Intelligent surface grinding machine with horizontal spindle and rotary table

A surface grinder and round table technology, applied in the field of intelligent horizontal axis round table surface grinder, can solve the problems of low efficiency of manual operation and large batches of saw blade substrates, and achieve the effects of improving production efficiency, improving quality and reducing human errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

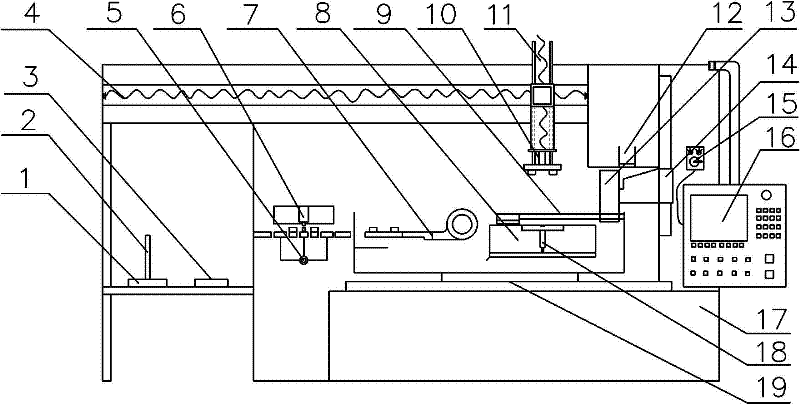

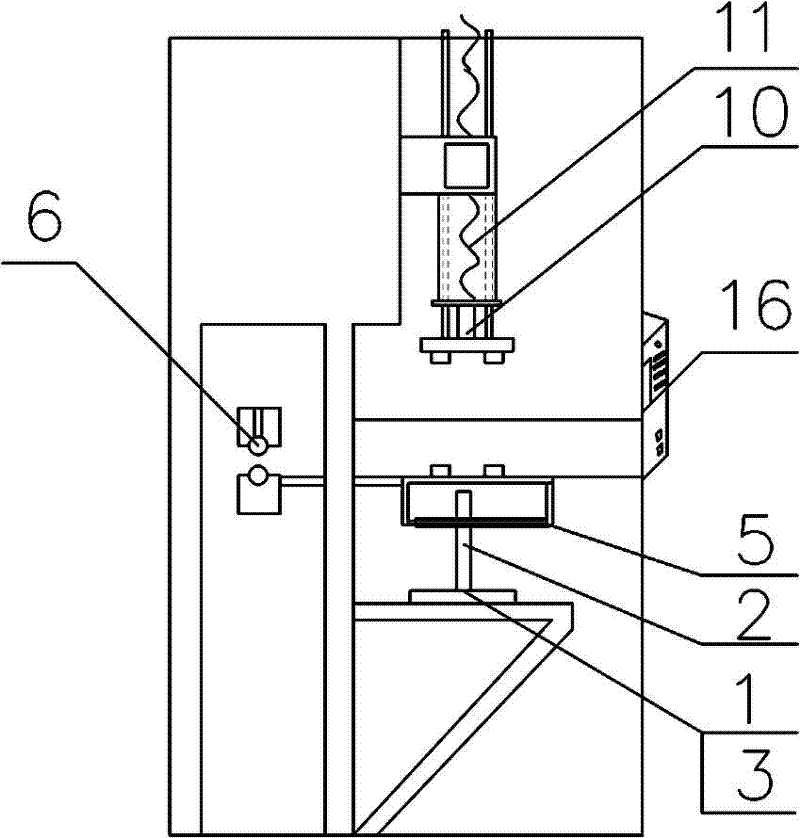

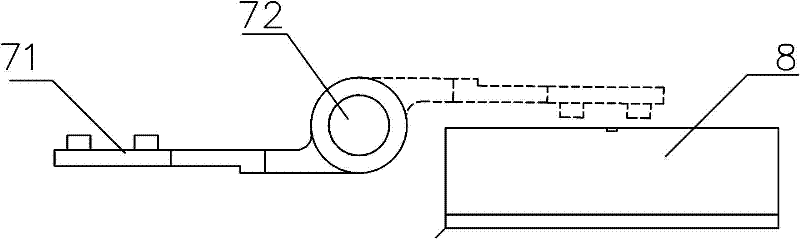

[0029] Such as figure 1 , figure 2 and Figure 5 Among them, an intelligent surface grinding machine with a horizontal axis and a circular table includes a grinding machine bed 17 and a workbench 8, and one side of the workbench 8 is provided with a turning device 7, an automatic thickness measuring device 6 and a workpiece storage position; the workpiece storage The position is provided with the workpiece placement boss 1 before grinding and the workpiece placement boss 3 after grinding, and the workpiece placement boss 1 before grinding is provided with an alignment mandrel 2 . The alignment mandrel 2 is used to keep the workpiece at the initial position, and all subsequent actions are based on the initial position of the workpiece. The workpiece in this example is the saw blade base body.

[0030] Such as figure 1 Among them, a manipulator 10 is provided above the workbench 8, the turning device 7 and the workpiece storage position. Specifically, the manipulator horiz...

Embodiment 2

[0045] Embodiment 1 has adopted the mode of off-line thickness measurement, can obtain higher measurement accuracy like this, embodiment 2 has adopted the mode of online thickness measurement on the basis of embodiment 1, specifically, in described workbench 8 One side is provided with automatic thickness measuring device 6, such as Figure 6 Among them, the automatic thickness measuring device 6 is provided with a displacement sensor 604 that can move above the worktable 8 . The specific structure is that a screw rod is installed in the sensor frame 602, the screw rod is connected with the sensor drive motor 601, the screw rod is provided with a nut, the nut is fixedly connected with the sensor clamp 603, and the sensor clamp 603 is provided with a displacement sensor 604, and the displacement The lower end of the sensor 604 is provided with a sensor roller 606 . Before and after grinding, the sensor drive motor 601 drives the screw to rotate, and drives the nut to move to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com