Clamping device for processing external diameter groove of thin-wall tubular part

A groove processing and tube-type technology is applied in the field of outer diameter groove processing and clamping devices for thin-walled tubular parts, which can solve the problems of deformation of thin-walled tubular parts, inability to ensure workpiece accuracy, and uneven clamping force, etc. To achieve the effect of balanced force, avoid deformation, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

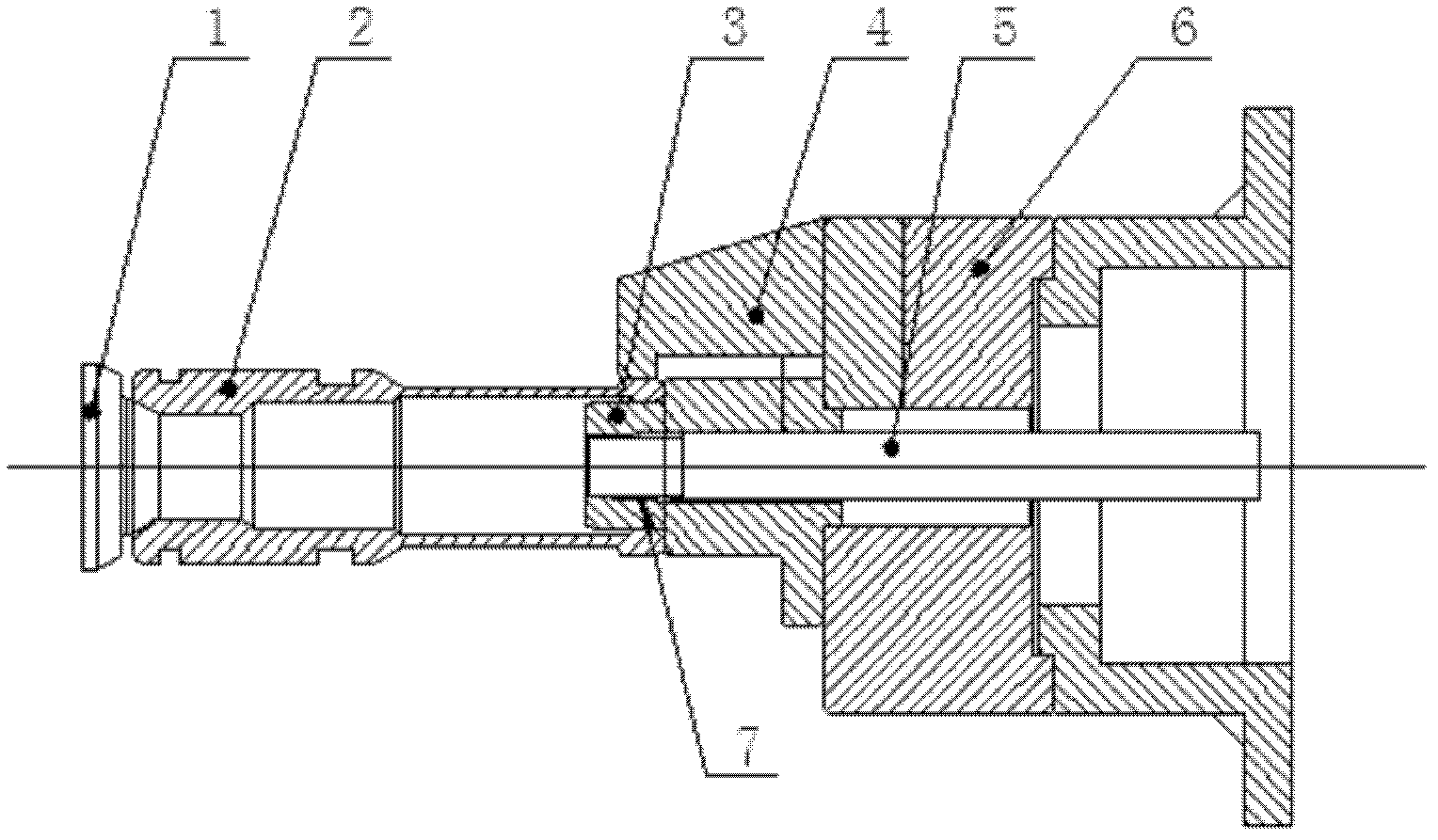

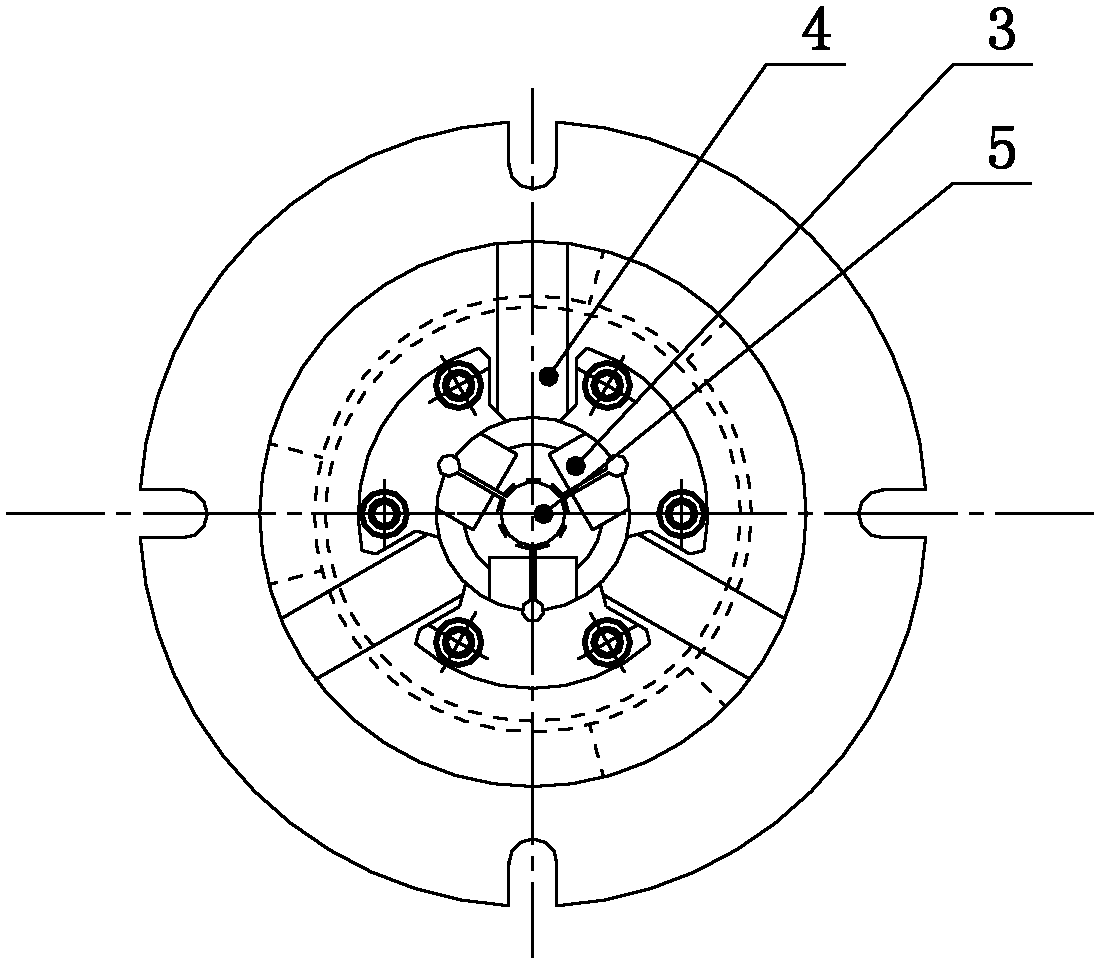

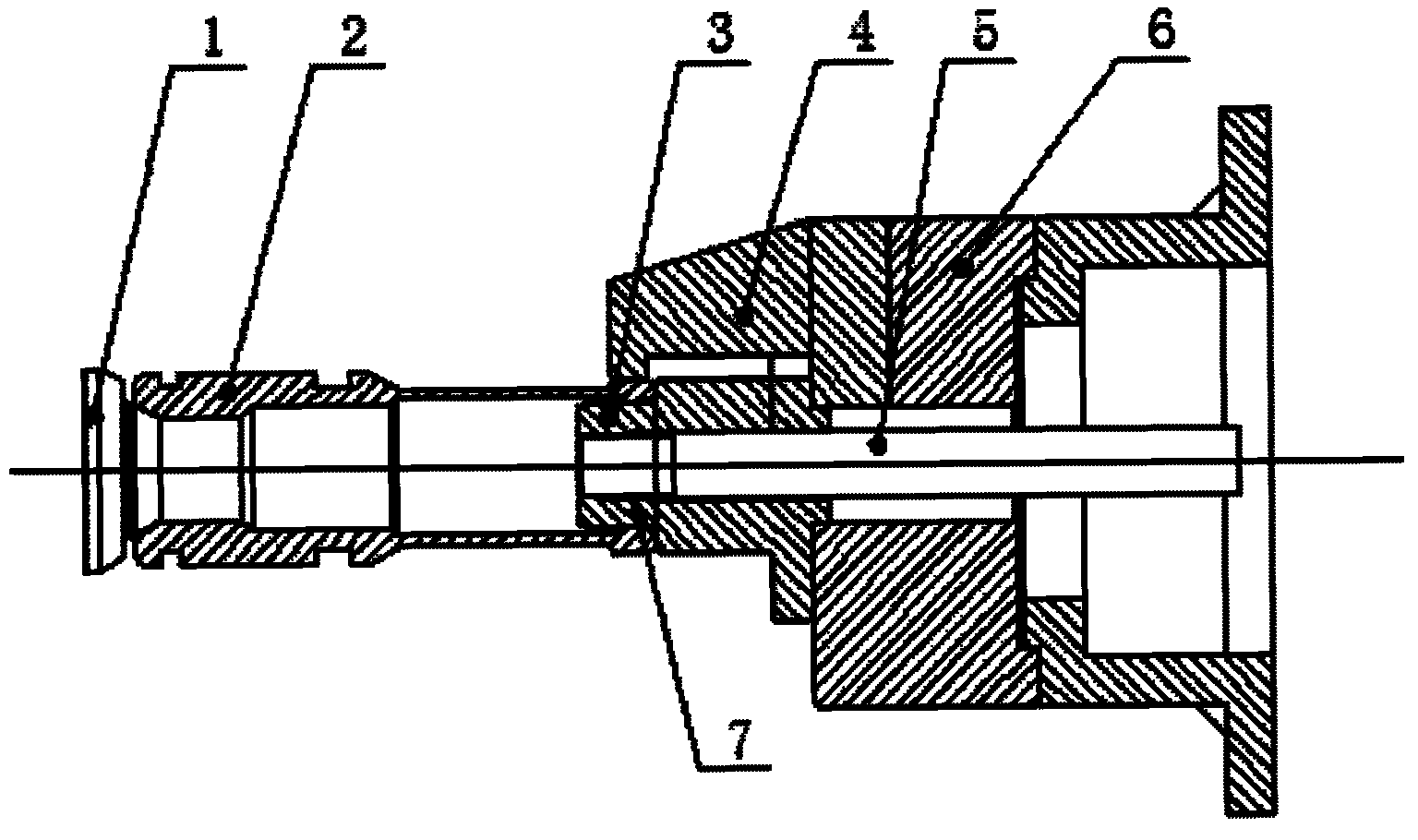

[0012] A clamping device for processing outer diameter grooves of thin-walled tubular parts, including a three-jaw chuck, the three-jaw chuck is composed of claws 4 and an adjustment seat 6, and the clamping is realized through the adjustment seat to realize linkage clamping or opening. The innovation of the present invention is that: an expansion core 5 is installed at the axis of the three-jaw chuck, and three groups of centering rods 3 are evenly distributed on the circumference between the expansion core and the jaws of the three-jaw chuck. The front end is shaped on a tapered thread section 7, which engages with the front ends of three sets of centering rods, forming a workpiece clamping position between the centering rods and the jaws o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com