Separator type heat exchange method and separator type heat exchange device

A heat exchange device and clapboard-type technology, which is applied in combustion methods, lighting and heating equipment, and indirect carbon dioxide emission reduction, can solve the problems of low energy utilization rate and low heat exchange efficiency of combustion furnaces, and improve energy utilization High efficiency, low exhaust gas temperature and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

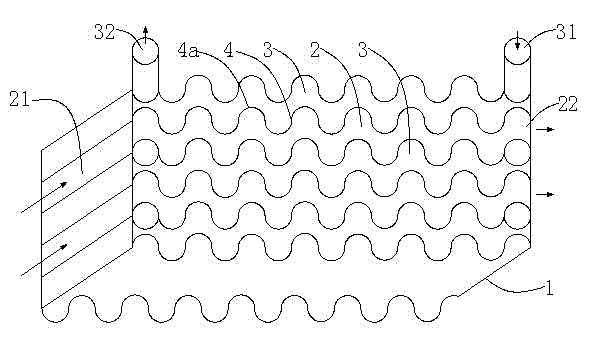

[0030] like figure 1 As shown, the baffle-type heat exchange device of this embodiment includes a housing 1, and at least two baffles 4 are fixed side by side at intervals in the housing 1, and the two sides of each of the baffles 4 are respectively used for passage of low temperature The low-temperature passage 2 for the medium and the high-temperature passage 3 passing through the high-temperature medium, and each low-temperature passage 2 is adjacent to the corresponding high-temperature passage 3 through a partition 4 . The partition plate 4 is formed with staggered protruding heat conduction surfaces 4a protruding toward both sides of the partition plate 4 respectively; the housing 1 is provided with a low-temperature passage inlet 21 and a low-temperature passage outlet 22 connected to each low-temperature passage 2, and connected with each low-temperature passage. A high-temperature channel inlet 31 and a high-temperature channel outlet 32 connected to the high-temper...

Embodiment 2

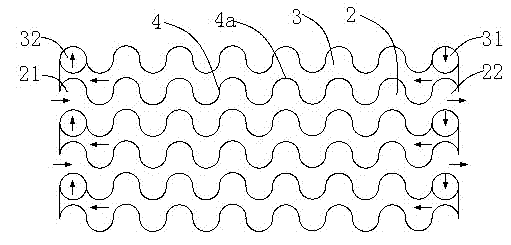

[0034] like figure 2 As shown, the baffle-type heat exchange device of this embodiment includes a housing 1, and at least two baffles 4 are fixed side by side at intervals in the housing 1, and the two sides of each of the baffles 4 are respectively used for passage of low temperature The low-temperature passage 2 for the medium and the high-temperature passage 3 passing through the high-temperature medium, and each low-temperature passage 2 is adjacent to the corresponding high-temperature passage 3 through a partition 4 . The partition plate 4 is formed with staggered protruding heat conduction surfaces 4a protruding toward both sides of the partition plate 4 respectively; the housing 1 is provided with a low-temperature passage inlet 21 and a low-temperature passage outlet 22 connected to each low-temperature passage 2, and connected with each low-temperature passage. A high-temperature channel inlet 31 and a high-temperature channel outlet 32 connected to the high-tempe...

Embodiment 3

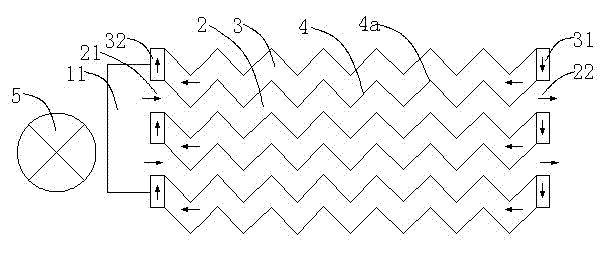

[0039] like Figure 4 and Figure 5 As shown, this implementation is a further improvement on the low-temperature channel inlet 21 and the low-temperature channel outlet 22 , as well as the high-temperature channel inlet 31 and the high-temperature channel outlet 32 on the basis of the above two embodiments. The low-temperature channel inlet 21 and the high-temperature channel outlet 32 are located side by side at one end of the housing 1 , and the low-temperature channel outlet 22 and the high-temperature channel inlet 31 are located side by side at the other end of the housing 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com