Thermoelectricity-separating high-heat-conducting LED (light emitting diode) light source substrate

An LED light source, thermoelectric separation technology, applied in the direction of light source, light source fixed, point light source, etc., can solve the problems of limited thermal conductivity improvement, reduced voltage resistance, high thermal resistance, etc., to reduce contact thermal resistance and improve thermal conductivity. efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

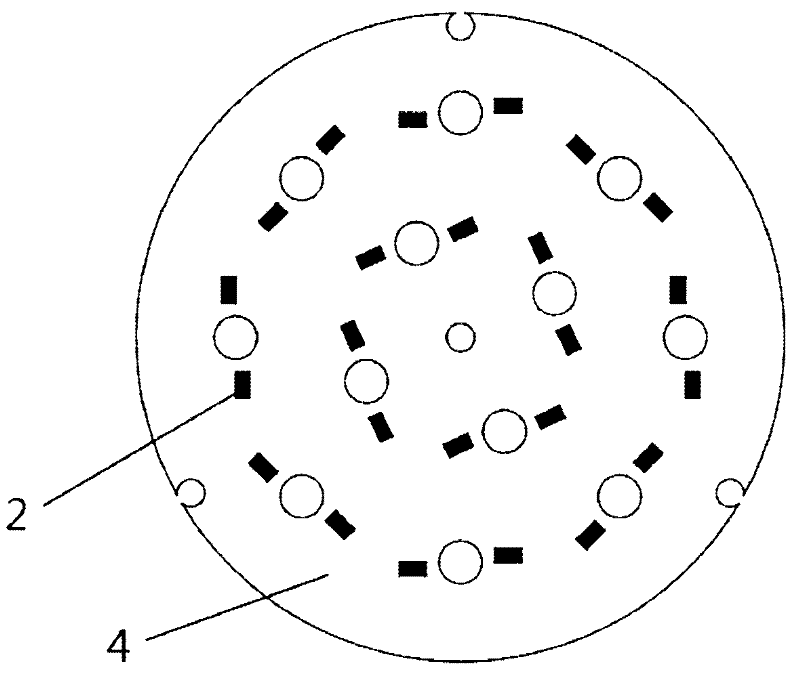

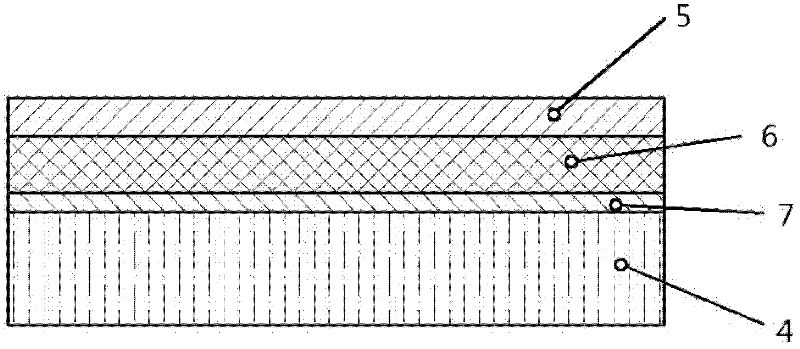

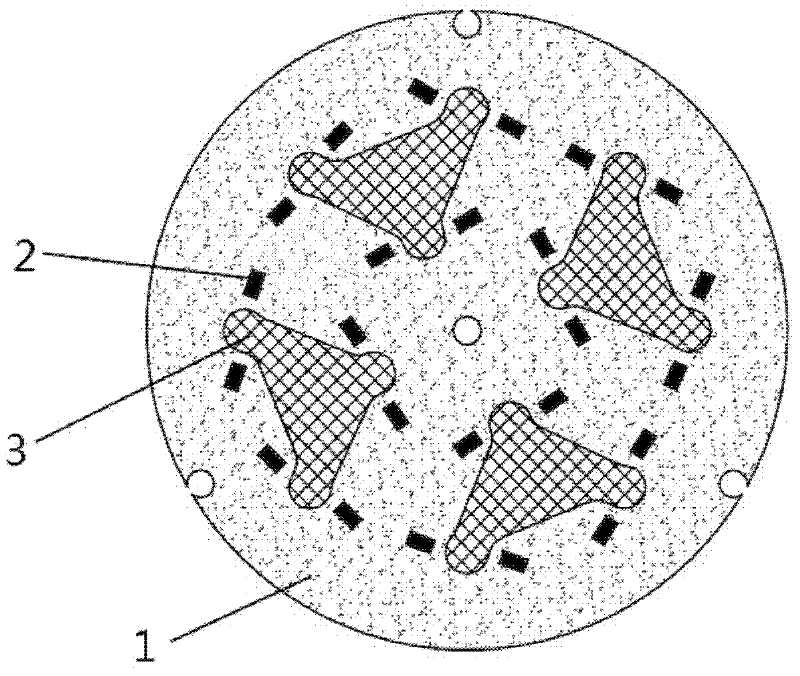

[0030] Such as figure 1 Shown is a LED light source board with thermoelectric separation and high thermal conductivity, including FR4 PCB substrate 1, said FR4 PCB substrate 1 is provided with LED conductive pin solder joints 2, said FR4 PCB is embedded with a heat-conducting metal plate 3, said heat-conducting The metal plate is insulated from the solder joints of the LED conductive pins. The heat-conducting metal plate can be an iron plate, an aluminum plate, a copper plate or a stainless steel plate with good heat-conducting effect. The preferred heat-conducting metal plate is copper plate.

[0031] Solder the LED, FR4 PCB, and copper plate together by reflow soldering, and then fix the LED light source board on the radiator to form a whole. Use reflow soldering to directly solder the copper plate and the heat sink on the LED together with solder paste.

[0032] Since the thermal conductivity of the copper plate is 384W / m.K, this light source board can greatly reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com