Temperature and pressure control method of dry quenched coke circulating system

A circulation system, temperature and pressure technology, applied in coke cooling, non-electric variable control, control/regulation system, etc., can solve the problems of poor accuracy of air volume and coke discharge, frequent adjustment, insufficient application, etc., and achieve the optimization of operation indicators , Reduce labor intensity, wide range of application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

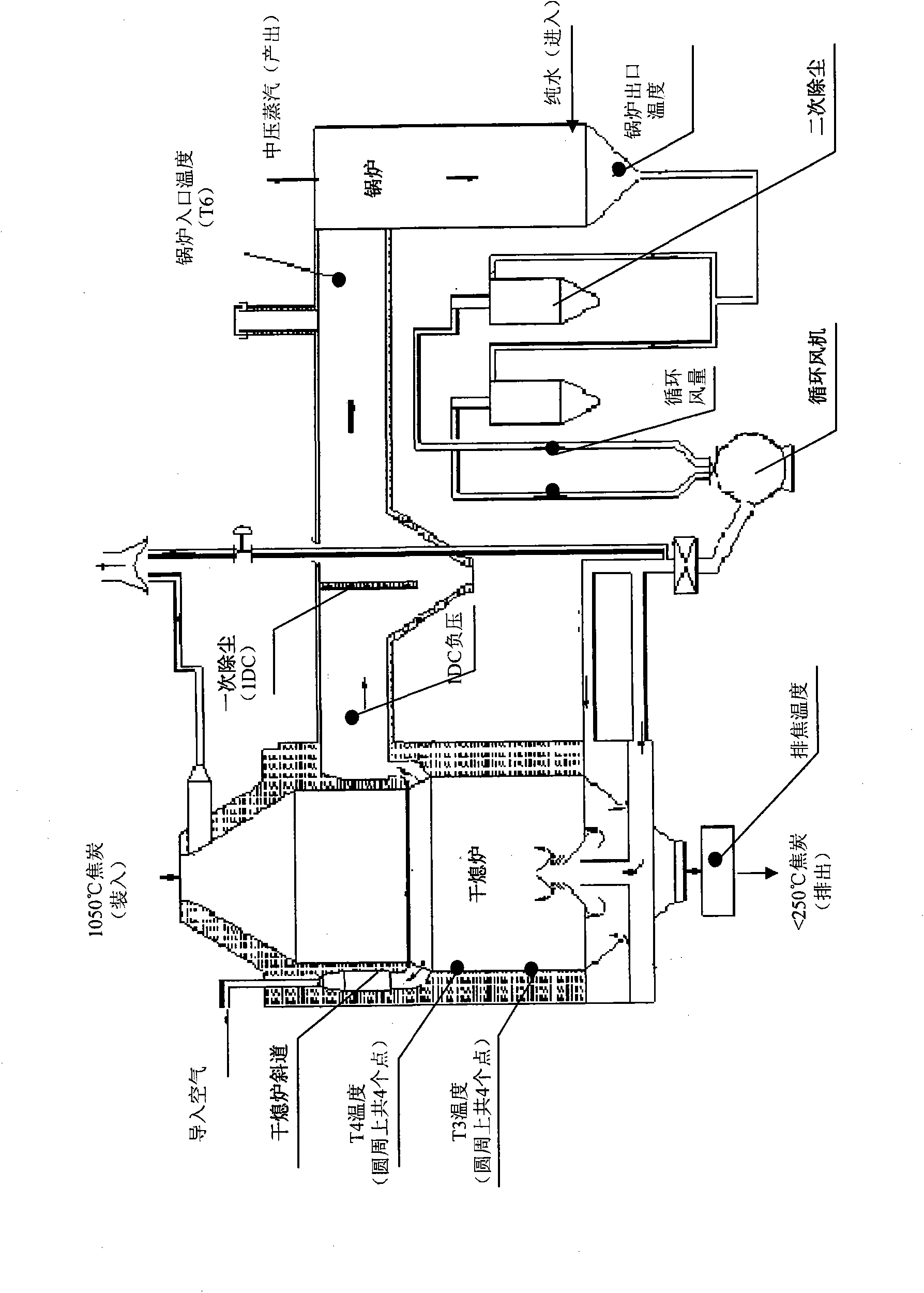

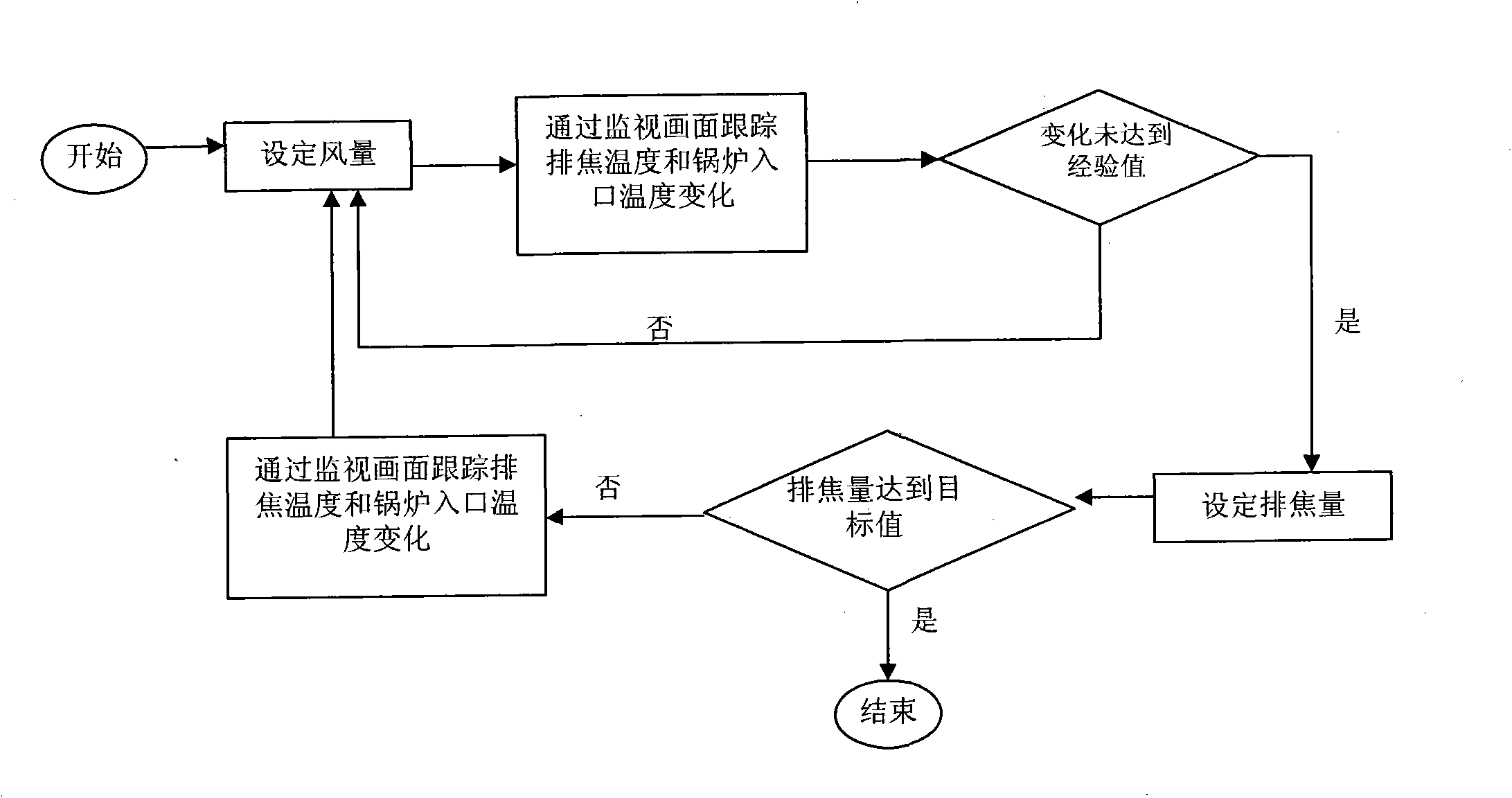

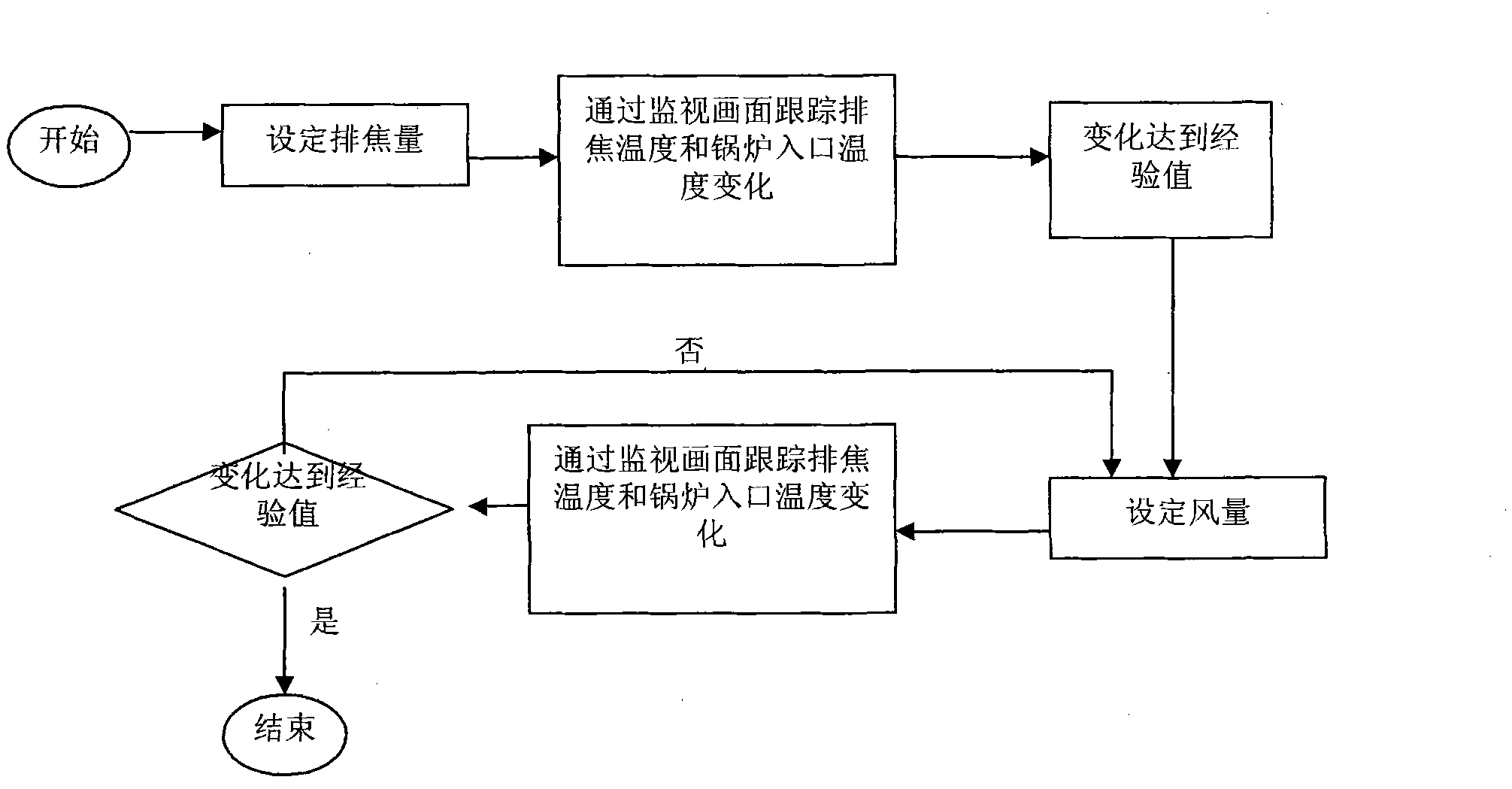

[0033] refer to Figure 4 As shown, the present invention proposes a temperature and pressure control method of a coke CDQ cycle system, comprising the following steps:

[0034] S1. Timely collect the first key control parameter, the first key parameter is controlled as the coke discharge amount.

[0035] S2. Collect a second key control parameter, where the second key control parameter is the circulating air volume.

[0036]S3. Correcting the first key control parameter and the second key control parameter to obtain the corrected first key control parameter and the second key control parameter. Among them, the correction of the second key control parameter includes: setting a flow meter in the discharge pipe of the fan outlet to measure the air volume released; measuring the total air volume entering and exiting the CDQ; and correcting the circulating air volume to the measured total air volume entering and exiting the CDQ The difference between the wind volume and Fang San...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com