Natural plant flavoring machine

A technology of natural plants and fragrance machines, which is applied in gasification substances, deodorization, disinfection, etc., can solve problems such as side effects of human health, and achieve the effects of stimulating the sense of smell, improving work efficiency, and feeling comfortable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

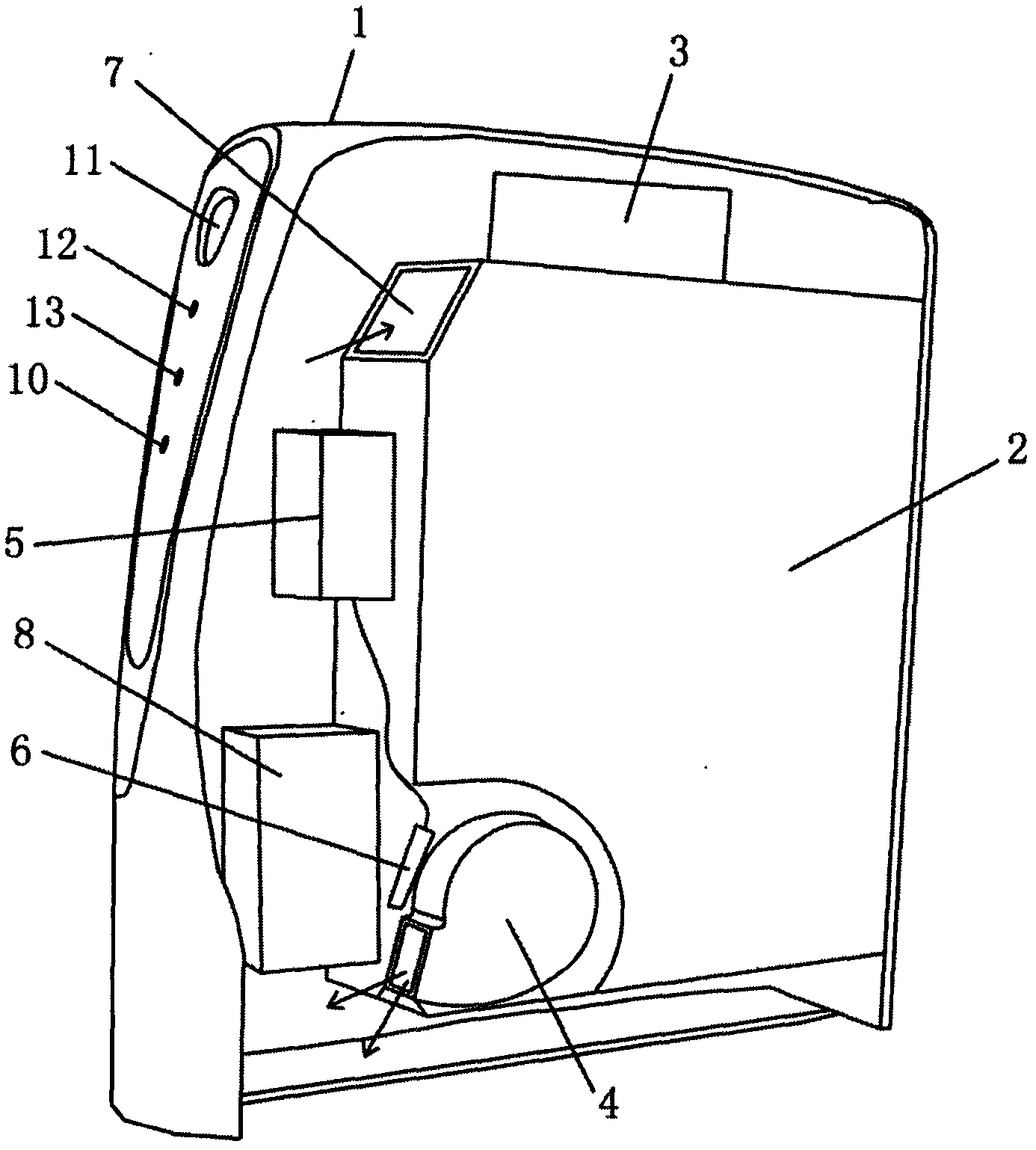

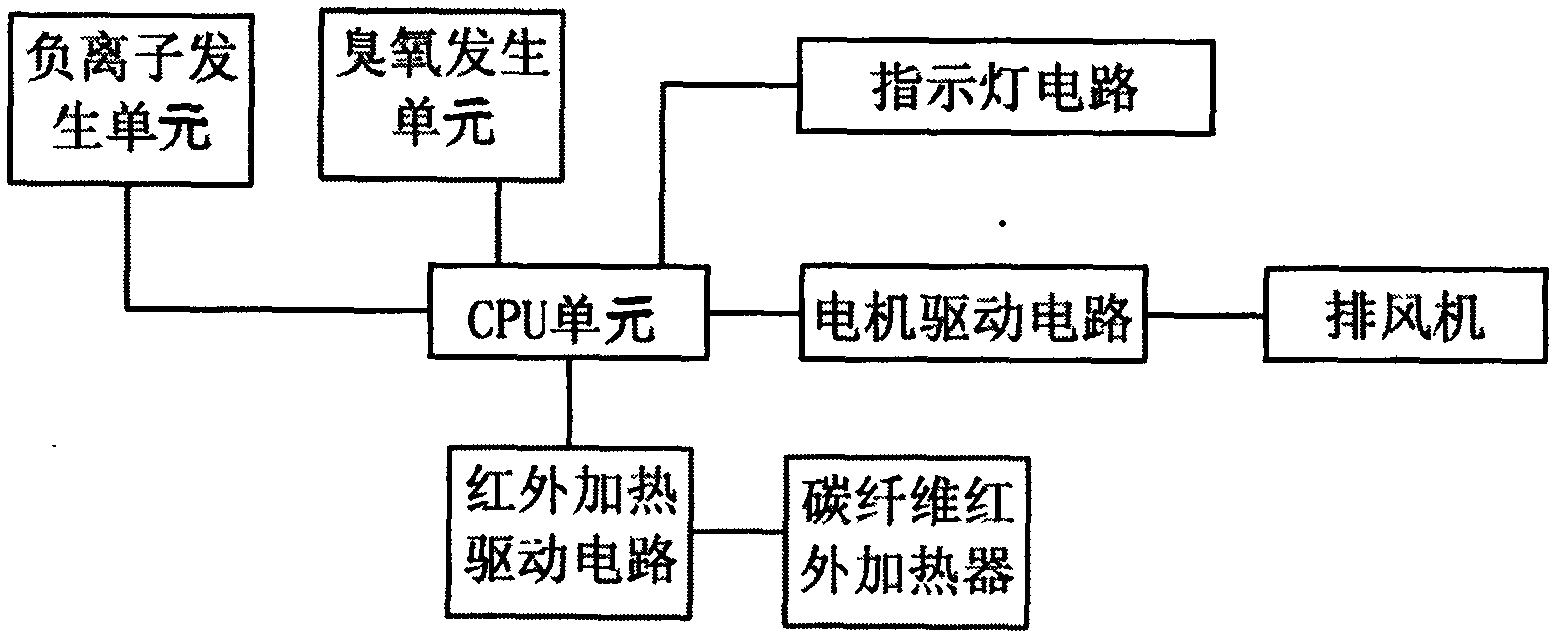

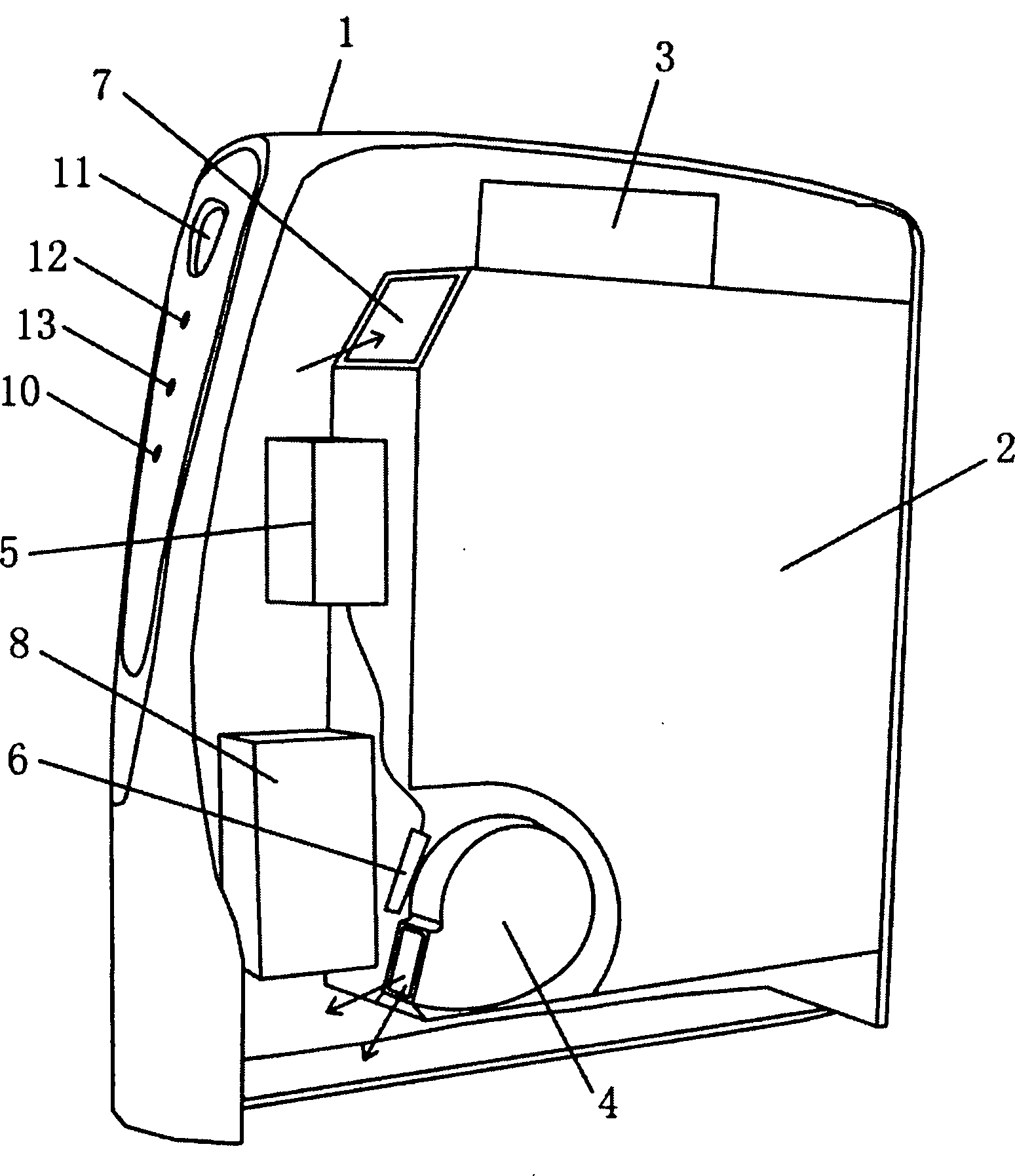

[0019] See Figure 1-2 , the natural plant fragrance machine of the present embodiment includes: a material storage box 2 for storing fragrant plants or formula Chinese herbal medicines, the material storage box 2 is provided with an air inlet 7 and an air outlet, and the air outlet is provided with an exhaust fan 4; the air inlet 7 is provided with a carbon fiber infrared heater, and an air humidifying device for humidifying hot air is provided in the material storage box 2 and downstream of the wind flow of the carbon fiber infrared heater, and the material storage box 2 is also provided with an air humidifier There is an ultraviolet generator or an ozone generating unit, and the outlet of the exhaust fan 4 is provided with an anion releasing tip 6 that links to each other with an anion generating unit 5 .

[0020] During specific implementation, the air humidifying device is a mass of water-absorbing wood fiber or water-absorbing sponge, etc., and an ultrasonic humidifier c...

Embodiment 2

[0025] The working method of the above-mentioned natural plant fragrance machine is characterized in that it comprises the following steps:

[0026] A. When powered on, the CPU unit controls the ultraviolet generator or the ozone generating unit to work for 5-15 minutes to disinfect and sterilize the fragrant plants or formula Chinese herbal medicines in the storage box 2;

[0027] B, then, the CPU unit first controls the carbon fiber infrared heater in the air inlet 7 of the material storage box 2 to start heating, and then controls the exhaust fan 4 on the air outlet of the material storage box 2 to start exhausting; under the action of the exhaust fan 4, The air enters from the air inlet 7, is heated by the carbon fiber infrared heater and is blown to the air humidifier to generate hot humid air; Fragrance molecules in fragrant plants or herbal medicines in formula are discharged from the outlet of exhaust fan 4, so that fragrance is produced indoors; at this time, extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com