Trackless rubber-tired vehicle for mining

A technology for trackless rubber-tyred vehicles and mines, which is applied to vehicle components, control devices, transportation and packaging, etc., and can solve the problems of unsuitable for underground water and slime, low climbing ability of transport vehicles, and strong driver operation intensity, etc. Problems, achieve excellent climbing ability and passing performance, improve climbing ability and passing performance, and reduce driving fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

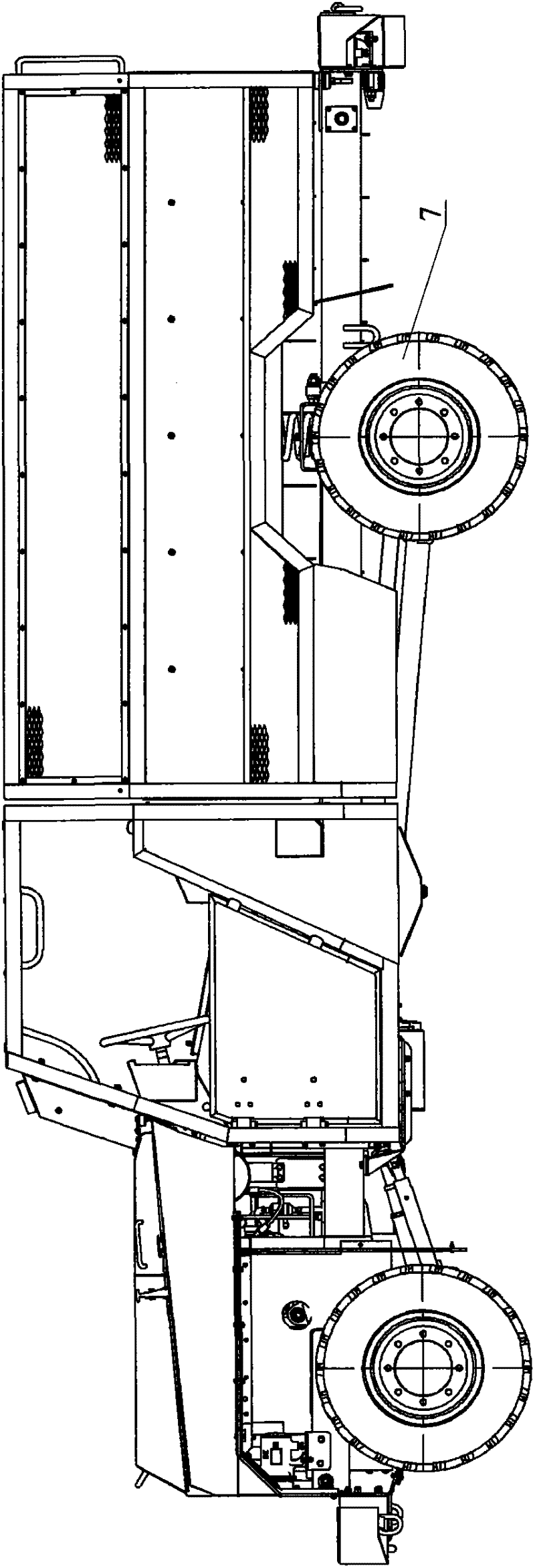

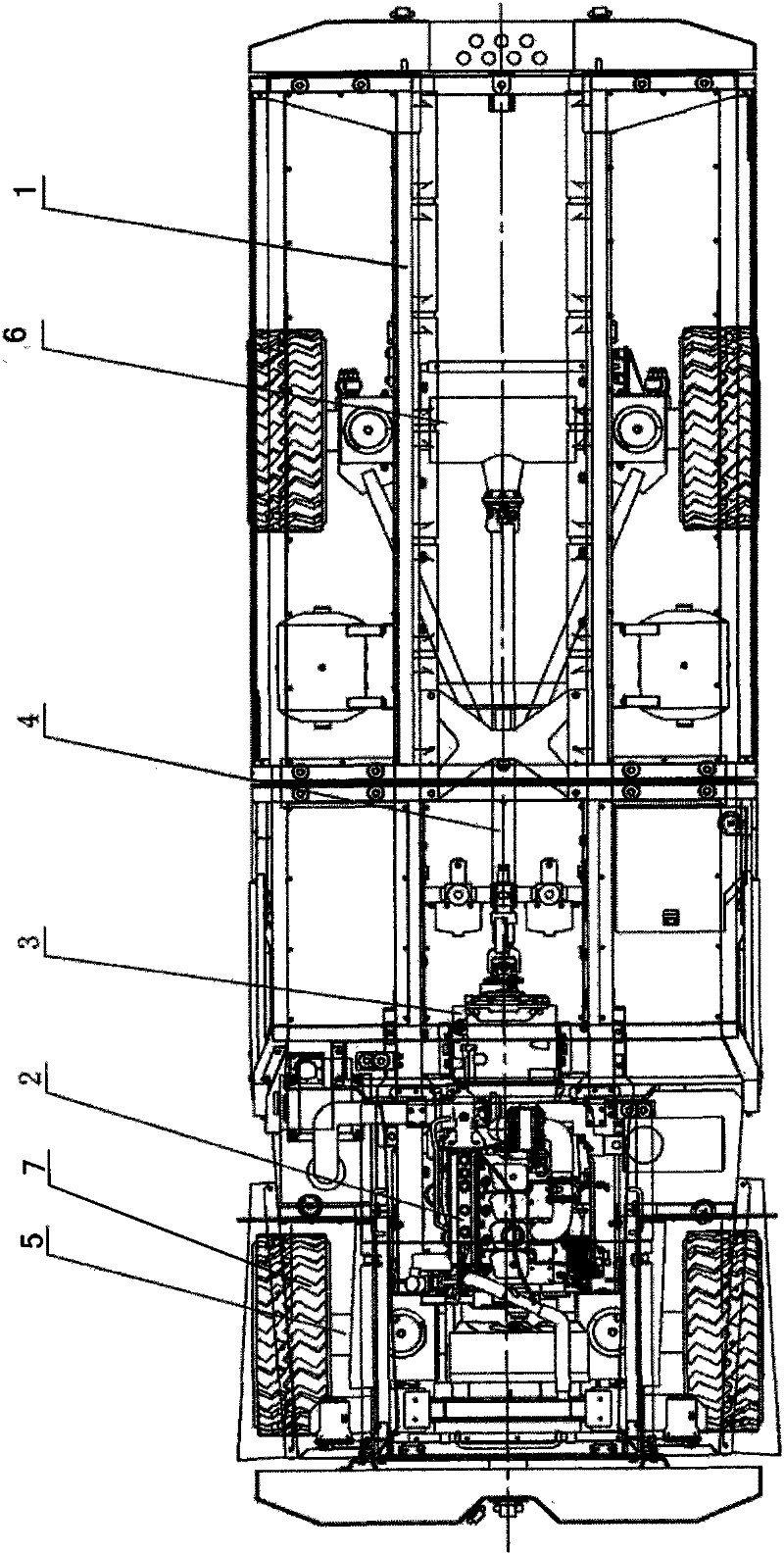

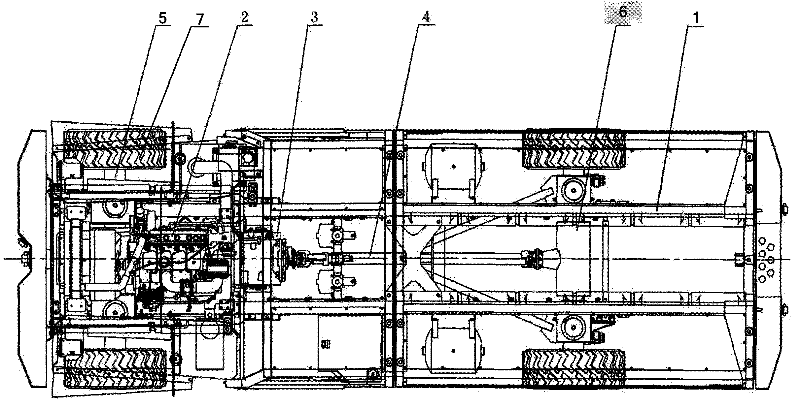

[0020] figure 1 , figure 2 A schematic structural view of the mine trackless rubber-tyred vehicle according to the present invention is shown. in, figure 1 It shows a schematic front view of an embodiment of the mine trackless rubber-tyred vehicle according to the present invention, figure 2 show figure 1 The top view diagram of the mine trackless rubber-tyred vehicle shown.

[0021] Such as figure 1 , figure 2 As shown, the present invention provides a diesel engine trackless rubber-tyred vehicle, comprising a vehicle frame 1, an explosion-proof diesel engine 2 installed on the vehicle frame 1, a power shift gearbox 3, a drive shaft 4, and a front brake steering drive axle 5. Rear brake drive axle 6 and tires 7, the explosion-proof diesel engine 2 transmits power to the power shift gearbox 3, the front brake steering drive axle 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com