Machine tool chuck clamping detection device

A detection device and clamping technology, used in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the problem of parts not meeting processing requirements, achieve less workpiece processing scrap, and ensure workpiece processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

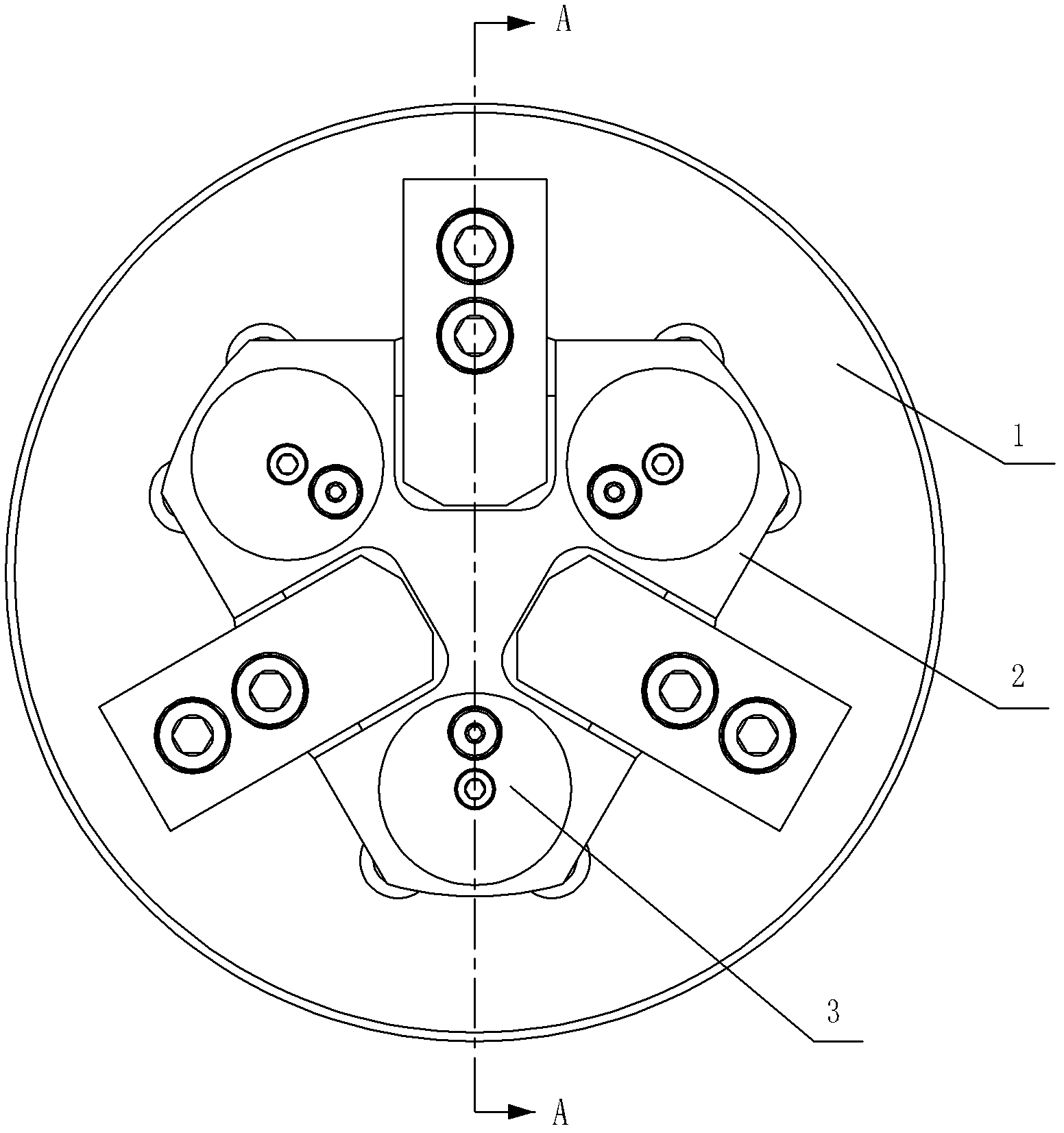

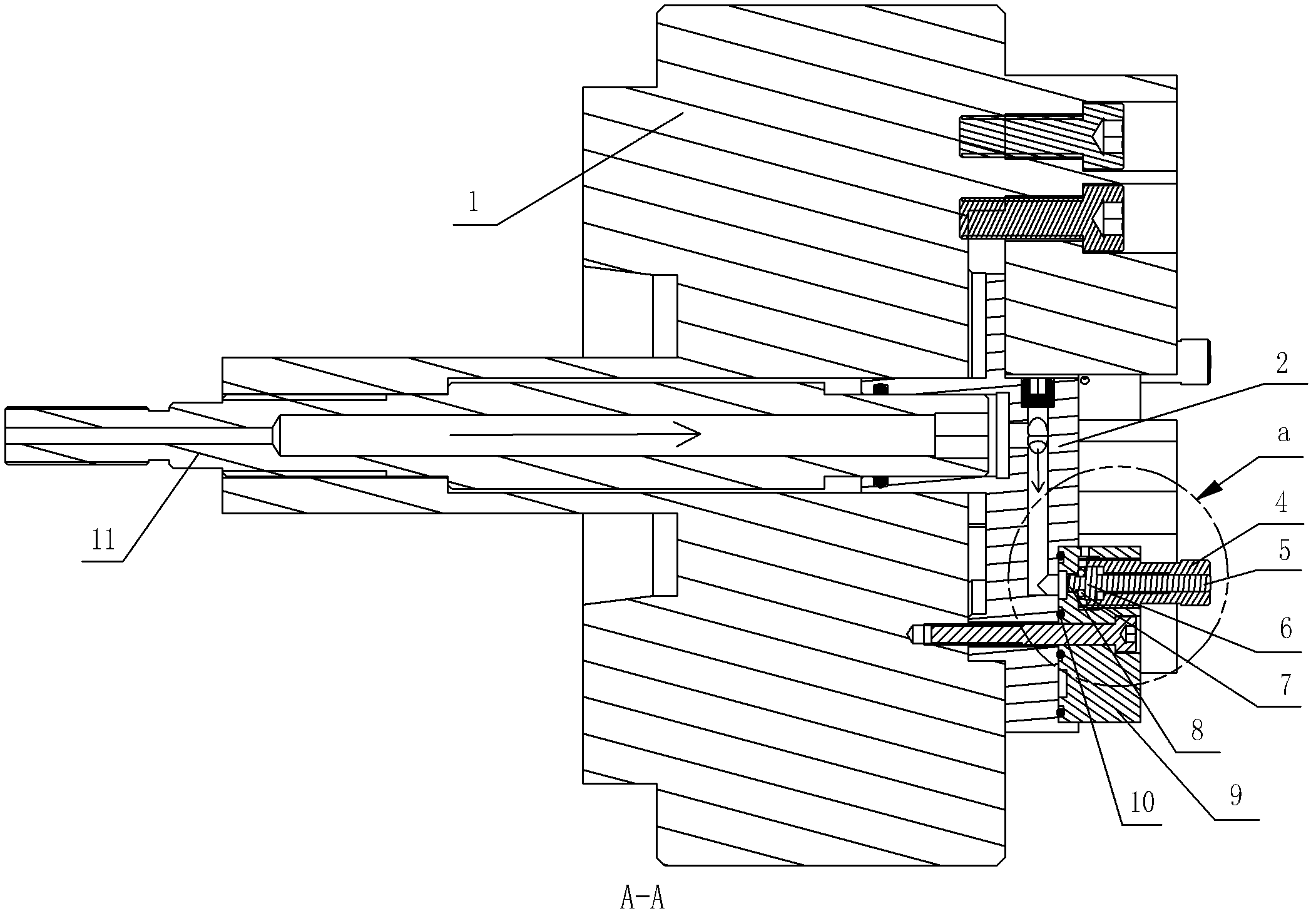

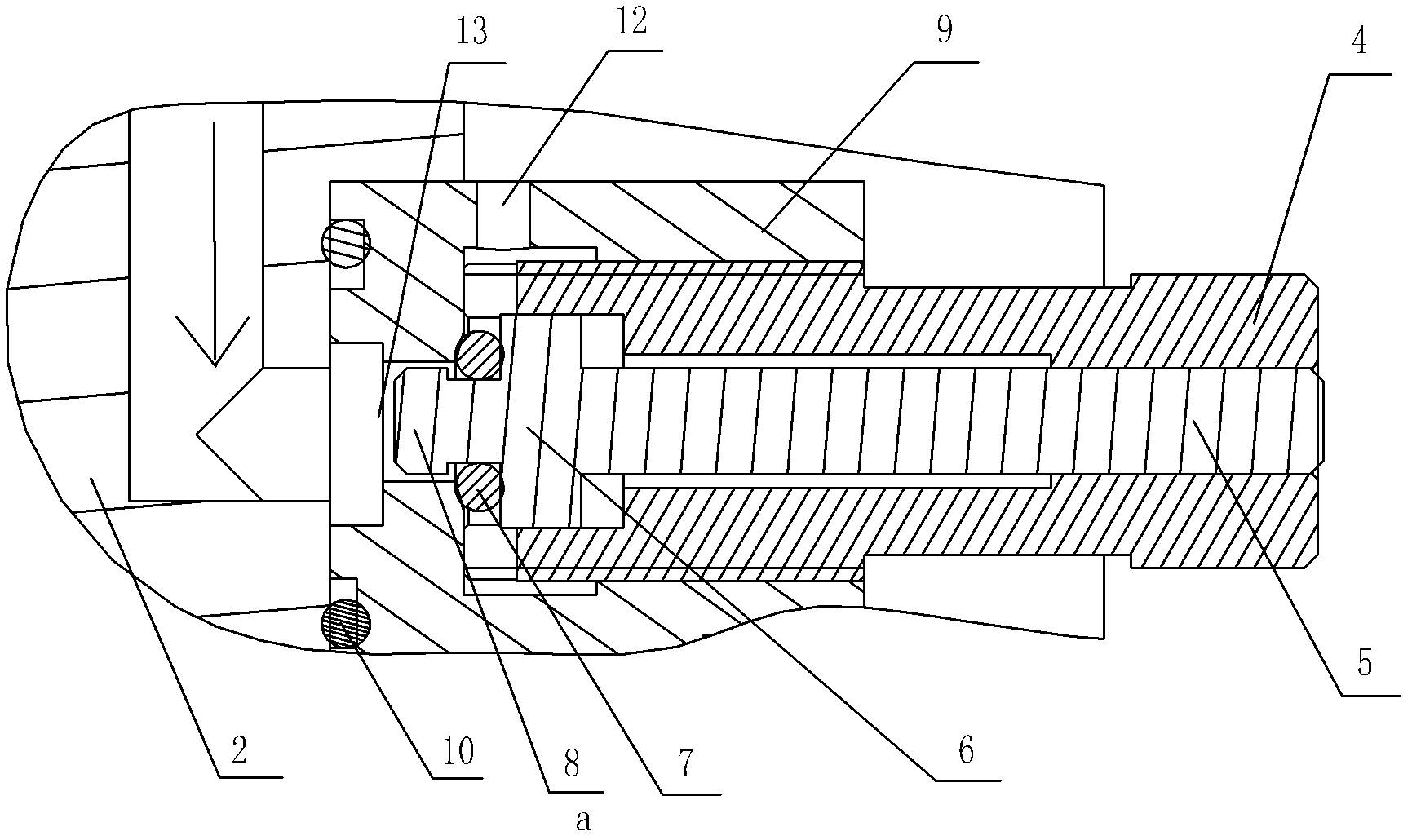

[0015] like figure 1 , figure 2 , image 3 As shown, the present invention includes a pull rod 11, a detection seat mounting block 2, a pressure detection valve and three identical positioning detection mechanisms. In the hole, the detection seat mounting block 2 is fixedly installed on the front end of the chuck body 1 and connected to the front end of the pull rod 11, and three positioning detection mechanisms are installed on the detection seat mounting block 2 at intervals along the circumferential direction; each positioning detection mechanism Including the detection seat 9, the positioning column 4 and the detection ejector rod 5, the detection seat 9 is installed on the detection seat installation block 2, the detection seat 9 is provided with a groove cavity with an open front end, the front end of the positioning column 4 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com