Novel muffler for excavator

A muffler and excavator technology, which is applied in the direction of mufflers, machines/engines, mechanical equipment, etc., can solve the problems of unsatisfactory noise reduction effect, little difference in perforation rate, and insufficient noise reduction effect, etc., and achieves significant noise reduction effect, The effect of high working reliability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

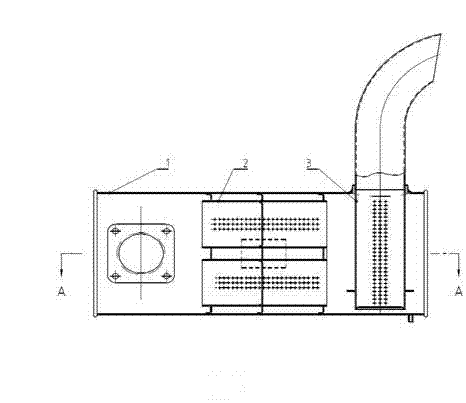

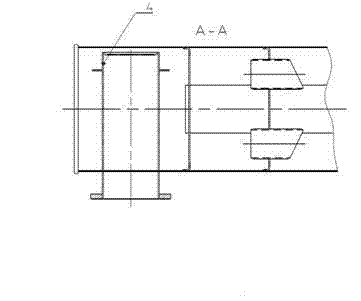

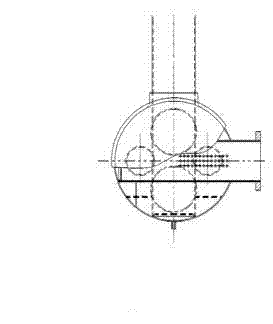

[0020] The air exhausted by the engine passes through the muffler I (see attached Figure 7 ) into the first chamber of the muffler, the first-stage perforated pipe is used for preliminary noise reduction and silencer, and then enters into the front chamber of the muffler barrel II respectively (see attached Figure 4 ), the upper and lower mufflers (2) of the muffler, that is, the left expansion chamber, after noise reduction and muffler, enter the rear chamber of the muffler II through the inner tubes (4) on both sides, that is, the right expansion chamber, After passing through the upper and lower two mufflers (2) for noise reduction and silencer, it enters the muffler III, and after the perforation passes through the muffler III for the last noise reduction and muffler, it is discharged from the exhaust tailpipe. After the muffler of the present invention is optimized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com