Purification system of high dust-laden supersaturated odorous gas and purification method

A purification system and gas technology, which is applied in the field of purification systems for highly dusty and supersaturated odorous gases, can solve the problems of poor tolerance to fluctuations in pollutant content, high investment and operating costs, and large equipment, and achieve low operating costs, Good effect and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

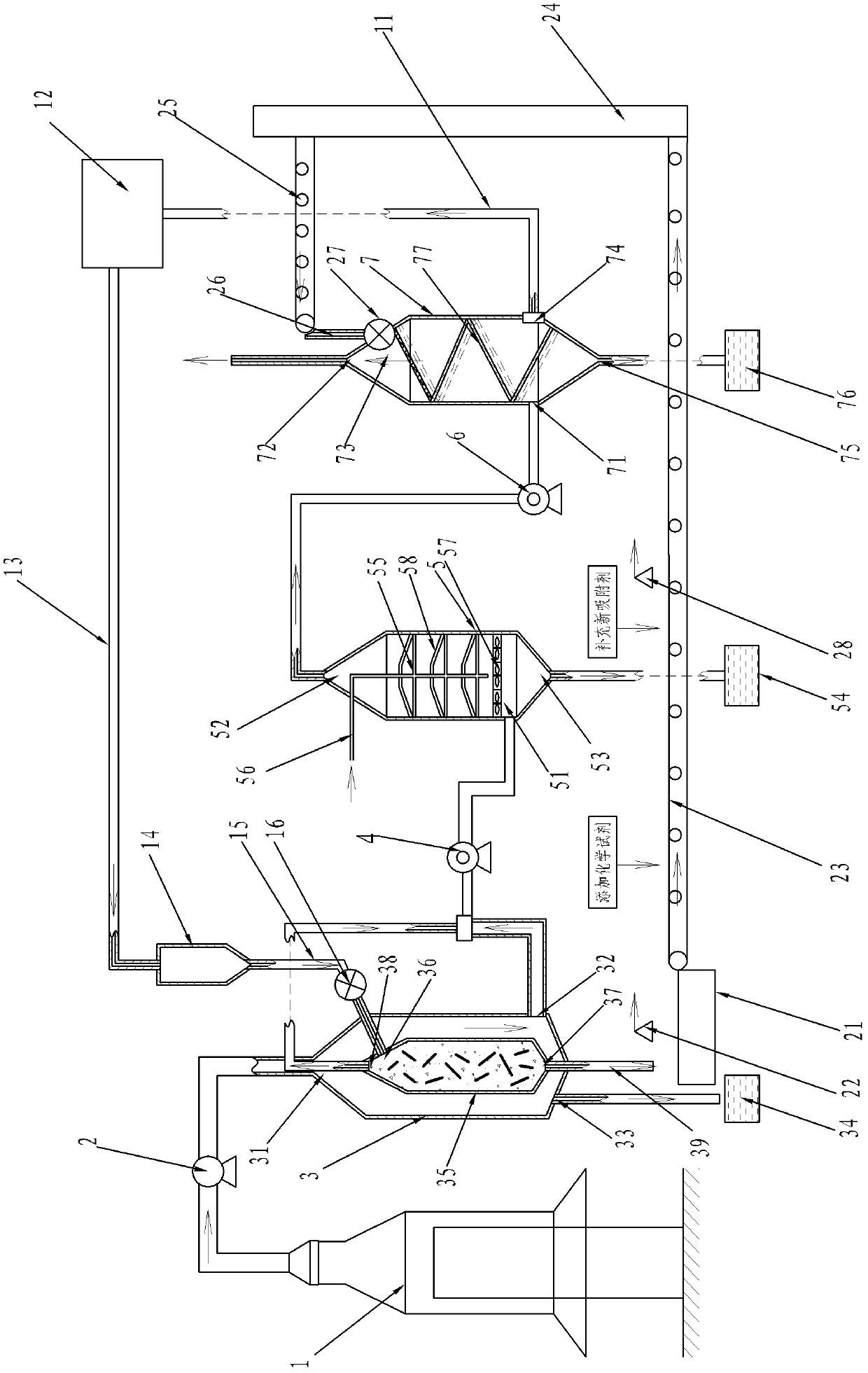

[0017] Such as figure 1 As shown, the purification system of the present invention's high dust-containing supersaturated odor gas comprises a gas collection cover 1, a first induced draft fan 2, a drying tower 3, a second induced draft fan 4, a demisting and dedusting tower 5, a third induced draft fan 6, Adsorption purification tower 7.

[0018] The top of the drying tower 3 is provided with a flue gas inlet 31 , one side of the lower part is provided with a flue gas outlet 32 , the other side of the lower part is provided with a condensed water drain outlet 33 , and a condensed water drain tank 34 is arranged below the condensed water drain outlet 33 . An adsorbent cartridge 35 is arranged inside the drying tower 3 , an adsorbent inlet 36 is arranged at the top of the adsorbent cartridge 35 , an adsorbent outlet 37 is arranged at the bottom of the adsorbent cartridge 35 , and a gas outlet 38 is arranged at the top of the adsorbent cartridge 35 .

[0019] A flue gas inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com