Fixture for part of sewing machine

A technology for sewing machines and parts, which is applied in the field of fixtures for sewing machine parts. It can solve the problems of affecting the position accuracy of holes, difficulty in fixtures, and low precision of through grooves, and achieve the effects of improving processing efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

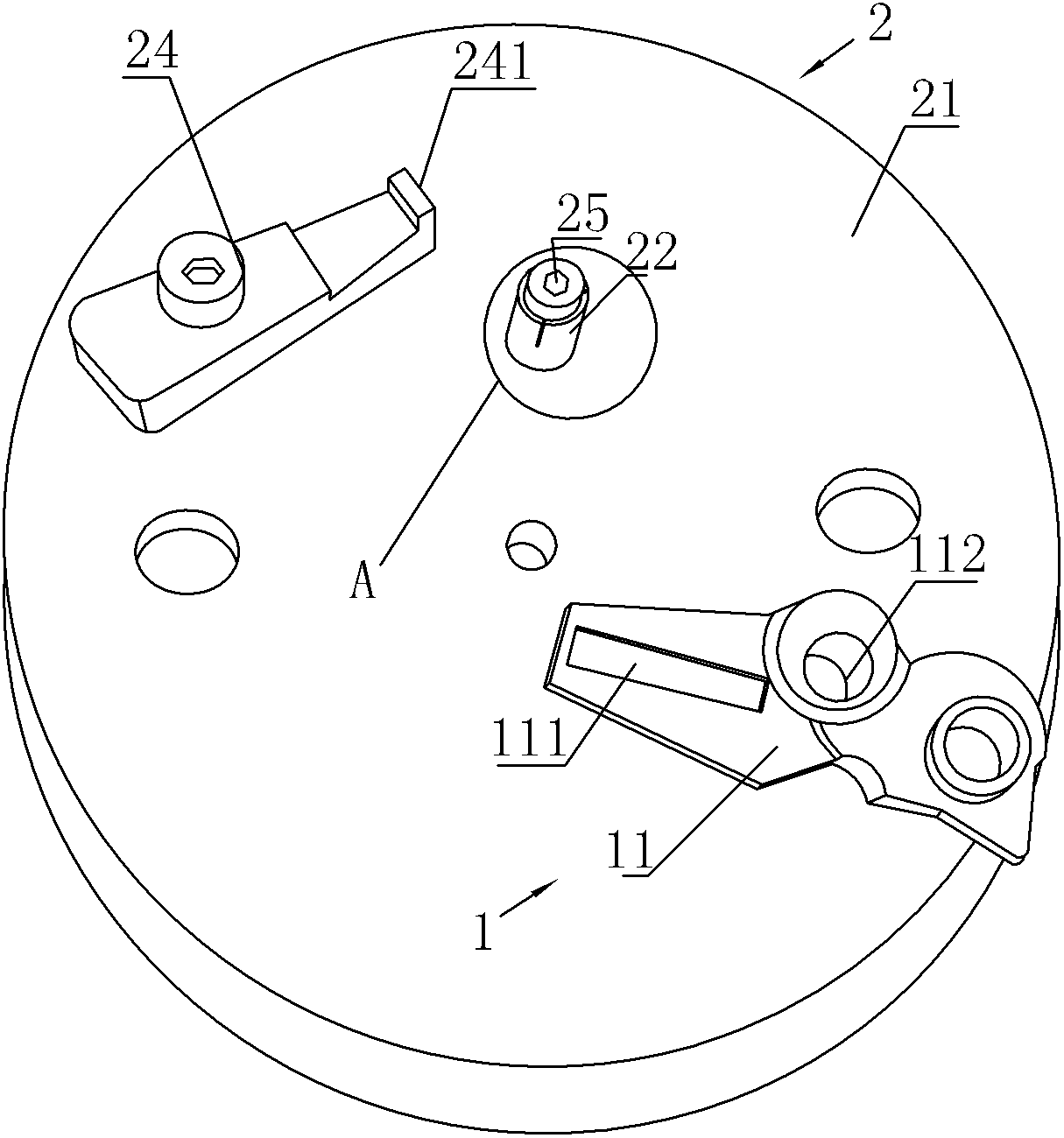

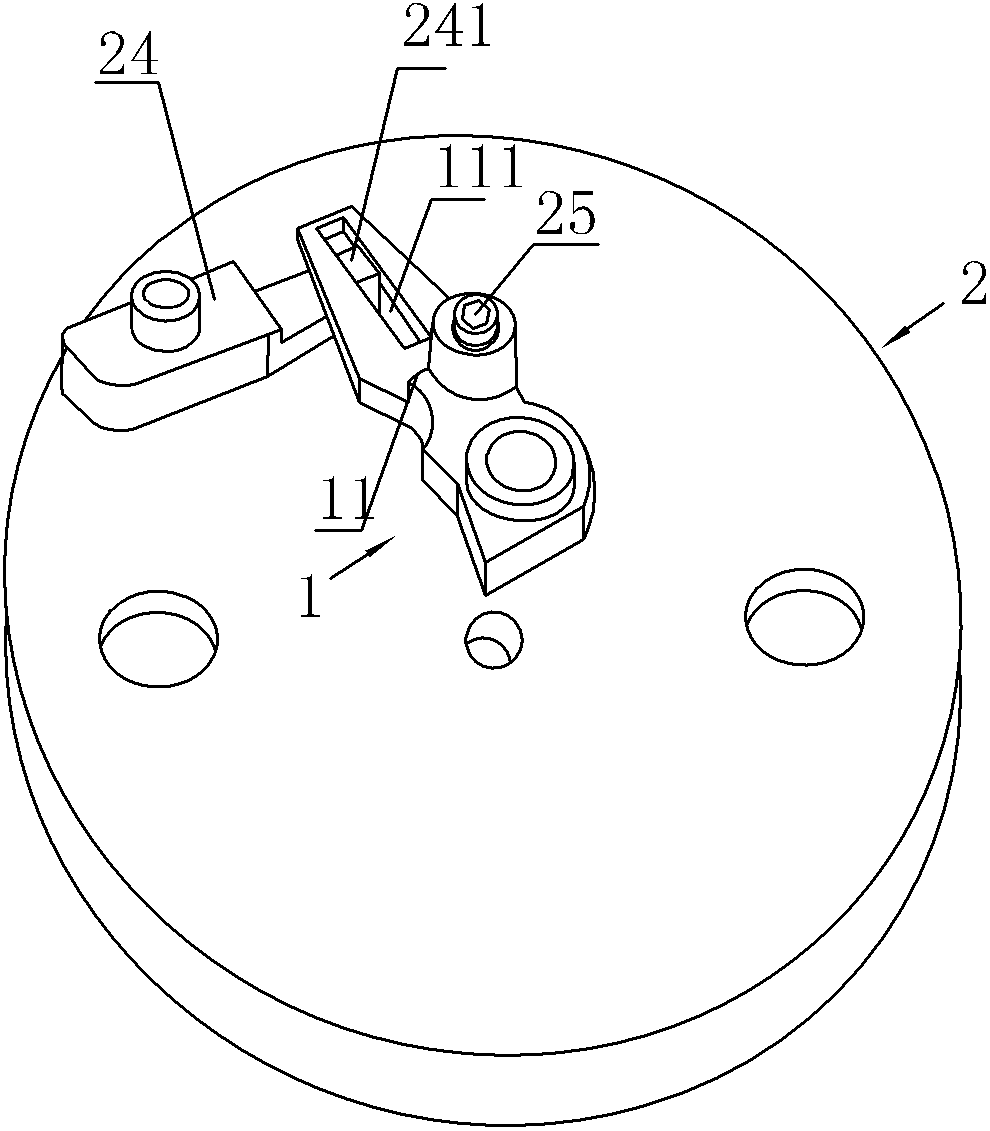

[0017] Such as figure 1 As shown, the part 1 is elongated, the part 1 has a side 11, and the side 11 is provided with a long through groove 111 and a circular through hole 112, and the clamp 2 fixes the part 1 On the drill press, said drill press drills holes on the side 11 of the component 1 .

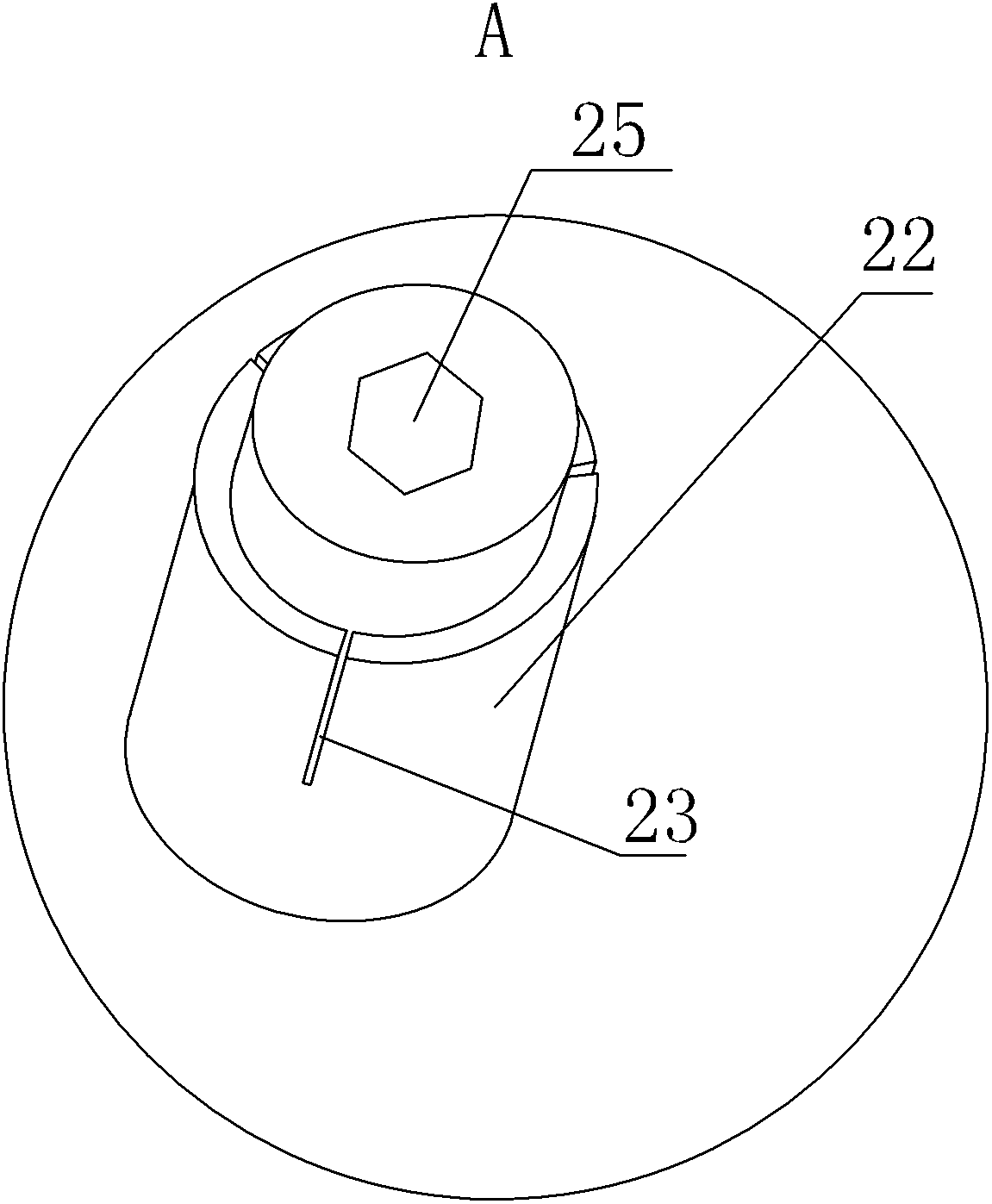

[0018] The fixture 2 includes a fixed seat 21 detachably connected to the drill press, a positioning sleeve 22 perpendicular to and fixedly connected to the fixed seat 21, a positioning block 24 fixedly connected to the fixed seat 21, and a positioning sleeve 22 connected to the fixed seat 21. Threaded bolts 25, the upper half of the positioning sleeve 22 are provided with a plurality of slits 23, each of the slits 23 is parallel to the axis of the positioning sleeve 22, the bolts 25 are tightened, and the positioning sleeve 22 The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com