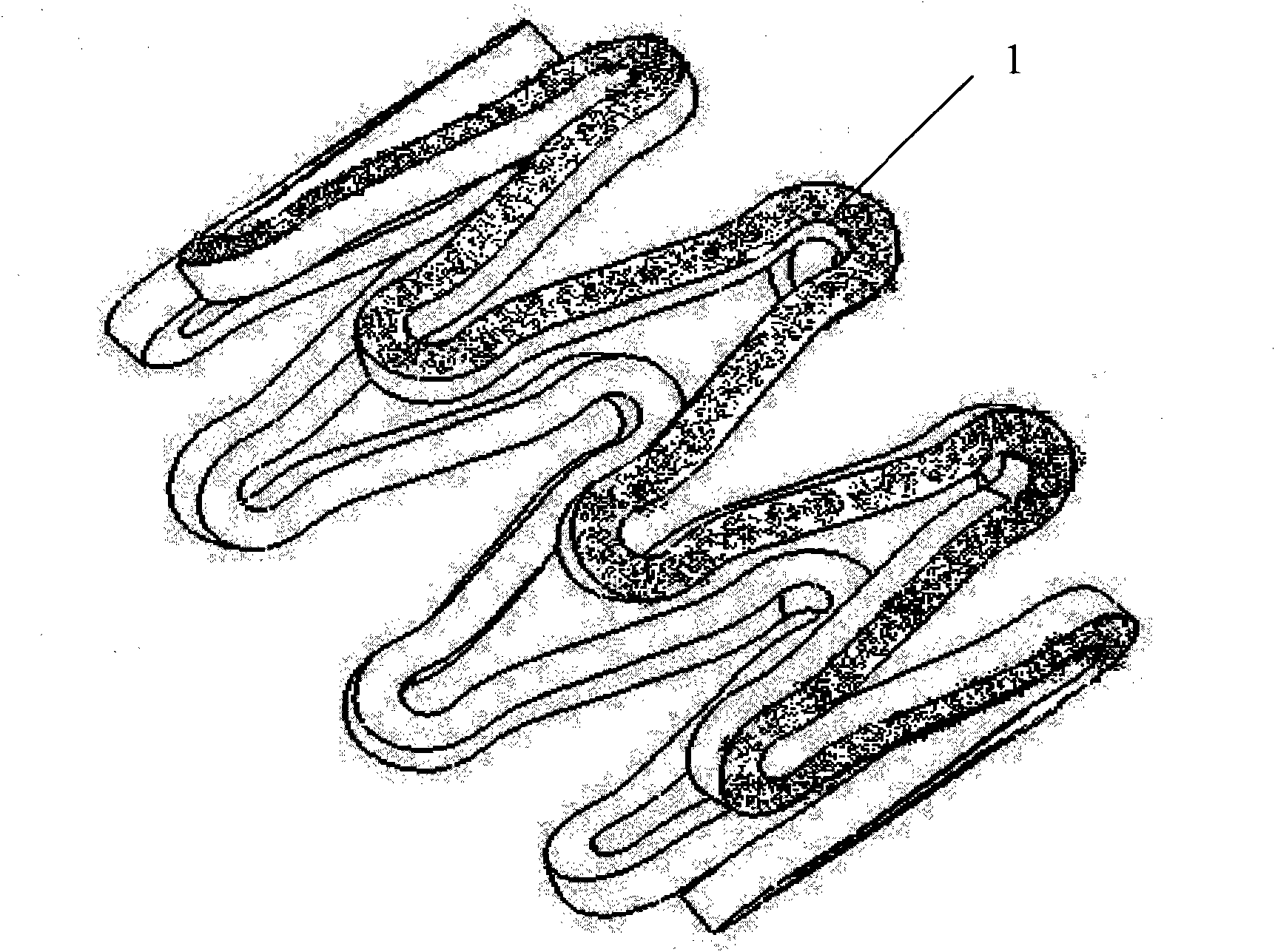

Image

Examples

preparation example Construction

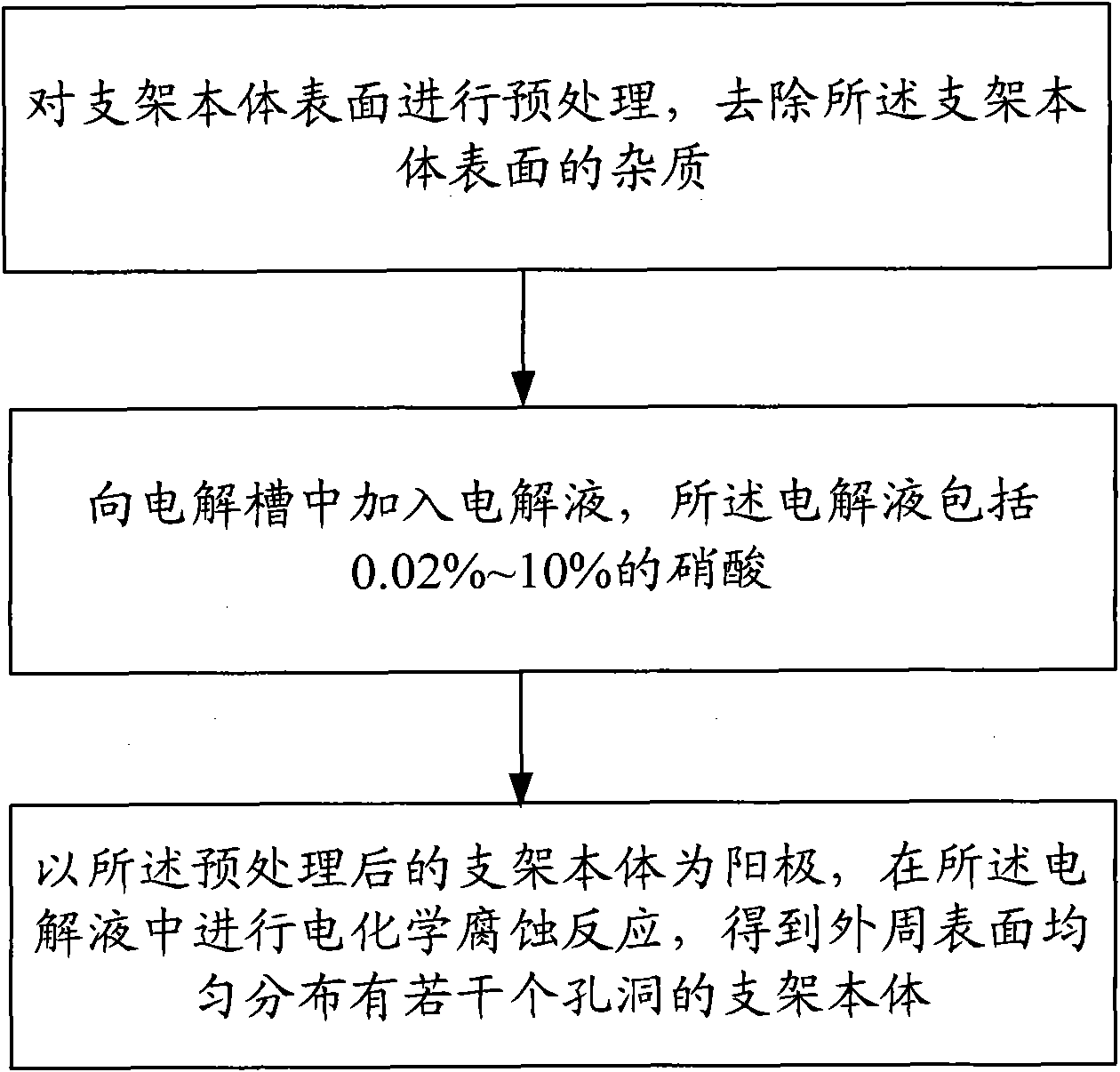

[0030] The embodiment of the present application also provides a preparation method of the above-mentioned metal stent, image 3 Shown is the process flow chart of this method, as image 3 Shown, this preparation method comprises:

[0031] The surface of the stent body is pretreated to remove impurities on the surface of the stent body.

[0032] Pretreatment of the surface of the stent body includes but is not limited to polishing, cleaning and / or drying, and other methods well known to those skilled in the art can also be used. Pretreatment is to remove the oxide layer, grease or other impurities on the surface of the stent body, so as to avoid affecting the electrochemical corrosion effect of the stent body, which will lead to uneven distribution of holes on the surface of the stent body 1 or the inability to control the pore diameter and hole depth of the holes.

[0033] An electrolytic solution is added into the electrolytic cell, and the formula of the electrolytic solu...

Embodiment 1

[0042] The bracket body is polished, then cleaned, and finally dried.

Embodiment 2

[0044] Follow the steps below to prepare the electrolyte solution:

[0045] Add 0.1ml of nitric acid, 100ml of ethylene glycol solution and 300ml of glycerol solution into 100ml of purified water, mix well, and set aside.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap