Method for installing rotary vane type steering engine

A technology of turning vane steering gear and steering gear, which is applied in the direction of steering, transportation and packaging, and ship parts with rudder, can solve the problems of oil leakage of steering gear, deformation of hull, complicated installation process, etc., so as to improve work efficiency and increase The effect of space height and accident risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A method for installing a rotary vane steering gear, comprising the following steps:

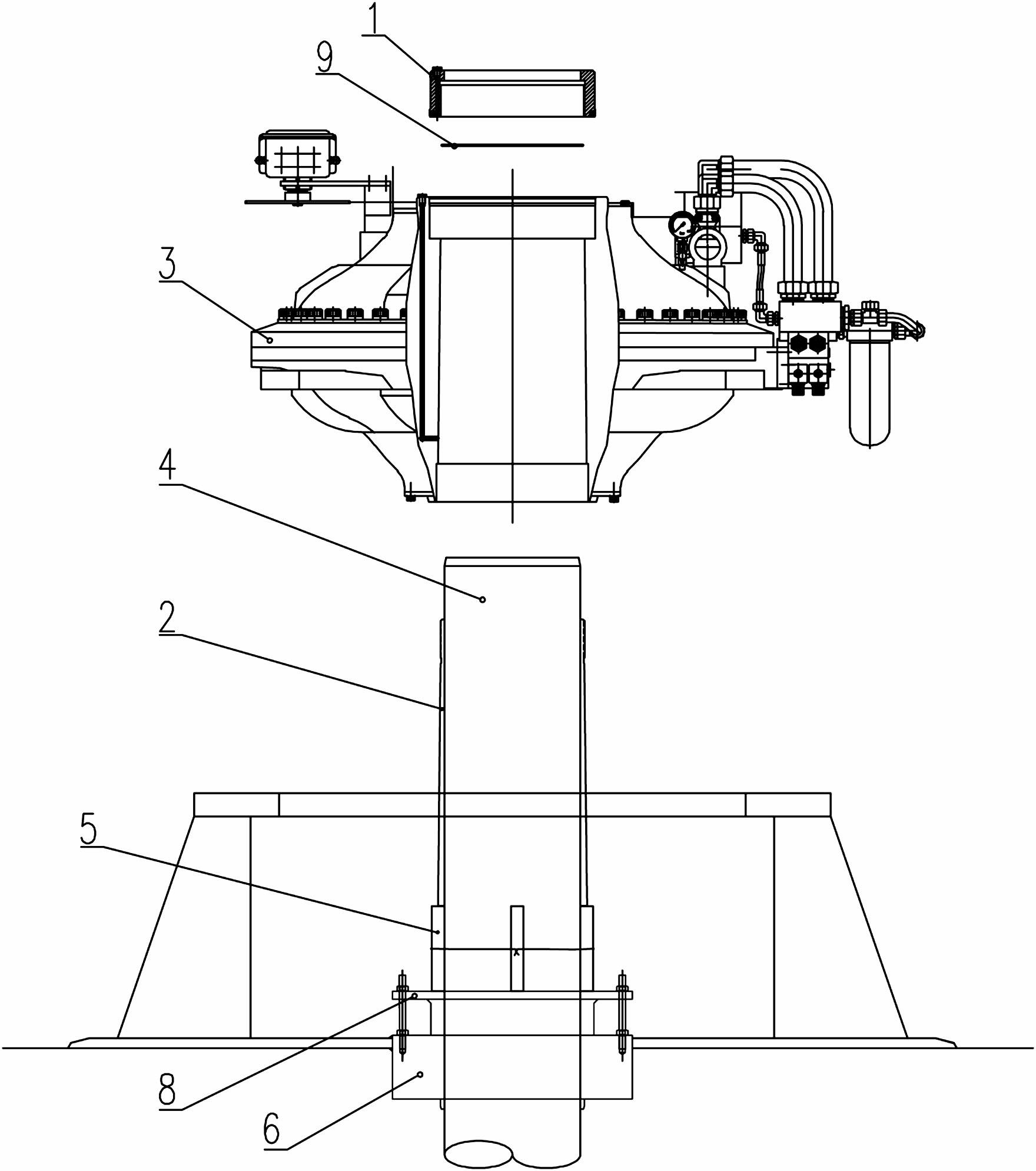

[0029] A. If image 3 As shown in , place the steering gear bushing 2 in the steering gear 3, install the bushing top sealing ring 9 and the bushing hydraulic nut 1, the bushing hydraulic nut 1 cannot be tightened, that is, the outer wall of the steering gear bushing 2 must be in contact with the rudder There is a certain gap between the inner holes of the machine 3 to facilitate subsequent installation;

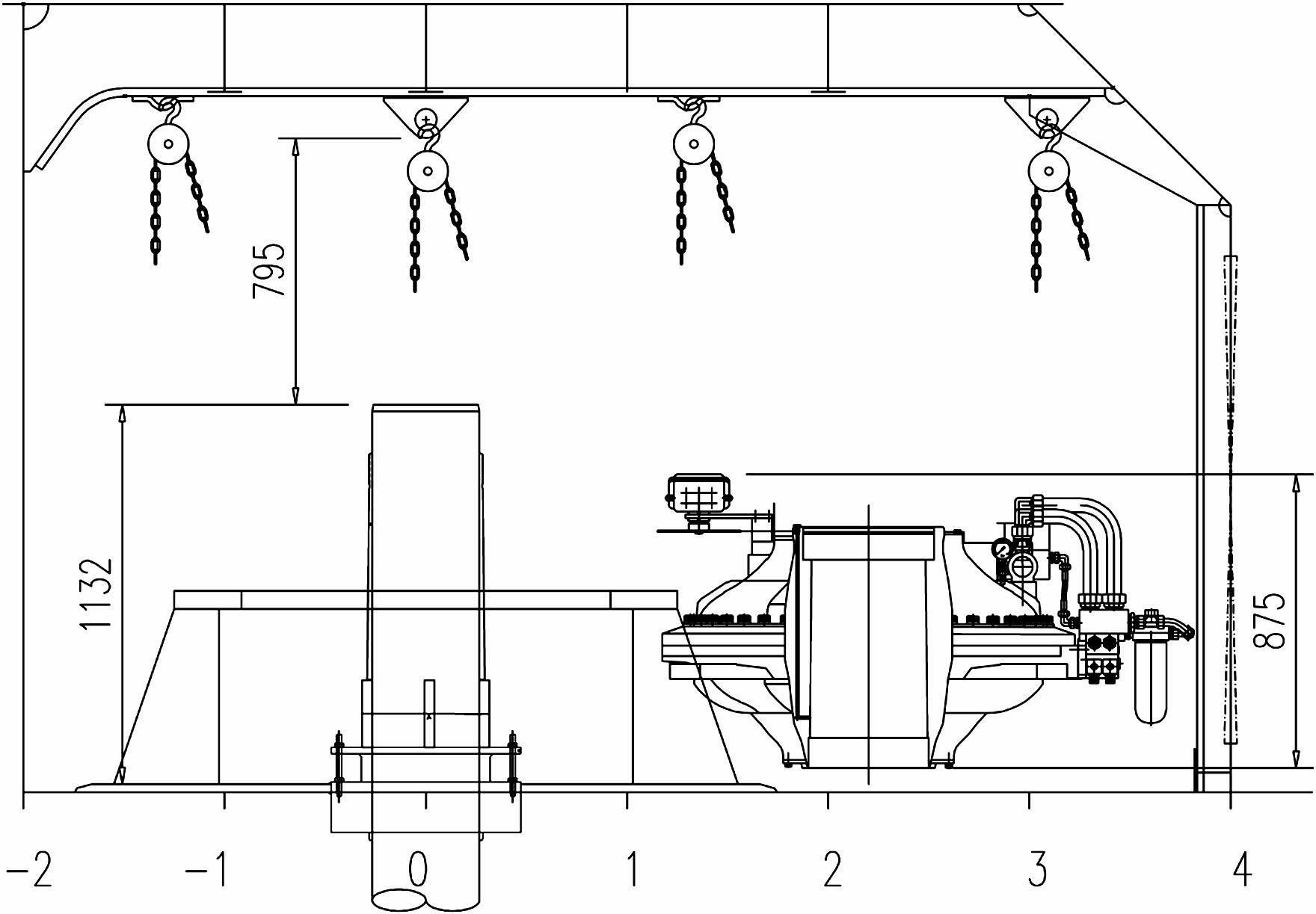

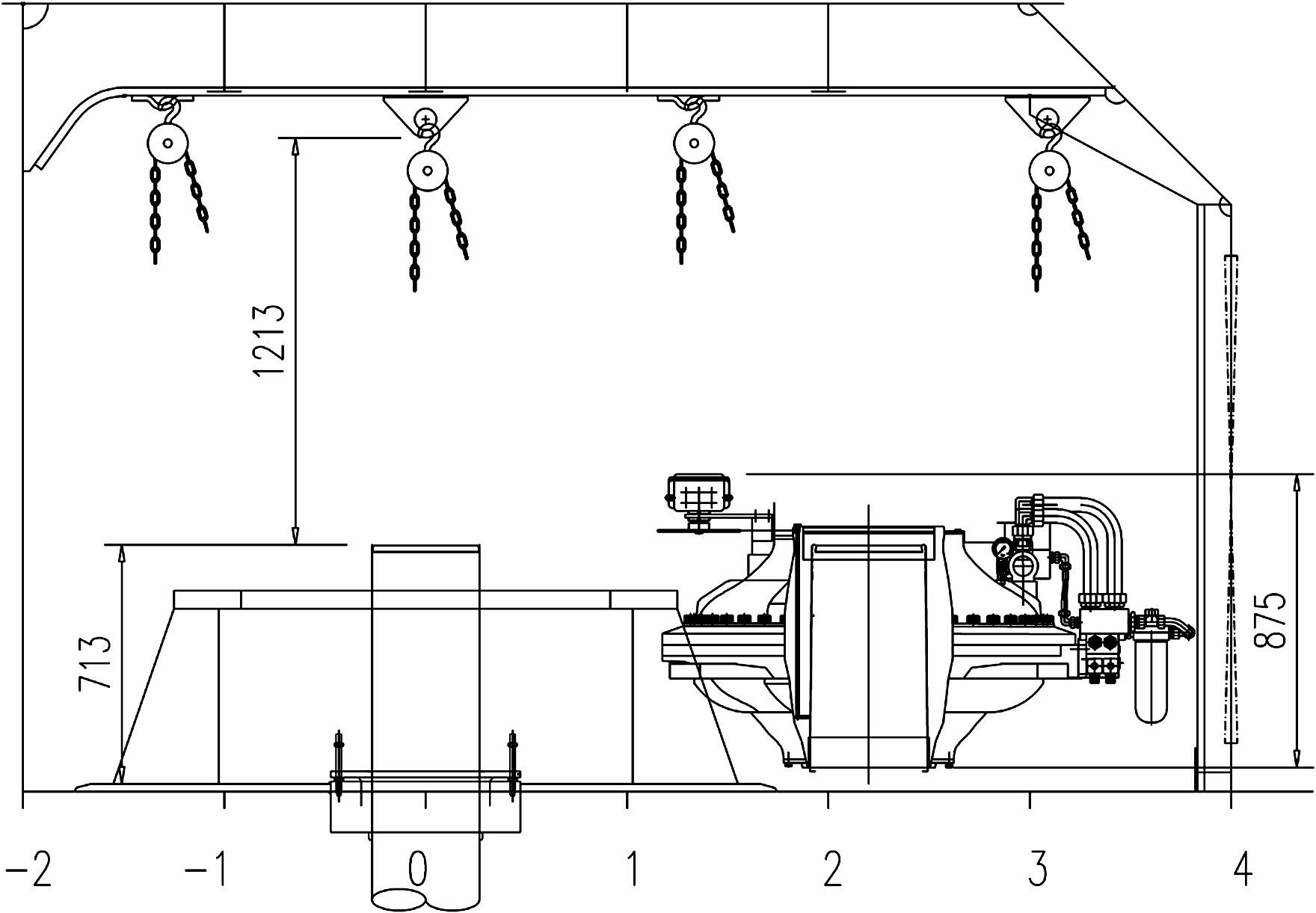

[0030] B. Move the rudder stock 4 downward until there is enough space above the rudder stock 4 to install the steering gear 3; in order to ensure the smooth settlement of the rudder stock 4, the bearing stuffing box 6 and stuffing box cover 8 cannot be installed at this time, and the bearing stuffing box 6 And stuffing box cover plate 8 just is enclosed within on the rudder stock 4.

[0031] C. When the steering gear 3 is above the rudder stock 4, pull up the rudder stock 4 until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com