Computerized flat knitting machine fault detection system

A computerized flat knitting machine and fault detection technology, used in textiles, papermaking, knitting, etc., can solve the problems of computerized flat knitting machines prone to failure, machine destruction, and catastrophic accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

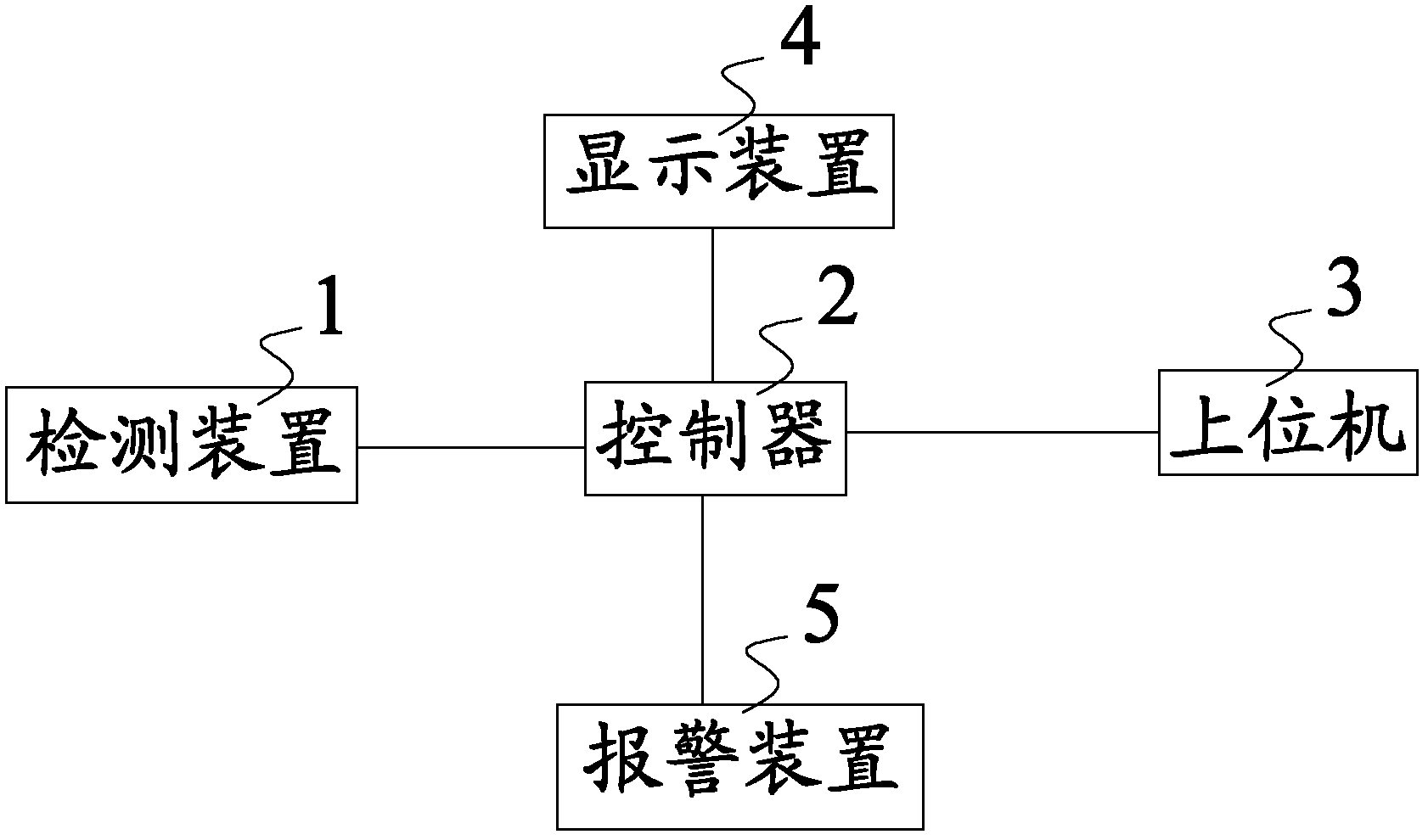

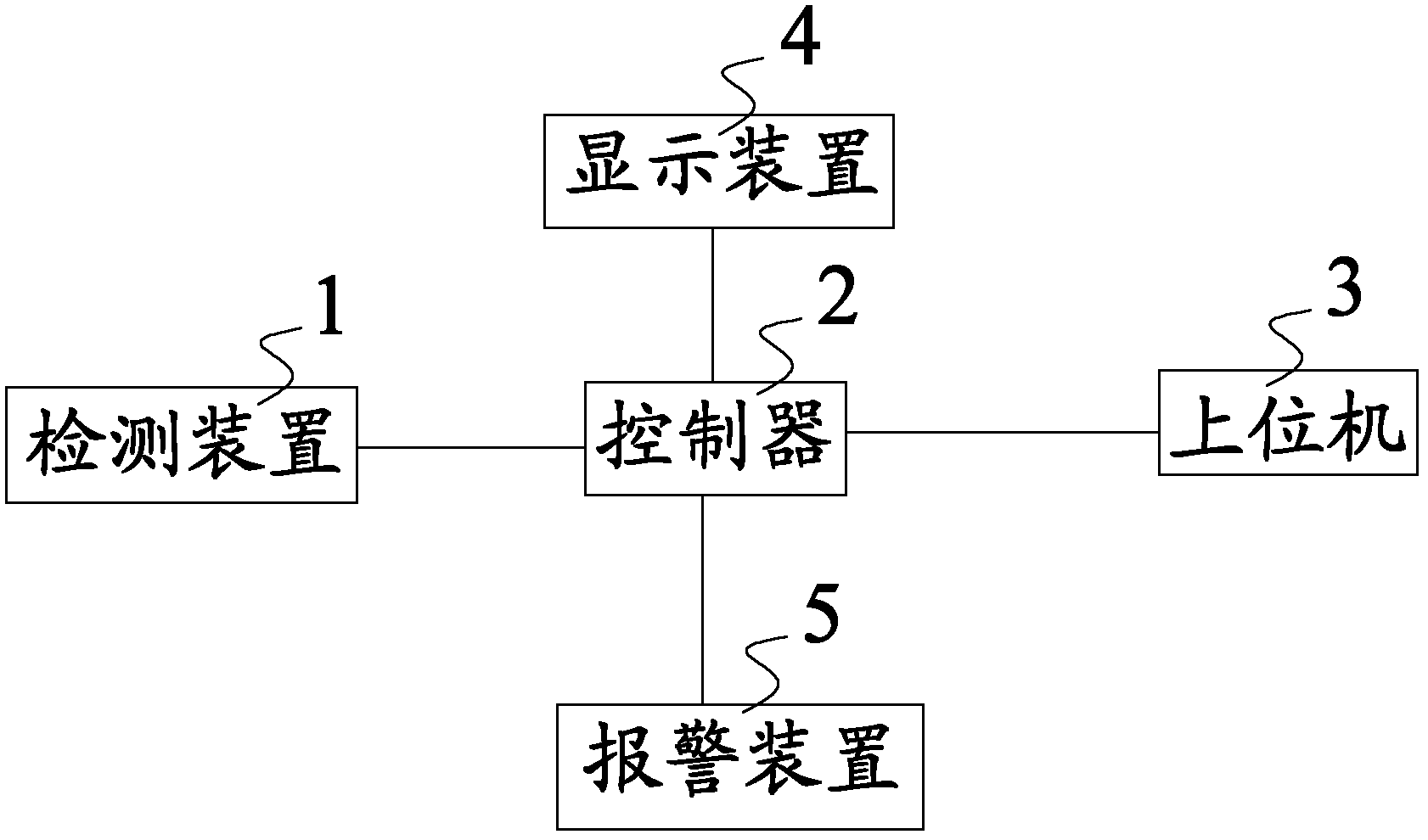

[0017] Please see figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the computerized flat knitting machine fault detection system provided by the present invention.

[0018] Please see figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the computerized flat knitting machine fault detection system provided by the present invention.

[0019] Such as figure 1 As shown, the computerized flat knitting machine fault detection system provided by the present invention includes a detection controller 2, a host computer 3, an alarm device 5, a display device 4 and a plurality of detection devices 1, and the detection devices 1 are evenly distributed along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com