Wireless positioning method of mine equipment and spraying dust suppression control method of hydraulic supports

A mine equipment and wireless positioning technology, which is applied in mine roof support, mining equipment, positioning, etc., can solve the problems that the positioning system is susceptible to interference and low positioning accuracy, and achieve reliable positioning and enhanced positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

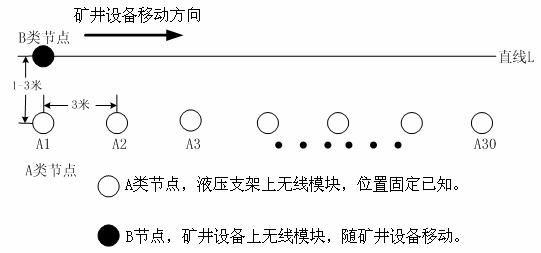

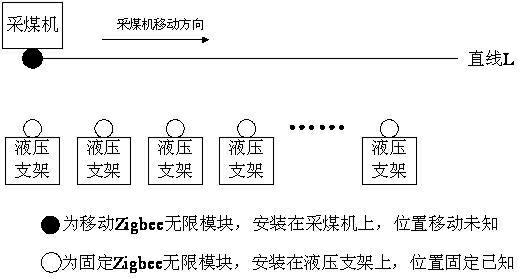

[0031] Such as figure 2Shown is the schematic diagram of the wireless positioning system of the mine equipment of the present invention, as can be seen from the figure, the system includes a group of fixed Zigbee wireless modules for being installed on the hydraulic supports arranged at intervals along the moving direction of the coal mining machine, these The wireless modules are arranged on a straight line at intervals, parallel to the straight line in the moving direction of the shearer, and the position is fixed; it also includes a mobile Zigbee wireless module for installation on the shearer, which moves with the shearer; each fixed The Zigbee wireless module and the mobile Zigbee wireless module constitute a communication network based on Zigbee wireless positioning; the mobile Zigbee wireless module sends data information during the traveling process, and each fixed Zigbee wireless module is used to receive the data information sent by the mobile Zigbee wireless module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com