Light mixing type monochromatic light source with function of fluorescent powder excitation and projection optical engine using same

A monochromatic light source and phosphor technology, applied in the field of projection optical engines, can solve the problems of shortening the service life of the light source, limiting the development of liquid crystal projection, and high cost of liquid crystal projection, achieving good projection display effect, improving light output purity, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

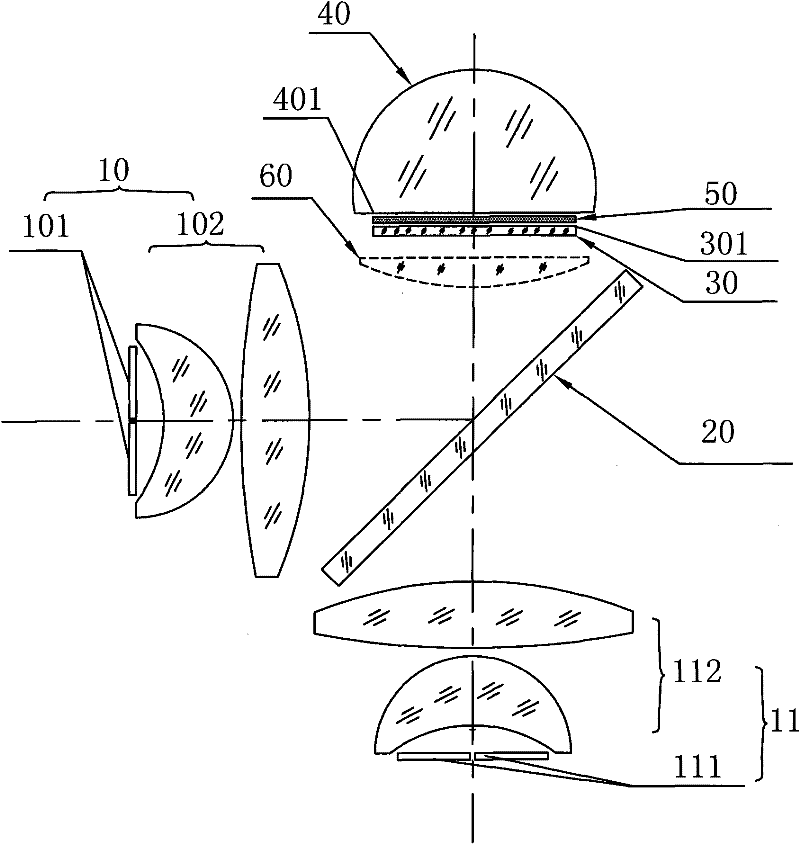

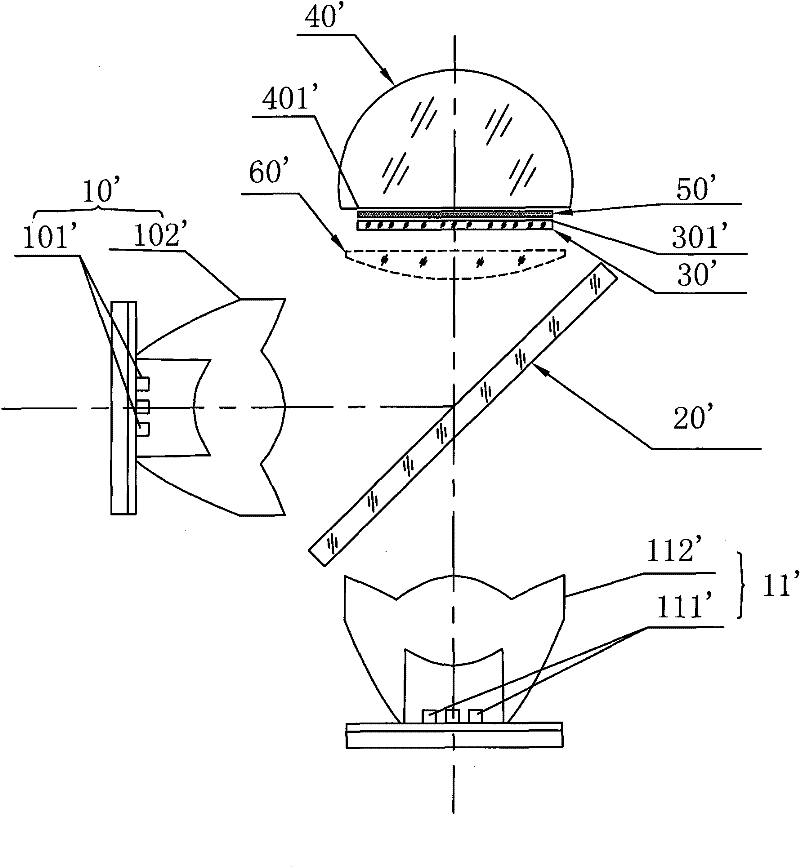

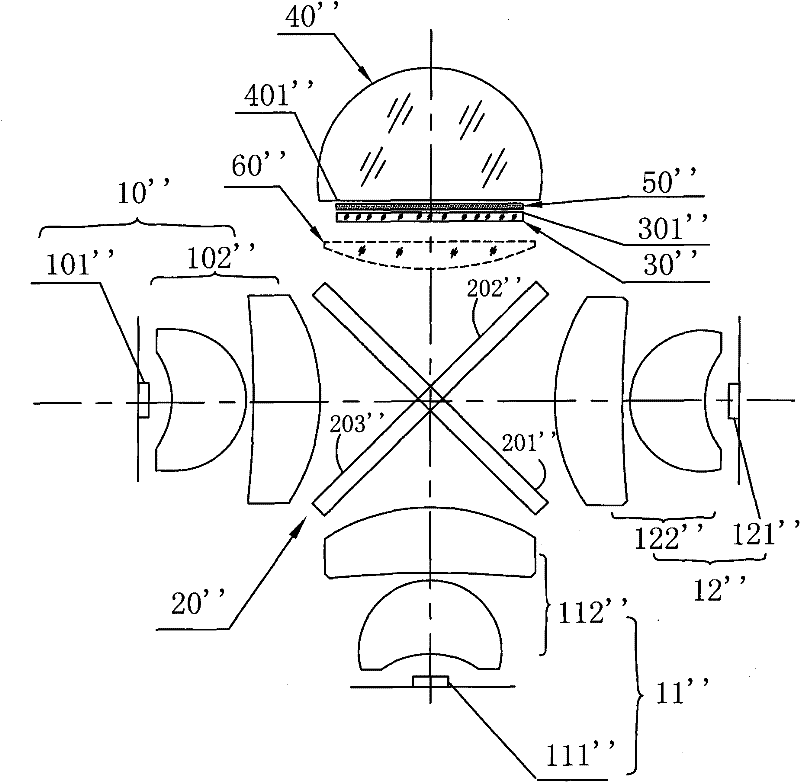

[0018] figure 1 Shown is a schematic diagram of the planar structure of the mixed-light monochromatic light source with phosphor excitation according to the first embodiment of the present invention, which includes a first pump light source module 10, a second pump light source module 11, a color combining mirror 20, A filter 30 , an optical lens 40 and a phosphor layer 50 .

[0019] The first pumping light source module 10 emits the first pumping light, which includes a first light-emitting chip 101 and a first light source shaping mirror group 102 for collecting and shaping the first pumping light. The second pumping light source module 11 emits the second pumping light (the peak wavelength of the second pumping light is different from the peak wavelength of the first pumping light), which includes a second light-emitting chip 111 and a The second light source shaping mirror group 112 for the second pump light. In the embodiment of the present invention, both the first lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com