A kind of ultraviolet lamp bead encapsulation structure and preparation method thereof

A technology of packaging structure and ultraviolet lamp, which is applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of light absorption or poor air tightness, poor antistatic ability, low optical packaging efficiency, etc., and achieve modification Improve light shape, heat dissipation effect, and improve packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

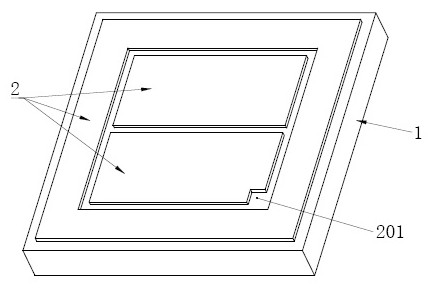

[0065] As shown in FIG. 1 to FIG. 15, the present embodiment provides an ultraviolet lamp bead packaging structure, including a substrate 1, a substrate

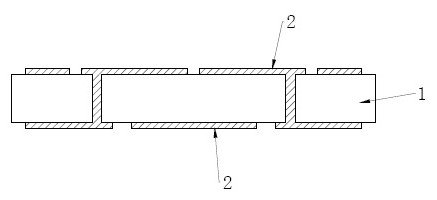

[0067] In this embodiment, the first metal layer 2 and the second metal layer 3 are both Ni layers, Cu layers, Ni layers, and Au layers.

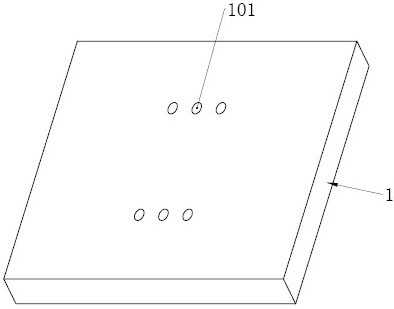

[0068] In this embodiment, the two ends of the substrate 1 are respectively provided with through holes 101, the first metal layer 2, the second metal layer 3

[0070] In the present embodiment, taking the specification as a substrate with a length of 3.8mm, a width of 3.8mm and a thickness of 0.5mm as an example, the diameter of the through hole is 60 mm

[0072] In this embodiment, the P electrode region of the first metal layer 2 on the package surface of the substrate 1 is provided with an electrode identification gap 201,

[0080] S1, a substrate 1 is provided, and a through hole 101 is opened on the substrate 1 to obtain a structure 1, as shown in Figure 1;

[0081] In this step, the equ...

Embodiment 2

[0101] This embodiment is the same as the UV lamp bead packaging structure in the first embodiment, the difference is that the

Embodiment 3

[0104] This embodiment is the same as the UV lamp bead packaging structure in the first embodiment, the difference is that the

[0107] In this embodiment, the glue with conductive particles is preferably conductive silver glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com