Differential pressure sensor for switching value

A technology of differential pressure sensor and switching value, which is applied in the direction of measuring fluid pressure, instruments, measuring devices, etc. It can solve the problems of unsatisfactory requirements, high price, and the sensor is easily affected by temperature, etc., and achieve stable signal and accurate acquisition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

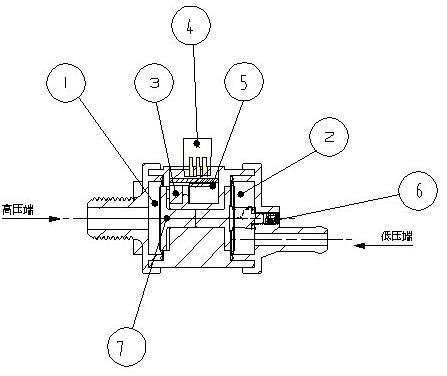

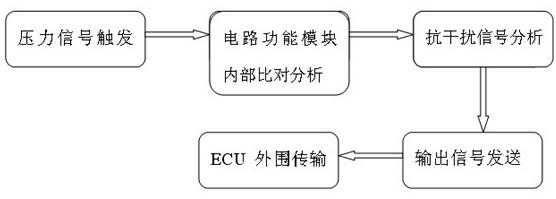

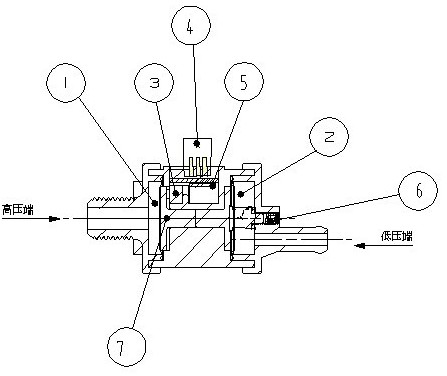

[0016] like figure 1 As shown, the present invention includes a housing and a signal control unit, and the housing is made of light materials such as plastics and alloys. A high-pressure chamber and a low-pressure chamber are arranged in the housing, a first pressure-sensing diaphragm 1 is arranged in the high-pressure chamber, a second pressure-sensing diaphragm 2 is arranged in the low-pressure chamber, and the gap between the first pressure-sensing diaphragm 1 and the second pressure-sensing diaphragm 2 Establish connecting rod 7. Due to the isolation of the diaphragm and the connecting rod, the high-pressure chamber and the low-pressure chamber are isolated from each other. The connecting rod 7 is in the shape of a barbell, and the connecting rod is bounded by the central point, and is divided into two symmetrical parts and combined together (it can also be divided into two parts in other asymmetrical forms, the main consideration is to facilitate installation). The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com