Inclination-angle-line-type fiber splicer capable of being opened and used repeatedly

An optical fiber splicer, tilt angle technology, applied in the coupling of optical waveguides, etc., can solve the problems of time-consuming and laborious, difficult splicing, splicing failure, etc., to reduce the cost of use, improve the quality of splicing, and simplify the degree of complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

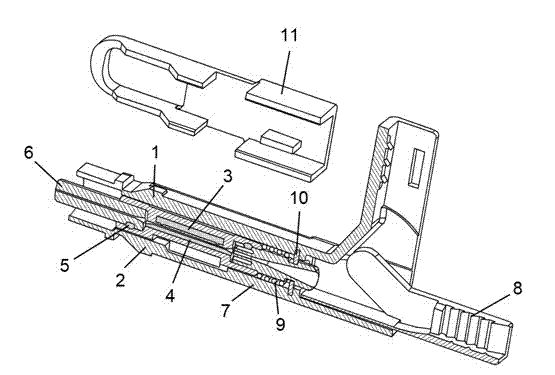

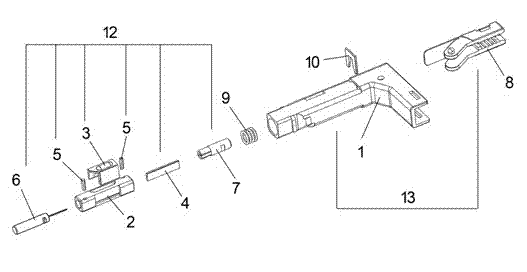

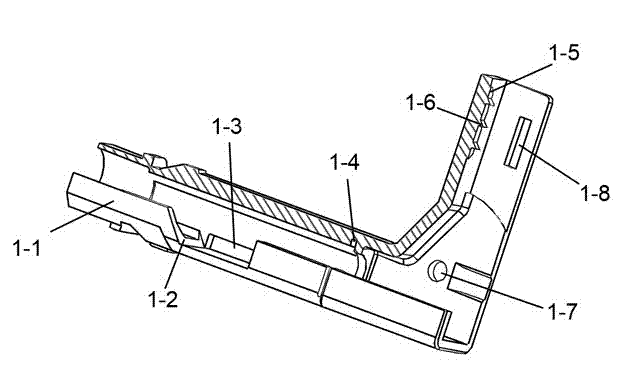

[0047] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13,

[0048] The adapter of the present invention includes a box assembly 12, a shell assembly 13, a spring 9, a card 10 and an opening cover 11, wherein the box assembly 12 includes a box body 2, a cover 3, a V-shaped groove metal block 4, and a latch 5. Ferrule 6 and guide block 7; a floating block 2-2 is arranged in the middle of the box body 2, and the two sides of the floating block 2-2 are respectively embedded groove 2-1 and building groove 2-5; the V-shaped The grooved metal block 4 is embedded in the embedded groove 2-5, and the opposite surface of the floating block 2-2 is provided with a V-shaped groove 4-1, and forms an optical fiber through hole 4-3 with it; the building cover 3 is attached to the box body 2 , the masonry 3-3 on one side of the cover 3 is pressed into the groove 2-5 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com