Rolling type universal joint movement mechanism

A universal joint and kinematic mechanism technology, which is applied to aircraft parts, transportation and packaging, etc., can solve the problems of undiscovered functional universal joint kinematic mechanism, etc., and achieve the effects of fast installation and debugging, simple installation and adjustment, and convenient maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below by means of specific embodiments:

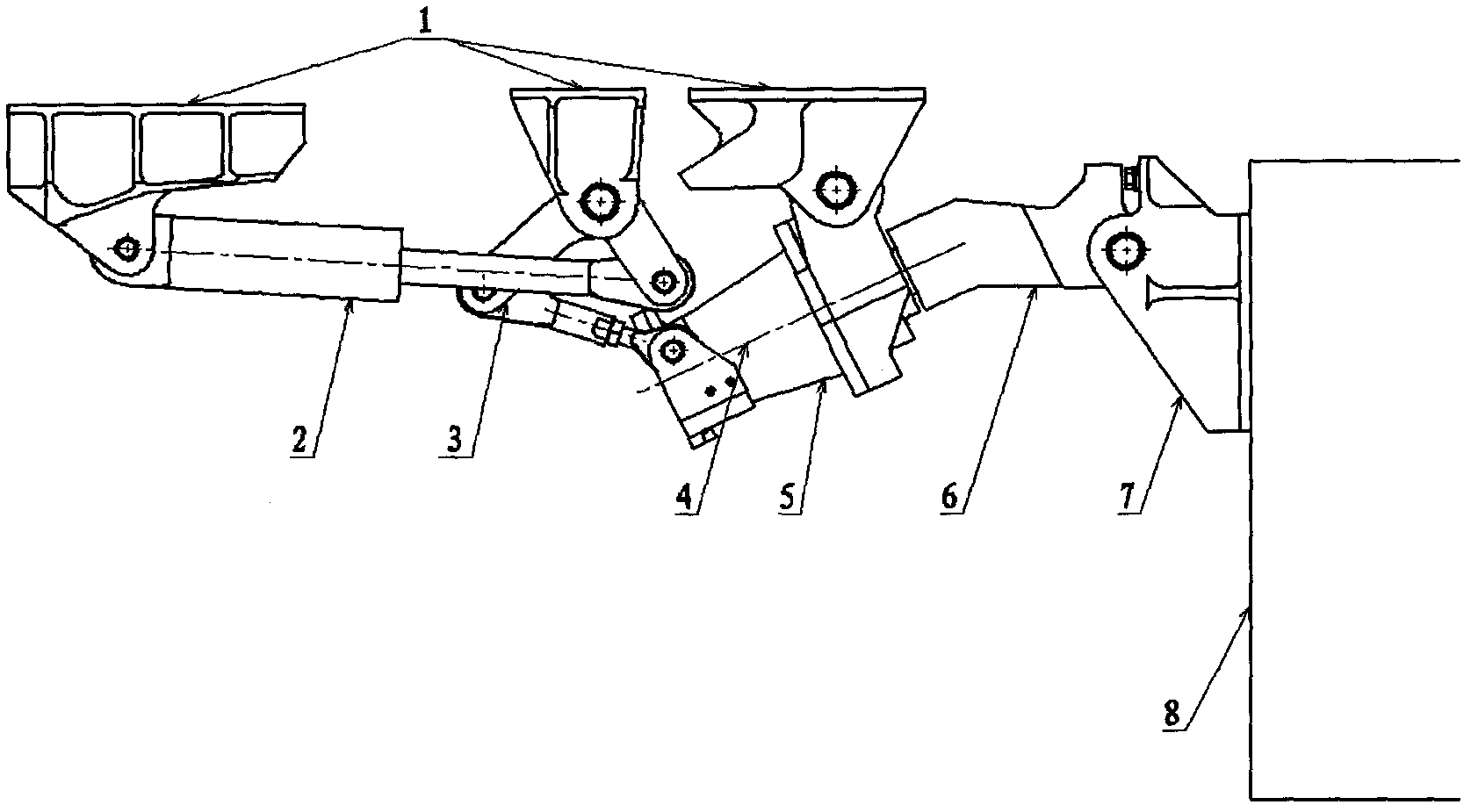

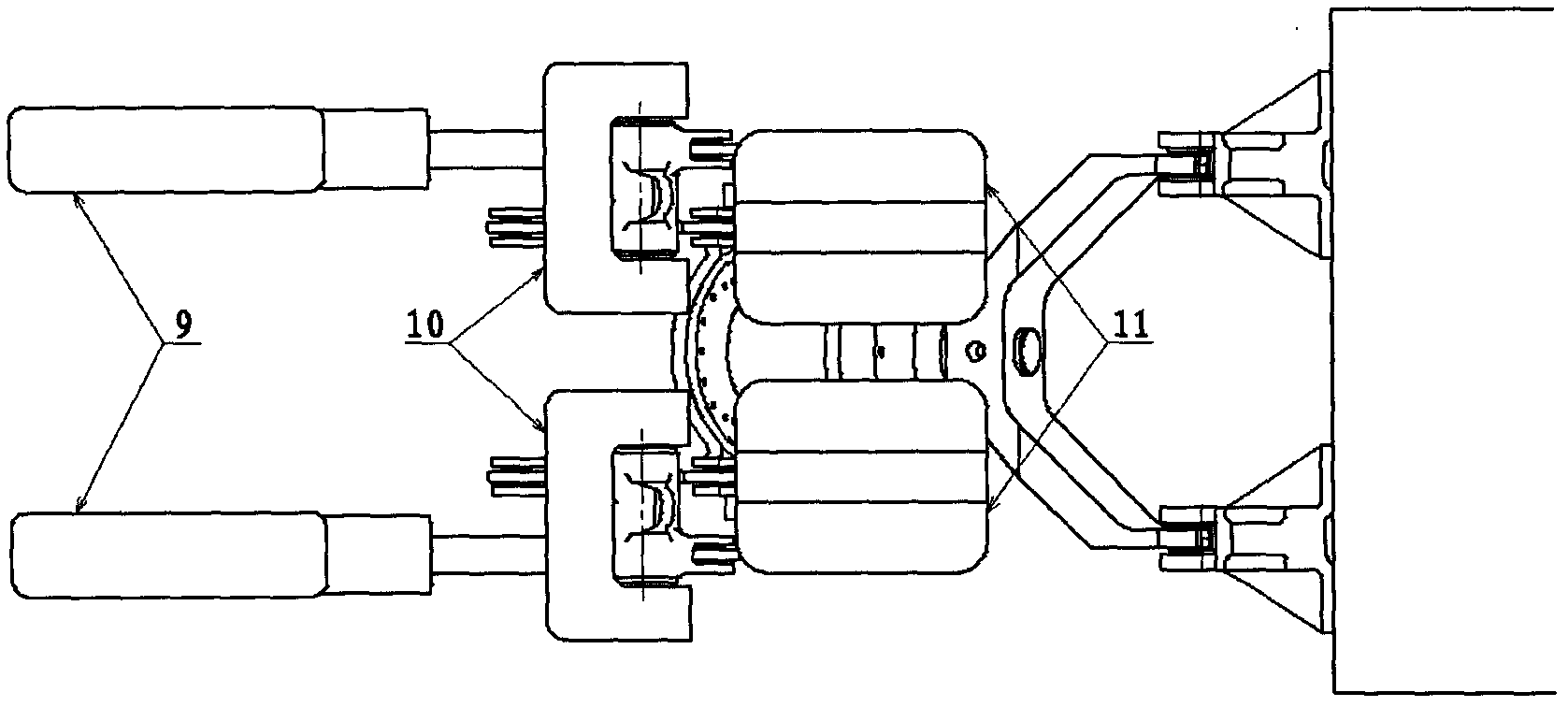

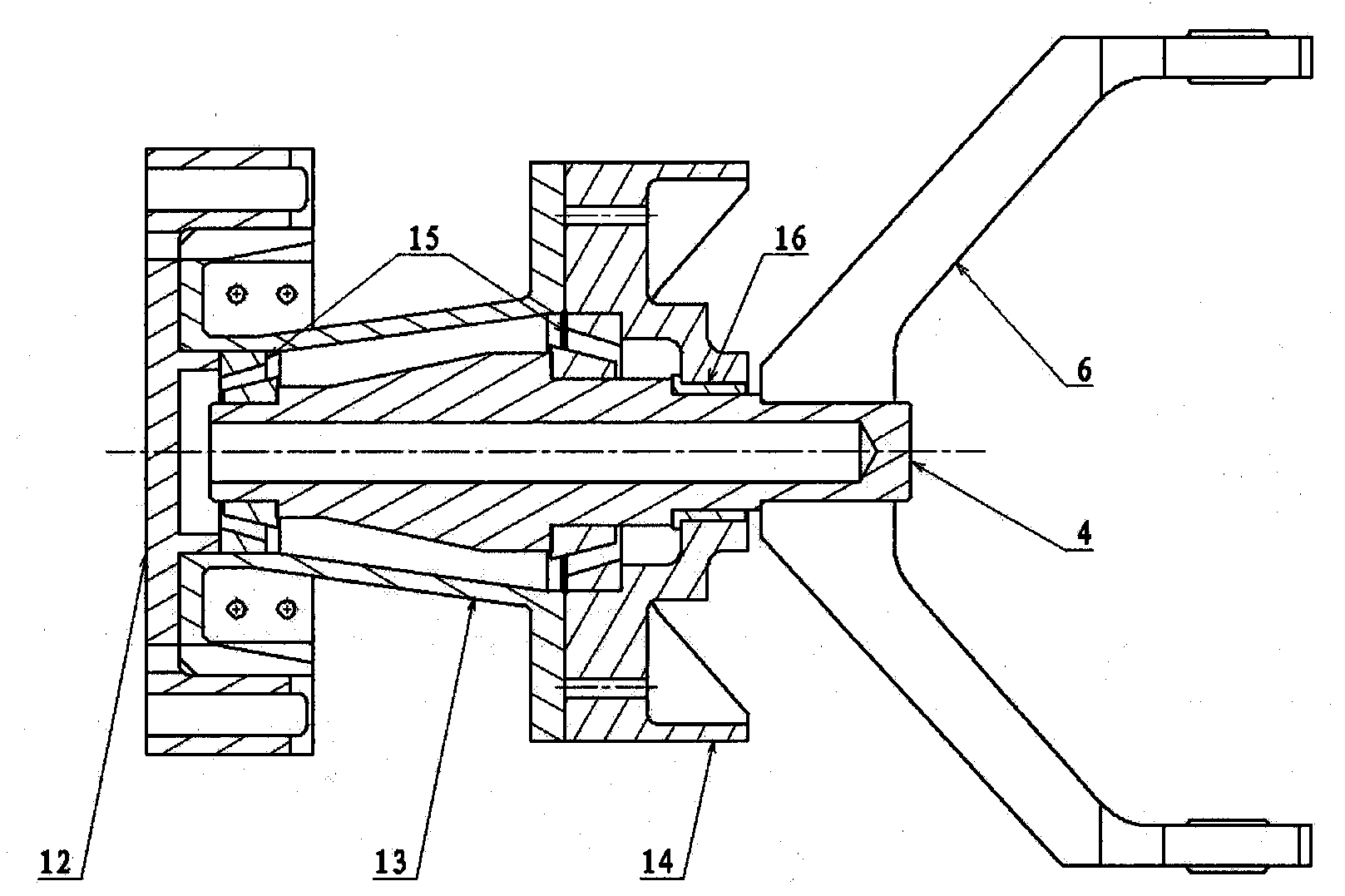

[0023] In the storage position, the included angle between the side roll axis and the horizontal reference line of the aircraft fuselage is relatively large, so that the refueling pipe is close to the aircraft fuselage for storage. When the refueling pipe is lowered, the actuator pushes the sleeve to rotate around the hinge point A through the rocker arm linkage mechanism, the angle between the side roll axis and the horizontal reference line of the aircraft decreases, the position of the hinge point B moves down, and the distance from the aircraft fuselage becomes farther , the refueling pipe moves up and down with the hinge point B as the axis, the side roller shaft can rotate in the sleeve, and the side roll of the refueling pipe is realized through the side rolling fork lug fixedly connected with it, and the refueling pipe is kept under the action of aerodynamic force The cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com