Cylindrical powder concentrator

A powder separator and cartridge technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of complex system structure, low efficiency of powder selection, high energy consumption, etc., to achieve The effect of small size, reduced cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

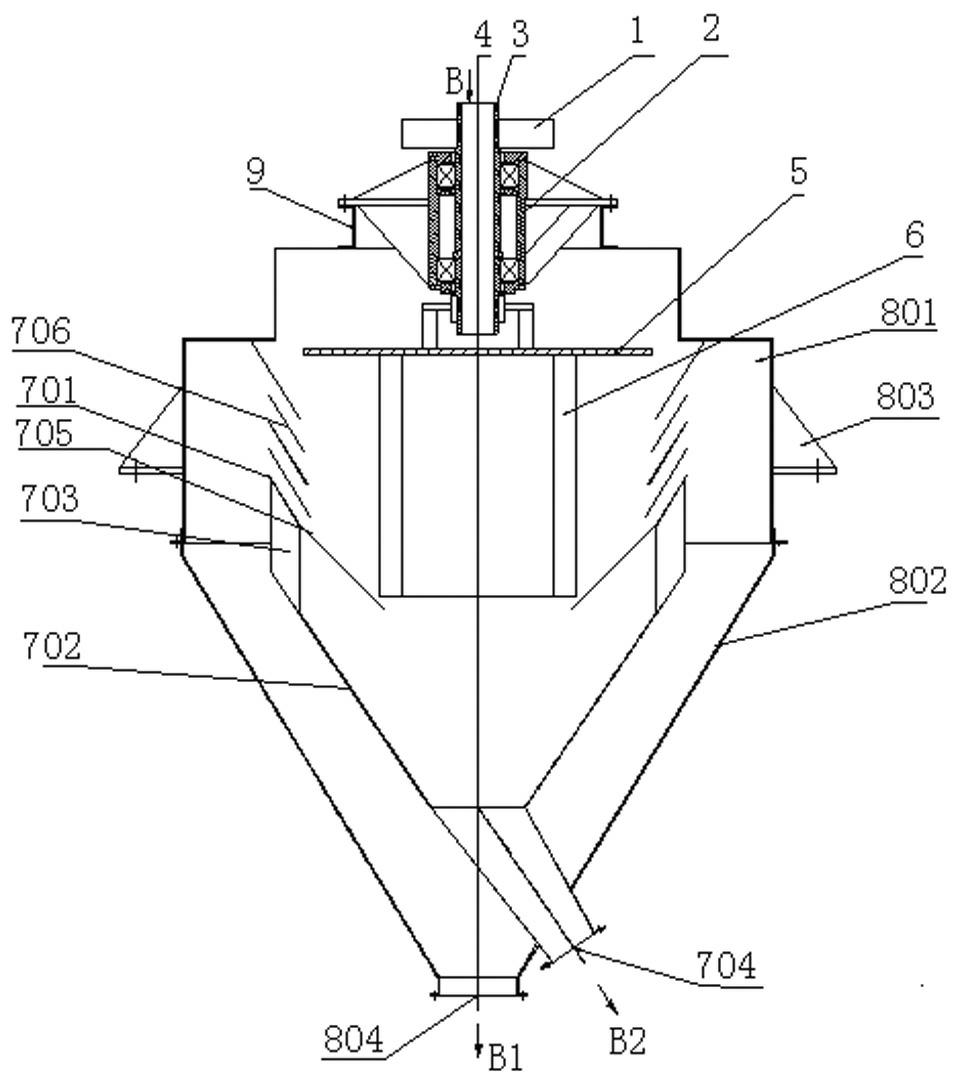

[0020] refer to figure 1 , this embodiment includes machine base 803, bearing seat 2, transmission wheel 1, hollow main shaft 3, material spreading disc 5, blade rotor 6, inner cylinder body, outer cylinder body, and the bearing seat 2 is installed on the machine cover 9 ; The hollow main shaft 3 is installed on the bearing housing 2 through bearings, and the feed port 4 is arranged above the hollow main shaft 3; A rotatable rotor part; the outer cylinder is composed of an upper outer cylinder 801 and a lower outer cylinder 802. The machine base 803 is arranged outside the outer cylinder for installation of the machine. Powder outlet 804; the inner cylinder is placed in the inner cavity formed by the outer cylinder. The inner cylinder is composed of an upper inner cylinder 701 and a lower inner cylinder 702. The upper inner cylinder 701 allows airflow to pass through the upper part to classify the material The functional cylindrical classifying device 706 (single-cylinder str...

Embodiment 2

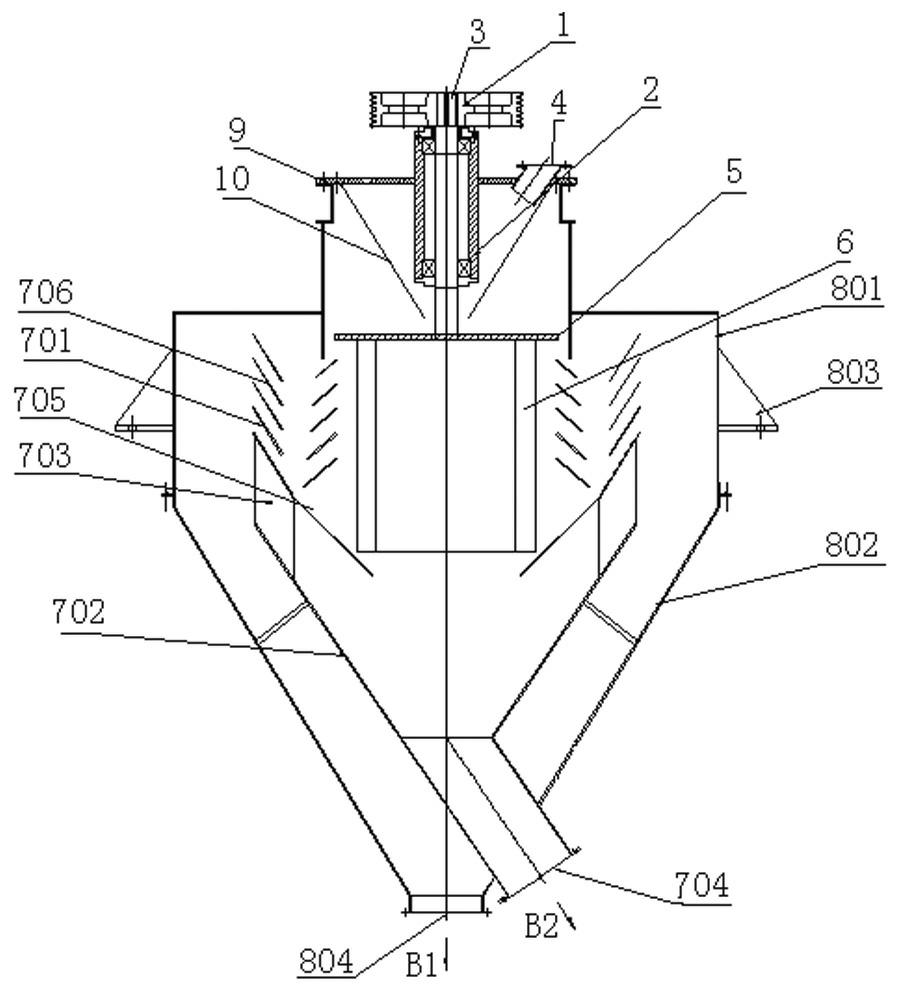

[0024] refer to figure 2 Compared with Embodiment 1, the main difference between this embodiment and Embodiment 1 is that the main shaft 3 is a solid shaft, and the feed port 4 is located outside the bearing seat 2, so that the material slips from the feed pipe 10 into the spreader 5; the cylindrical classification device 706 It is composed of two layers inside and outside.

Embodiment 3

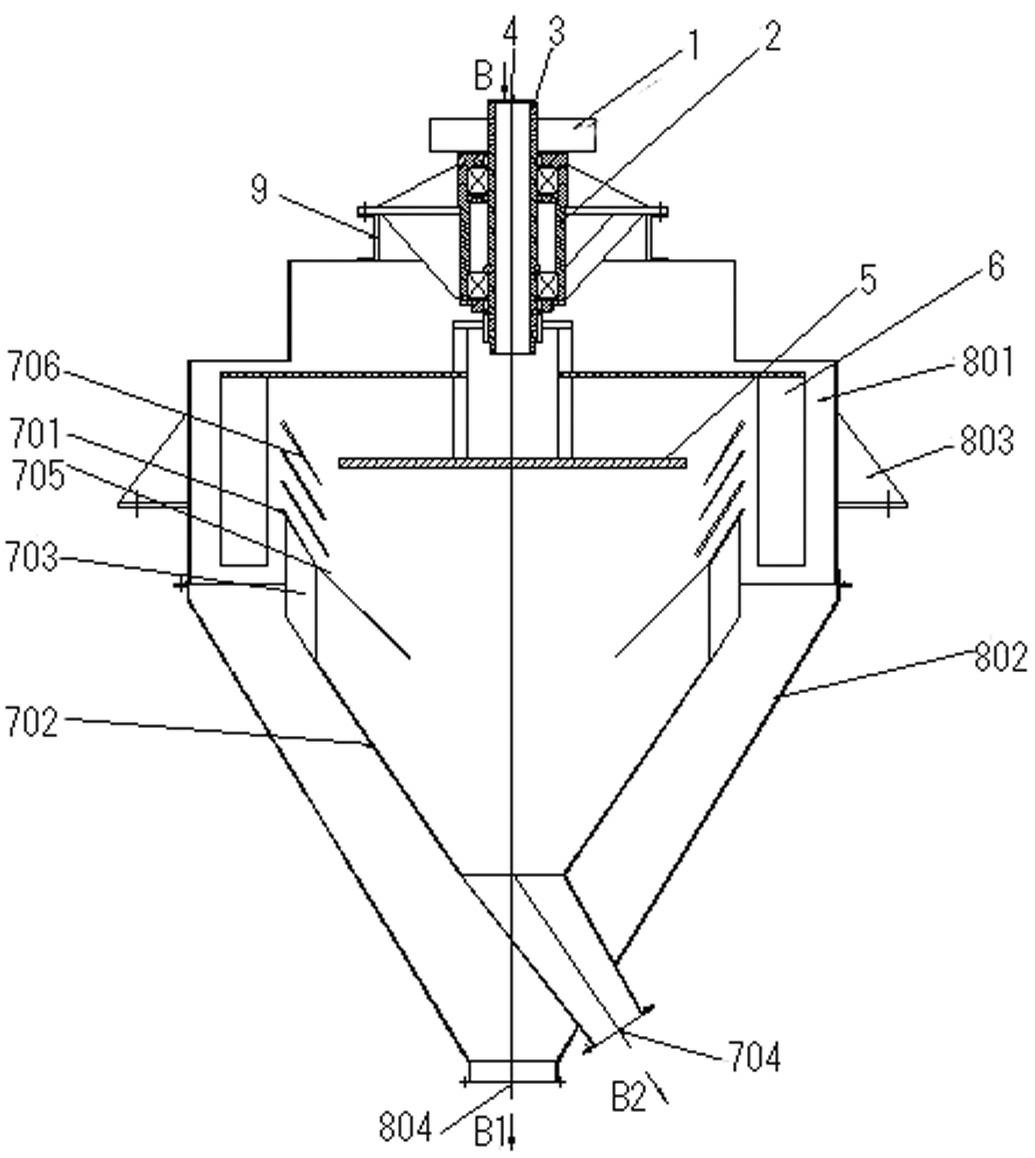

[0026] refer to image 3 In this embodiment, the blade rotor 6 of Embodiment 1 is assembled on the hollow main shaft 3 through a connecting piece, located inside the upper outer cylinder 801 and outside the upper inner cylinder 701, the wind generated by the rotation of the blade rotor 6, Compared with the cylindrical grading device 706, it is sucked from the inside to the outside. Its working principle is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com