Nanoparticle sealing channeling water shutoff agent for oil wells

A technology of nano-particles and water blocking agents, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of small oil well cement plugging radius, low organic strength, and short plugging validity period, etc., to achieve plugging High strength, long effective period, and long effective period of plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

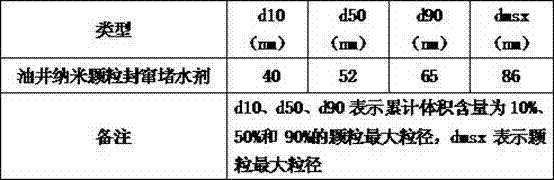

[0009] Embodiment 1: adopt nano particle size analyzer to carry out particle size determination to solution of the present invention

[0010] Table 1 Particle size characteristics of oil well nanoparticle water blocking agent

[0011]

Embodiment 2

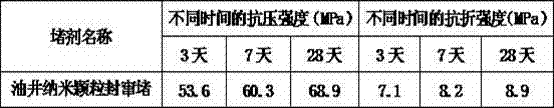

[0012] Embodiment 2: first adopt the planetary ball mill PM400 that German Restsch company produces respectively to calcium oxide, silicon oxide, aluminum oxide, iron oxide, Na 2 SiO 3 , Bentonite, acetone and formaldehyde condensation polymer are ground to make the particle size reach 1-100nm. Then pour 0.15 grams of triethanolamine, 0.06 grams of KCL, and 0.1 grams of iron chromium lignosulfonate into a high-speed mixing cup filled with 39.02 grams of fresh water to fully dissolve, then add 23 grams of ground calcium oxide and 18 grams of silicon oxide , 7 grams of alumina, 4 grams of iron oxide, Na 2 SiO 3 0.04 grams of bentonite, 0.42 grams of bentonite, 0.1 grams of polycondensate of acetone and formaldehyde, stirred in a high-speed mixing cup at 10,000 rpm for 3 minutes, poured the stirred blocking agent into a special pressure measurement mold to make a pressure measurement module, and heated it at 50°C Water bath for 3 days, 7 days, and 28 days respectively, and me...

Embodiment 3

[0015] Embodiment 3: first adopt the planetary ball mill PM400 that German Restsch company produces respectively to calcium oxide, silicon oxide, aluminum oxide, iron oxide, Na 2 SiO 3 , Bentonite, acetone and formaldehyde condensation polymers are ground to make the particles reach 1-100nm. Then pour 0.18 grams of triethanolamine, 0.08 grams of KCL, and 0.15 grams of iron chromium lignosulfonate into a high-speed mixing cup filled with 47.13 grams of fresh water to fully dissolve, then add 25 grams of ground calcium oxide and 21 grams of silicon oxide , 8.5 grams of alumina, 5.4 grams of iron oxide, Na 2 SiO 3 0.05 grams of bentonite, 0.5 grams of bentonite, 0.12 grams of acetone and formaldehyde polycondensate, stirred in a high-speed mixing cup at 10,000 rpm for 3 minutes, mixed the stirred test slurry with the soaked core particles and poured it into a steel cylinder ( Due to the poor bonding of the core-steel cylinder interface, the plugging agent is mixed with the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com