Pulse laser cutting method for fragile materials

A pulsed laser, brittle material technology, used in laser welding equipment, metal processing equipment, welding equipment, etc., to achieve the effect of simplifying processing procedures, low laser energy, and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following, the cutting steps of the present invention will be described in detail by taking cutting a brittle ceramic plate-shaped material with a thickness of 0.5 mm as an example in conjunction with the accompanying drawings.

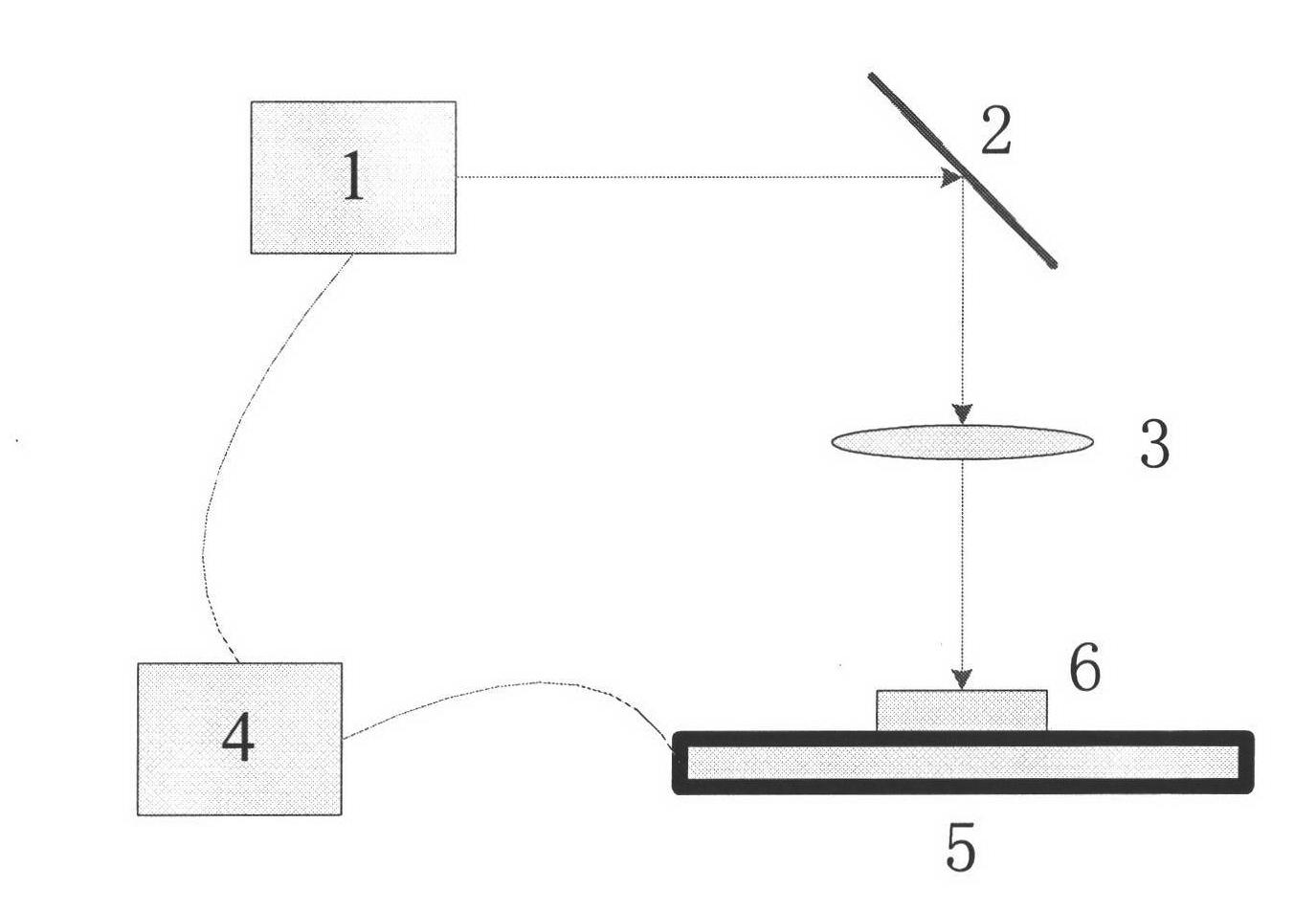

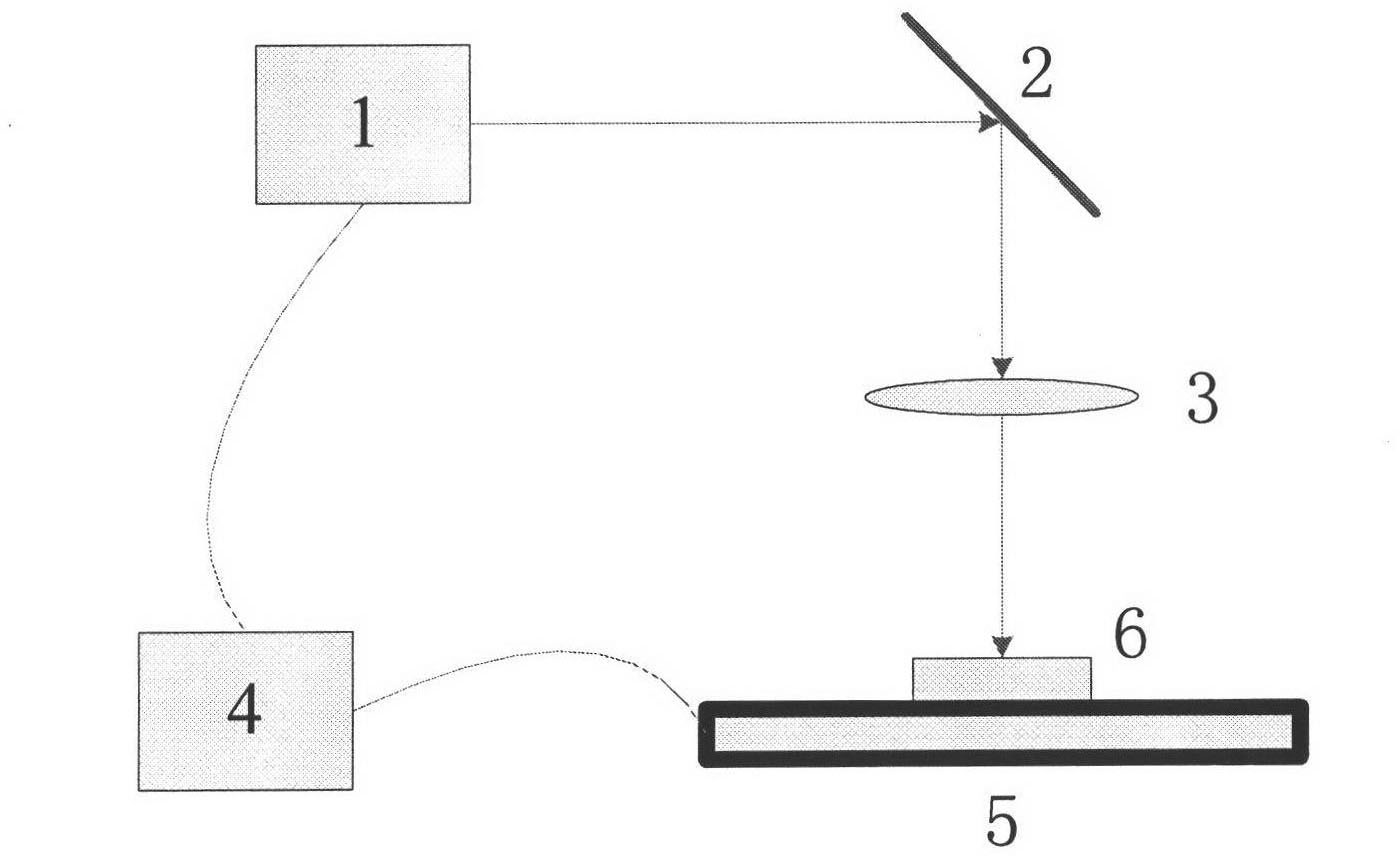

[0017] The inventive method finishes in the pulse laser cutting system to the processing of 0.5mm brittle ceramic plate material, see figure 1 , the system is composed of a pulse laser 1, a mirror 2, a focusing lens 3, an electric translation stage 5 and a computer 4. Its specific implementation steps are as follows:

[0018] Step 1: Fix the 0.5mm brittle ceramic plate to be cut on the electric translation table in the pulse laser cutting system;

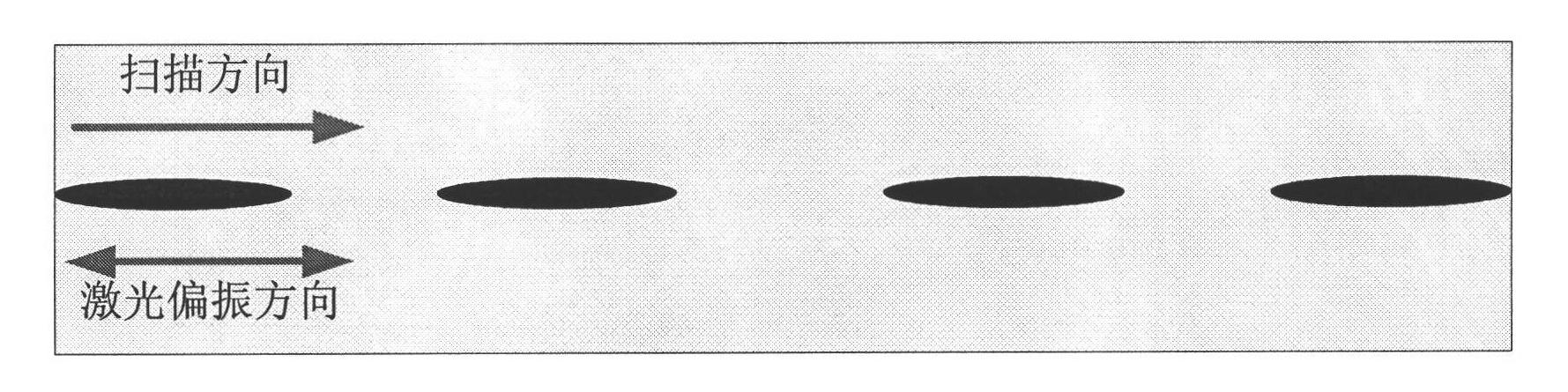

[0019] Step 2: Start the pulse laser cutting system, and use the computer to adjust the single pulse energy and laser frequency in the range of 0.5J to 80J and 0 to 100Hz. In this example, the laser energy is adjusted to 2J, the laser frequency is 10Hz, and the pulse width is 1 millisecond. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com