Numerical-control angle forming and processing machine

A processing machine and angle forming technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of manual pressing, inability to realize functions automatically, and low production efficiency, so as to improve the quality of finished products and prevent incorrect feeding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

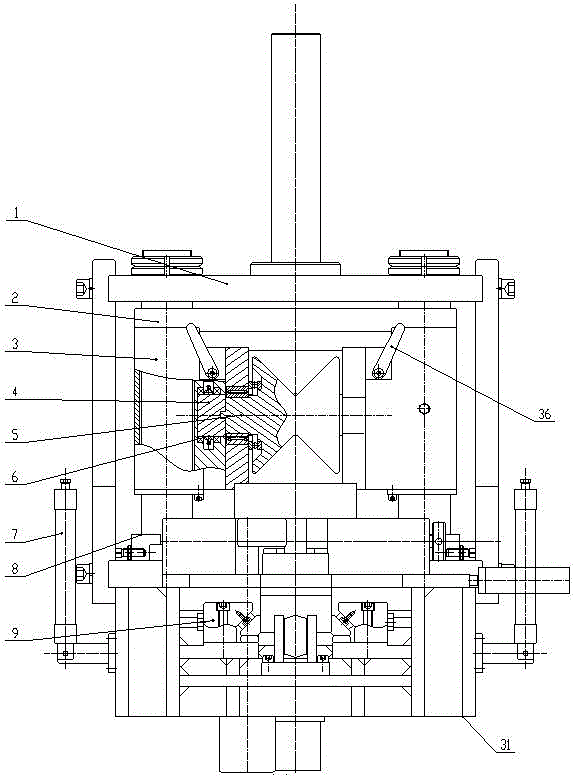

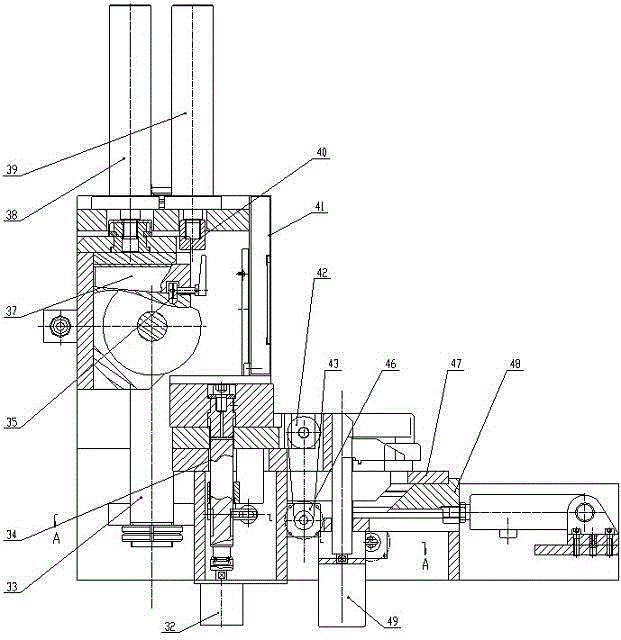

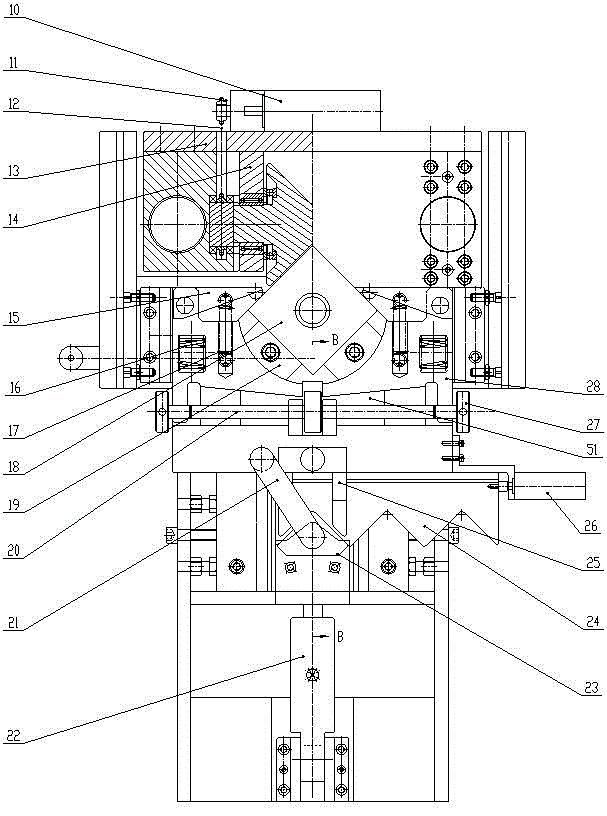

[0030] Next, a numerically controlled corner forming machine of the present invention will be described in detail with reference to the accompanying drawings.

[0031] A kind of numerical control angle forming processing machine, its structure comprises forming device and shearing device that are arranged on frame 1; Described forming device and shearing device are all connected and controlled by intelligent controller; Described forming device is matched by Be arranged on the roller seat 14 together and be formed by the multi-position forming roller 5 that is rotated by the roller shaft 4 and the multi-position square mold 18 that is arranged on the mold base 28; Correspondingly, the top of the multi-position square mold is provided with a molding cylinder 38; The multi-position forming rollers are connected with a roller transposition device that can change the different angles of the rollers, and the multi-position square molds are connected with a mold angle conversion devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com