Flat machine triangle processing technology

A processing technology and triangle technology, applied in the field of flat knitting triangle processing technology, can solve problems such as hindering the improvement of knitted products and backward triangle processing accuracy, and achieve the effects of bright and beautiful appearance, improved wear resistance and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Processing technology of plane triangle:

[0033] 1) Blank fixing: fix the blank on the workbench;

[0034] 2) Plane rough grinding: Use a 40-mesh surface grinder to carry out plane rough grinding on the upper and lower surfaces of the blank respectively. After the plane rough grinding, the machining allowance of the upper surface of the blank is measured as 0.25, and the machining allowance of the lower surface Measured to be 0.5mm;

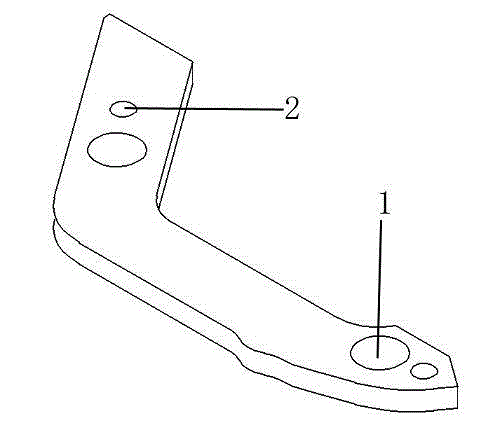

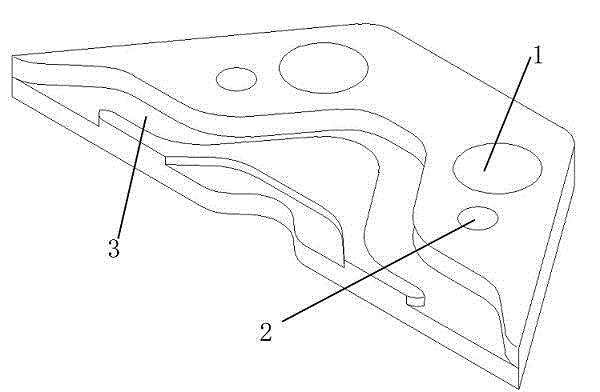

[0035] 3) Drilling: Drill the fixed hole 1 and the positioning hole 2 on the blank processed in step 2. The drilling of the fixed hole 1 is done by the machining center, and it is a one-time molding. The absolute error of the fixed hole 1 after punching is 0.05mm , the positioning hole 2 is initially drilled by the machining center, and the machining allowance of the positioning hole 2 after the initial drilling is measured to be 0.25mm;

[0036] 4) Heat treatment: first raise the temperature of the blank treated in step 3 to 700°C and ...

Embodiment 2

[0051] Processing technology of plane triangle:

[0052] 1) Blank fixing: fix the blank on the workbench;

[0053] 2) Plane rough grinding: Use 80-mesh sand surface grinder to carry out plane rough grinding on the upper and lower surfaces of the blank respectively. After the plane rough grinding, the machining allowance of the upper surface of the blank is measured as the machining allowance of the lower surface of 0.5mm Measured to be 0.25mm;

[0054] 3) Drilling: Drill the fixed hole 1 and the positioning hole 2 on the blank processed in step 2. The drilling of the fixed hole 1 is done by the machining center, and it is a one-time molding. The absolute error of the fixed hole 1 after punching is 0.05mm , the positioning hole 2 is initially drilled by the machining center, and the machining allowance of the positioning hole 2 after the initial drilling is measured to be 0.5mm;

[0055] 4) Heat treatment: first raise the temperature of the blank processed in step 3 to 750°C ...

Embodiment 3

[0070] Processing technology of plane triangle:

[0071] 1) Blank fixing: fix the blank on the workbench;

[0072] 2) Plane rough grinding: Use 80-mesh surface grinder to carry out plane rough grinding on the upper and lower surfaces of the blank respectively. After the plane rough grinding, the machining allowance of the upper surface of the blank is measured as the machining allowance of the lower surface of 0.28mm Measured to be 0.46mm;

[0073] 3) Drilling: Drill the fixed hole 1 and the positioning hole 2 on the blank processed in step 2. The drilling of the fixed hole 1 is done by the machining center, and it is a one-time molding. The absolute error of the fixed hole 1 after punching is 0.05mm , the positioning hole 2 is initially drilled by the machining center, and the machining allowance of the positioning hole 2 after the initial drilling is measured to be 0.42mm;

[0074] 4) Heat treatment: first raise the temperature of the blank treated in step 3 to 730°C and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com