Fixing structure of permanent magnet generator or motor permanent magnet

A permanent magnet generator and fixed structure technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of large air gap, time-consuming and labor-intensive, permanent magnets are not firmly fixed, etc., to achieve magnetic field distribution Uniformity, reduced air gap, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

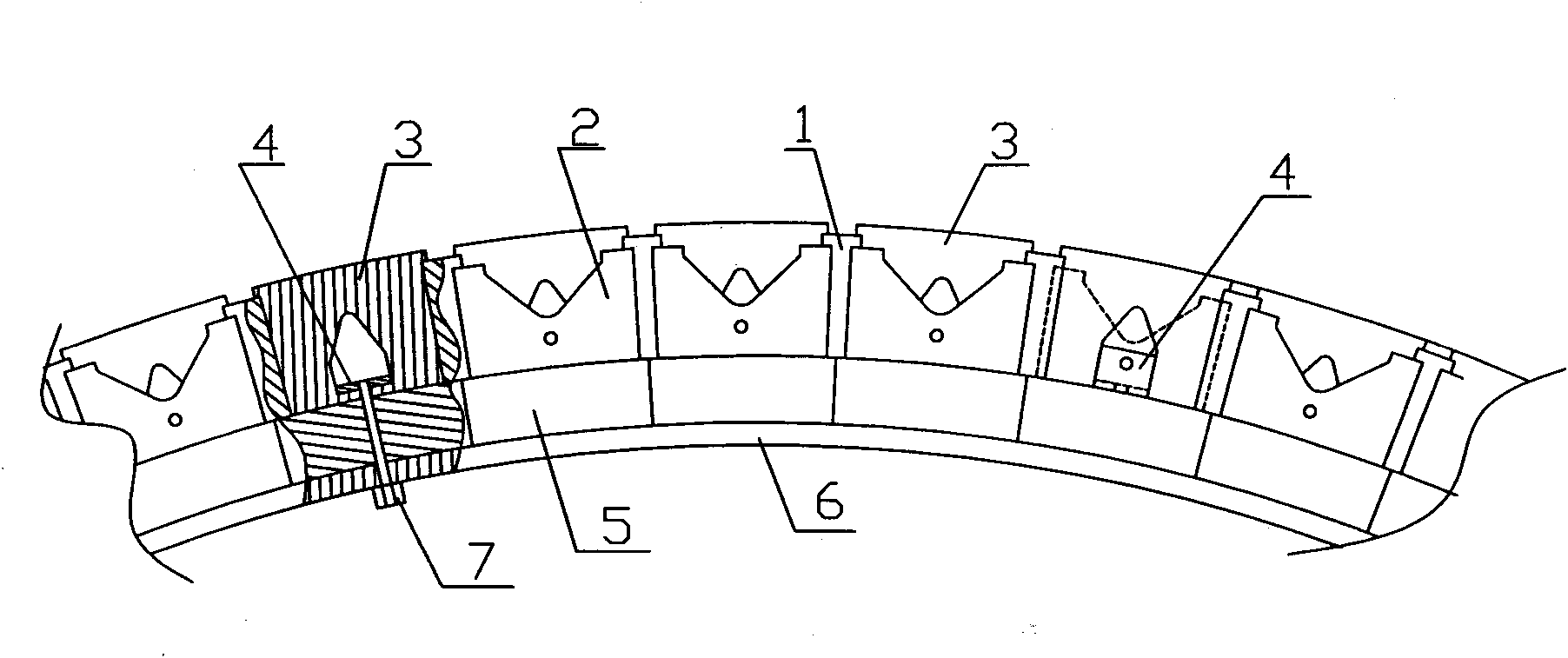

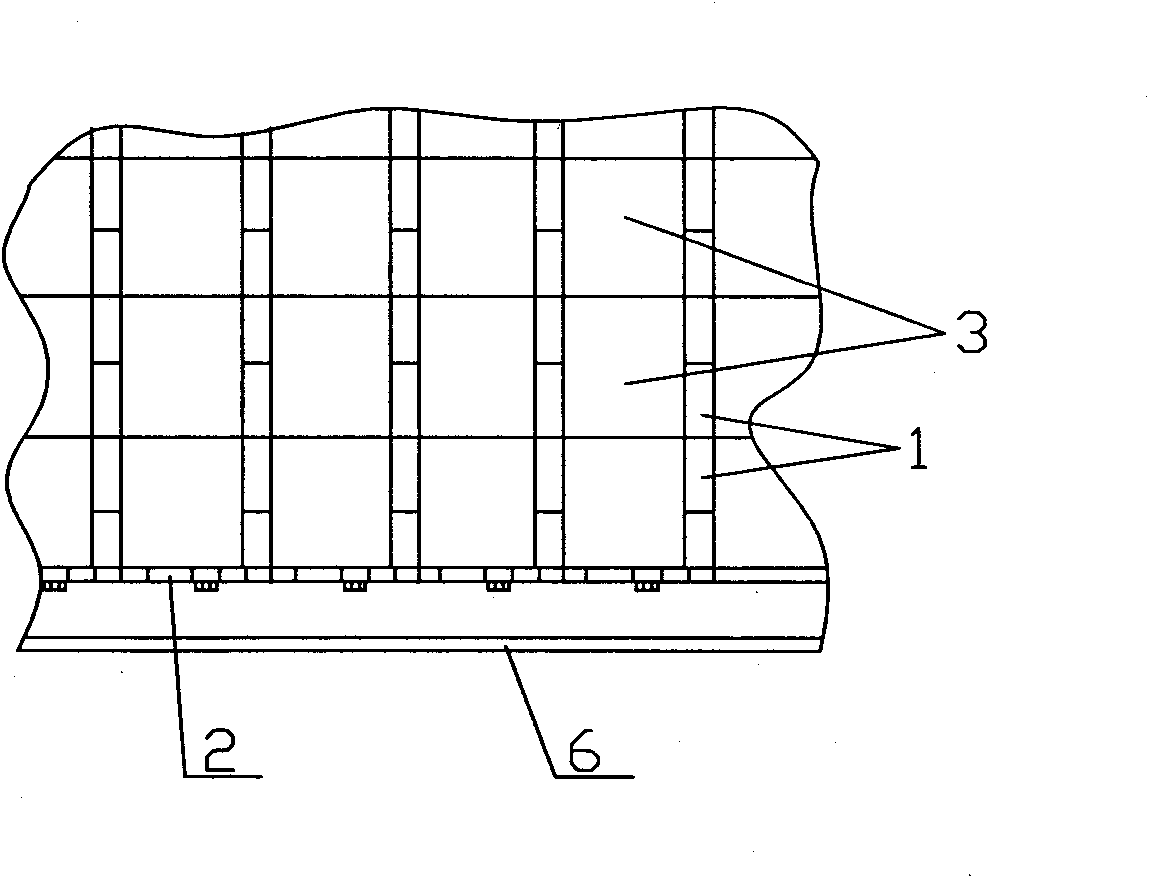

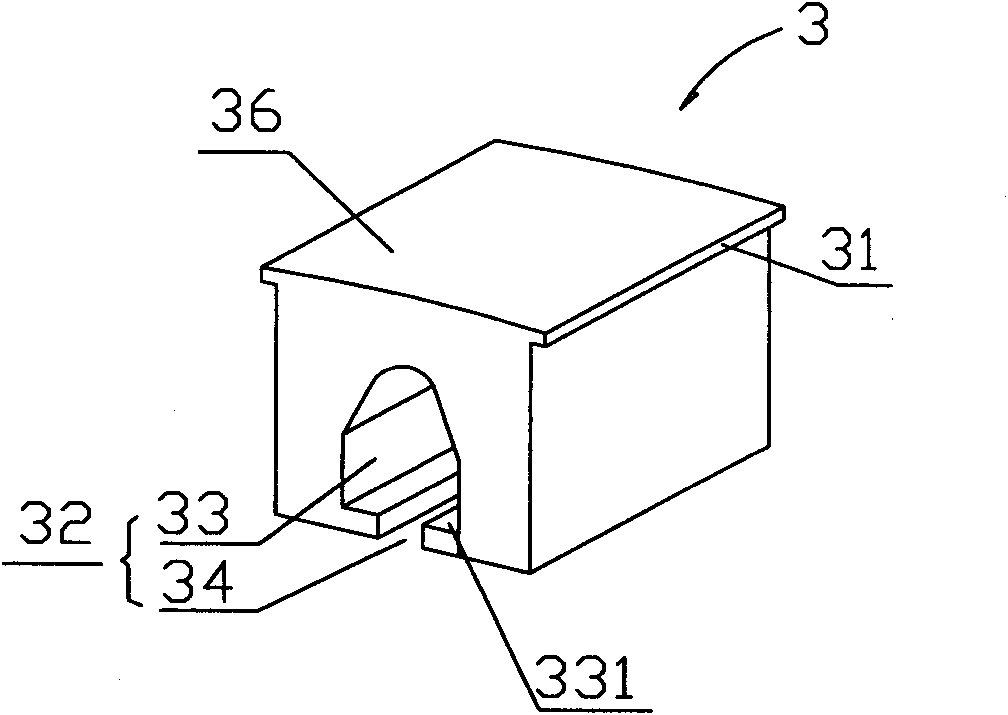

[0022] see figure 1 , 2 , the figure shows a permanent magnet generator or motor permanent magnet fixing structure according to the present invention, which includes a rotor cylinder 6, and several rows of permanent magnets 1 are arranged at uniform intervals along the surface circumference of the rotor cylinder 6; along the permanent magnets 1 is provided with a pole piece 3, and the two sides of the pole piece 3 are respectively provided with protrusions 31 for pressing the permanent magnets 1 on both sides; A channel for the permanent magnet 1 to penetrate is formed between two adjacent pole pieces, and the permanent magnet 1 is inserted into the channel and fixed on the two adjacent pole pieces 3 by the protrusions 31 on both sides thereof. Describe the surface of the rotor cylinder 6. Of course, the protruding portion 31 of the pole shoe 3 can be provided on the side of the pole shoe 3 , and at this time, only a groove is provided at a corresponding position on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com