Paper honeycomb light wallboard joint treatment method

A light-weight wall panel and joint treatment technology, applied in the direction of walls, building components, buildings, etc., can solve problems such as affecting the appearance and wall collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

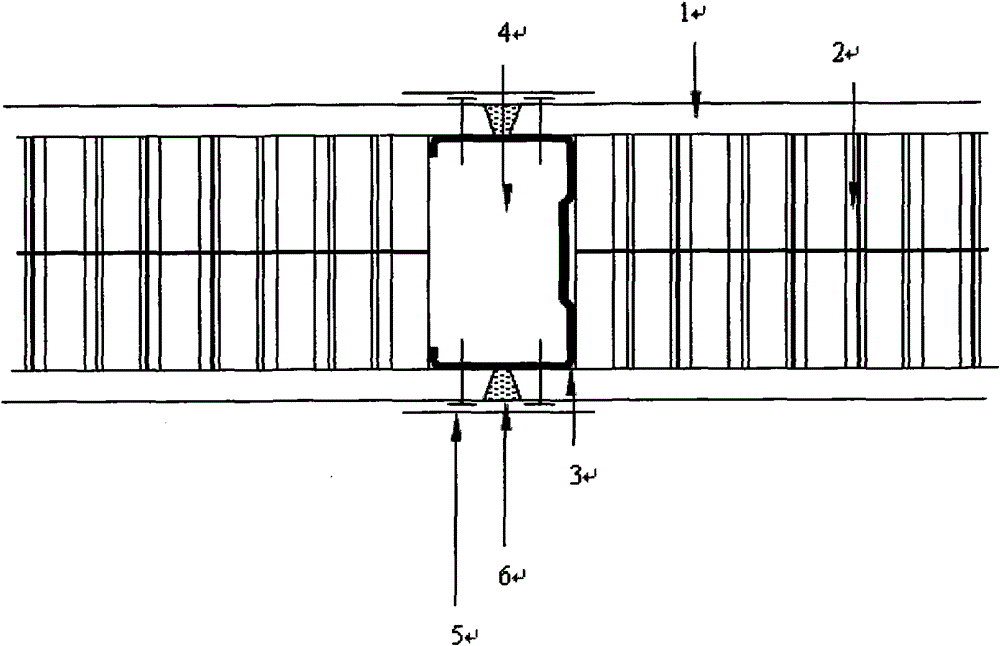

[0014] Examples of the present invention figure 1 As shown: the paper honeycomb lightweight wallboard is composed of two panels 1 and a core panel 2 bonded between the panels 1 . When the two wallboards are docked, the panel 1 at the butt joint of the two wallboards is repaired into a bevel, and a V-shaped groove is formed at the joint of the panel 1 of the two wallboards, and a light steel keel 3 and a light steel keel 3 are set at the core plate 2 at the joint. The filling material 4 is filled inside, and wallboard screws 5 are nailed from the panel 1 to the light steel keel filling material 4 on both sides of the V-shaped groove. When processing joints, brush construction glue in the V-shaped groove, then fill the V-shaped groove with caulking paste 6 and scrape it flat. The putty is scraped more than twice, and the thickness of each scrape is 0.3-0.5mm. The last time the putty is scraped, the scraper is scraped in the opposite direction from the previous scraper. After ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com