Autoanalyzer

A technology of automatic analysis device and moving distance, which is applied in the direction of measuring devices, analysis materials, instruments, etc., and can solve problems such as fluctuations in detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

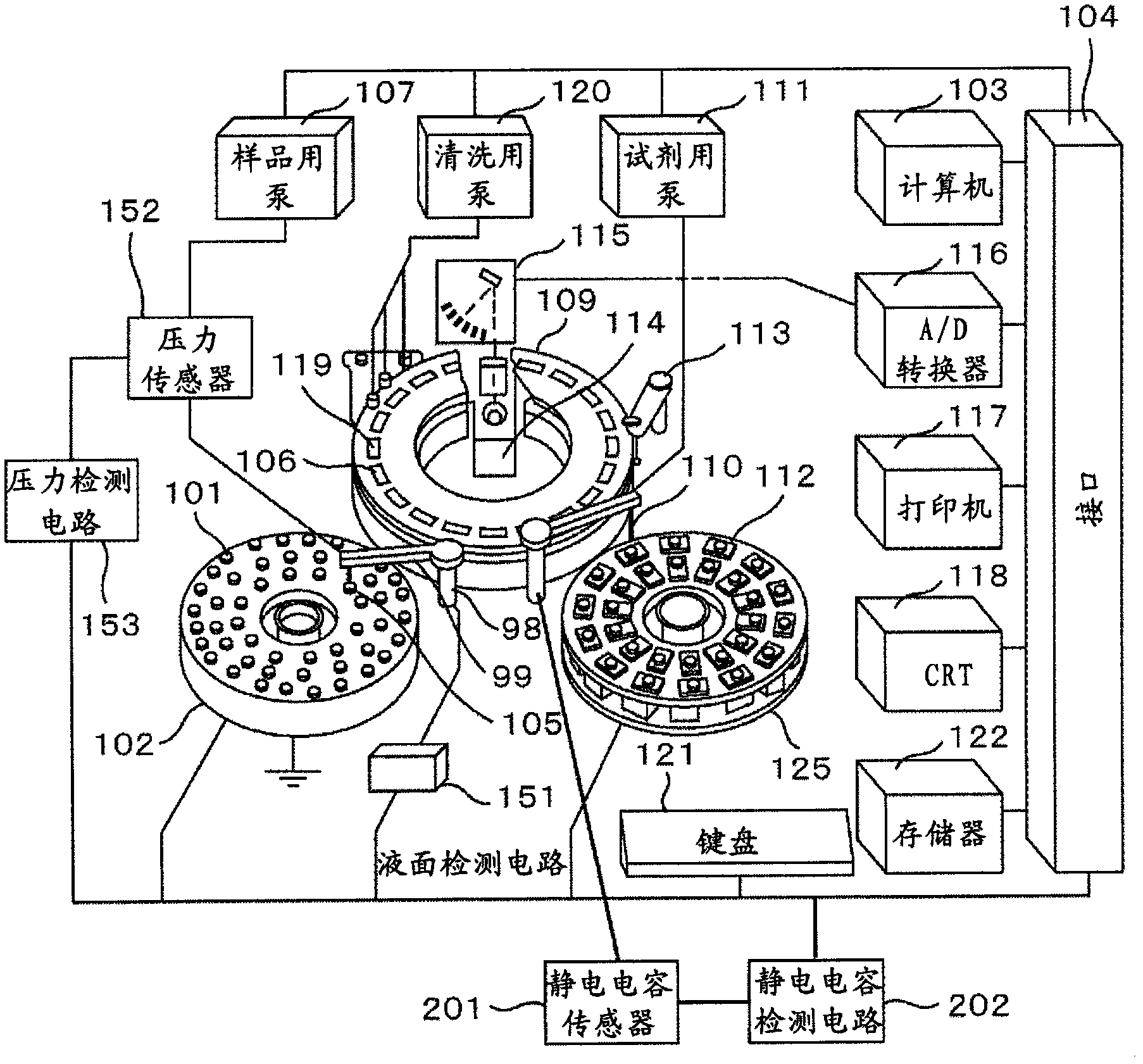

[0037] Below, the embodiment of the present invention is from figure 1 Start in sequence. figure 1 It is a schematic diagram of the automatic analyzer to which the present invention is applied, and shows the dispensing mechanism and its peripheral parts. The structure and function of each part are common to those of conventional automatic analyzers, so detailed descriptions are omitted. The sample dispensing arm 99 of the sample dispensing mechanism 98 rotates while moving up and down. The sample in the sample container 101 arranged on the sample disk 102 rotating left and right is sucked by the probe 105 attached to the sample dispensing arm 99 and discharged into the reaction container 106 . It should be noted that the tip side of the probe 105 is designed such that the nozzle that sucks and ejects the sample hangs down.

[0038] As can also be seen from this figure, the arrangement of the sample container 101 on the sample tray 102 is generally applicable to the case whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com