Self-adaptive microfiltration membrane compressor

An adaptive compactor technology, applied in ultrafiltration, membrane technology, semi-permeable membrane separation, etc., can solve problems such as rigid compaction and fixation under working conditions, structural size tolerance, etc., and achieve simple structure and mechanical size Consistency, meet the effect of axial compression and elastic cushioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific embodiments.

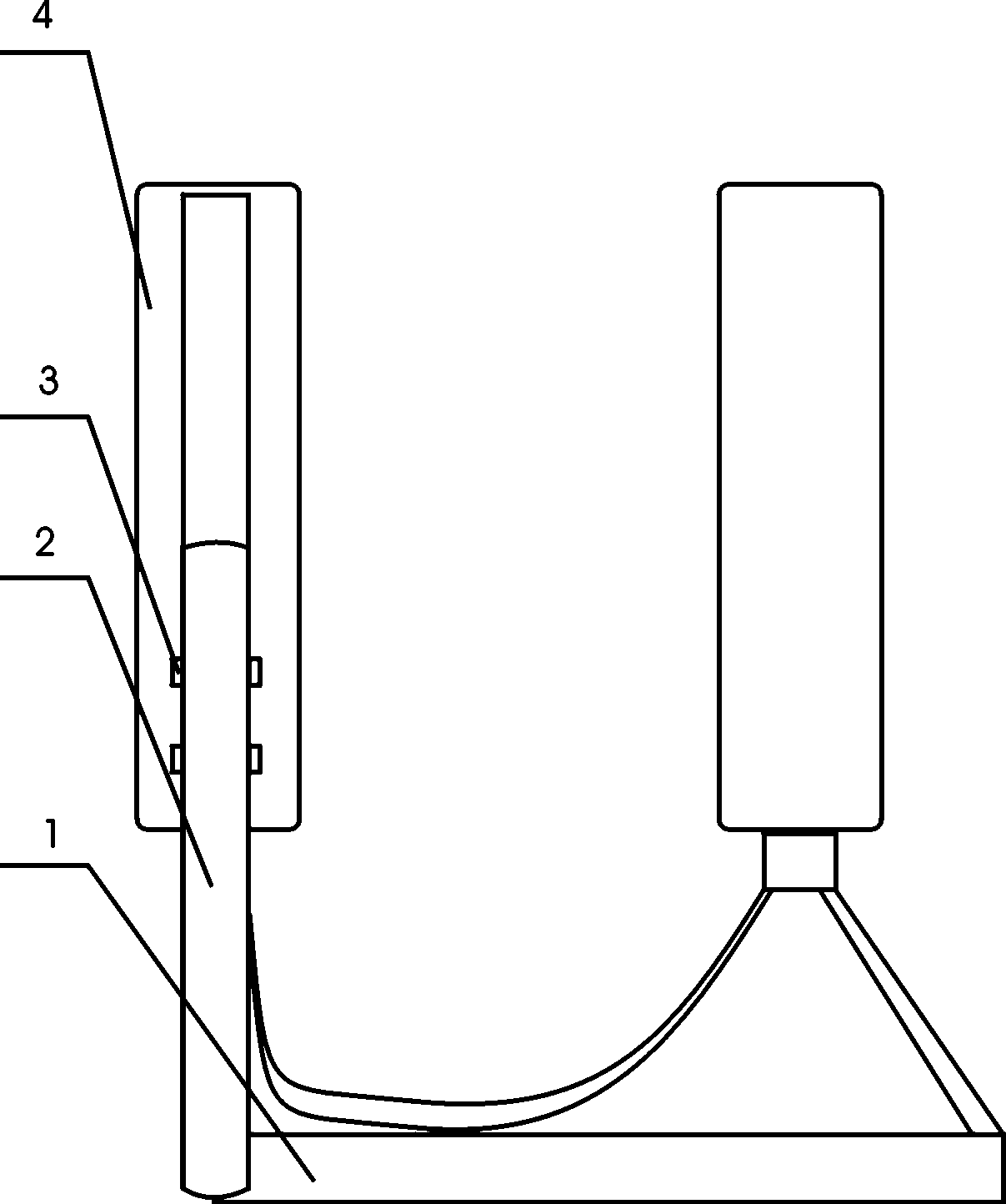

[0010] The microfiltration membrane self-adaptive compactor is composed of a triangular bracket, an axial support rod, an O-ring, and a gas chamber sleeve. It is characterized in that the triangular bracket is connected with the axial support rod, and the axial support rod is sleeved in the axial direction The O-ring of the support rod is tightly connected with the air chamber sleeve.

[0011] The microfiltration membrane self-adaptive compressor adopts the principle of air spring, which not only ensures the axial compression and fixation of the membrane element, but also has a certain elastic buffering effect. At the same time, the structure is simple, without precise and complicated machining requirements, and it is easy to assemble the membrane module. The technical characteristics of the present invention are: self-adaptability, using the principle of air springs, no need f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com