Novel UV (ultraviolet)-curable decoration adhesive

A new type of selected technology, applied in the field of curing glue, can solve the problems of weak visual impact, difficulty in production, poor color effect, etc., and achieve the effect of beautiful signboards or decorative items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

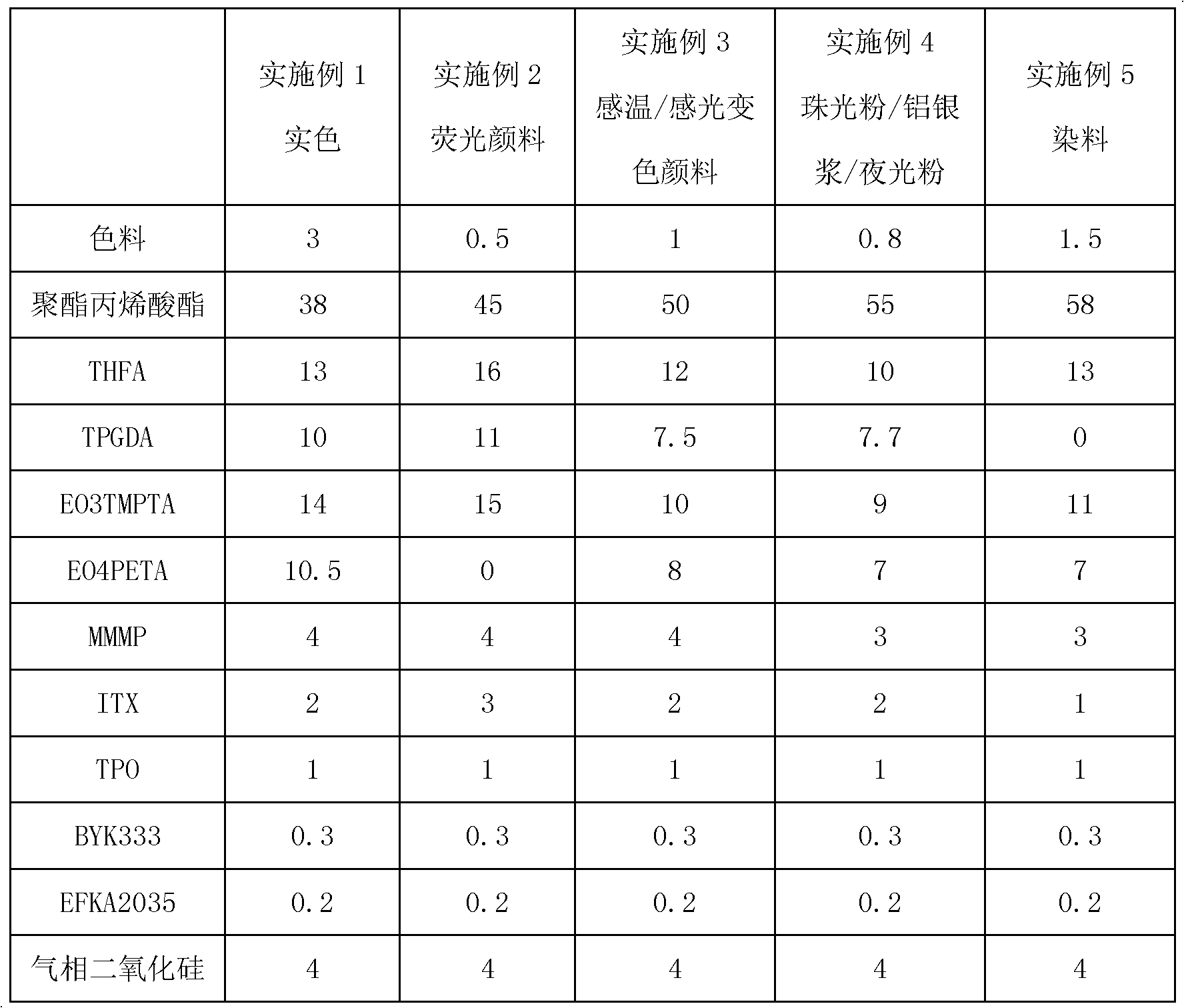

[0028] 1. Preparation of UV curable decorative adhesive: see Table 1 for the formula

[0029] Table 1.

[0030]

[0031] 2. The production process of UV curing decorative glue:

[0032] Prepare each component by the prescription of above-mentioned embodiment 1-5. First mix UV monomers in proportion, add photoinitiator, stir to dissolve, then add polyester acrylate, stir evenly, then add additives, add fumed silica under high-speed stirring, stir for about 1 hour, and then proportionally Add coloring material, stir for 30 minutes, and obtain UV curable decorative glue after filtering.

[0033] The products prepared according to the formula of Examples 1-5 all meet the requirements for use, that is, the viscosity is 120,000-200,000 cps / 25°C, the surface tension is 28-35 dyne / cm, and the curing energy is greater than 300mJ / cm 2 .

[0034]When in use, patterns and characters can be formed by extrusion dispensers. The extrusion dispensing machine is controlled by computer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com