Ground wire hitching apparatus

A grounding wire and grounding rod technology, applied in the field of grounding wire hooking devices, can solve the problems of time-consuming, laborious, and the grounding wire cannot guarantee reliable hooking, etc., and achieve the effects of ensuring reliability, improving efficiency and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

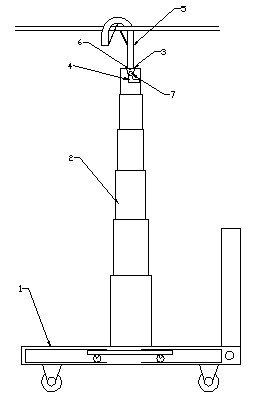

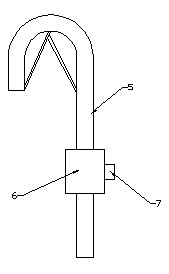

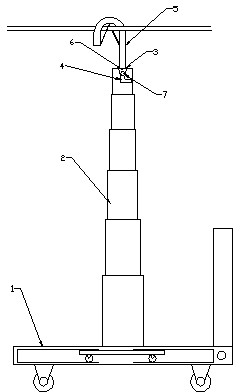

[0008] As shown in the figure, the ground wire hooking device includes a movable frame 1, on which a telescopic rod 2 that can be vertically telescopic under electric or manual operation is installed, and the telescopic rod as a whole can be operated electrically or manually. Under operation, it can rotate freely or move back and forth, left and right; the upper end of the telescopic rod is provided with a socket 3 for connecting with the grounding wire rod, and an L-shaped card slot 4 is opened on the hole wall of the socket, and the grounding rod part of the grounding wire 5 An insertion section 6 that can be matched with the socket is provided, and a radial detent 7 is provided on the outer wall of the insertion section, and the detent can move linearly along the vertical section of the above-mentioned L-shaped slot and can move along the L The horizontal section of the shaped clamping groove moves in a circle, so that the grounding rod part of the grounding wire can be clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com