Patents

Literature

33results about How to "Simple in nature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

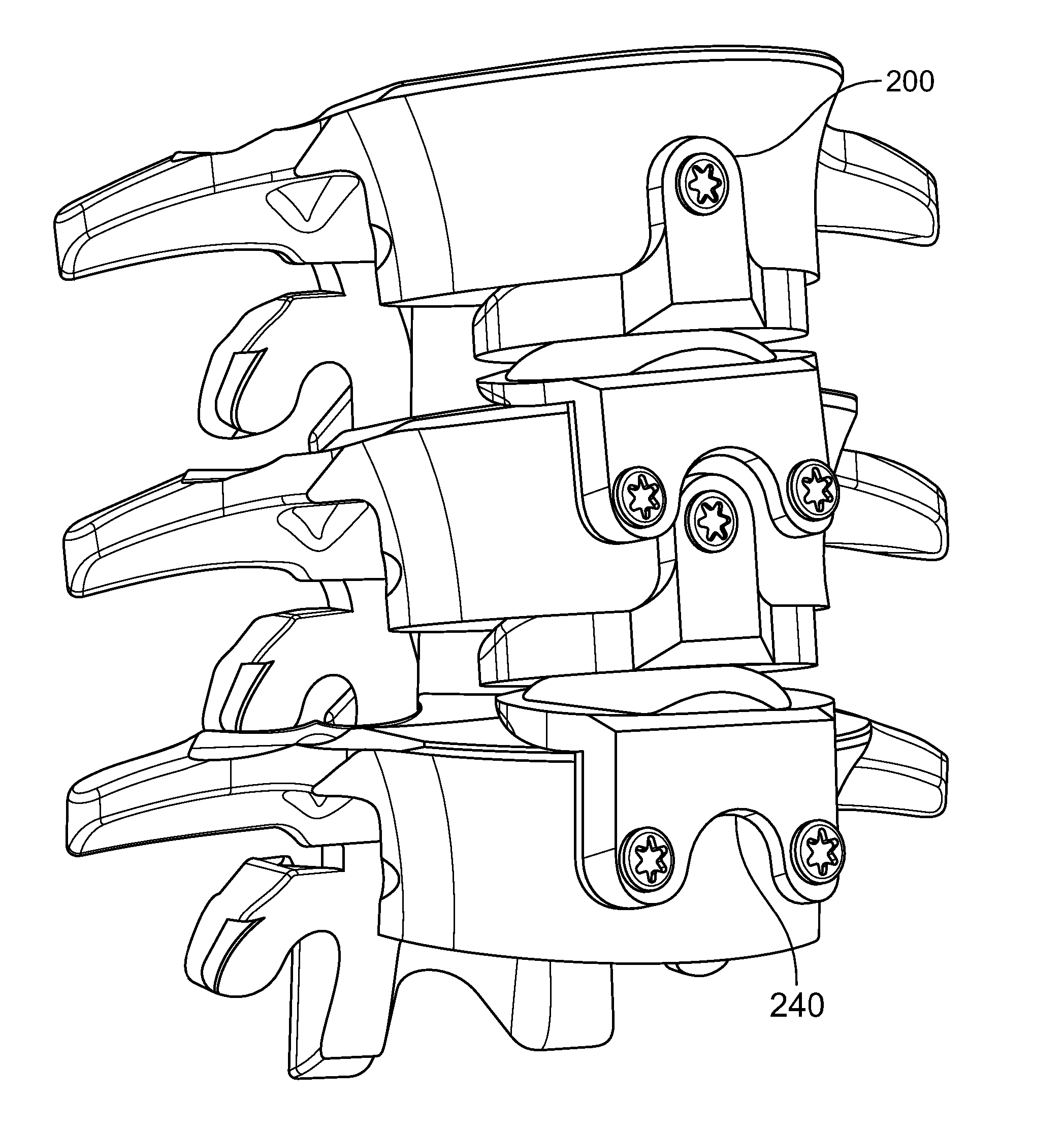

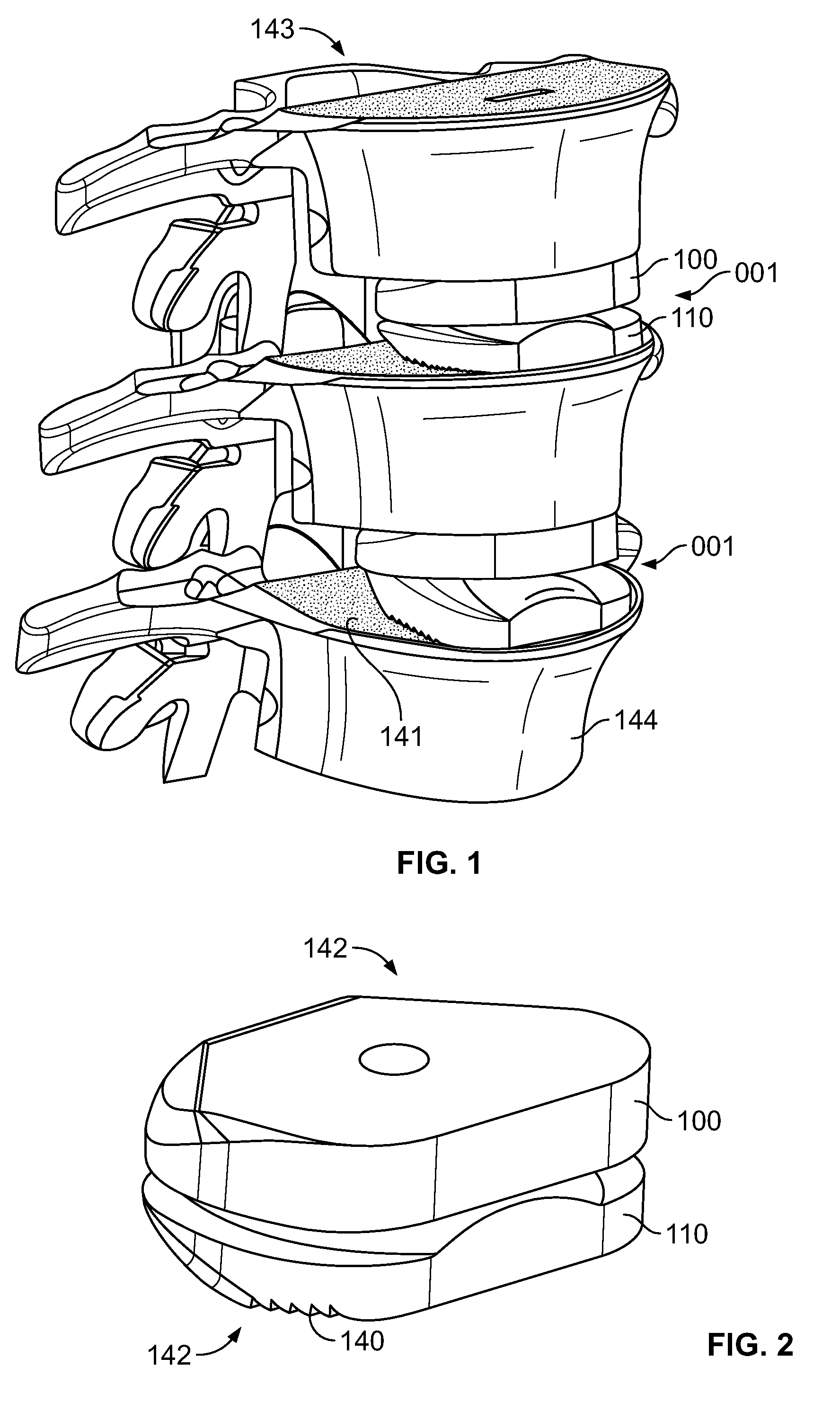

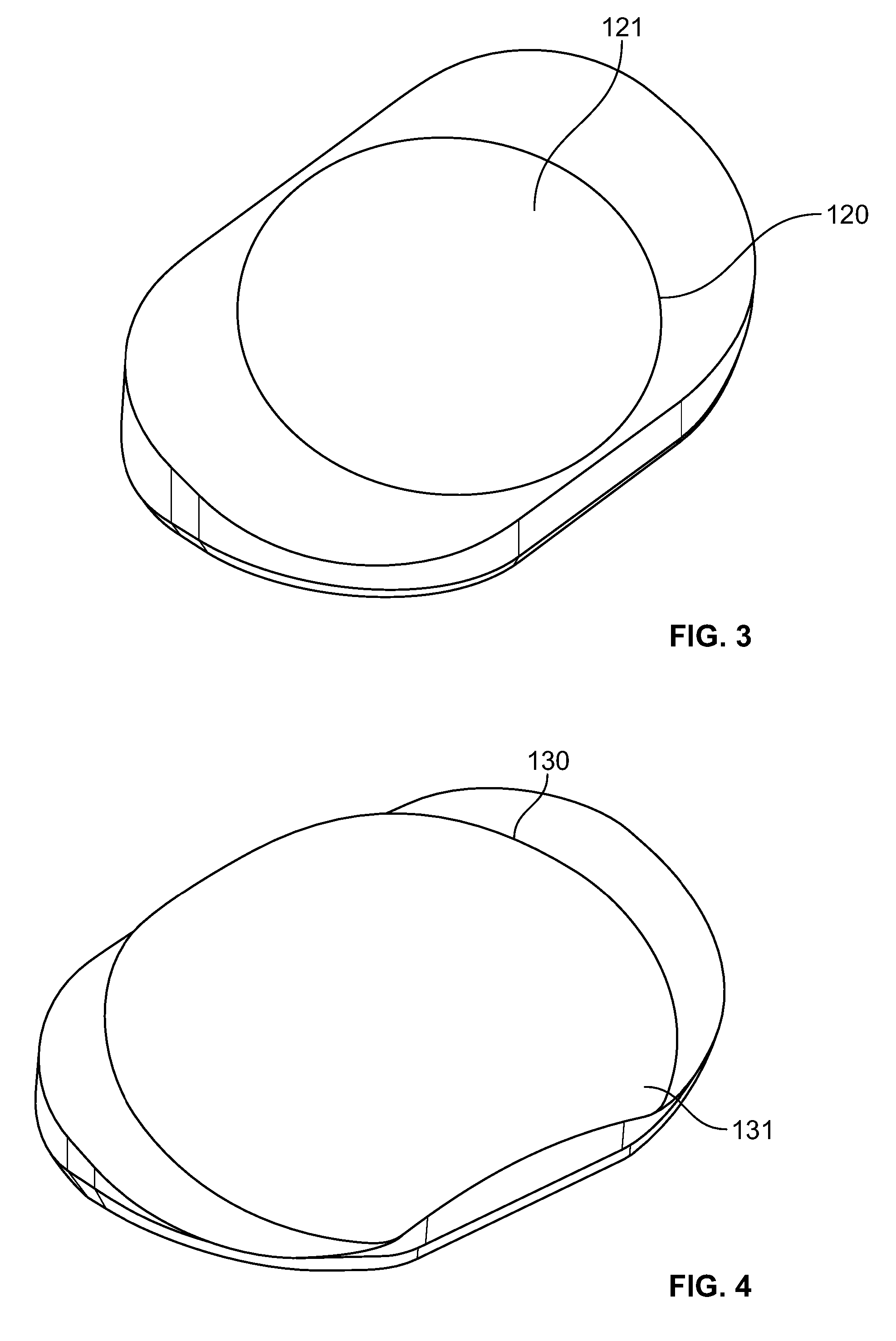

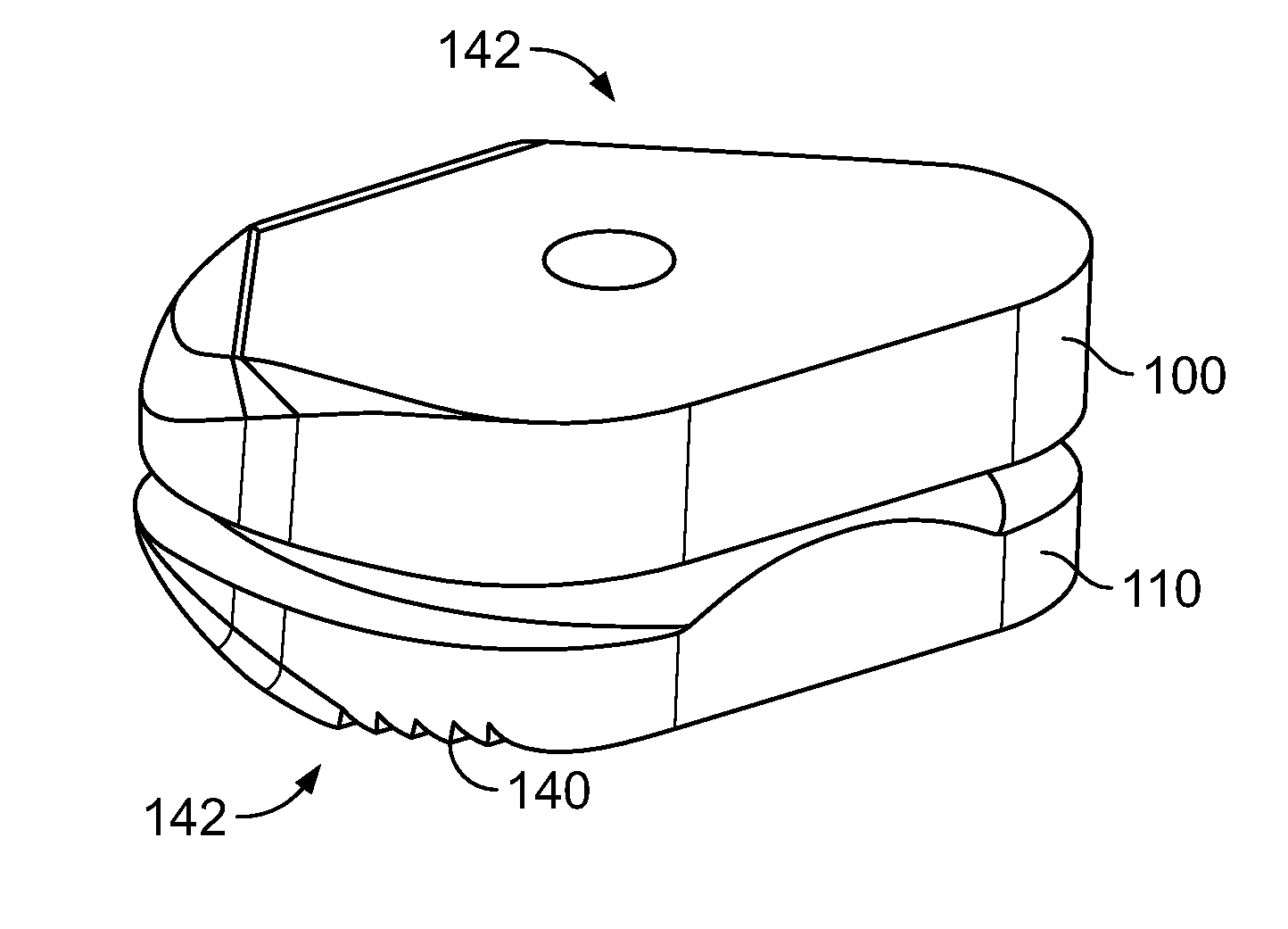

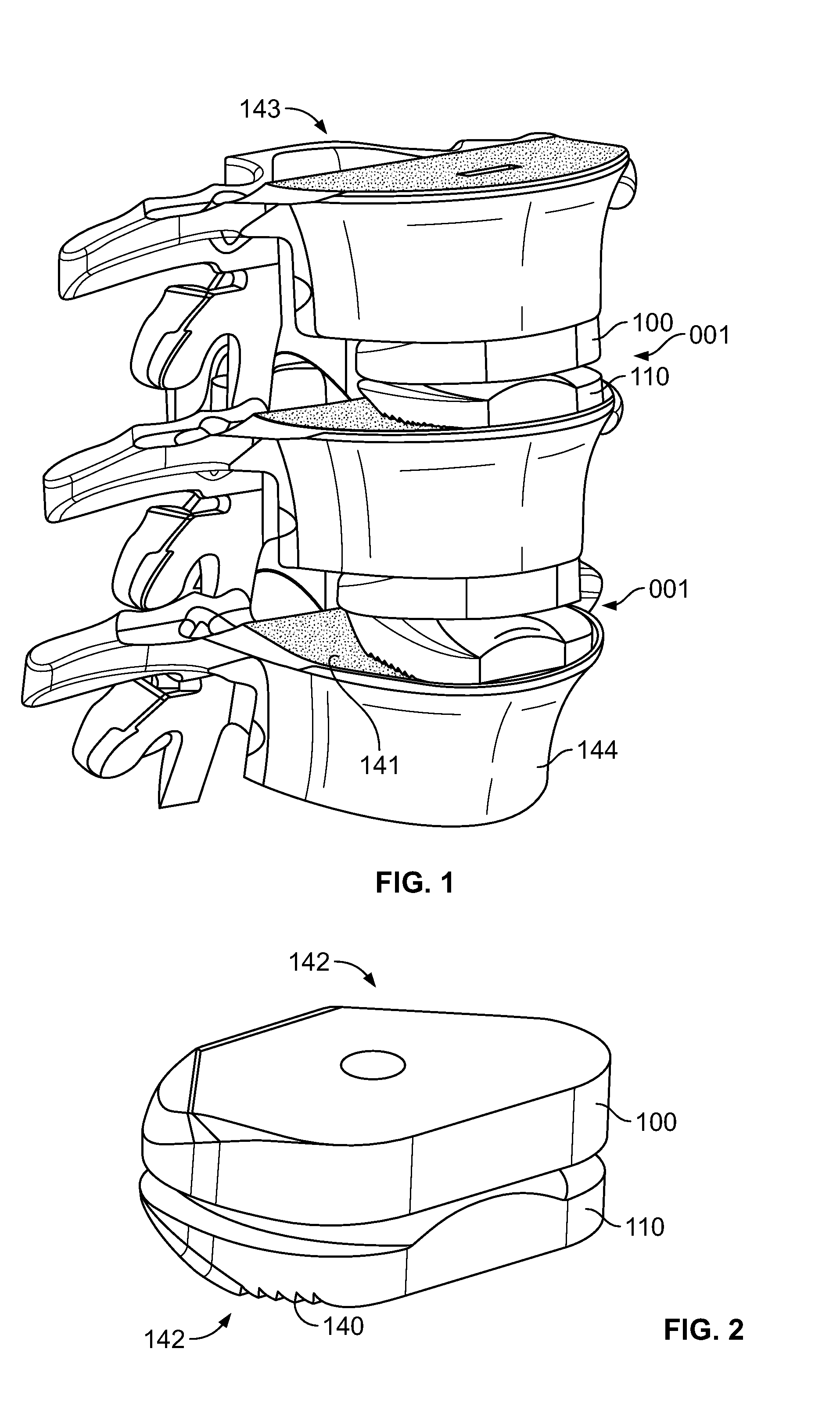

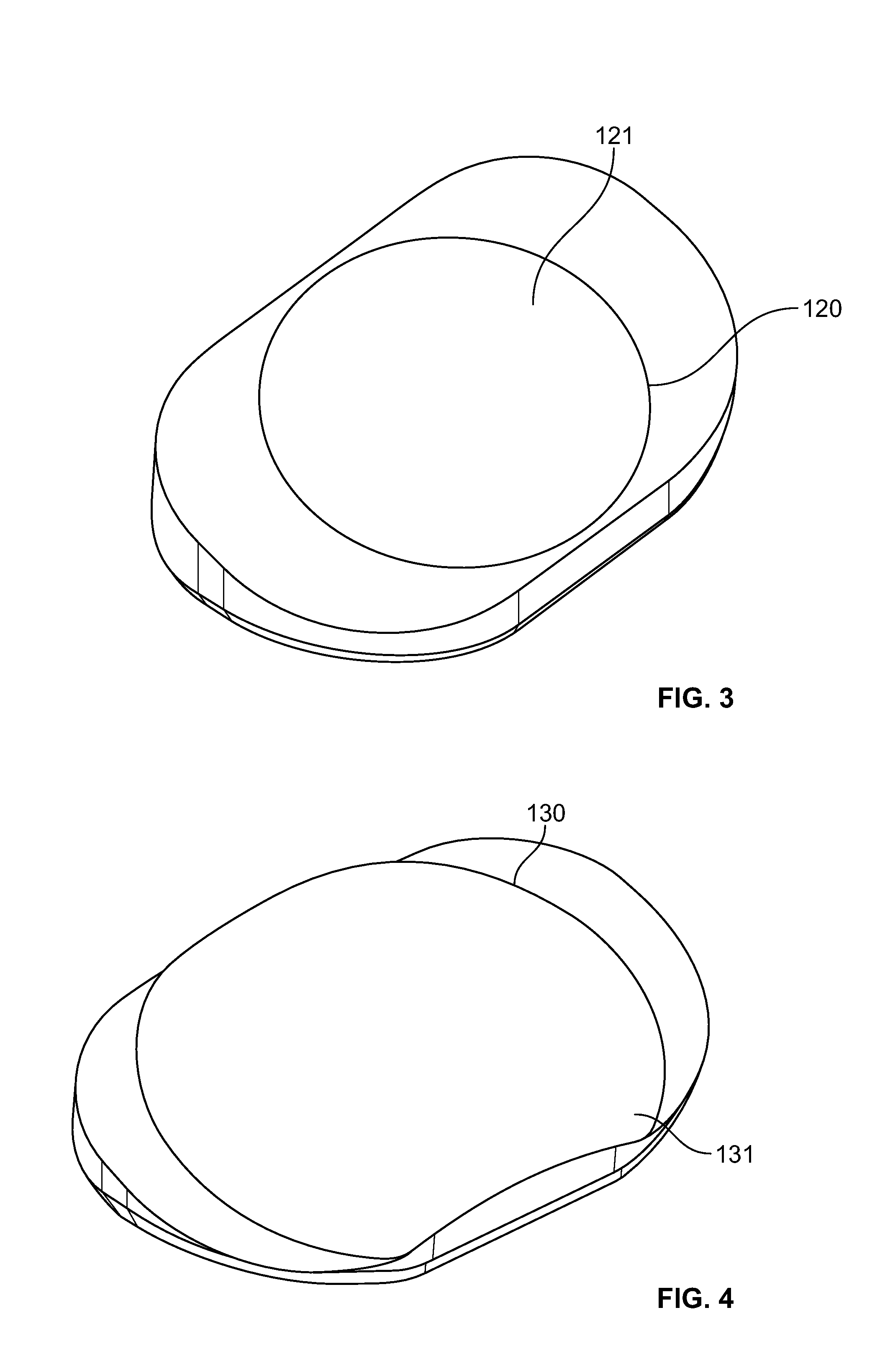

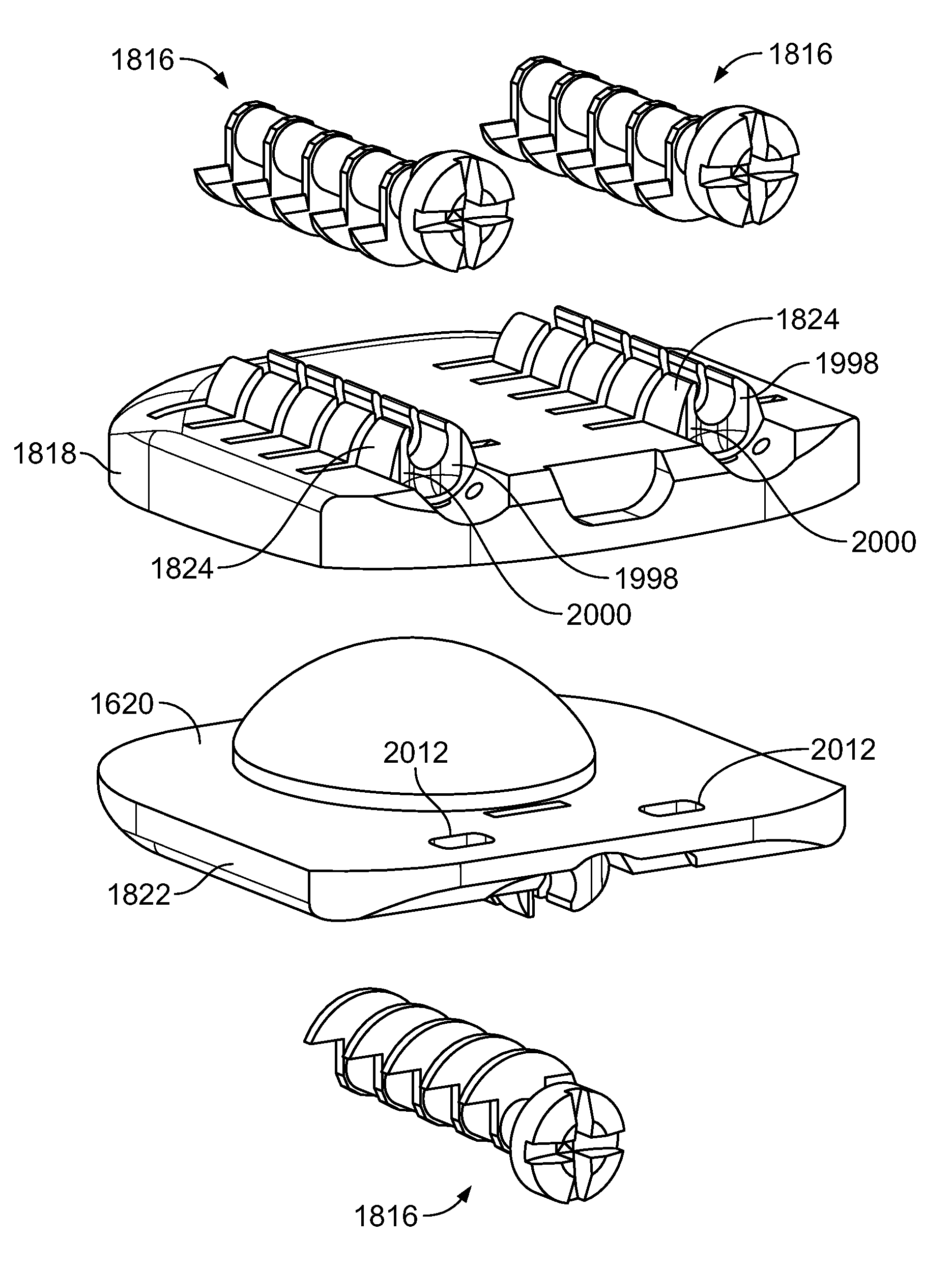

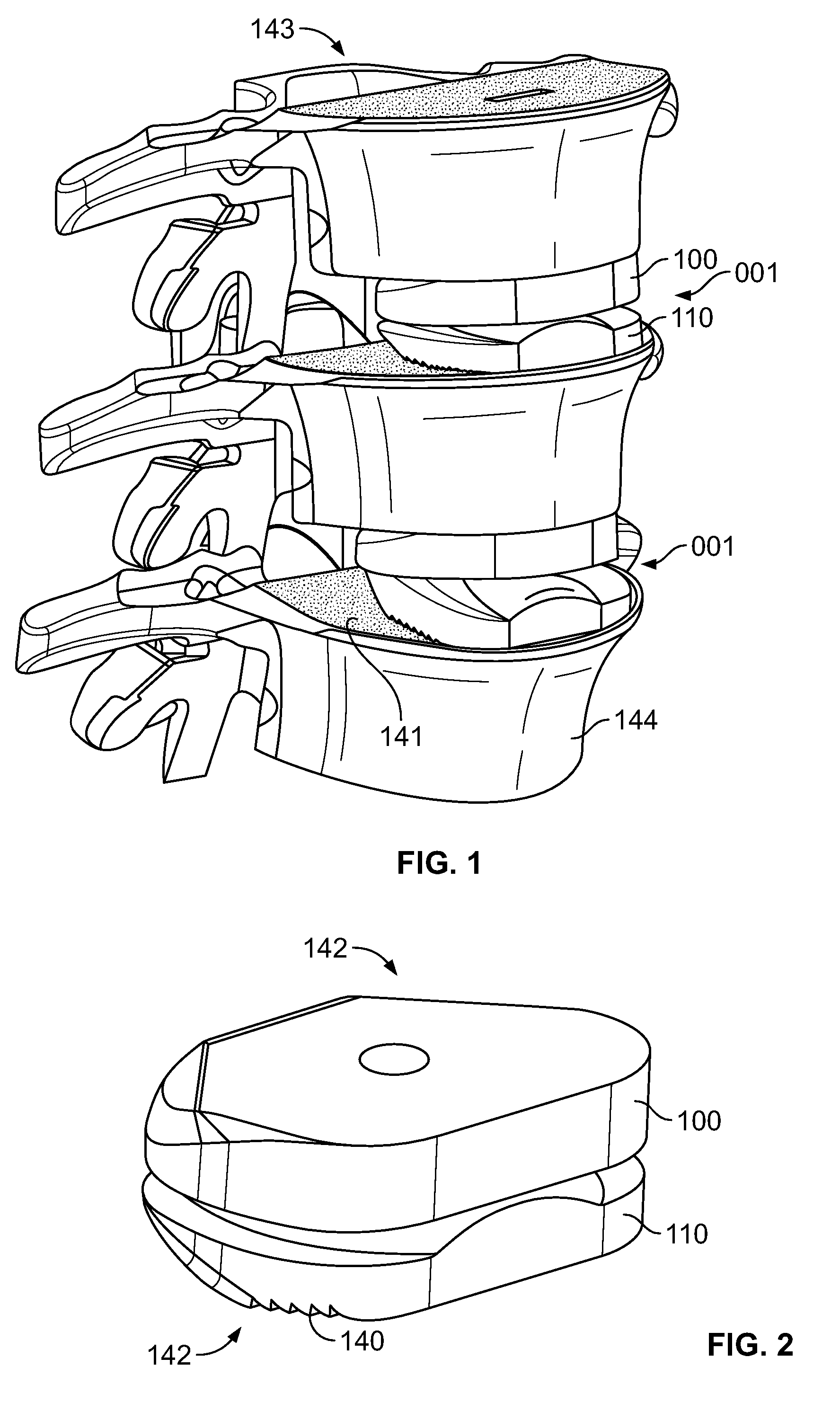

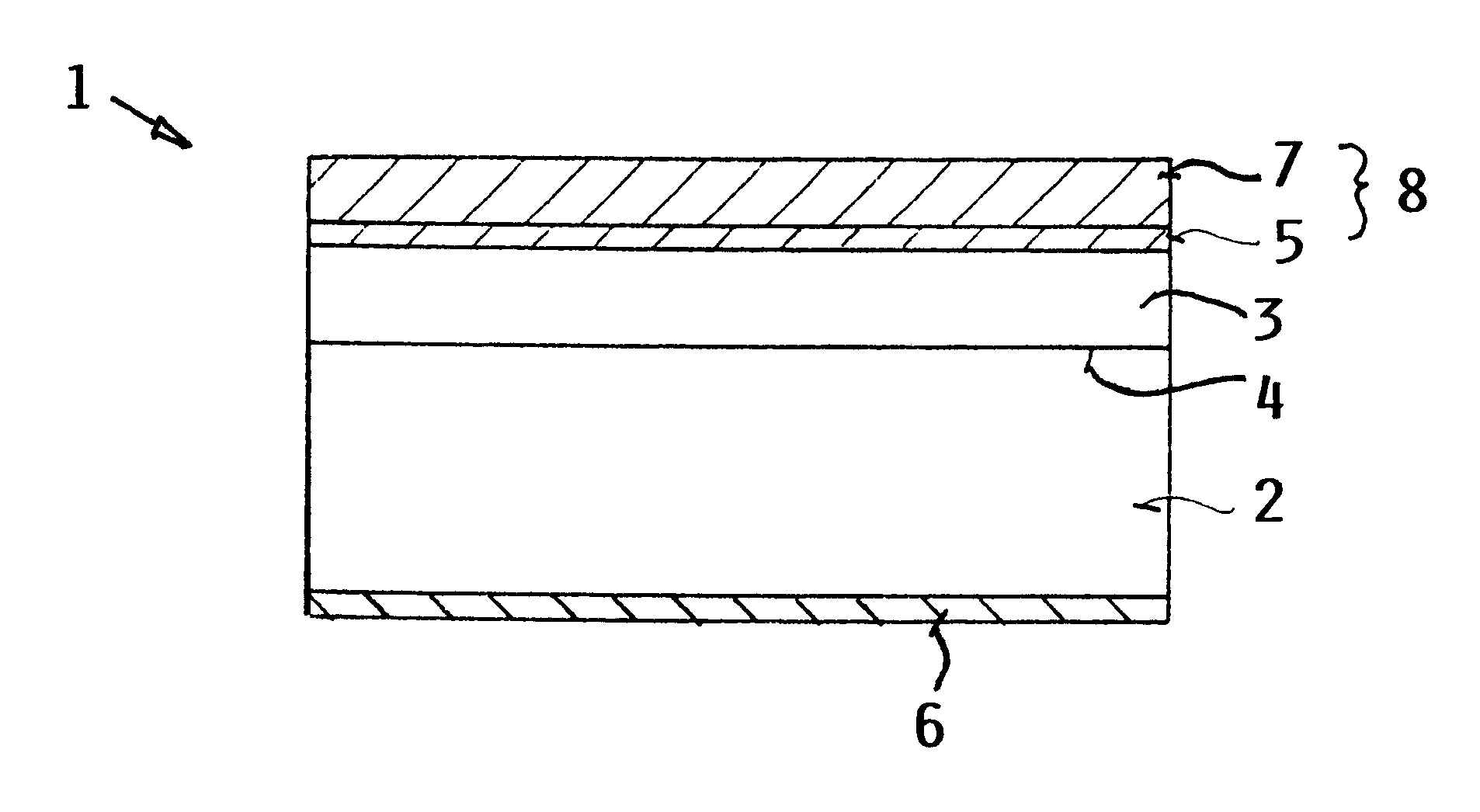

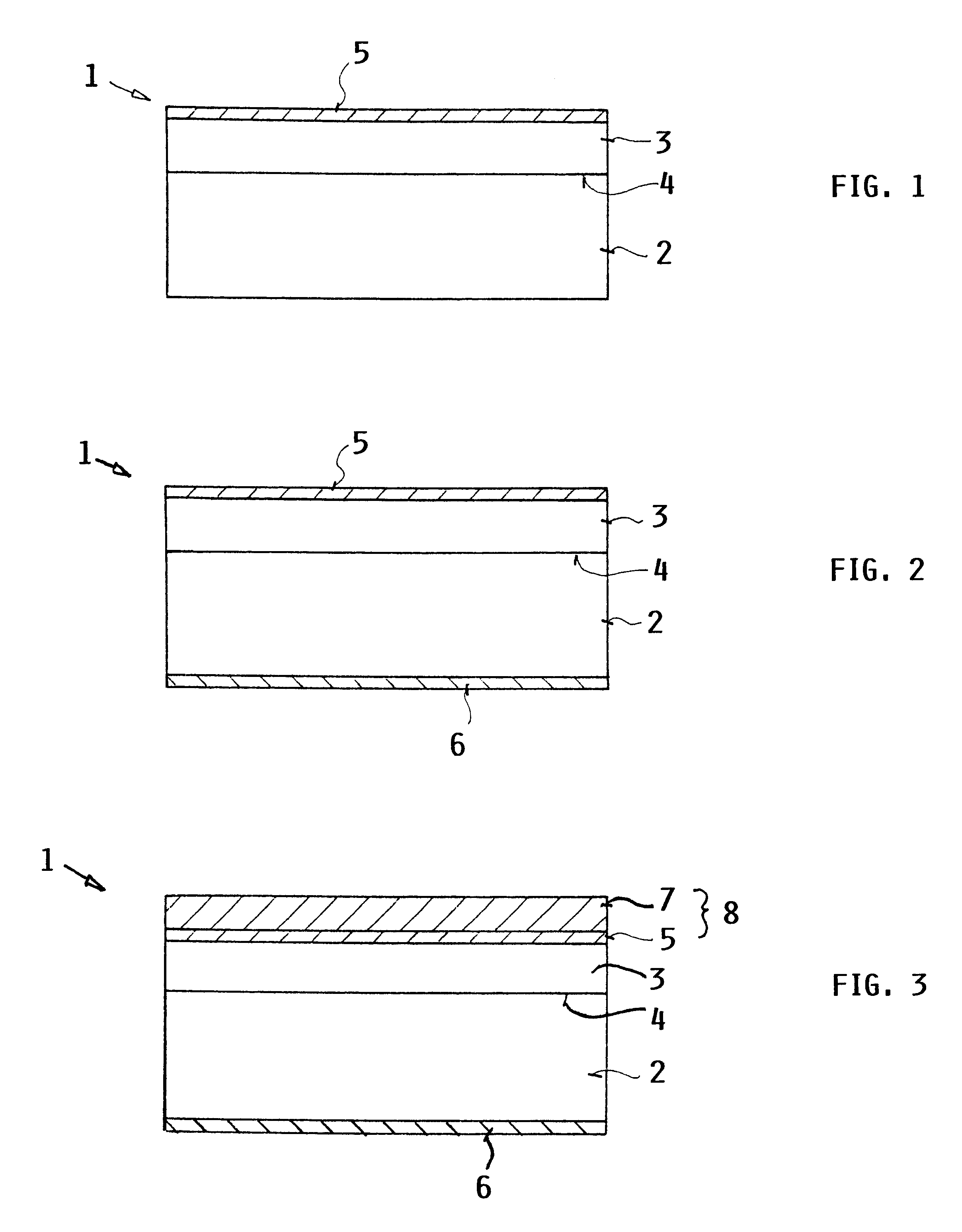

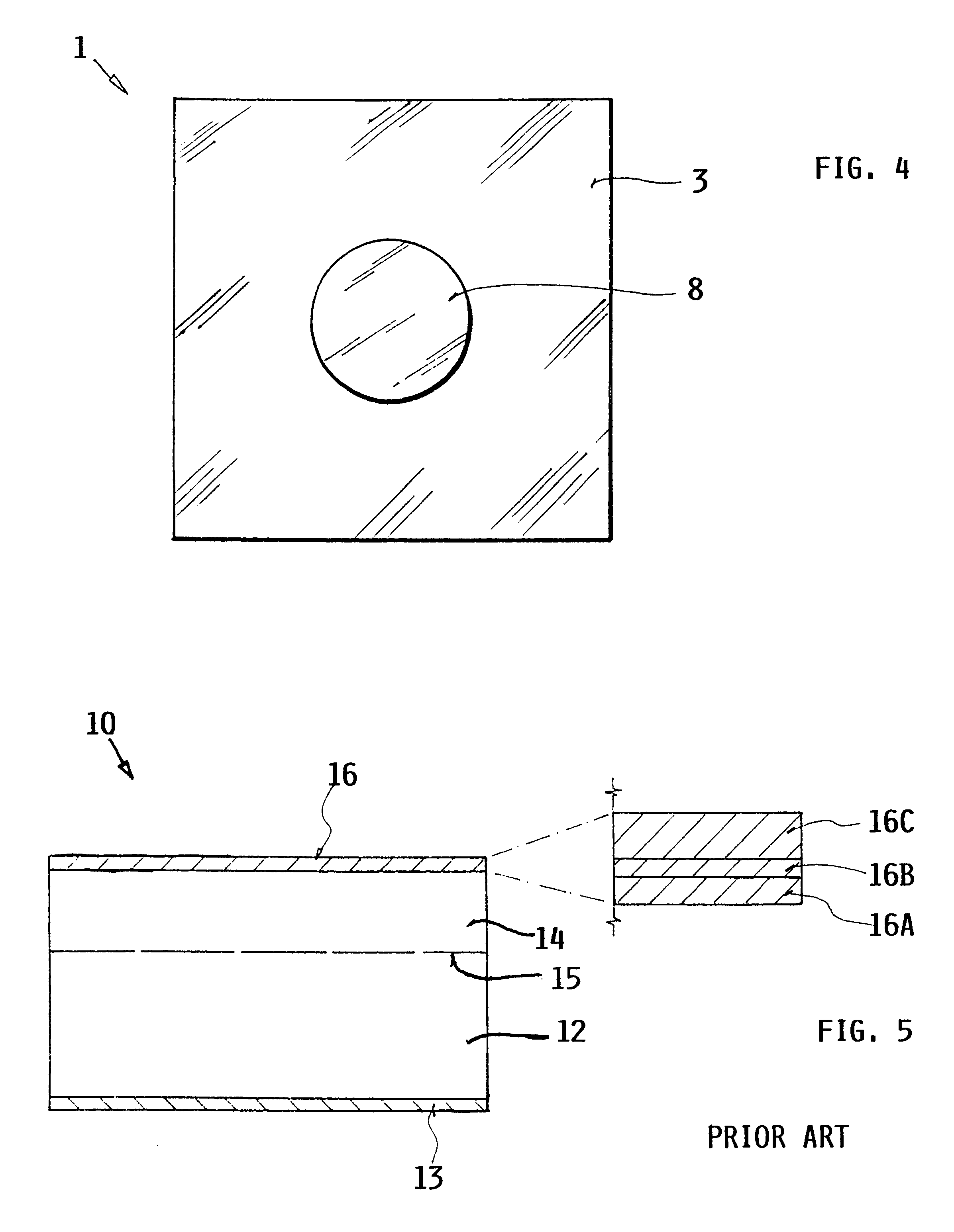

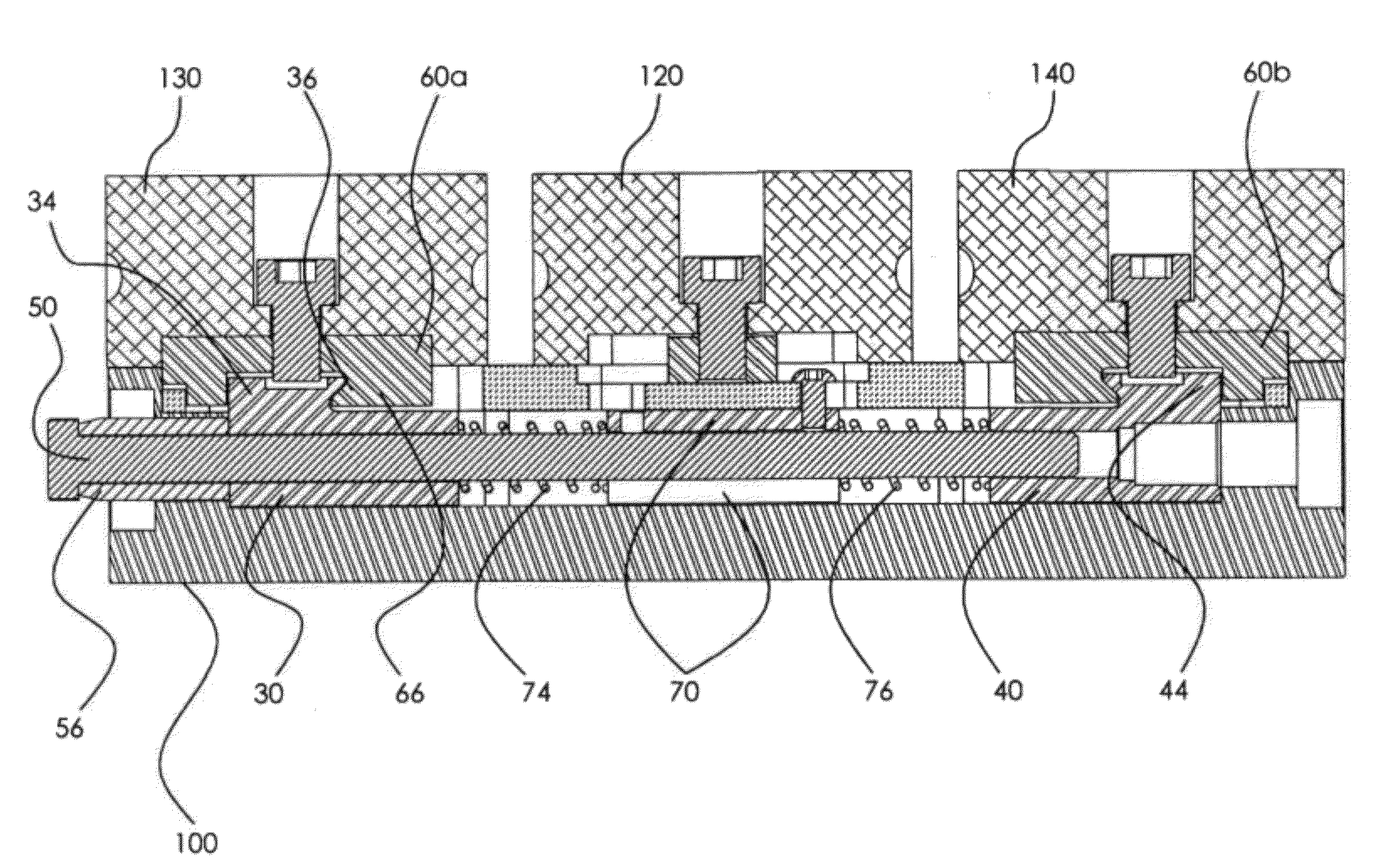

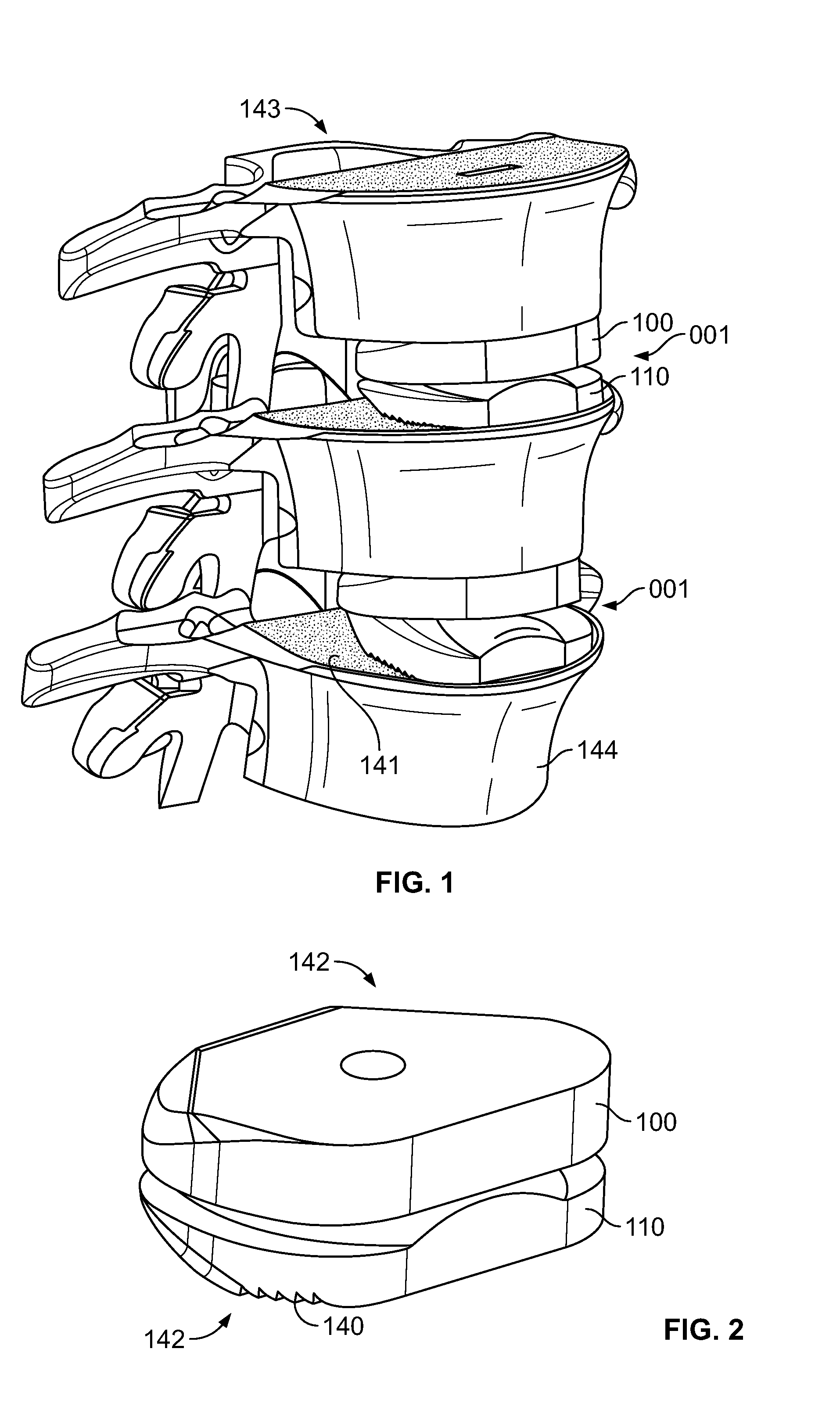

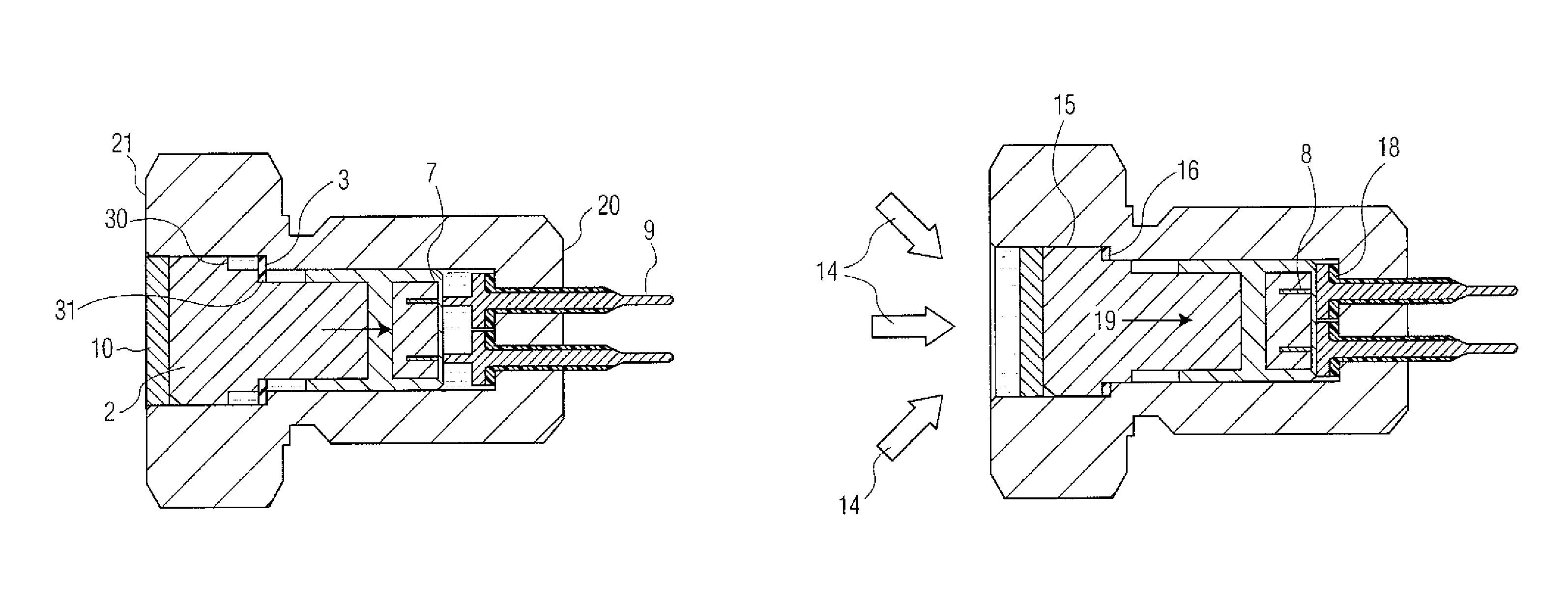

Systems and methods for sizing, inserting and securing an implant in intervertebral space

InactiveUS20100280619A1PerformancePerforms betterSurgerySpinal implantsIntervertebral spaceBearing surface

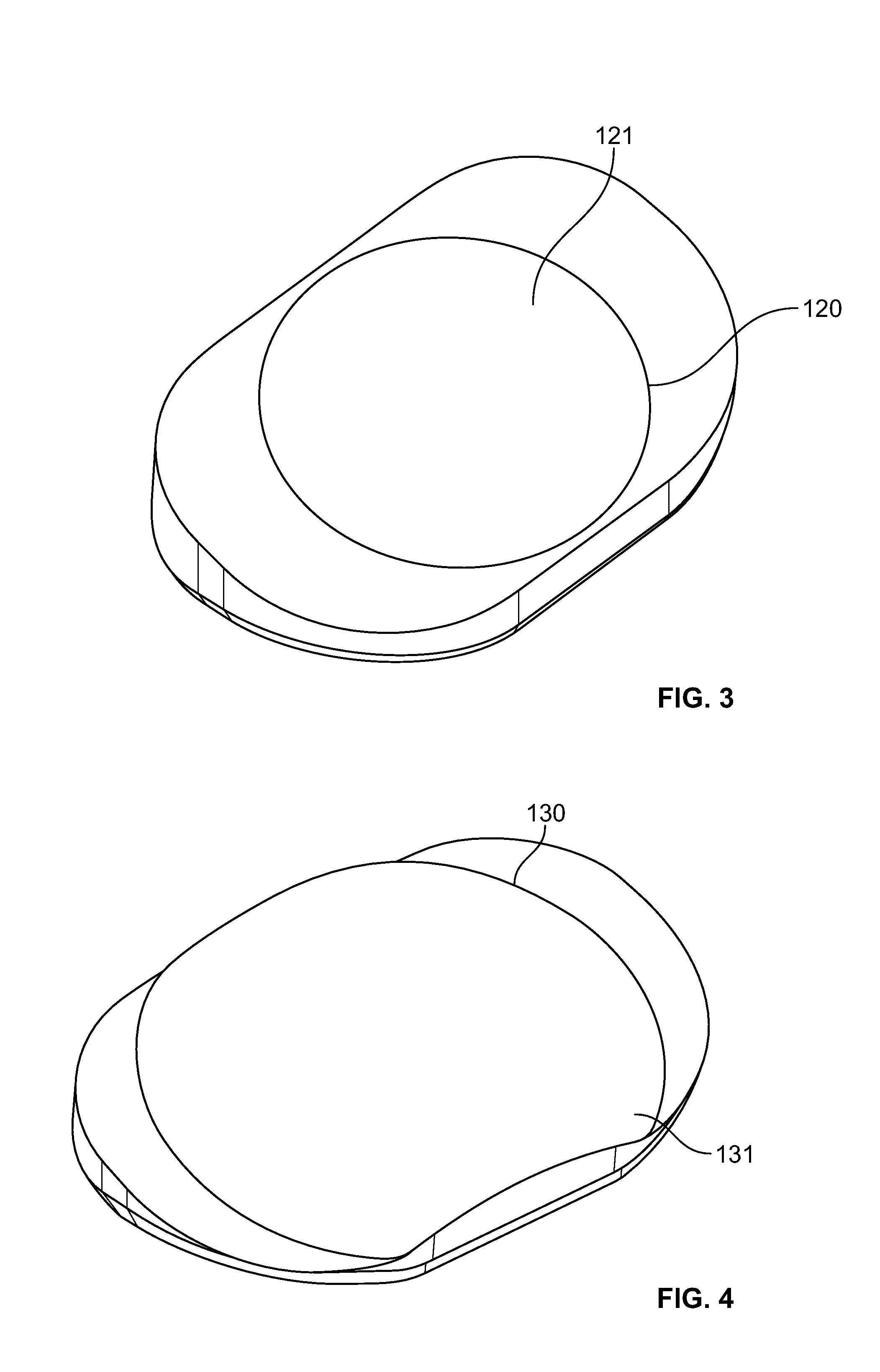

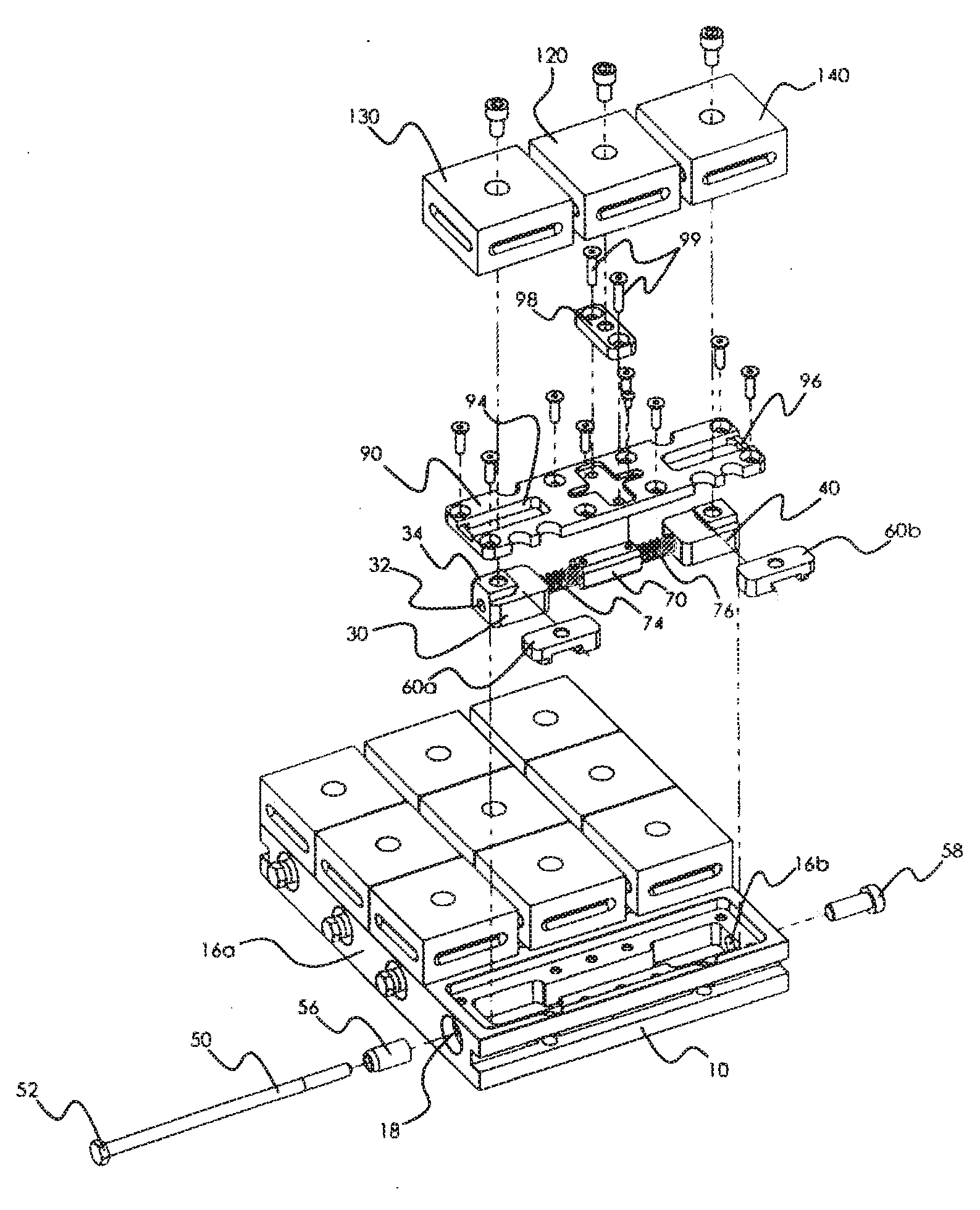

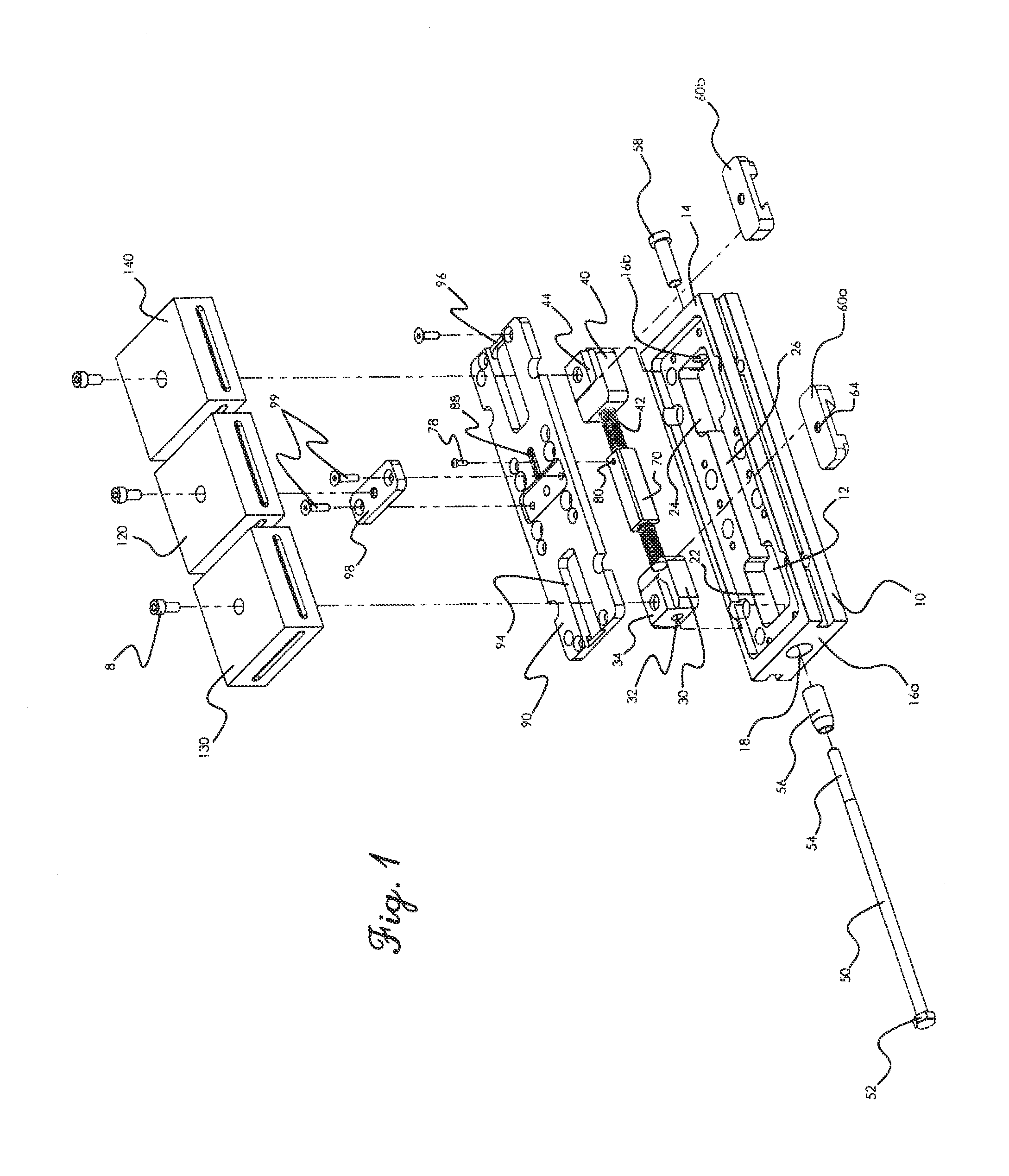

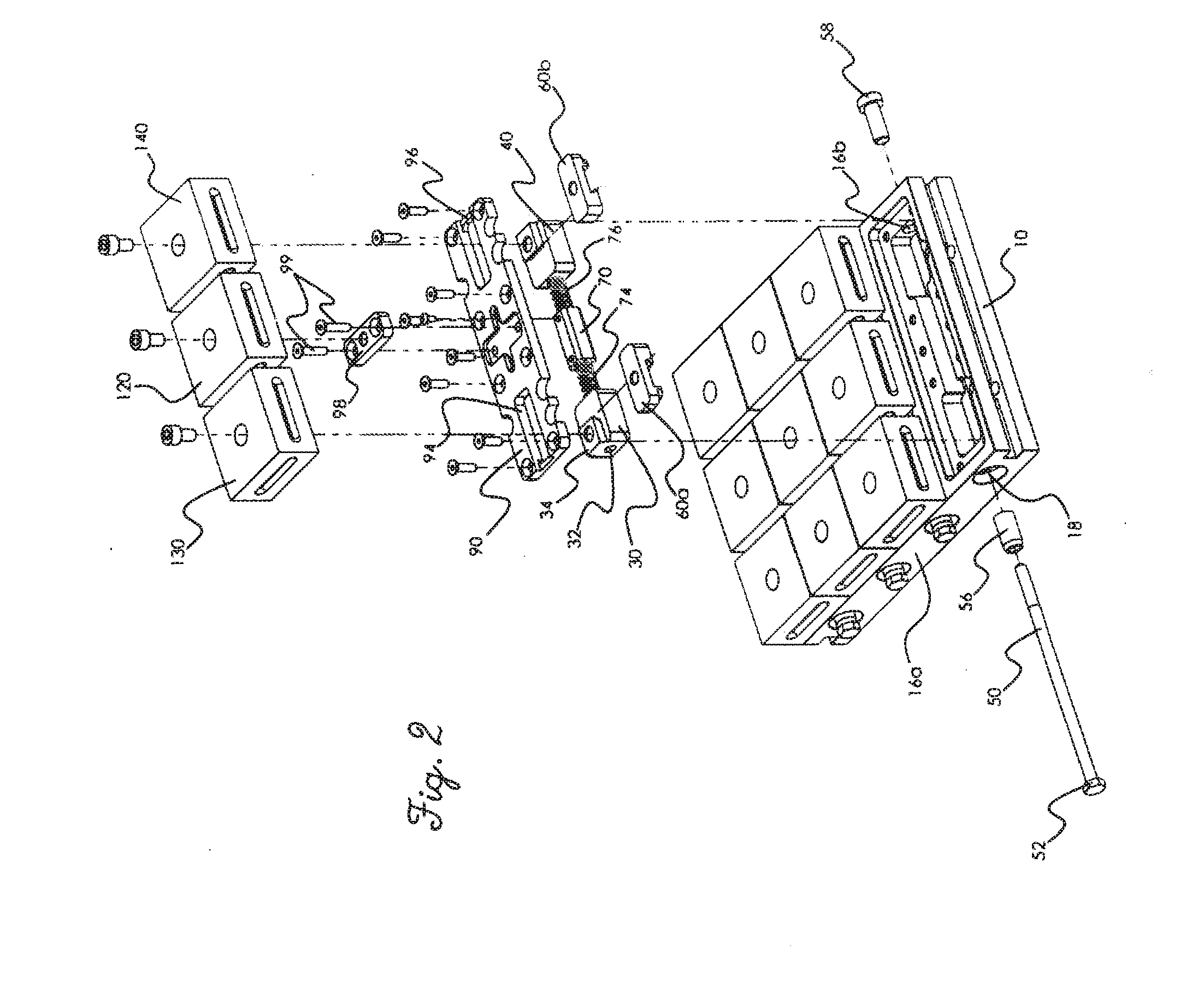

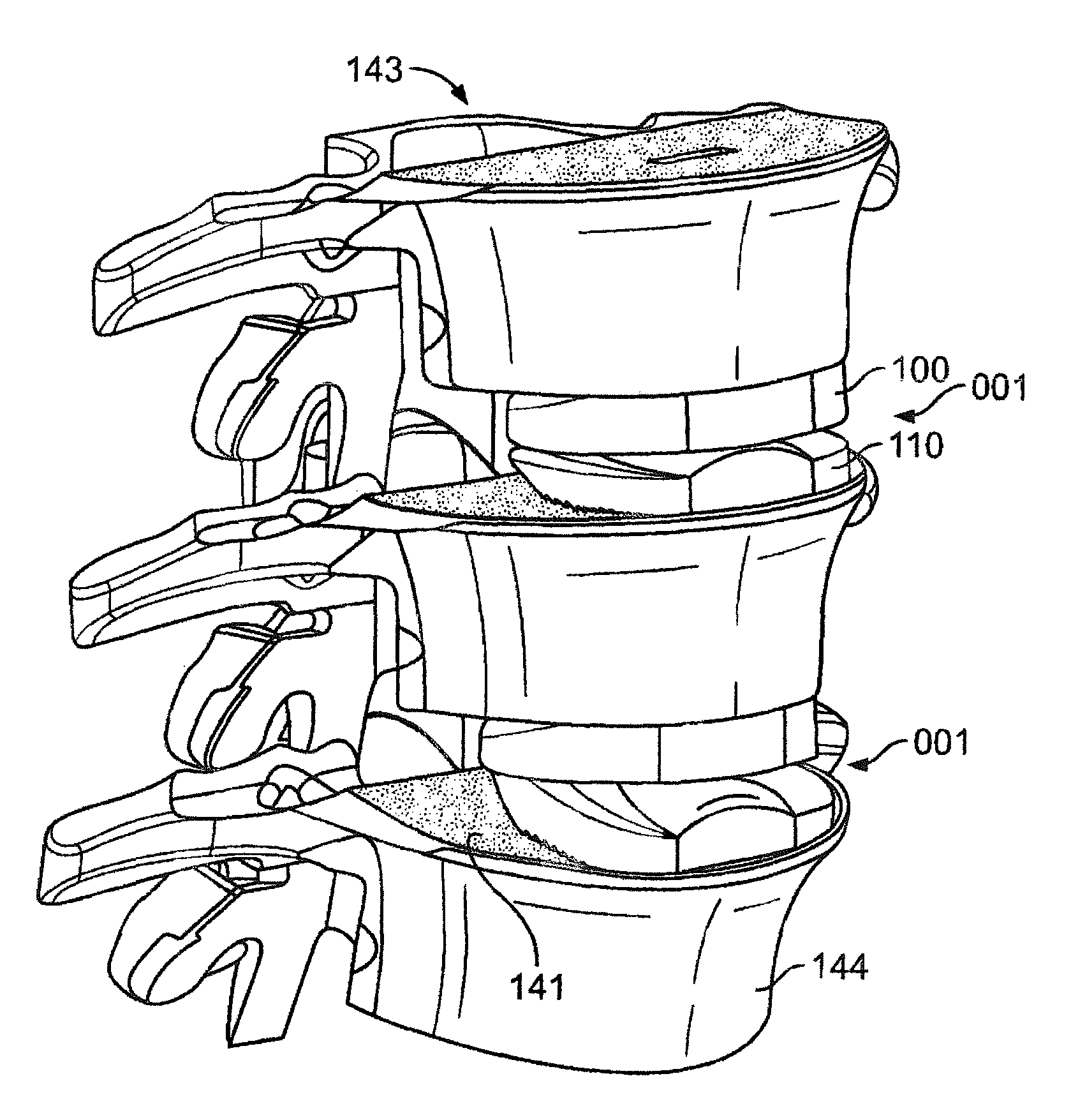

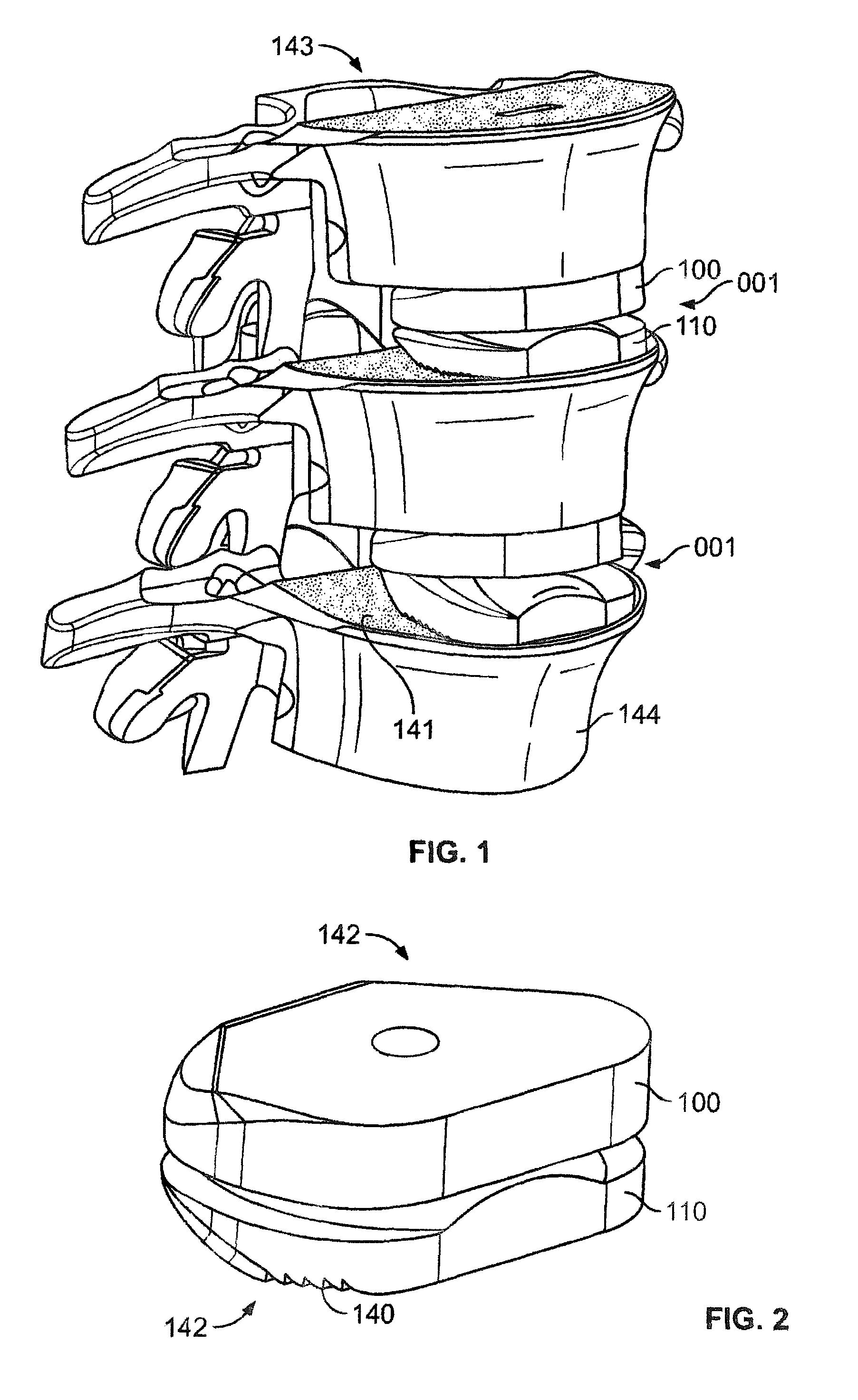

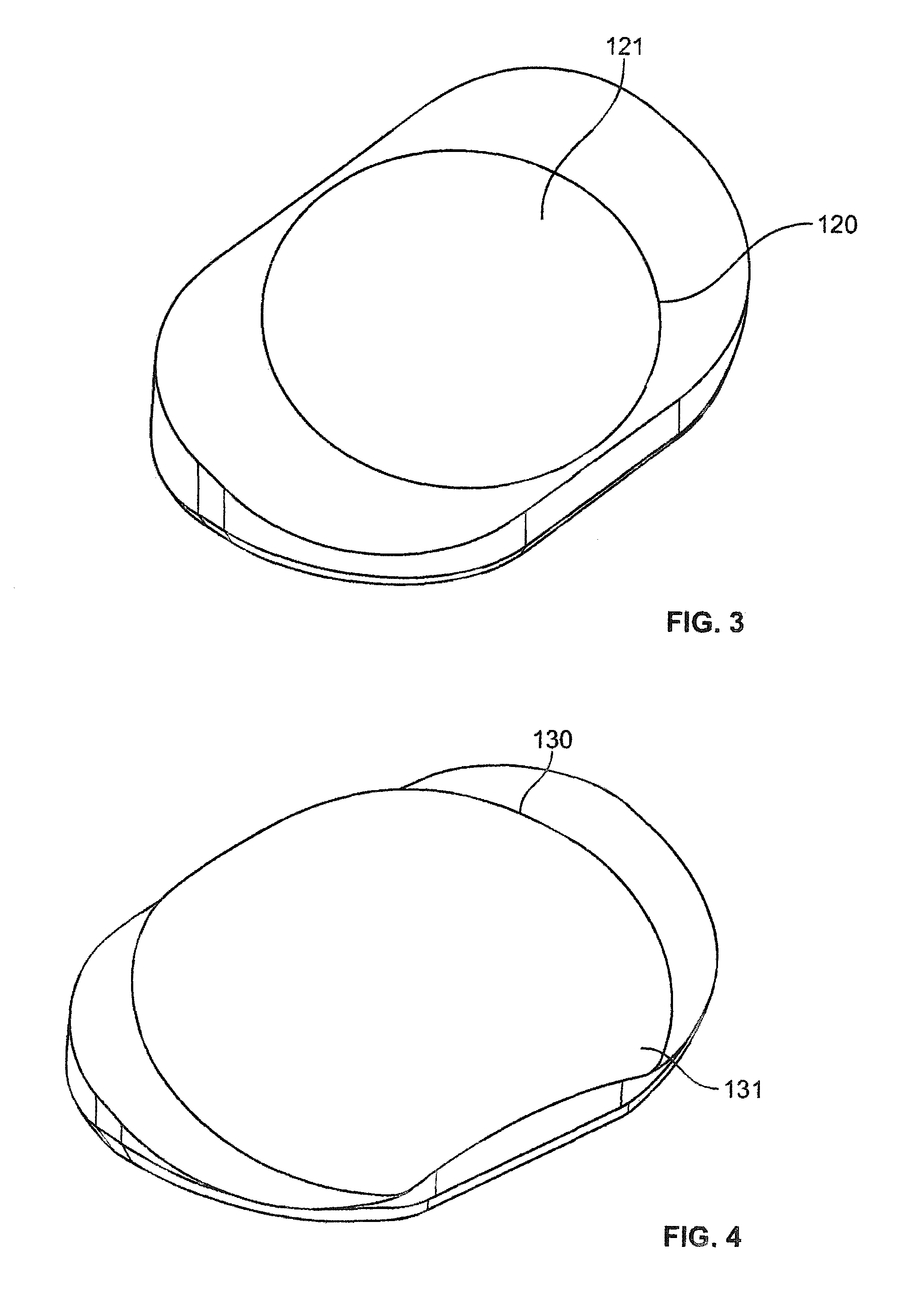

A prosthetic spinal implant having a securing member for fixing the implant relative to an adjacent bone. In one form, the securing member is deployable into a portion of the vertebral space for affixing the implant between the vertebrae. The securing member may be disposed substantially within the body of a bearing member of the implant when the securing member is in an undeployed orientation. In other forms, the securing member is provided separately from the implant such that it may be inserted into the intervertebral space after the implant has been placed in an implanted orientation between the vertebrae. In such forms, the securing member is configured for ease of insertion between an outer bearing surface of the implant and an adjacent bone via linear or rotary motion.

Owner:PIONEER SURGICAL TECH INC

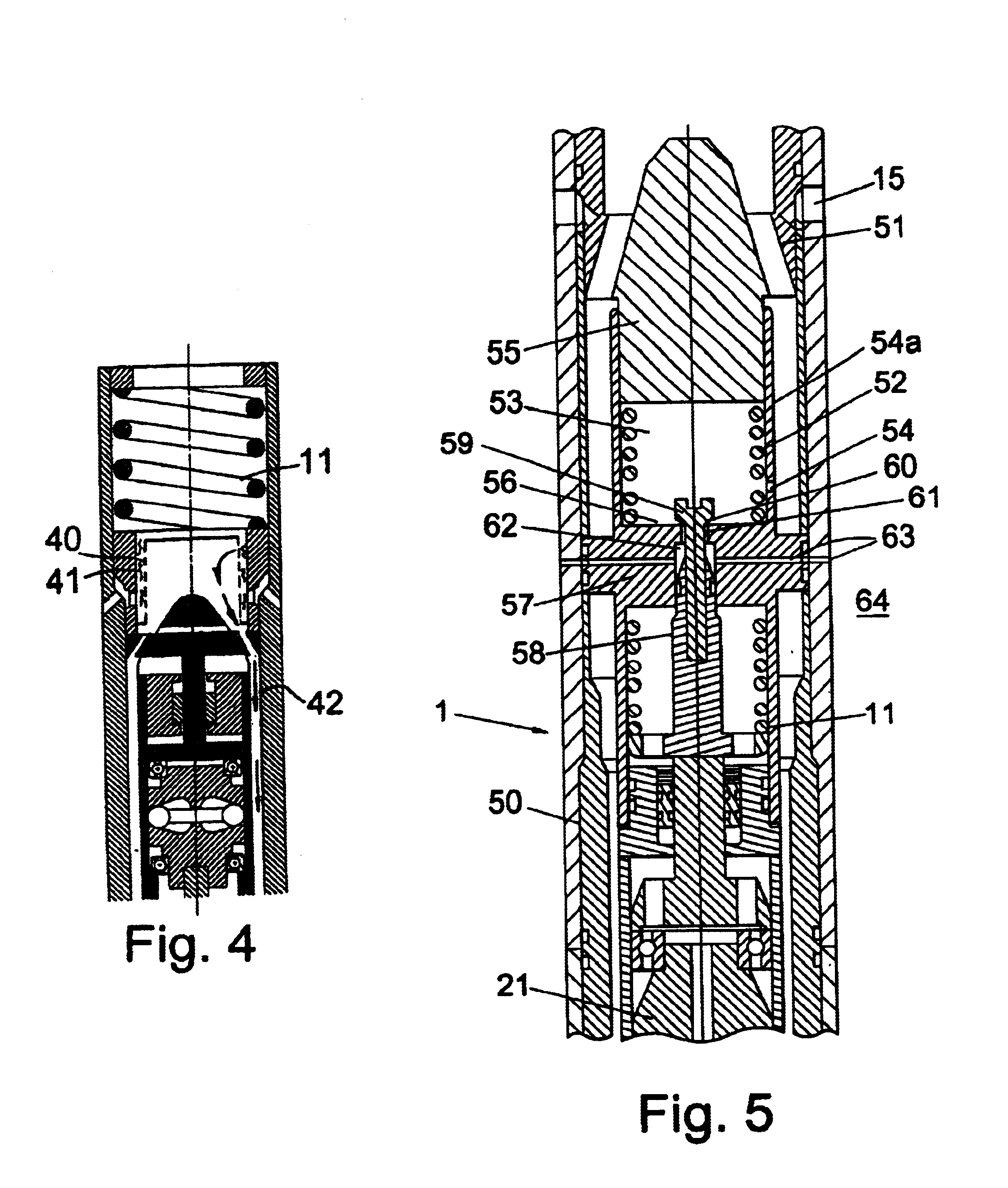

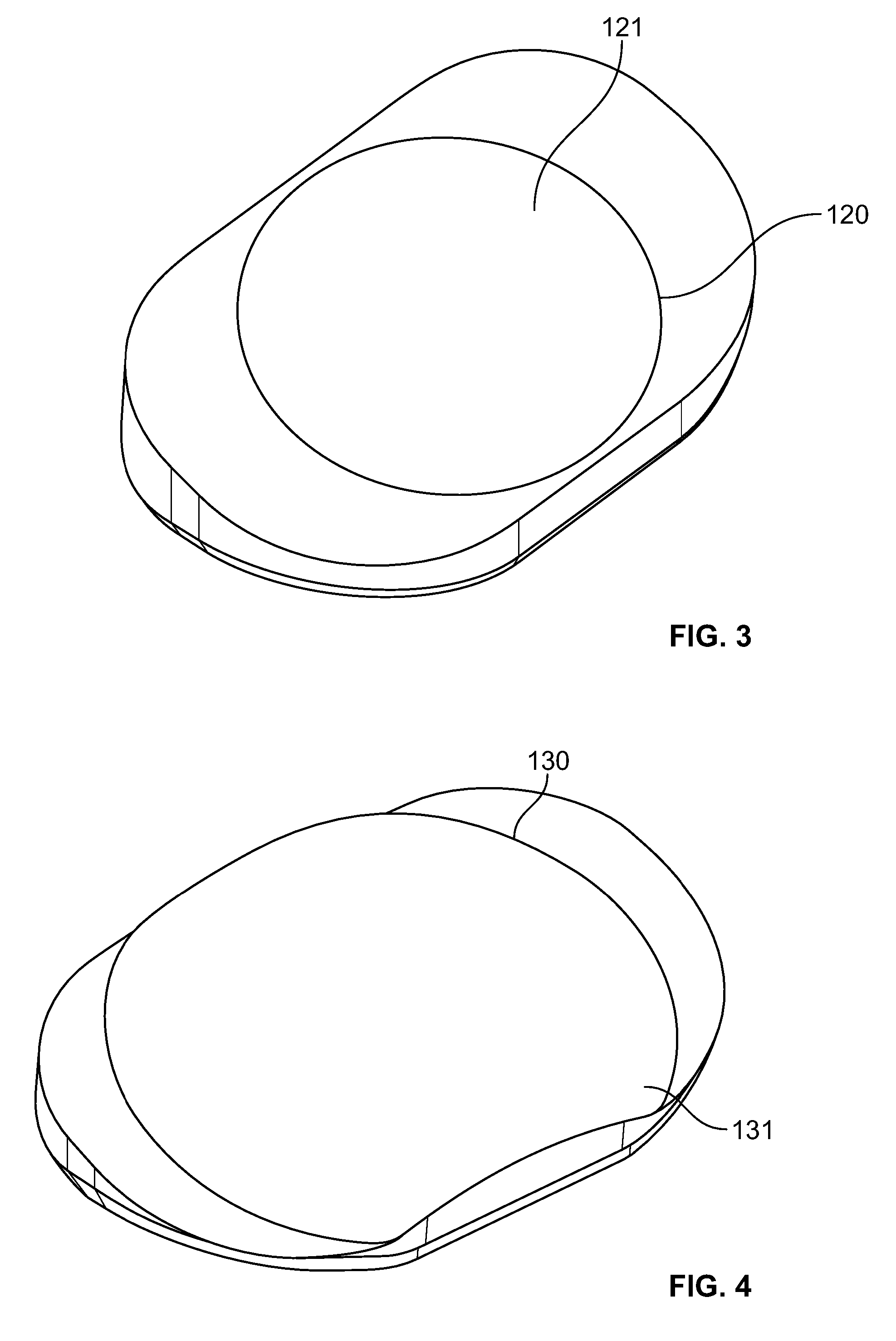

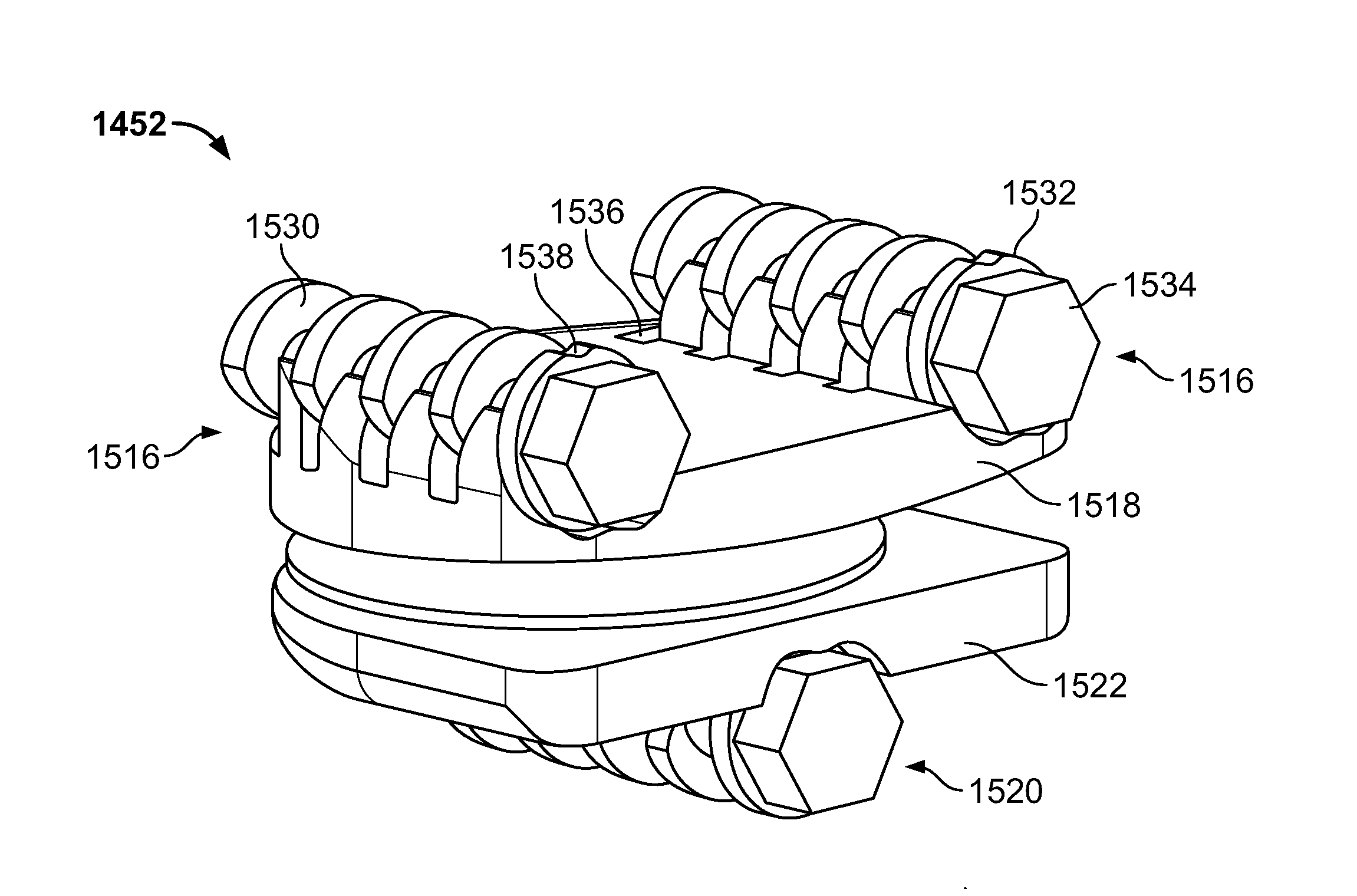

System and Method for Sizing, Inserting and Securing Artificial Disc in Intervertebral Space

InactiveUS20080103598A1Exceptional characteristicExceptional mechanical performanceSpinal implantsCoatingsMedicineIntervertebral space

A prosthetic spinal implant having a deployable securing mechanism that is deployable into a portion of the vertebral space for affixing the implant between the vertebrae, the securing mechanism having tactile feedback means comprising a surface for transmitting tactile feedback during deployment of the securing mechanism. A spinal implant having deployable securing means that interface with the implant to prevent the deployable securing means from retracting after deployment. An implant that utilizes its resilient properties to provide the user with tactile feedback with which the user may ascertain the position of the securing mechanism. A system and tools for sizing and implanting implants with the aforementioned characteristics.

Owner:PIONEER SURGICAL TECH INC

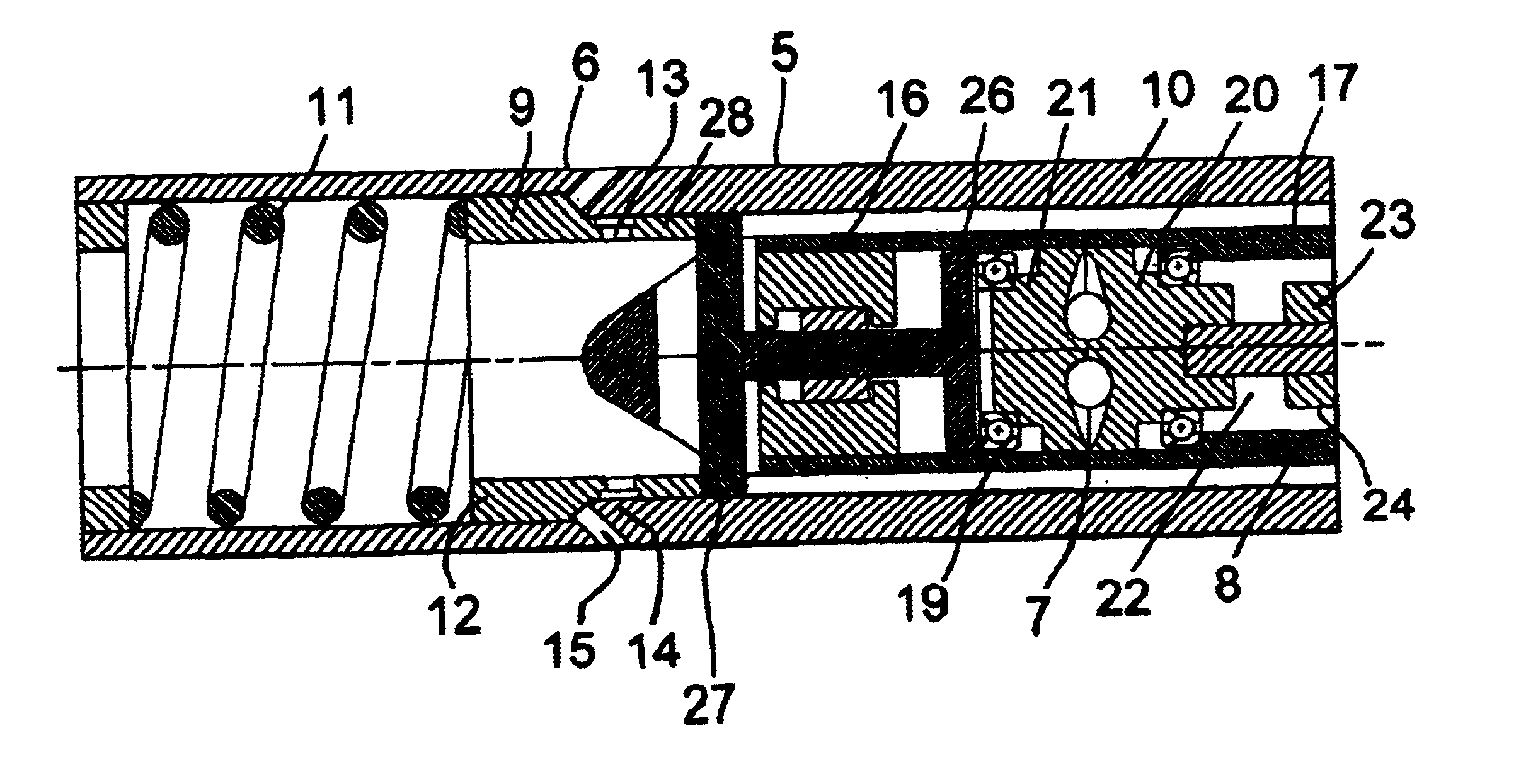

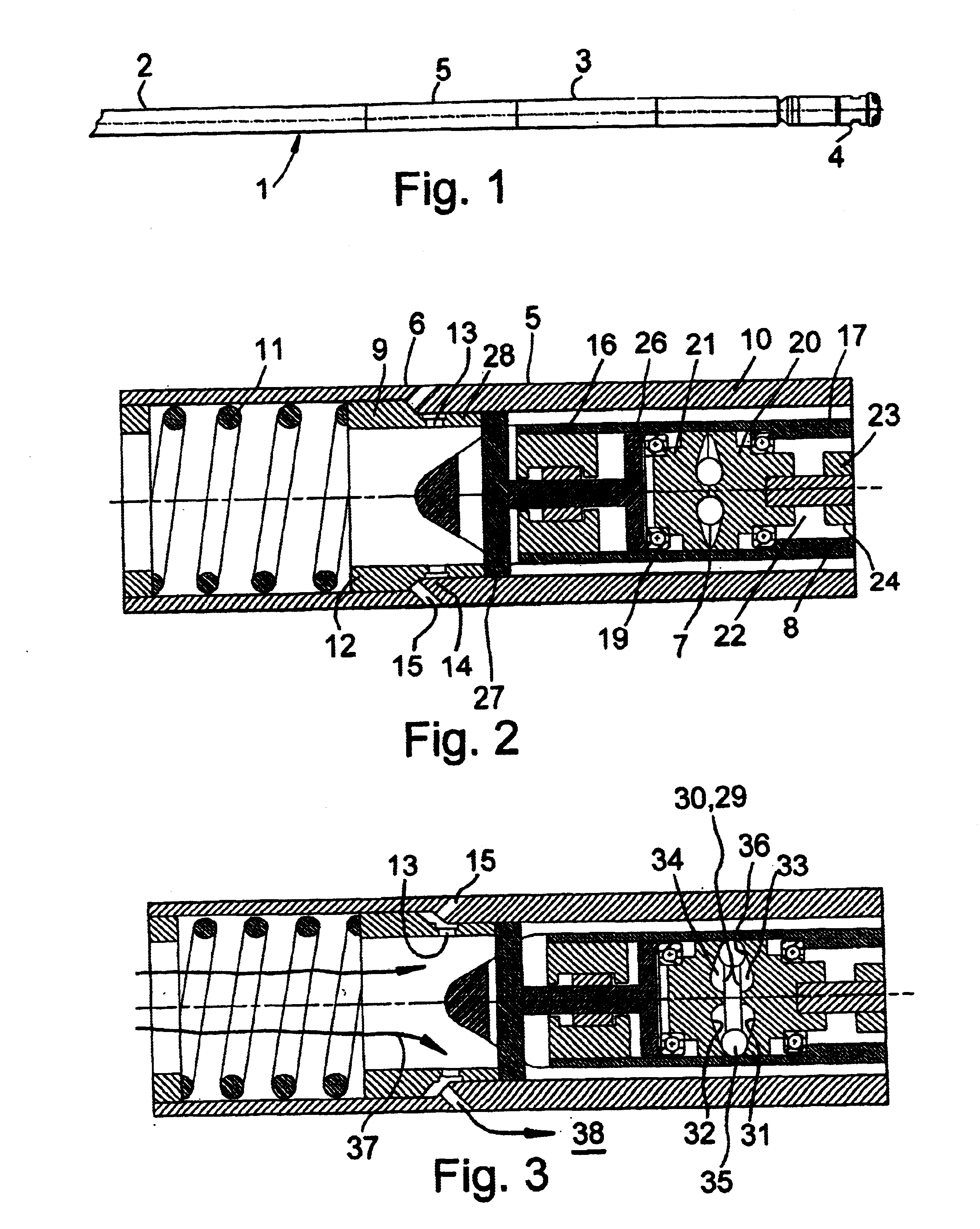

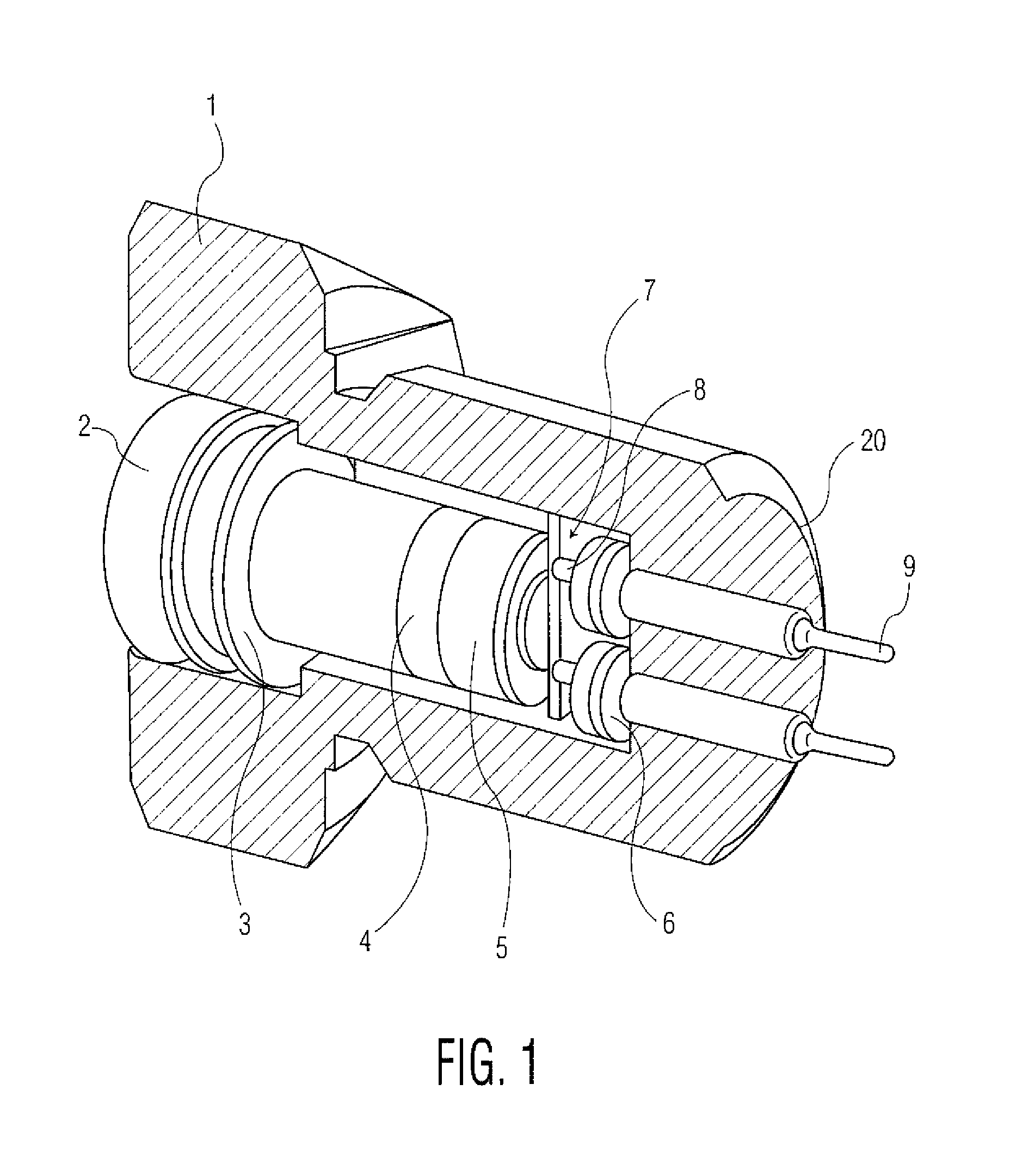

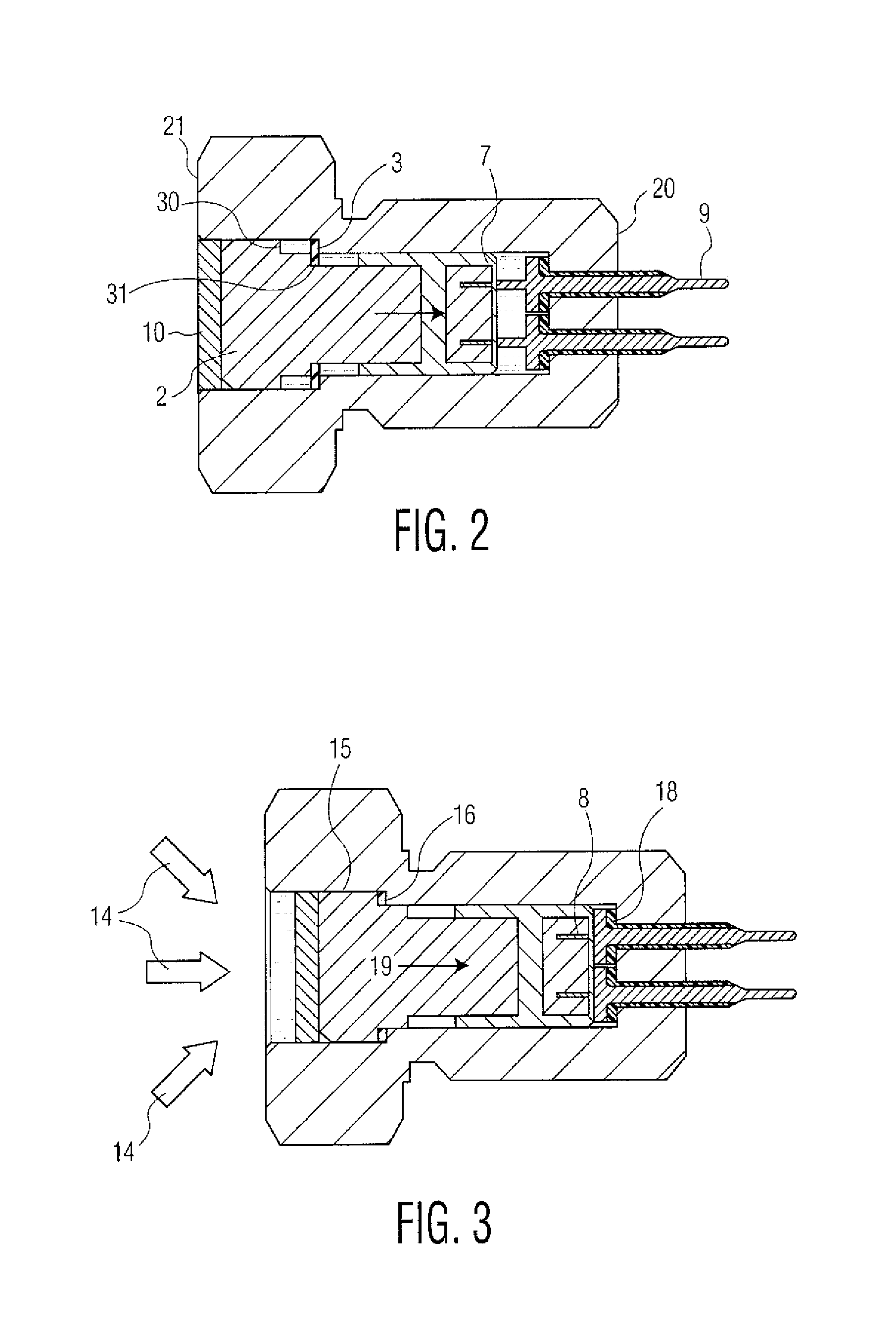

Speed governor

InactiveUS6854953B2Convenient and efficient mannerPrevent speedingWind motor controlServomotorsActuatorControl valves

The present invention provides a speed governor (5) suitable for use in a fluid driven down-hole tool (3). The speed governor comprises an actuator (7) operatively coupled to a motive fluid flow control valve (6). The actuator is and arranged so as to be activatable, directly or indirectly, in response to the running speed of the tool (3), for opening of the control valve (6) with increasing rotational speed of the motor (3) above a predetermined speed limit thereby to limit the rotational speed of the downhole tool (3).

Owner:ROTECH GROUP

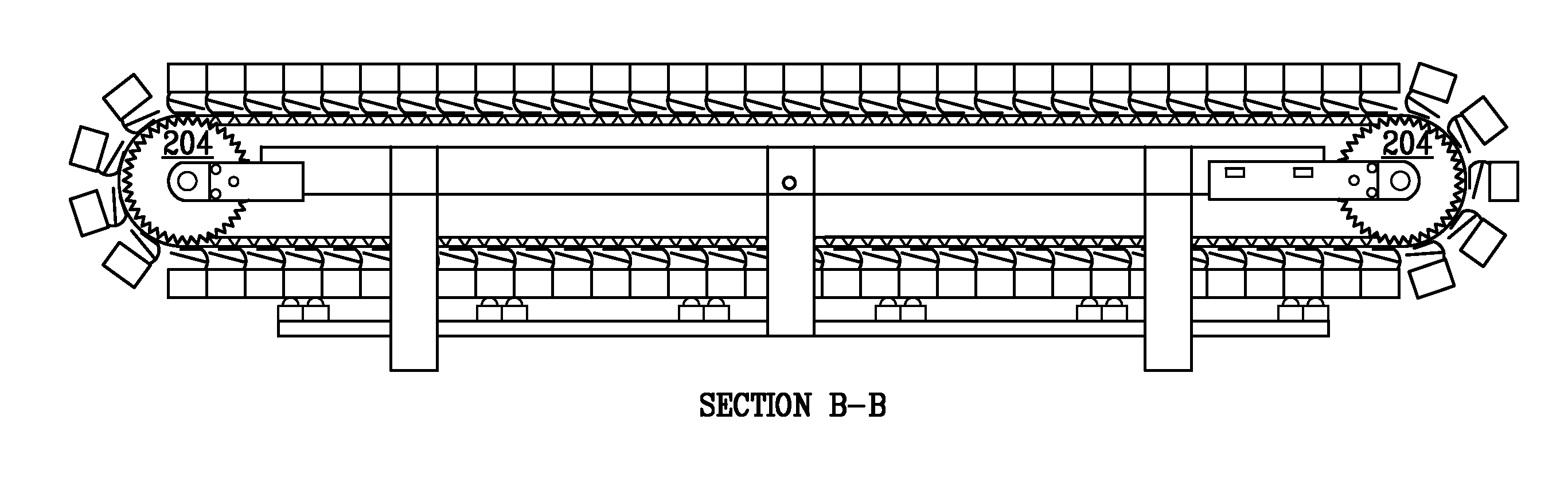

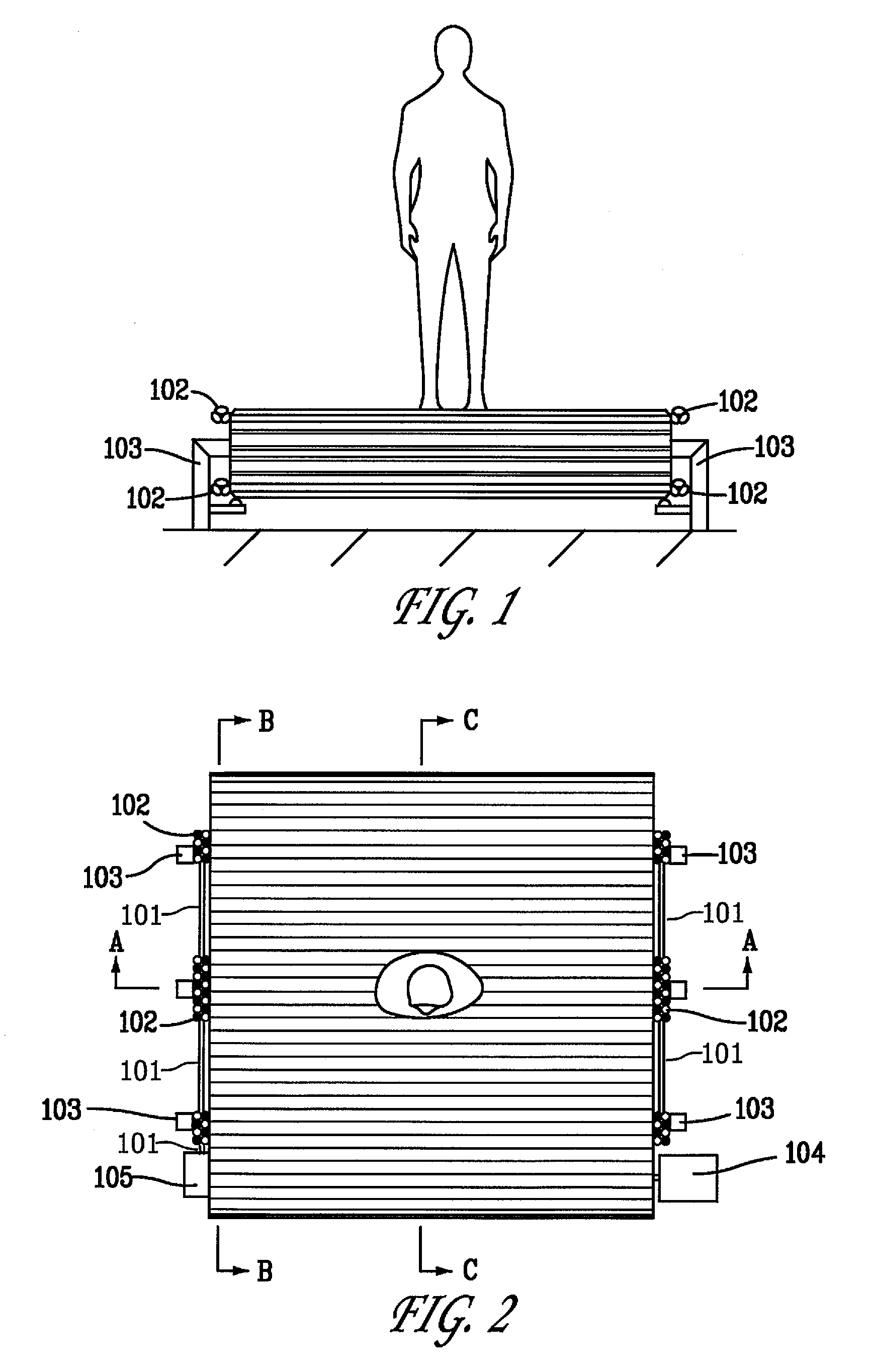

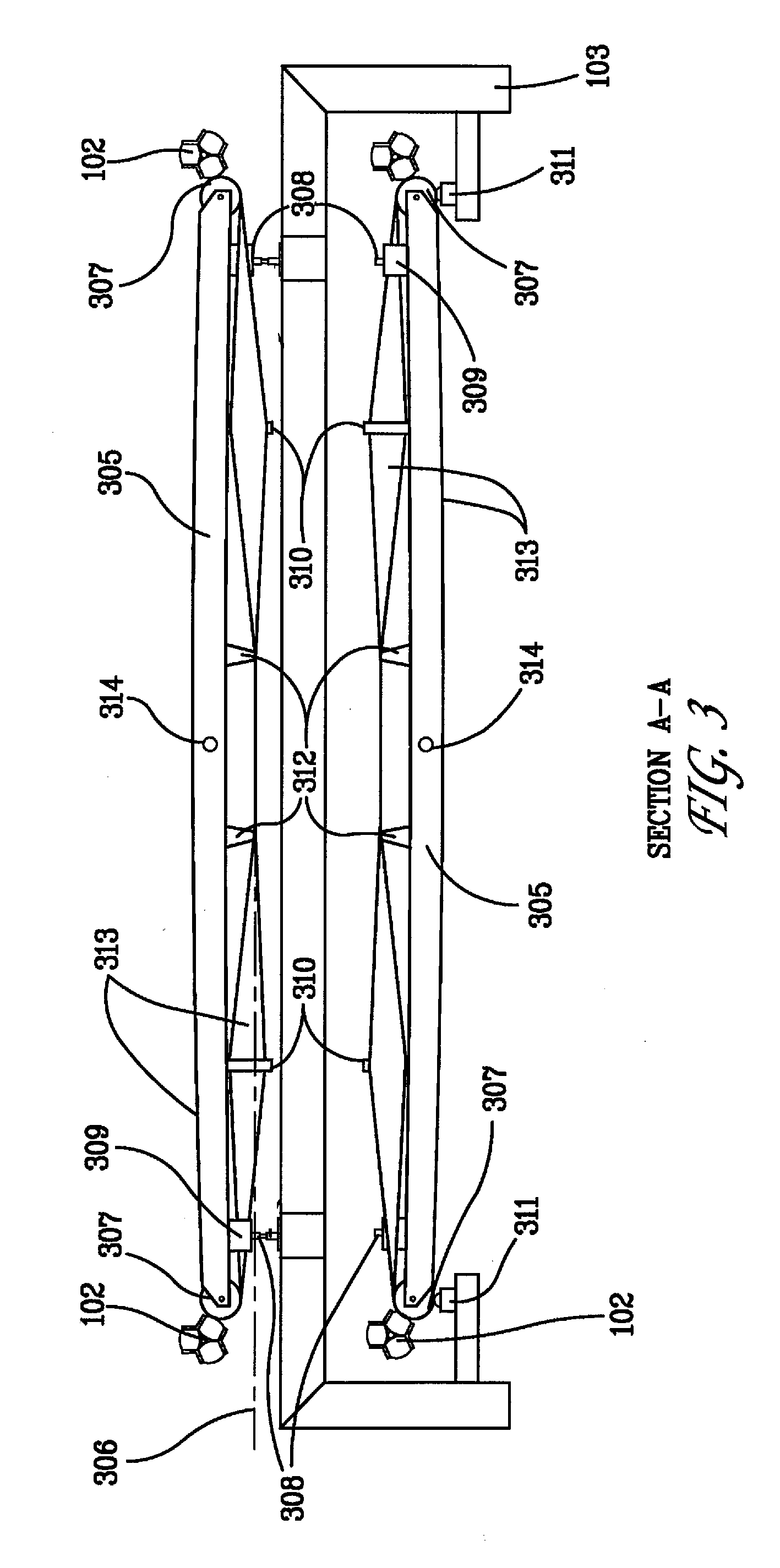

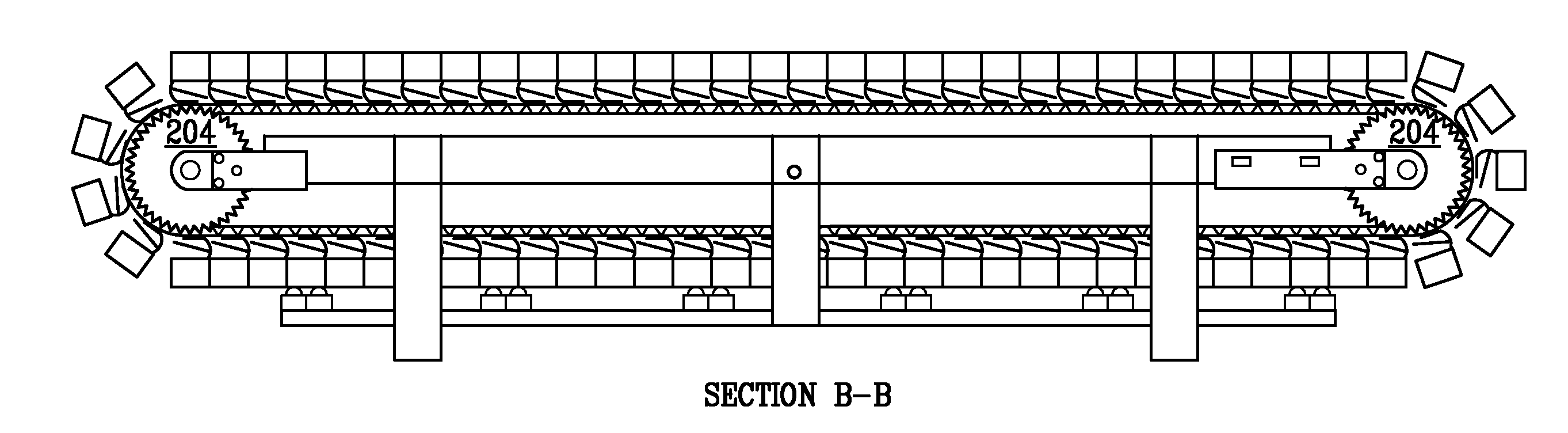

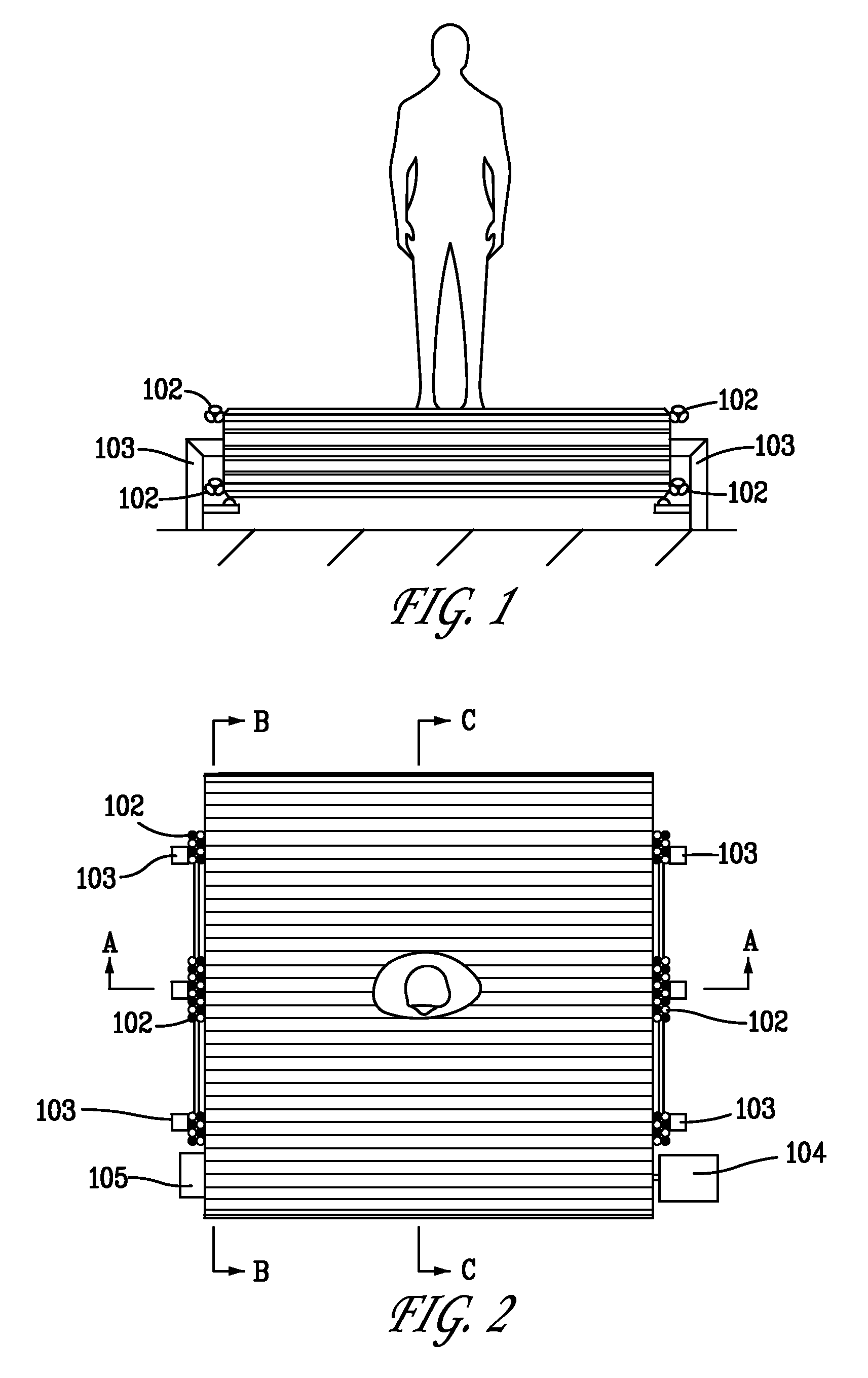

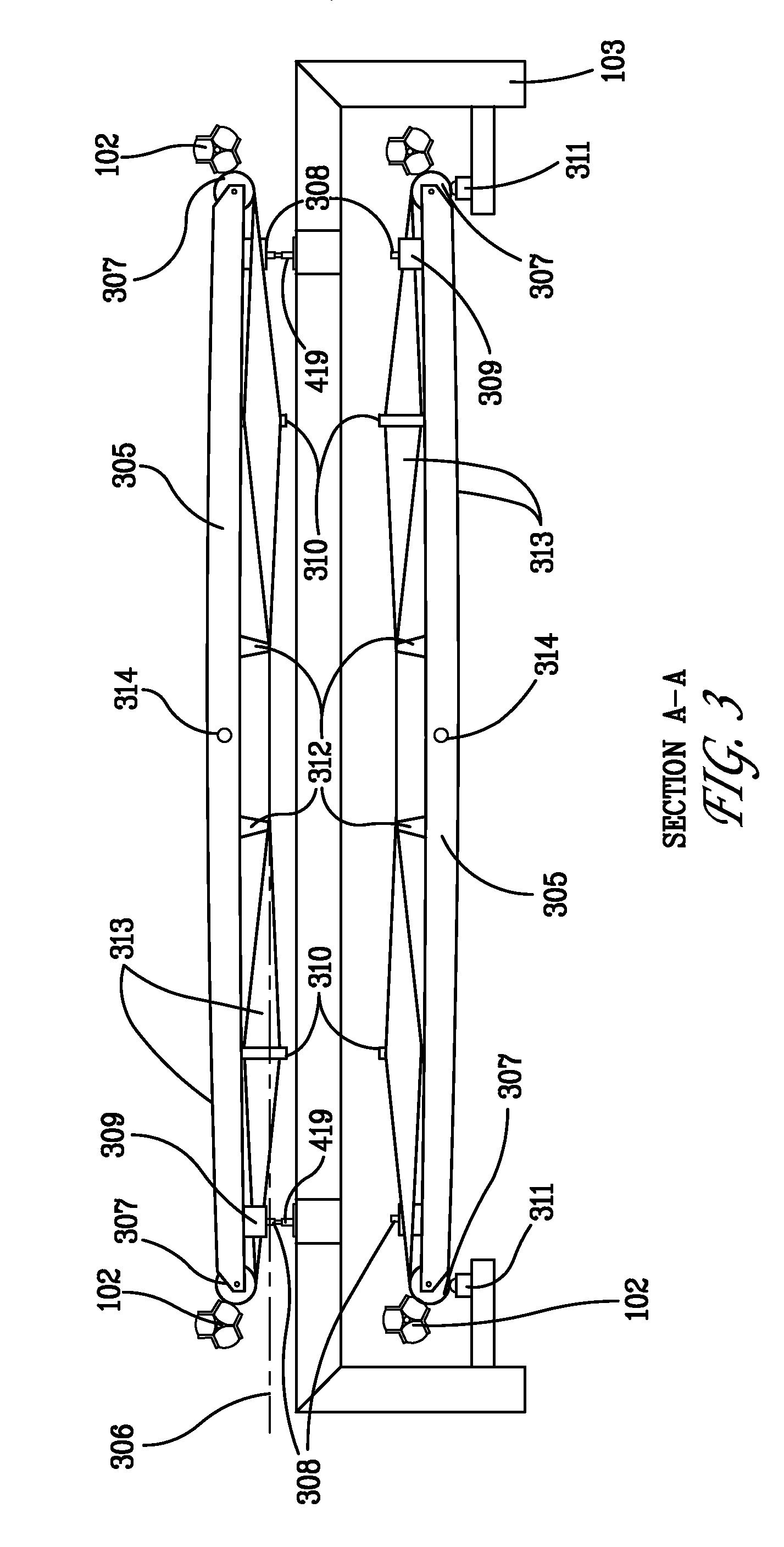

Single belt omni directional treadmill

ActiveUS8790222B2Simple in natureEasy to buildMuscle exercising devicesMovement coordination devicesEngineeringOmni directional

Owner:INFINADECK CORP

Systems and methods for sizing, inserting and securing an implant in intervertebral space

InactiveUS8377133B2PerformancePerforms betterSurgerySpinal implantsIntervertebral discIntervertebral space

A prosthetic spinal implant having a securing member for fixing the implant relative to an adjacent bone. In one form, the securing member is deployable into a portion of the vertebral space for affixing the implant between the vertebrae. The securing member may be disposed substantially within the body of a bearing member of the implant when the securing member is in an undeployed orientation. In other forms, the securing member is provided separately from the implant such that it may be inserted into the intervertebral space after the implant has been placed in an implanted orientation between the vertebrae. In such forms, the securing member is configured for ease of insertion between an outer bearing surface of the implant and an adjacent bone via linear or rotary motion.

Owner:PIONEER SURGICAL TECH INC

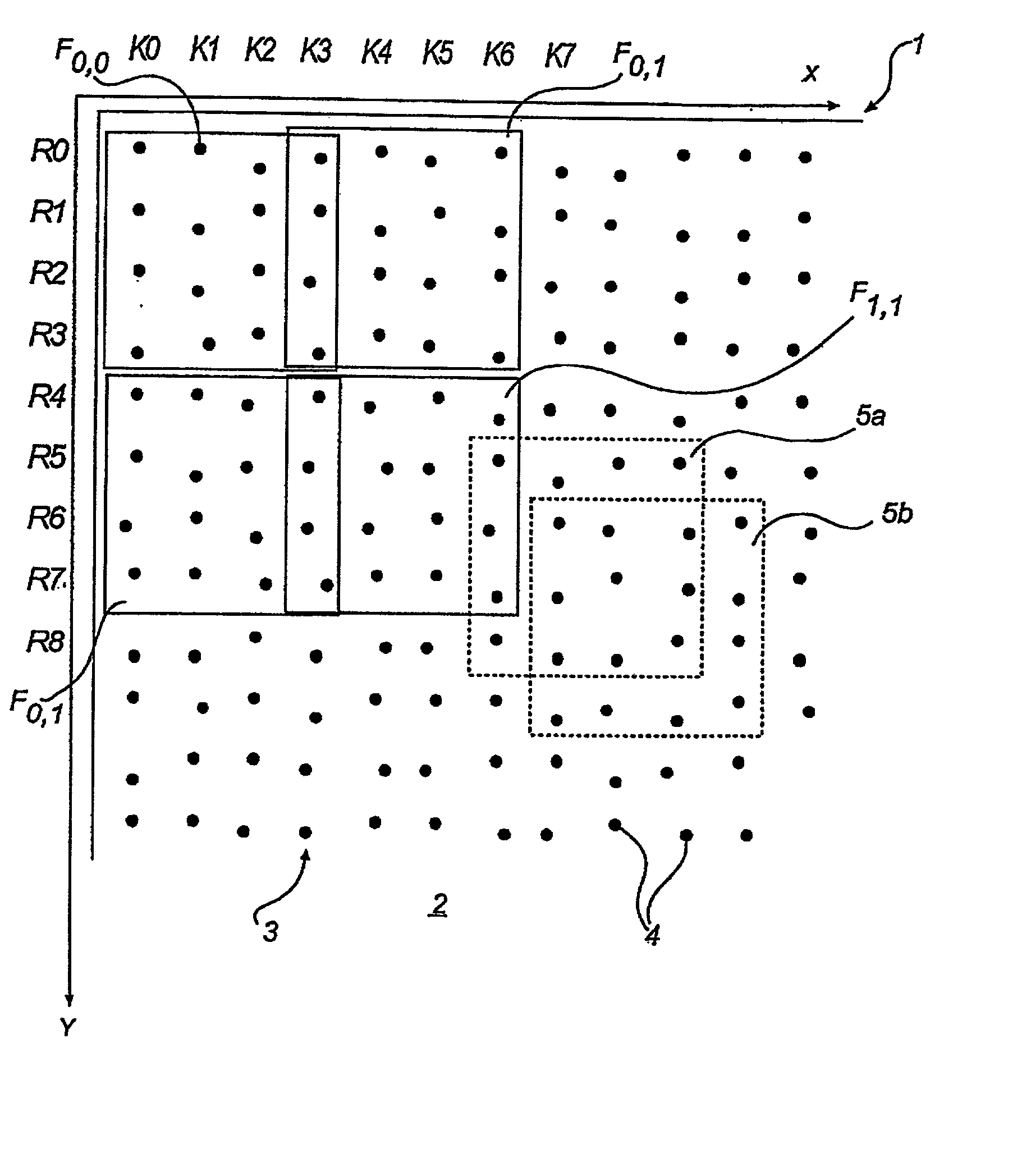

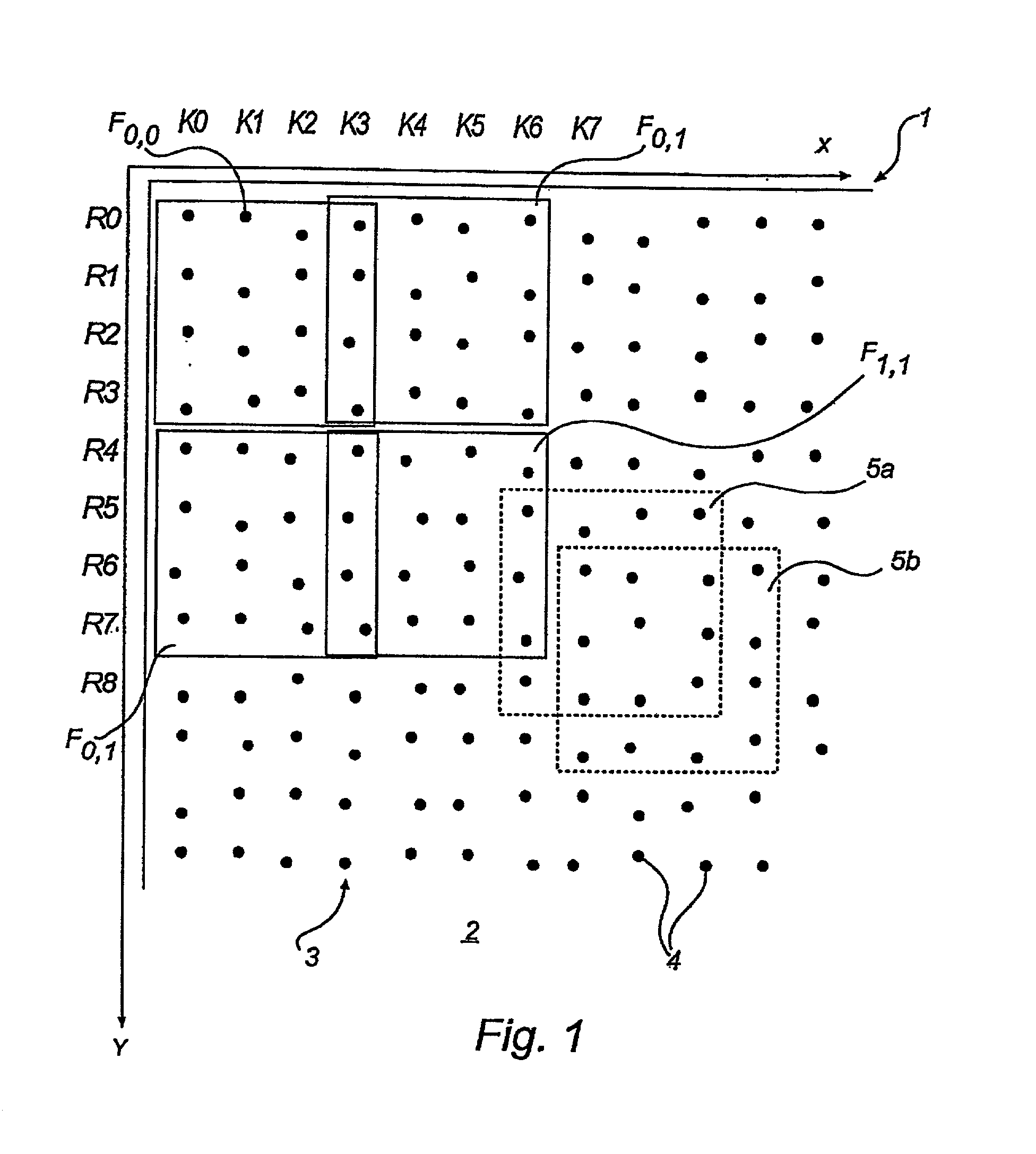

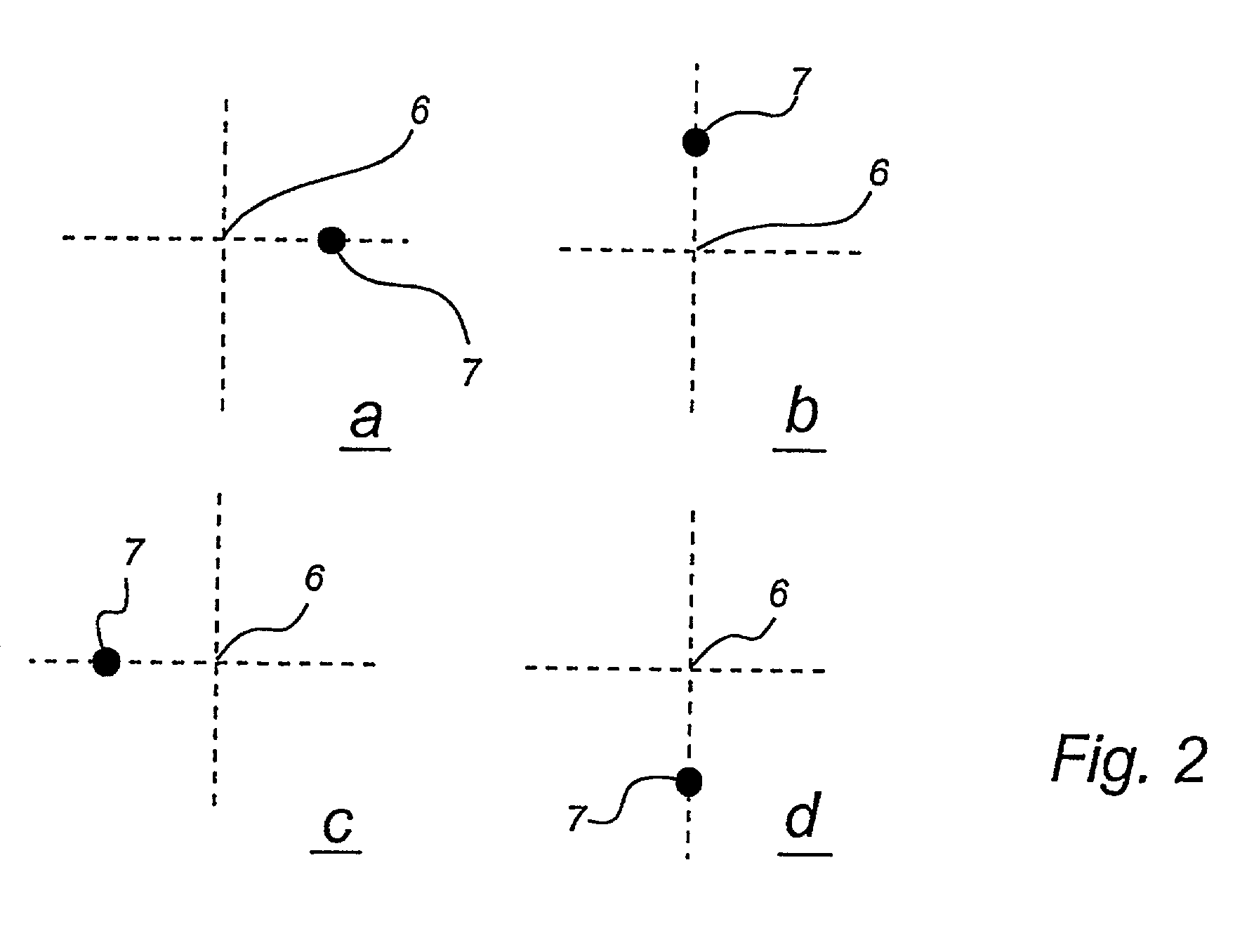

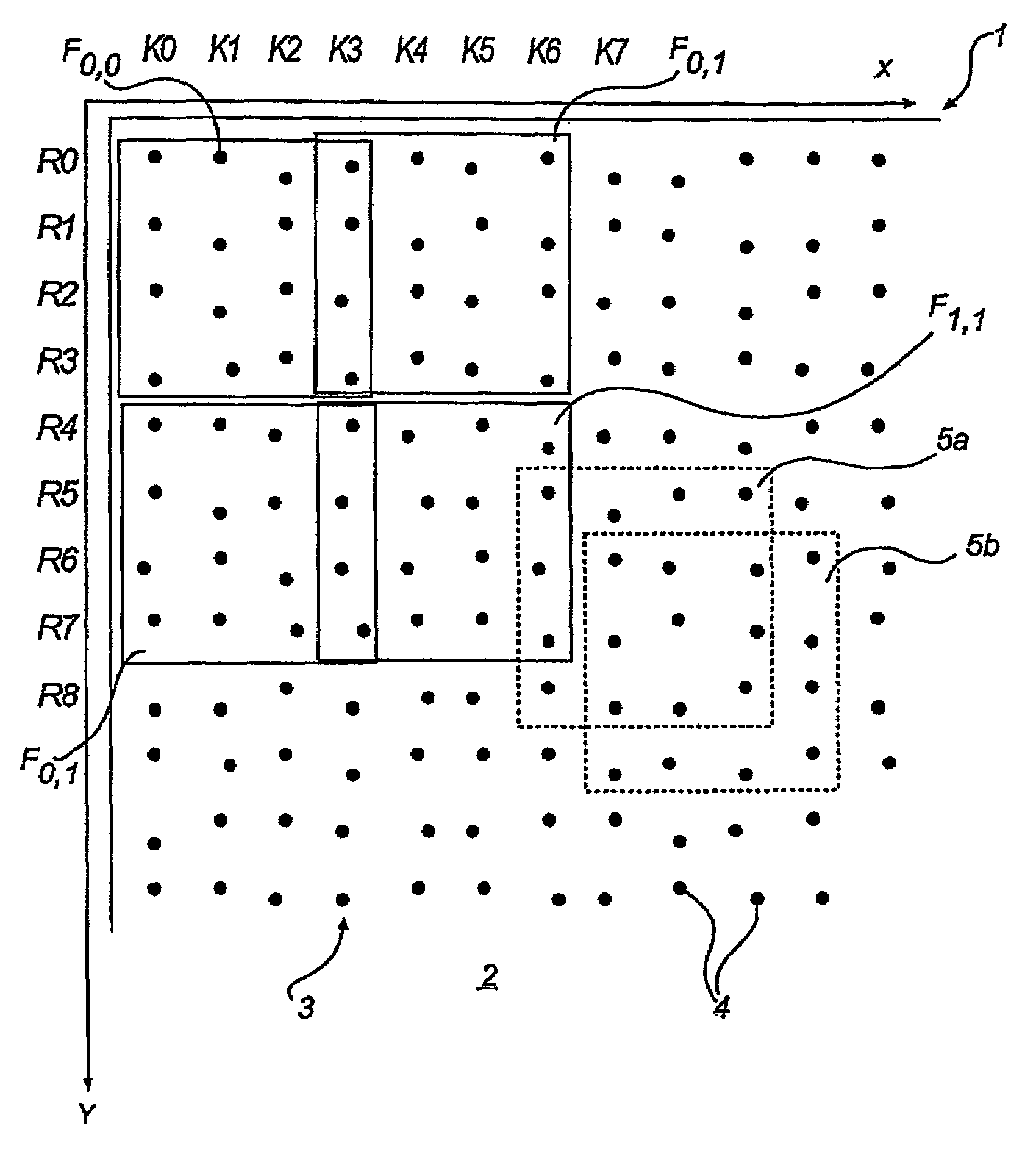

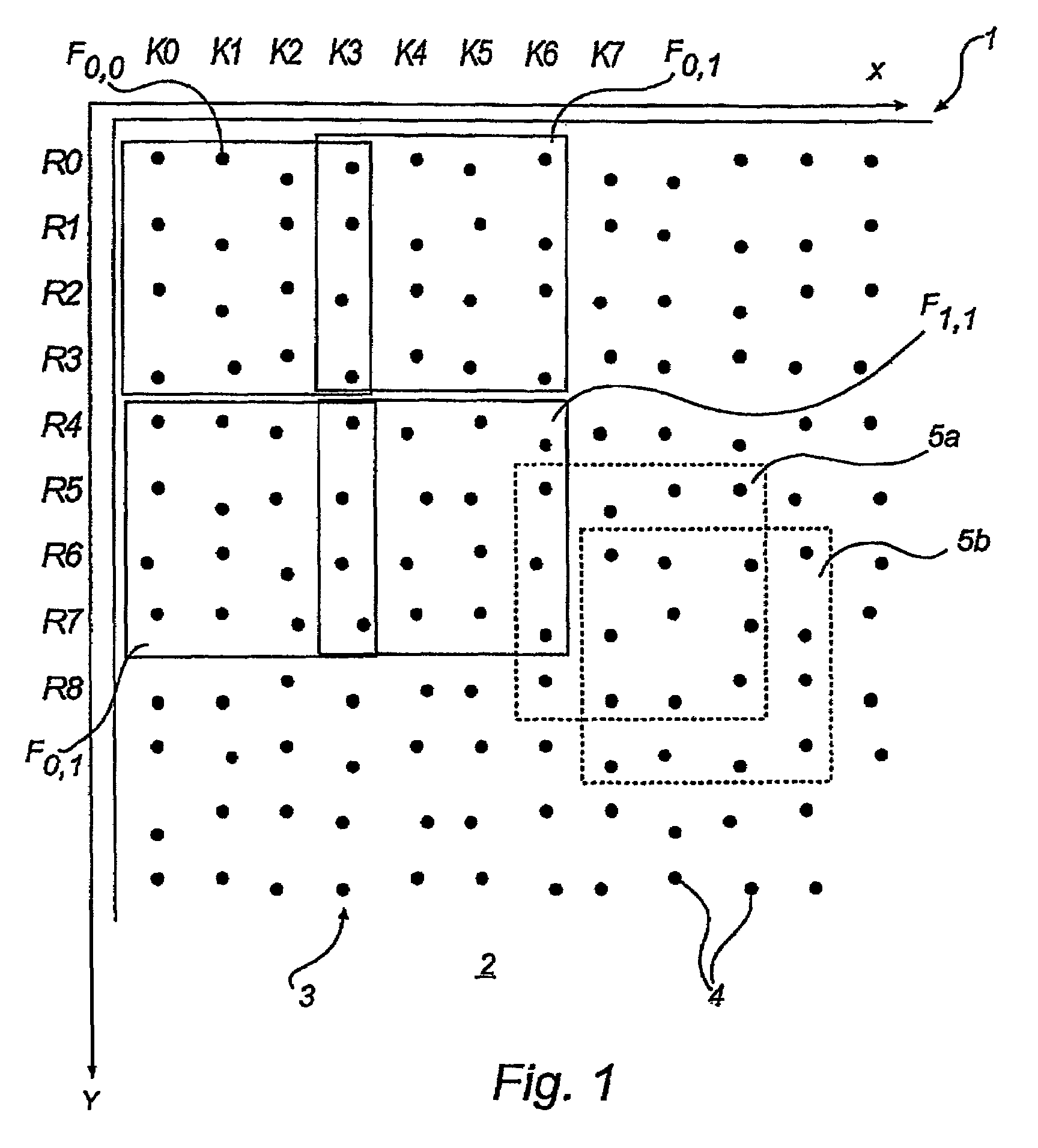

Apparatus and methods relating to image coding

InactiveUS20020084335A1More flexibilitySimple in natureInput/output for user-computer interactionCharacter and pattern recognitionSpatial extentComputer science

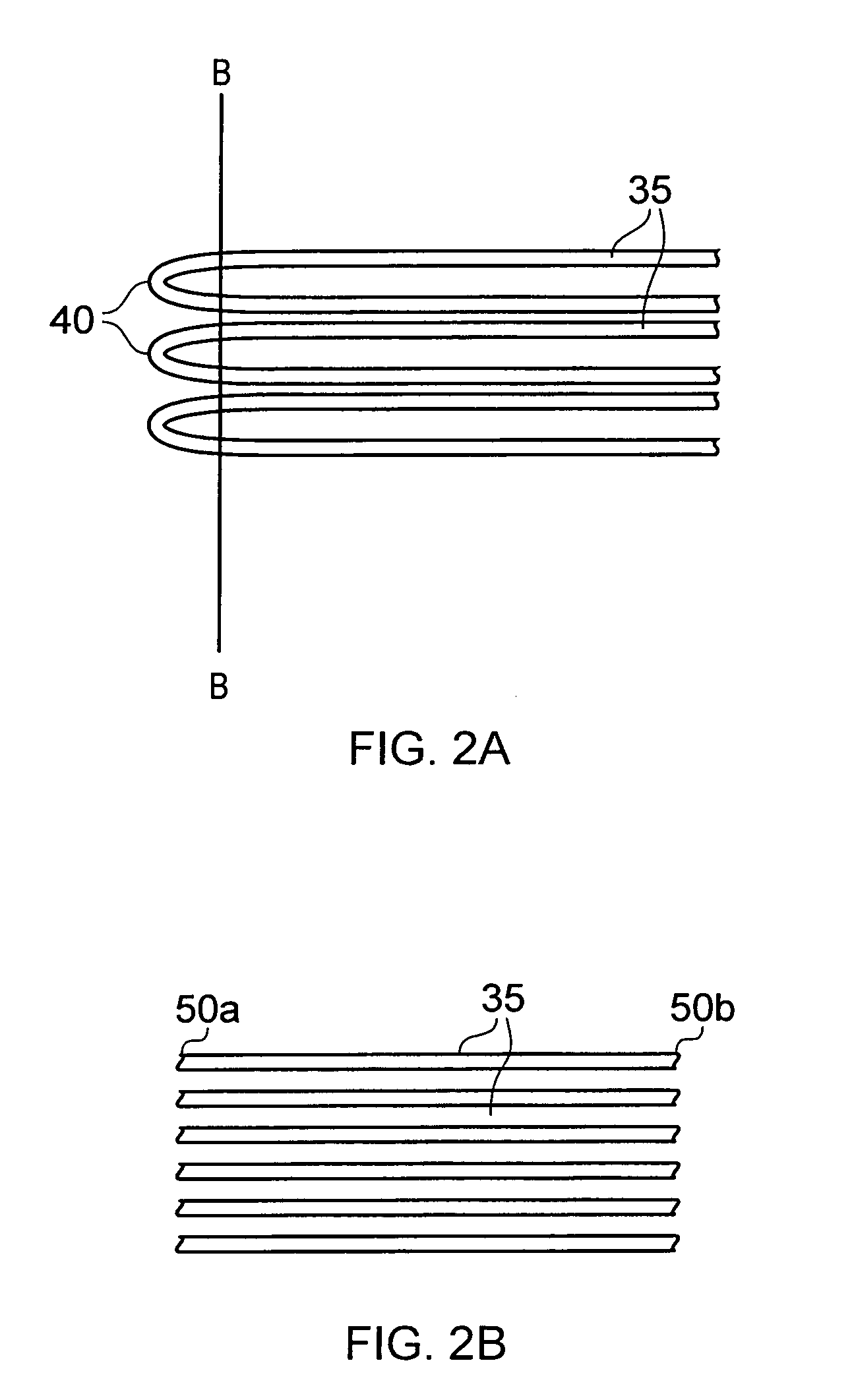

A product has a coding pattern on its surface. The coding pattern may include symbols representing at least two different values and where each symbol comprises a raster point and at least one marking. The raster point is included in a raster that extends over the surface and the value of each symbol is indicated by the placement of the marking in relation to the raster point. The markings may each have a spatial extent that, in combination, may at least partially form the image.

Owner:ANOTO AB

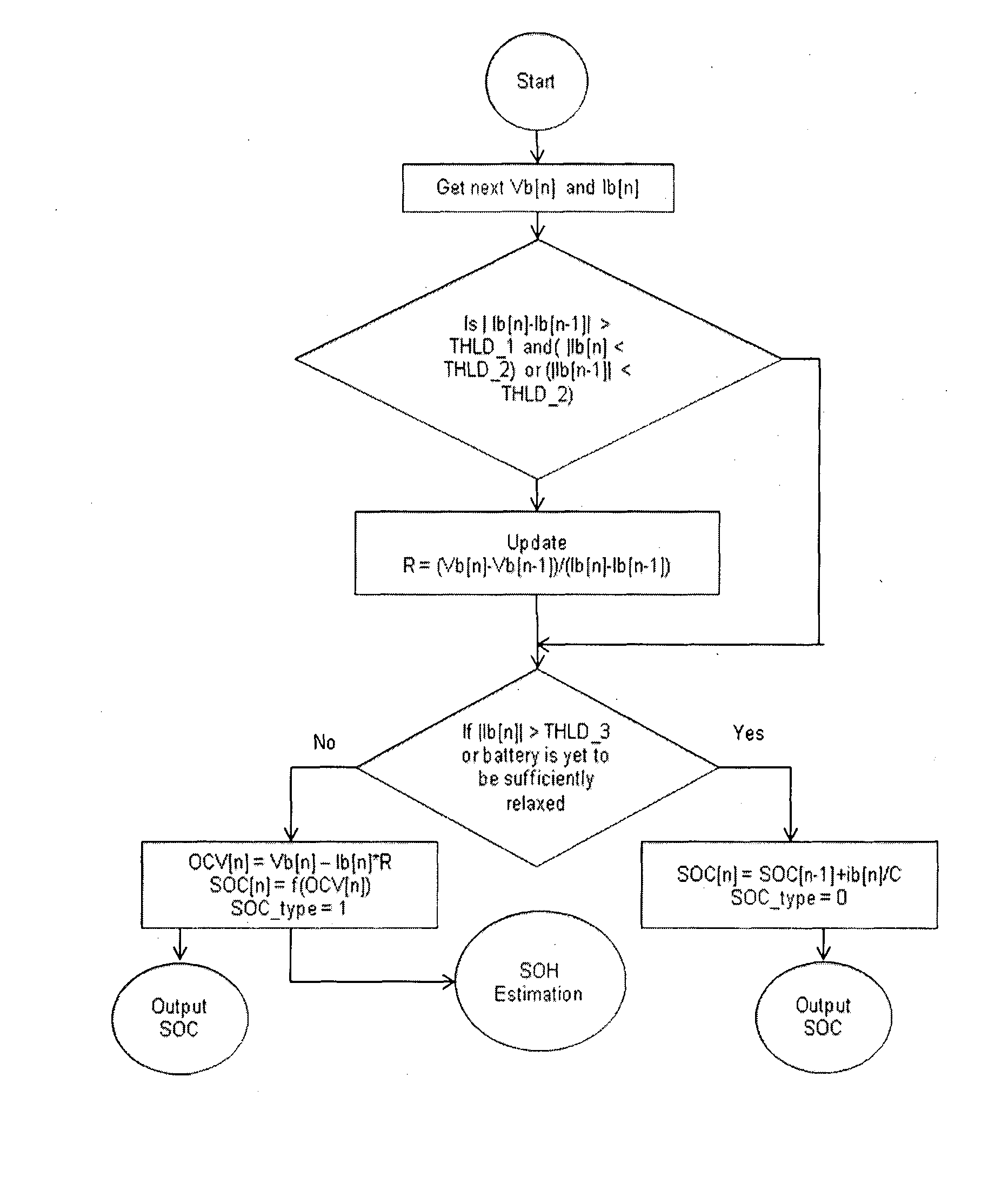

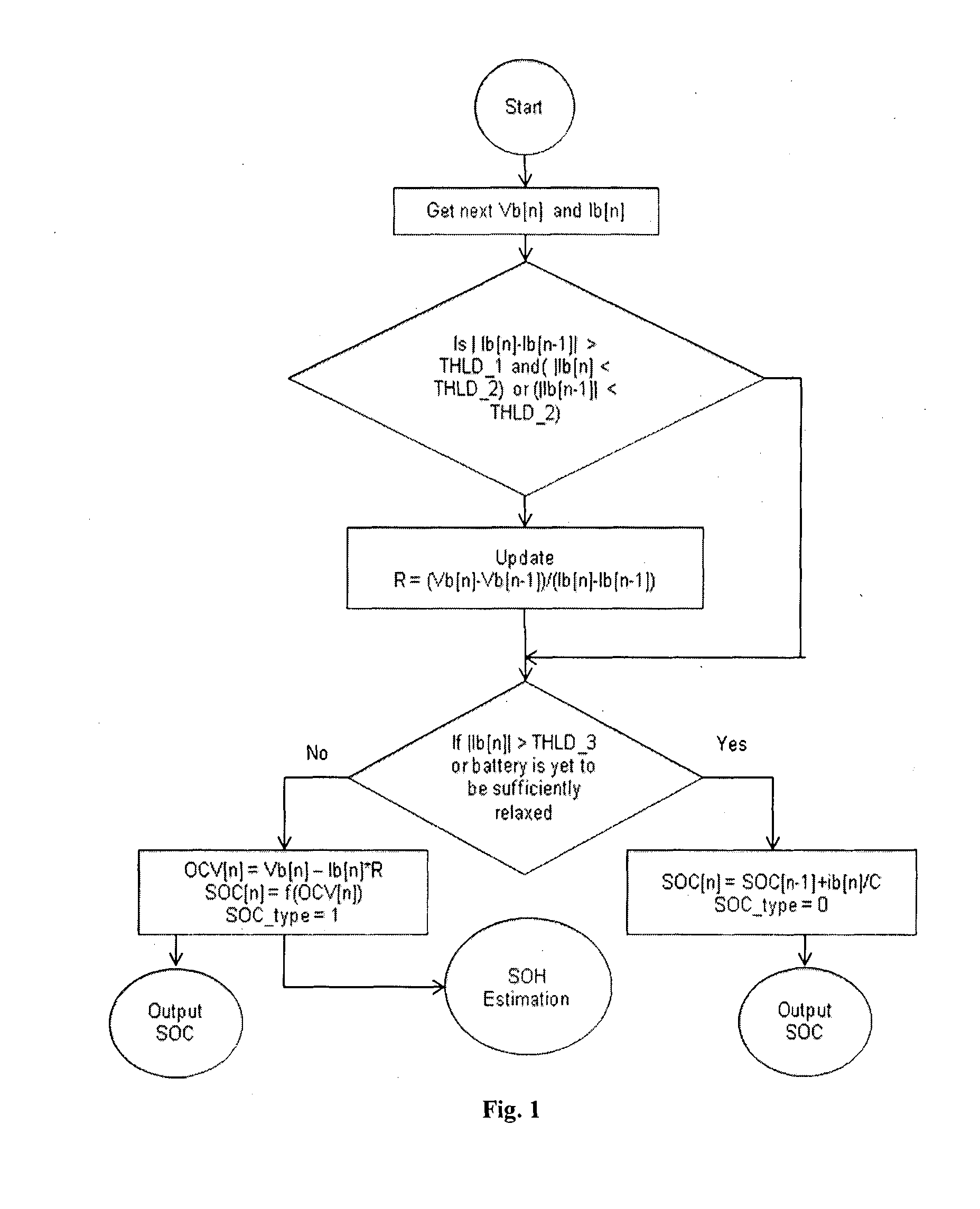

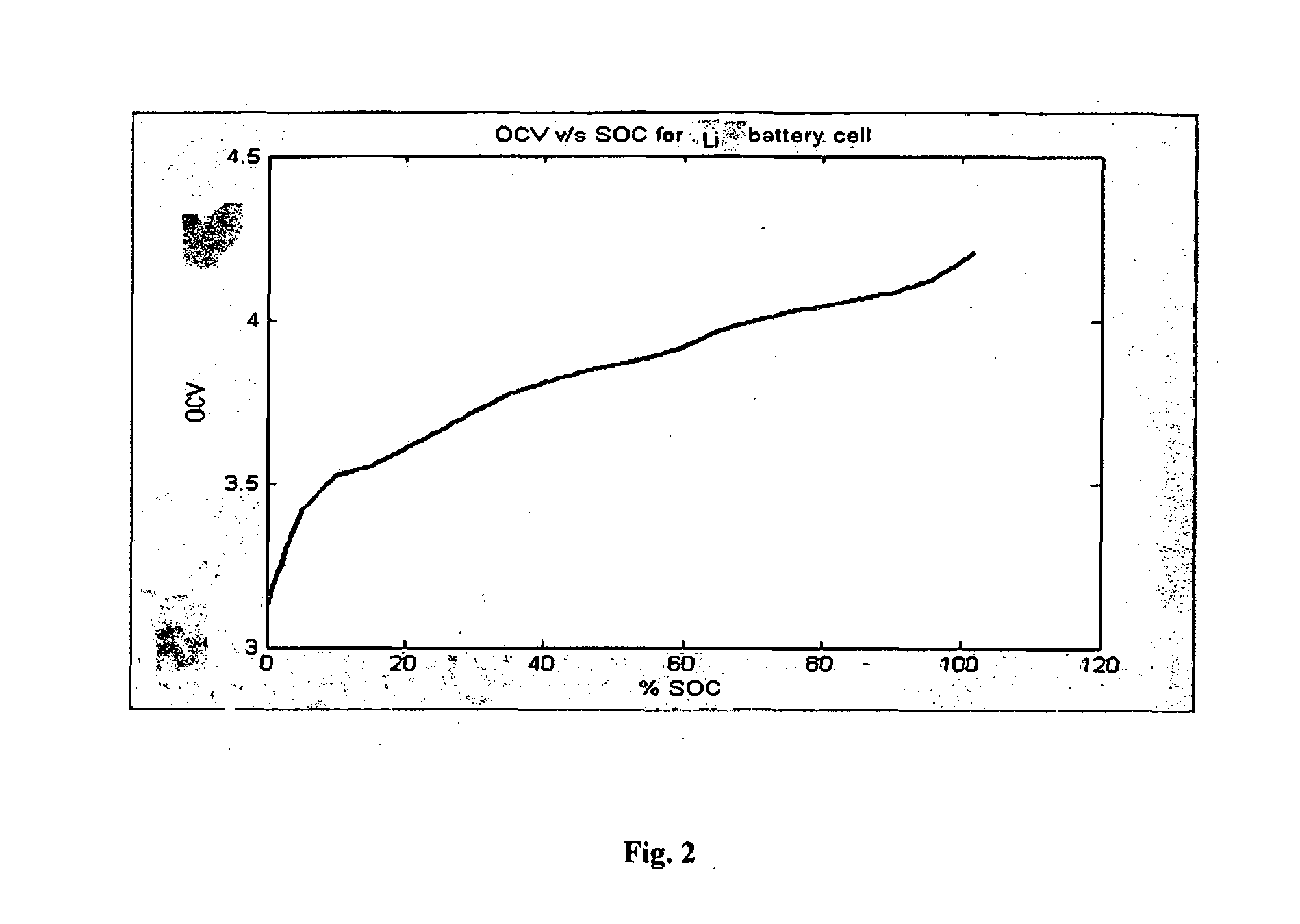

System and method for determining state of charge of a battery

InactiveUS20140236511A1Minimizes requirement of division operationComparable performanceElectrical testingSpecial data processing applicationsCapacitanceBattery state of charge

A novel method and system for determining state of charge of a battery (SOC) is disclosed wherein the direct method and the indirect method are not used at the same time, but alternately as indicated by battery current status. The method of the invention compensates for the exiting modeling errors and parameter estimation errors to provide an accurate SOC estimation. The method of the invention computes the DC offset and the battery capacitance to compensate for the exiting modeling errors and parameter estimation errors.

Owner:KPIT TECH LTD

Single belt omni directional treadmill

ActiveUS20120302408A1Work hardLimit movementMuscle exercising devicesMovement coordination devicesEngineeringOmni directional

Owner:INFINADECK CORP

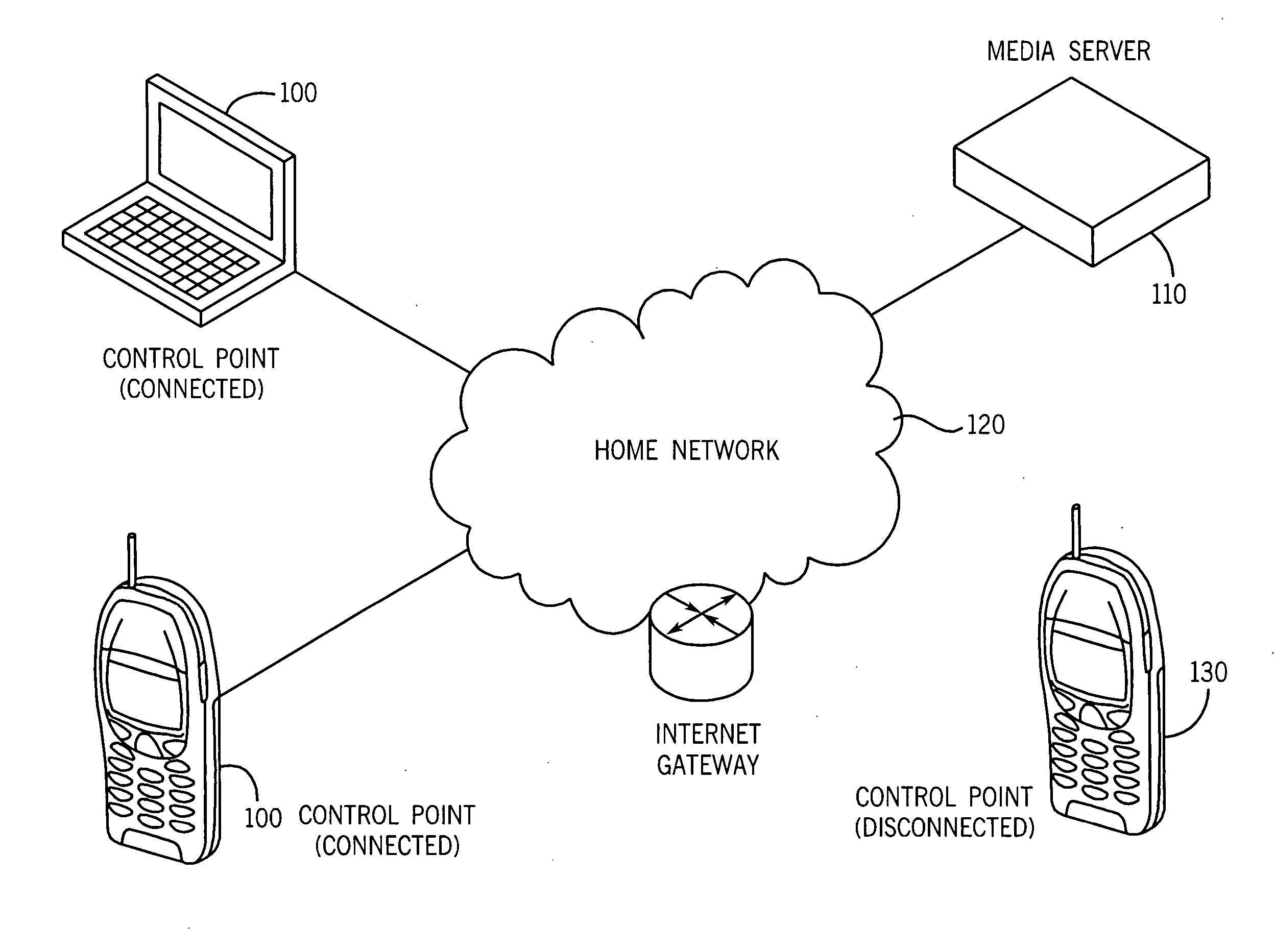

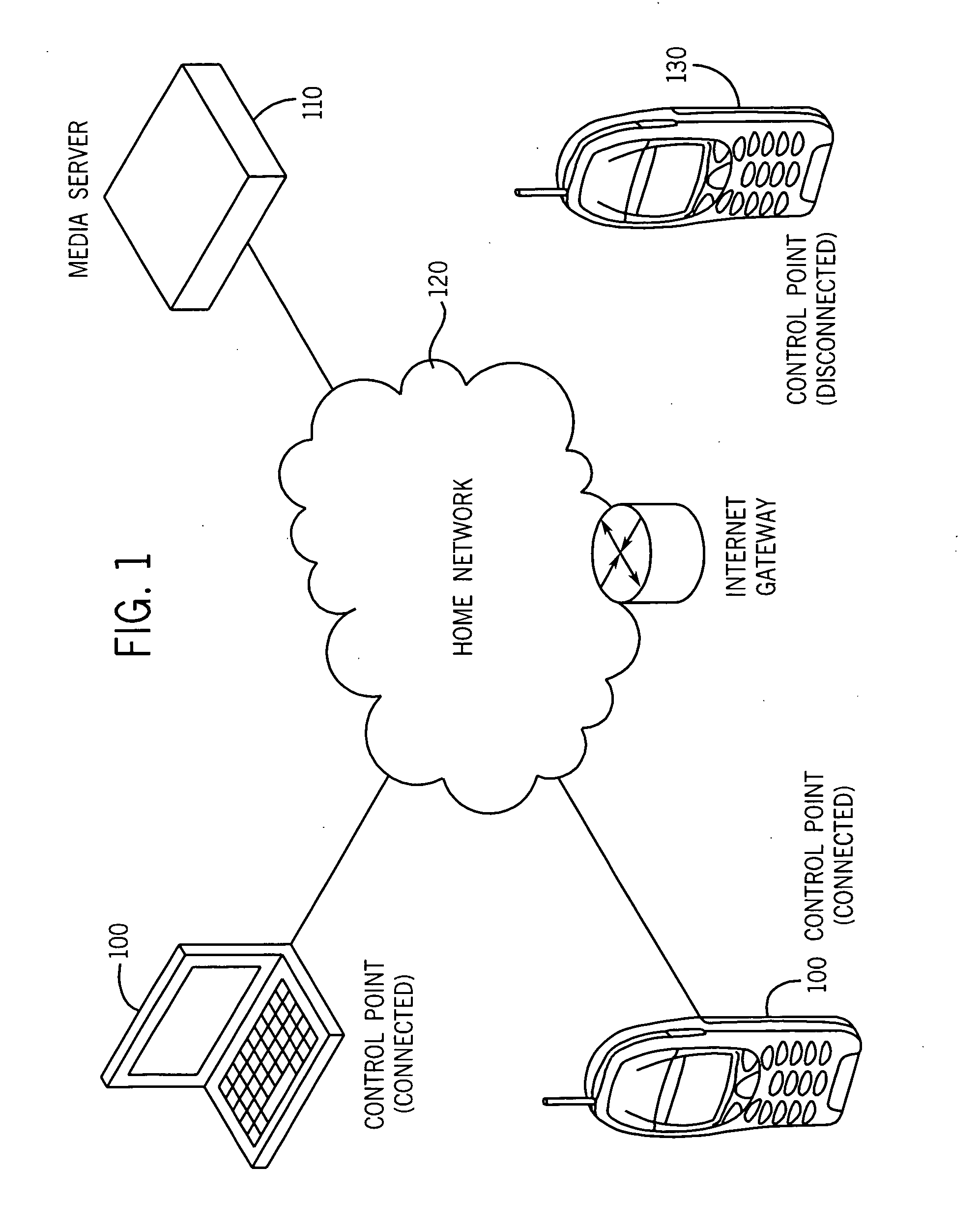

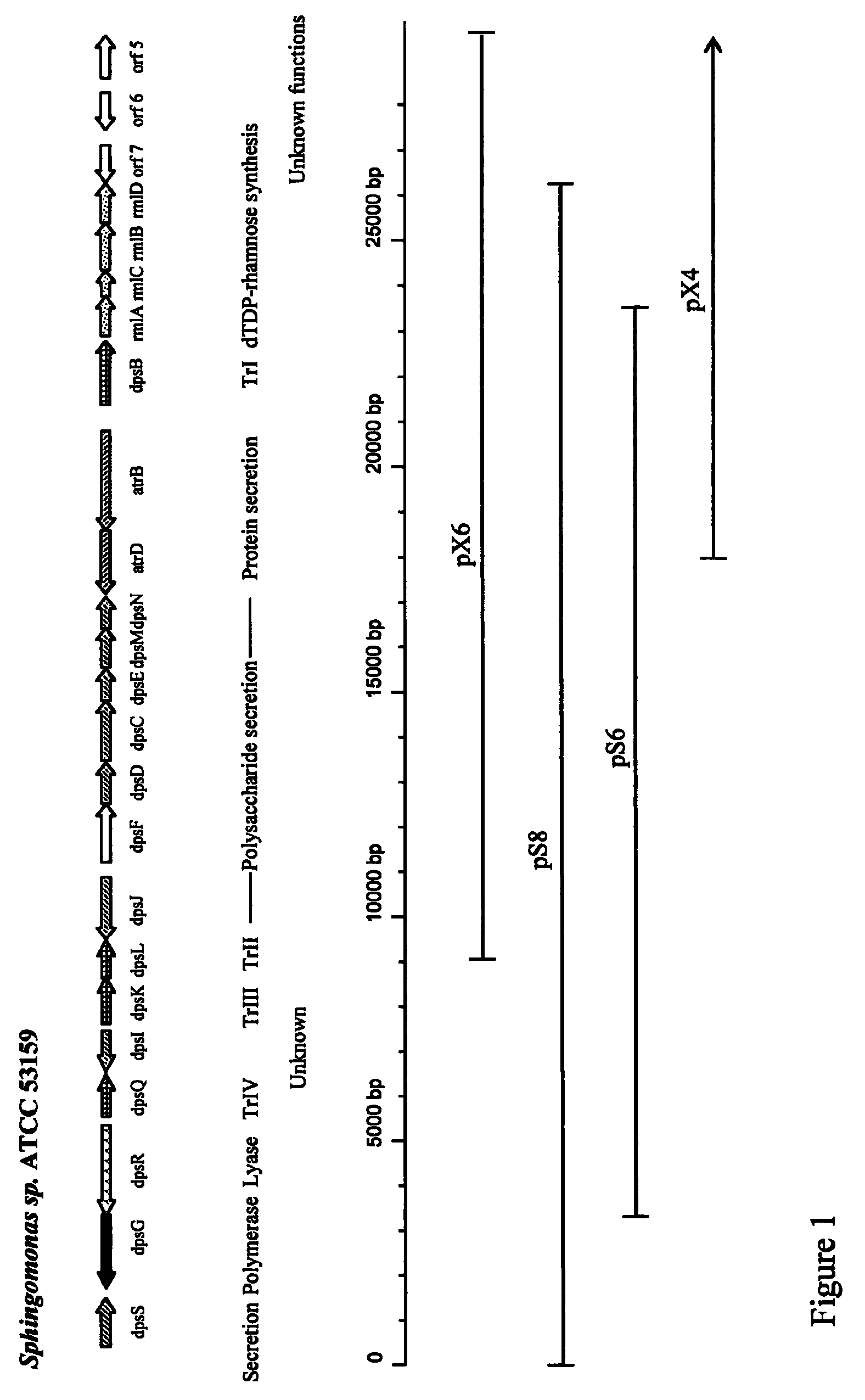

System and method for using web syndication feeds as a change log for synchronization in a UPnP audio/video environment

InactiveUS20070226312A1Simple in natureEasy to implementMultiple digital computer combinationsElectric digital data processingAudio frequencyComputer science

The use of ATOM / RSS feeds as a change log for web syndication. According to the present invention, whenever the SystemUpdateID changes, the CDS logs the change as a new entry in the ATOM feed. The SystemUpdateID is checked by a control point whenever it joins the network. If the SystemUpdateID is different, the control point promptly fetches the log, thereby eliminating the need to browse the entire CDS. When all of the items have been synchronized, the control point updates the time of last synchronization to reflect the current time. The control point then invokes other UPnP methods as necessary or desired.

Owner:NOKIA CORP

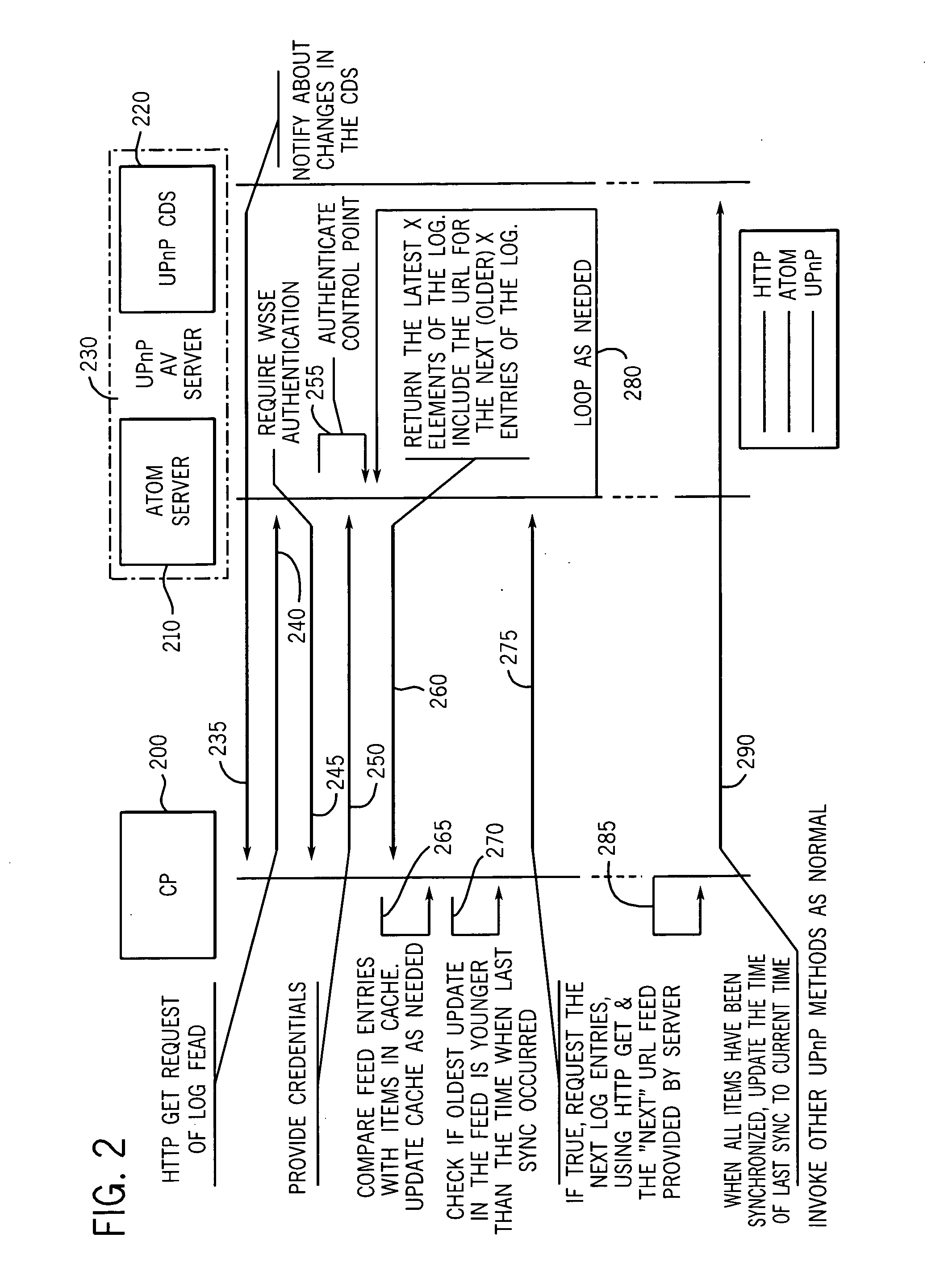

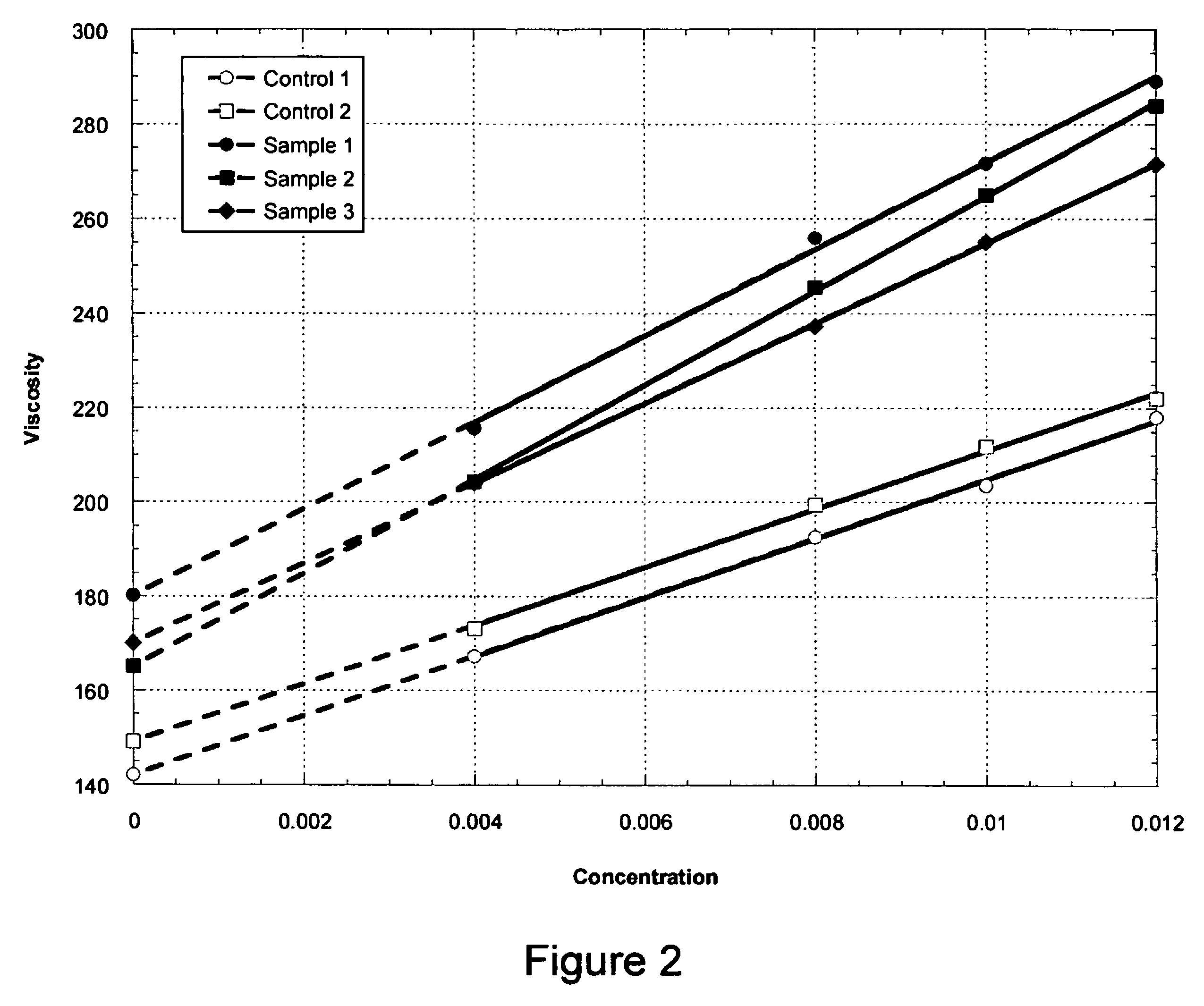

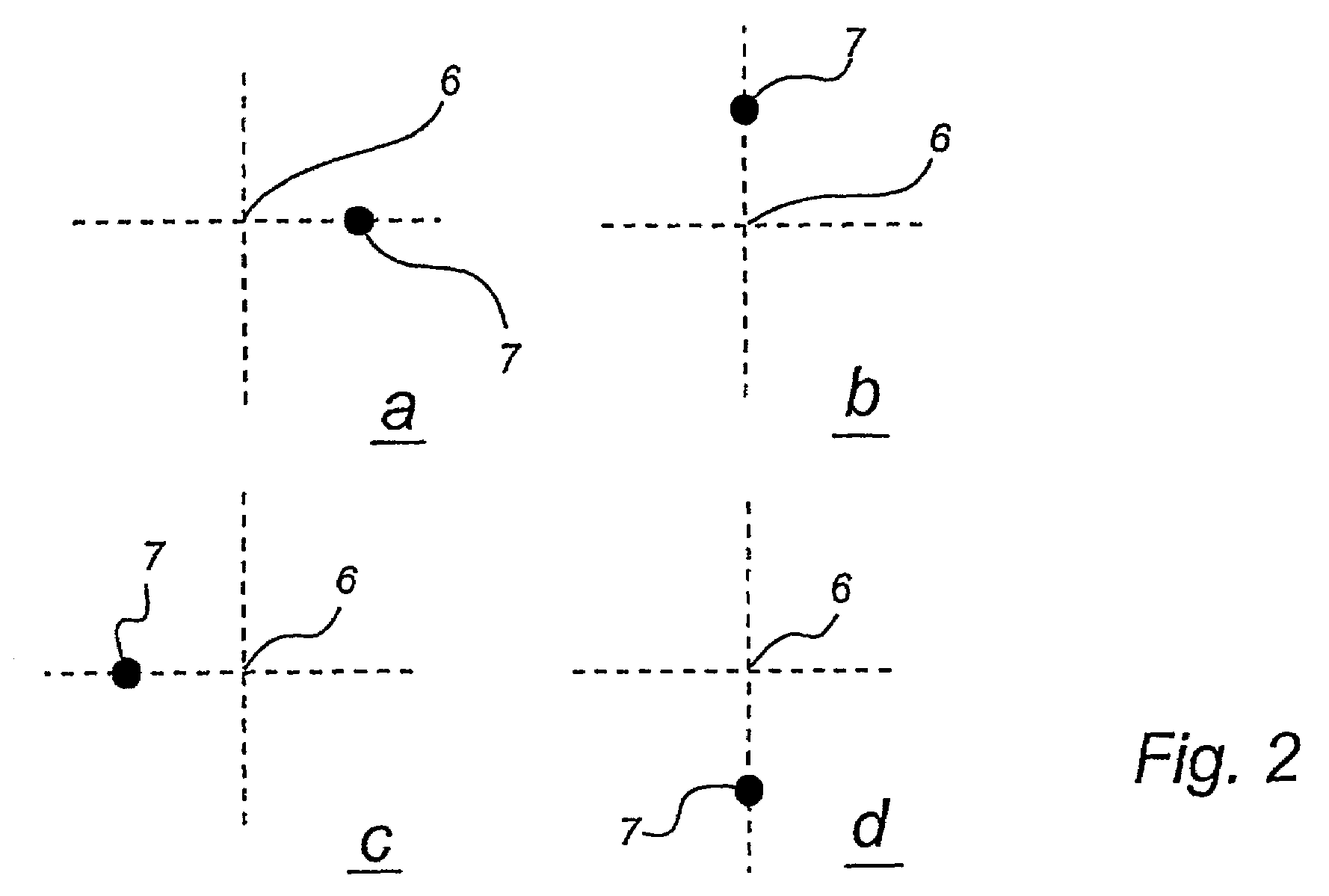

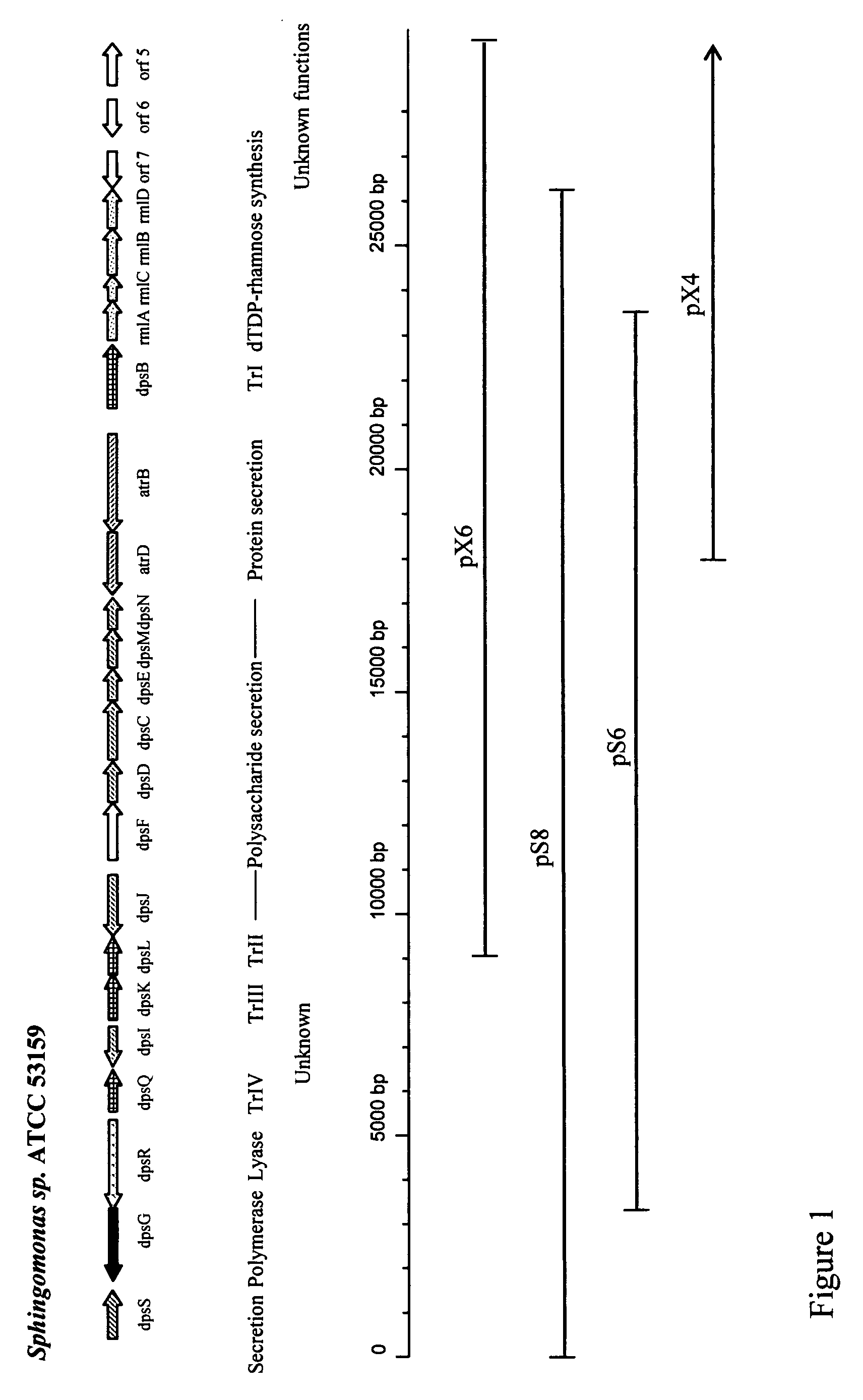

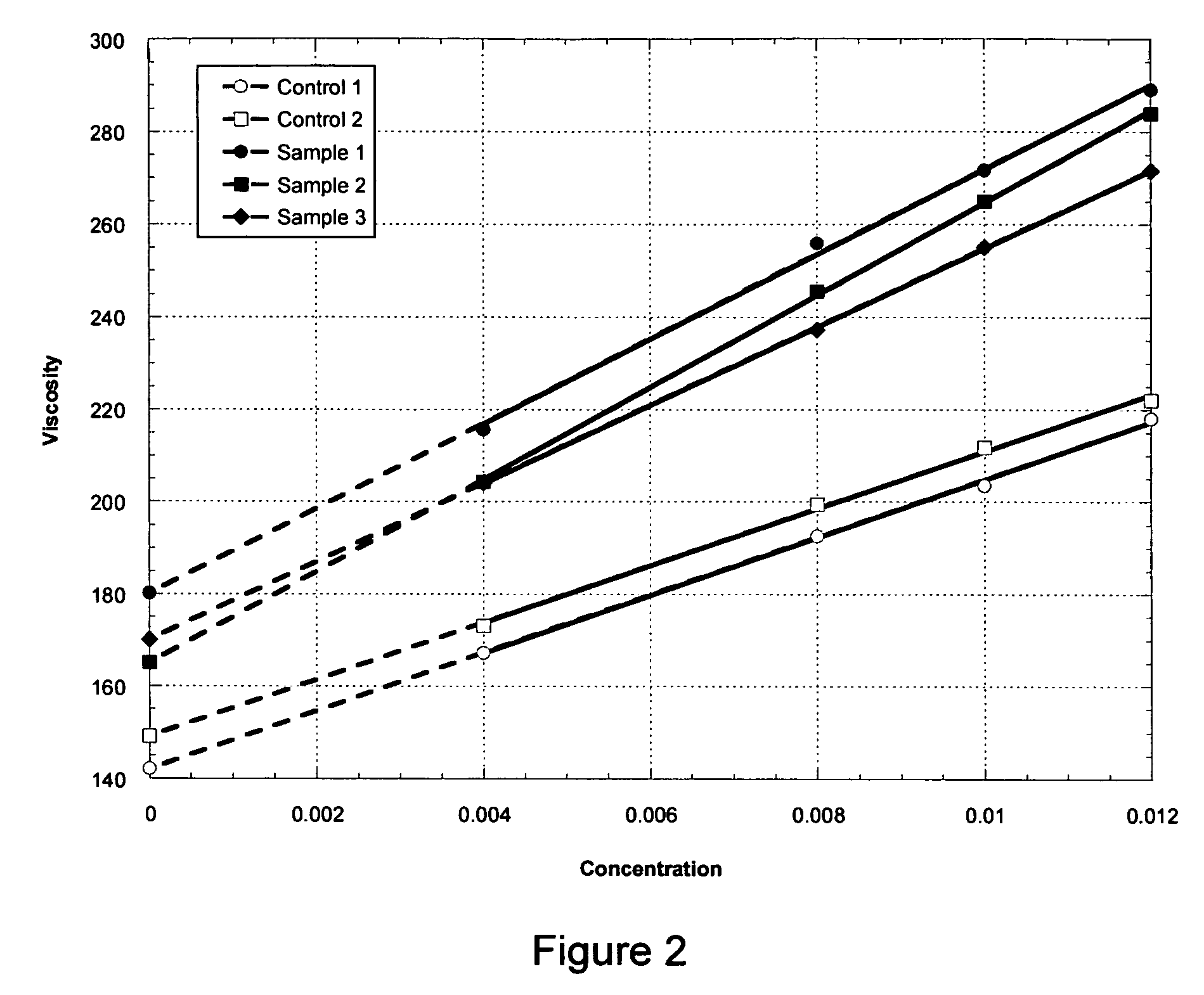

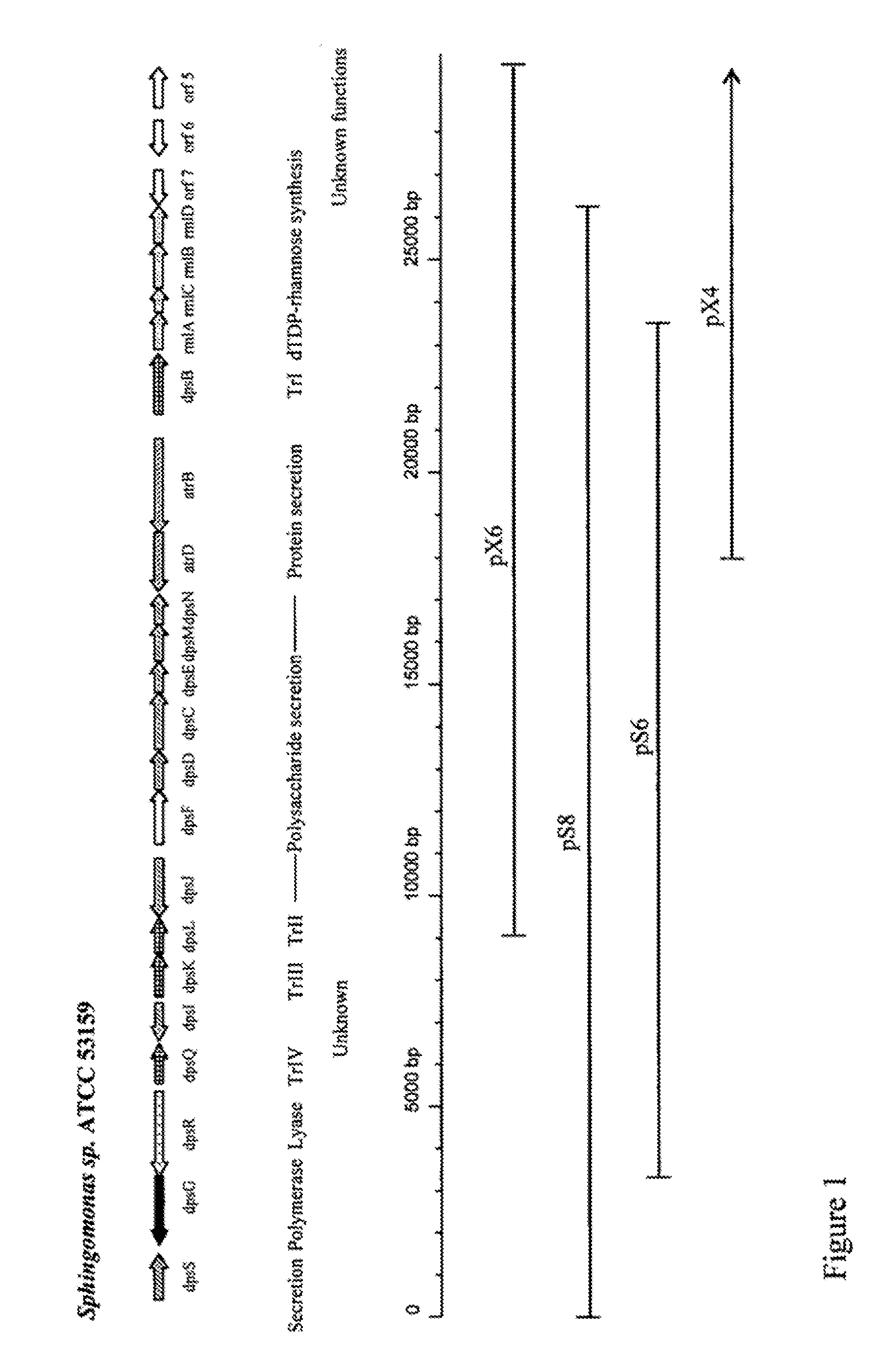

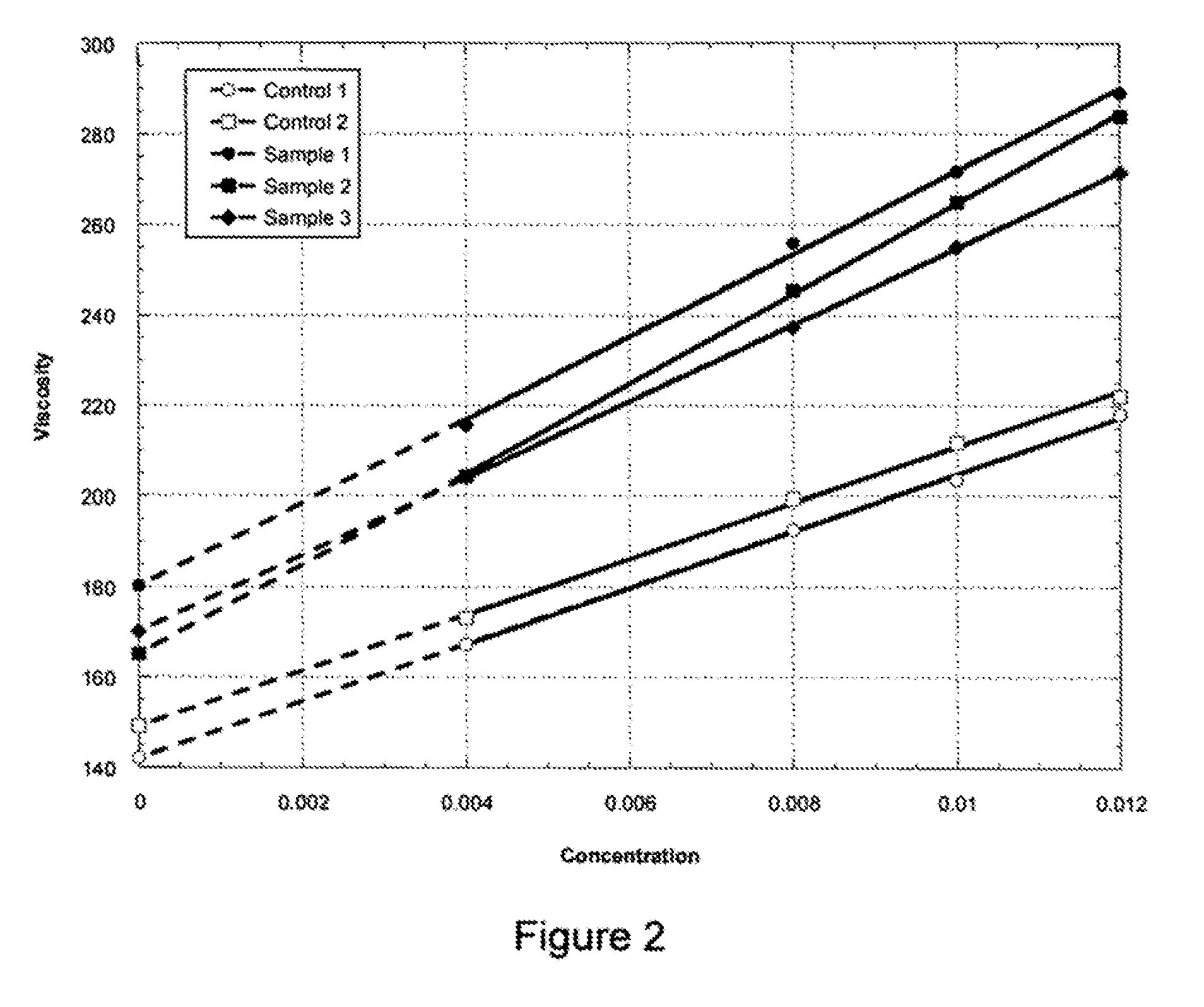

High viscosity diutan gums

ActiveUS7868167B2Increase productionImproved viscosity propertiesBiocideBacteriaBiotechnologyPhysical property

The production of a diutan polysaccharide exhibiting increased viscosity properties as compared with previously produced polysaccharide of the same type of repeating units. Such an improved diutan polysaccharide is produced through the generation of a derivative of Sphingomonas sp. ATCC 53159 that harbors a multicopy broad-host-range plasmid into which genes for biosynthesis of diutan polysaccharide have been cloned. The plasmid provides the capability within the host Sphingomonas strain to produce multiple copies of genes for such polysaccharide synthesis. In such a manner, a method of not just increased production of the target diutan polysaccharide, but also production of a diutan polysaccharide of improved physical properties (of the aforementioned higher viscosity) thereof is provided. Such a diutan polysaccharide has proven particularly useful as a possible viscosifier in oilfield applications and within cement materials. The inventive methods of production of such an improved diutan polysaccharide, as well as the novel cloned genes required to produce the improved diutan within such a method, are also encompassed within this invention. Additionally, the novel engineered Sphingomonas strain including the needed DNA sequence is encompassed within this invention.

Owner:CP KELCO U S INC

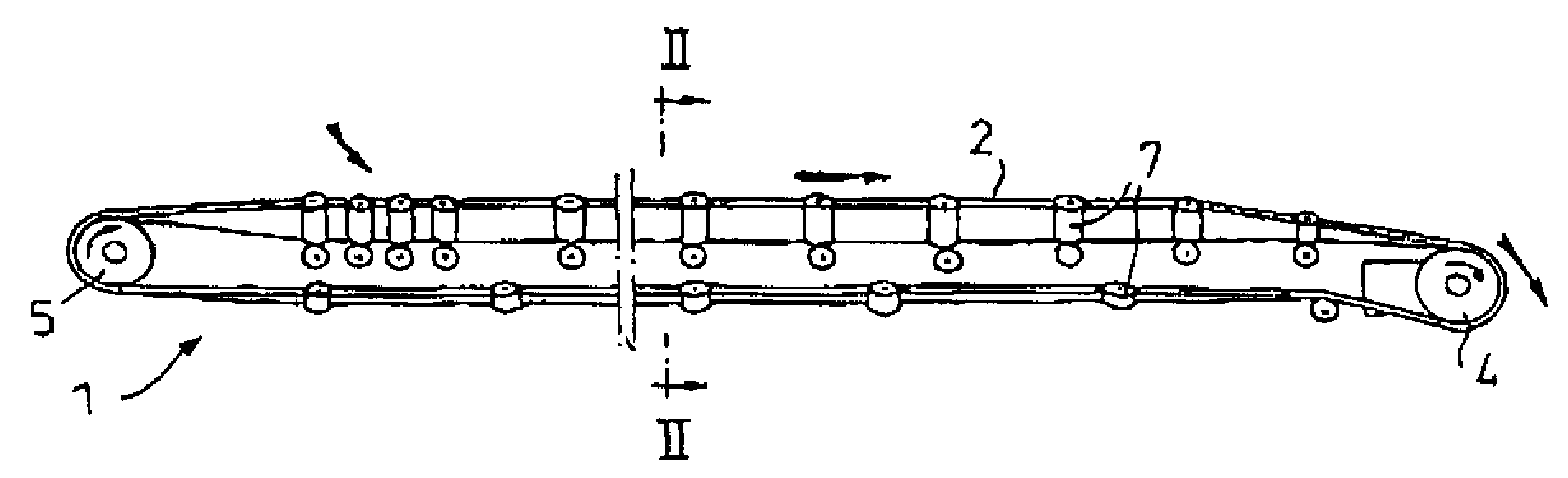

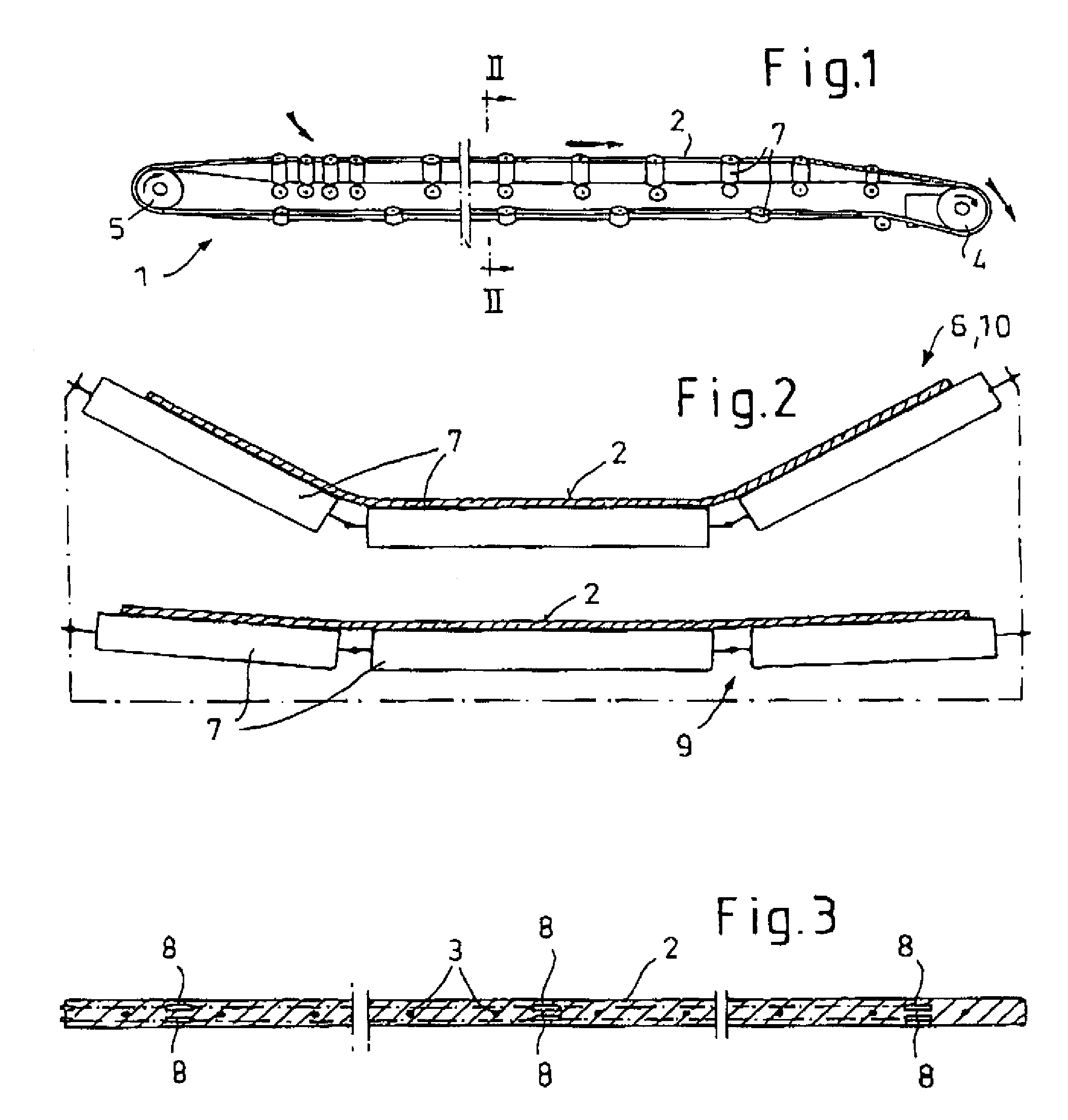

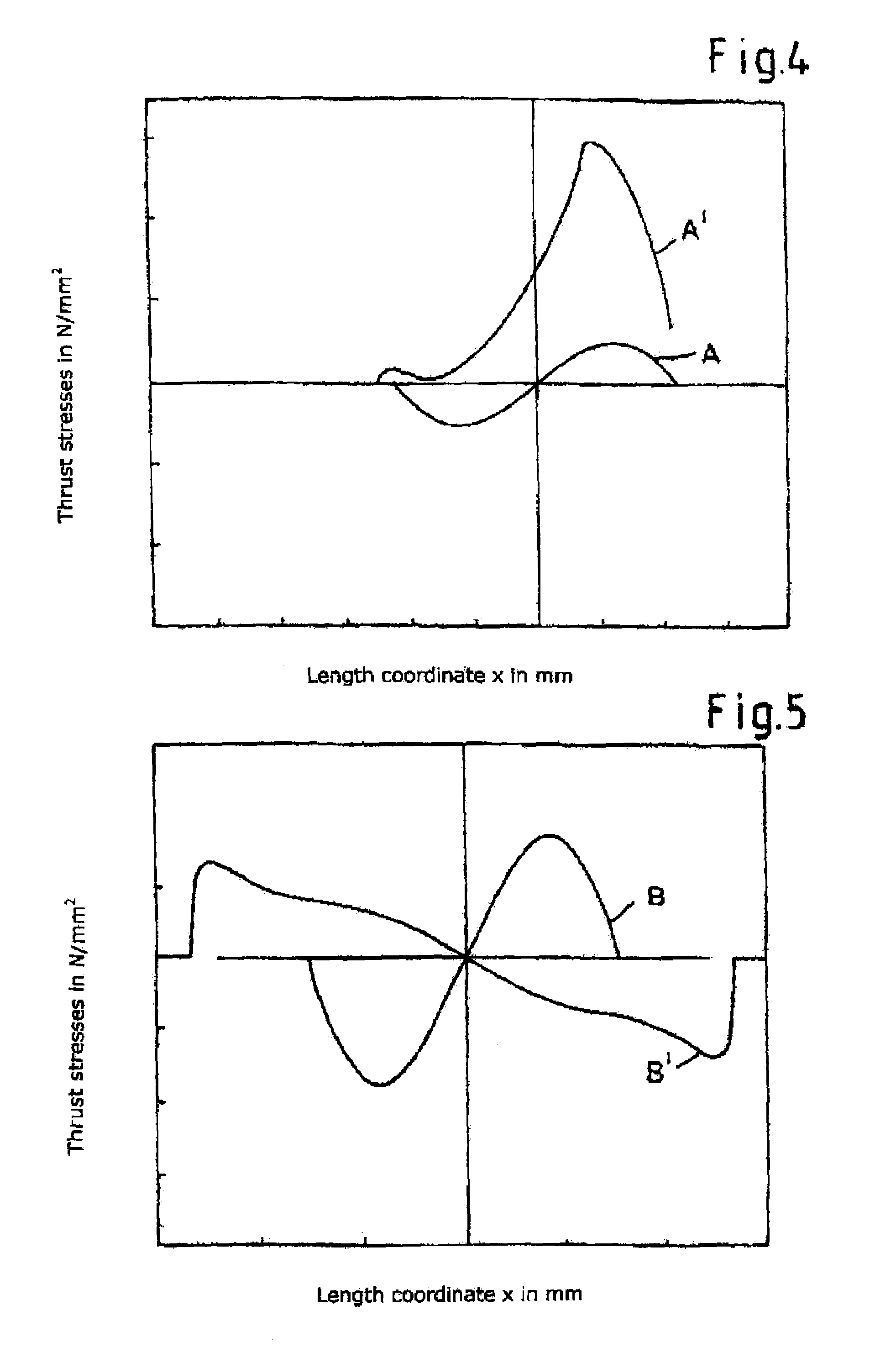

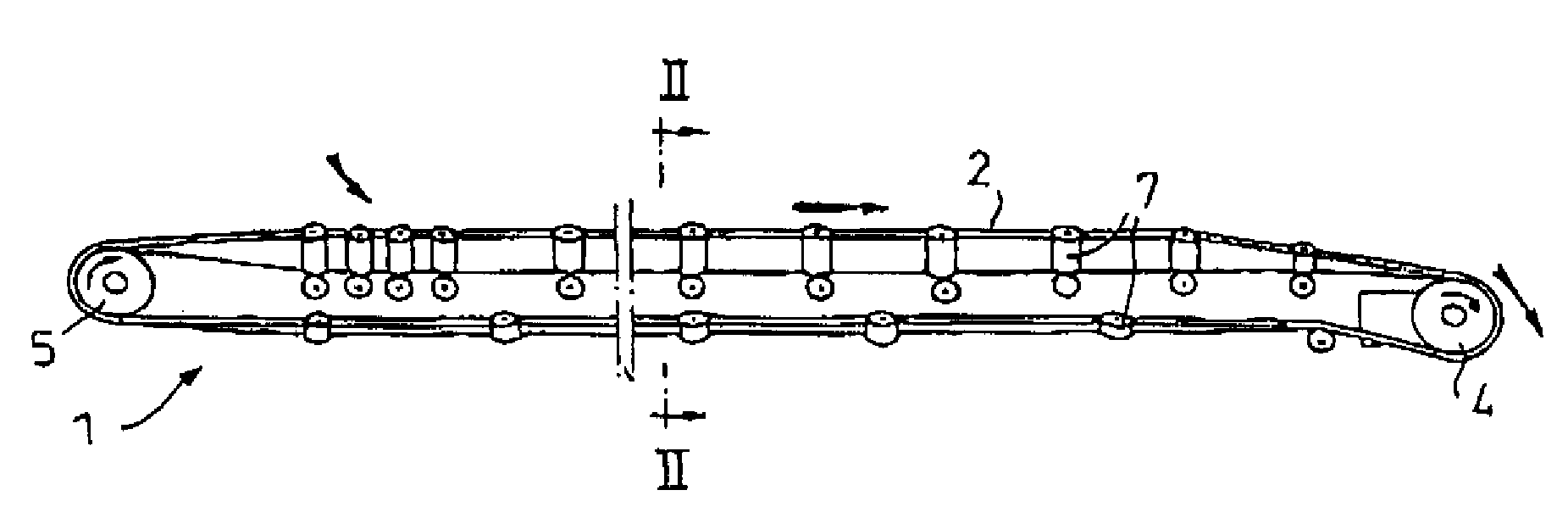

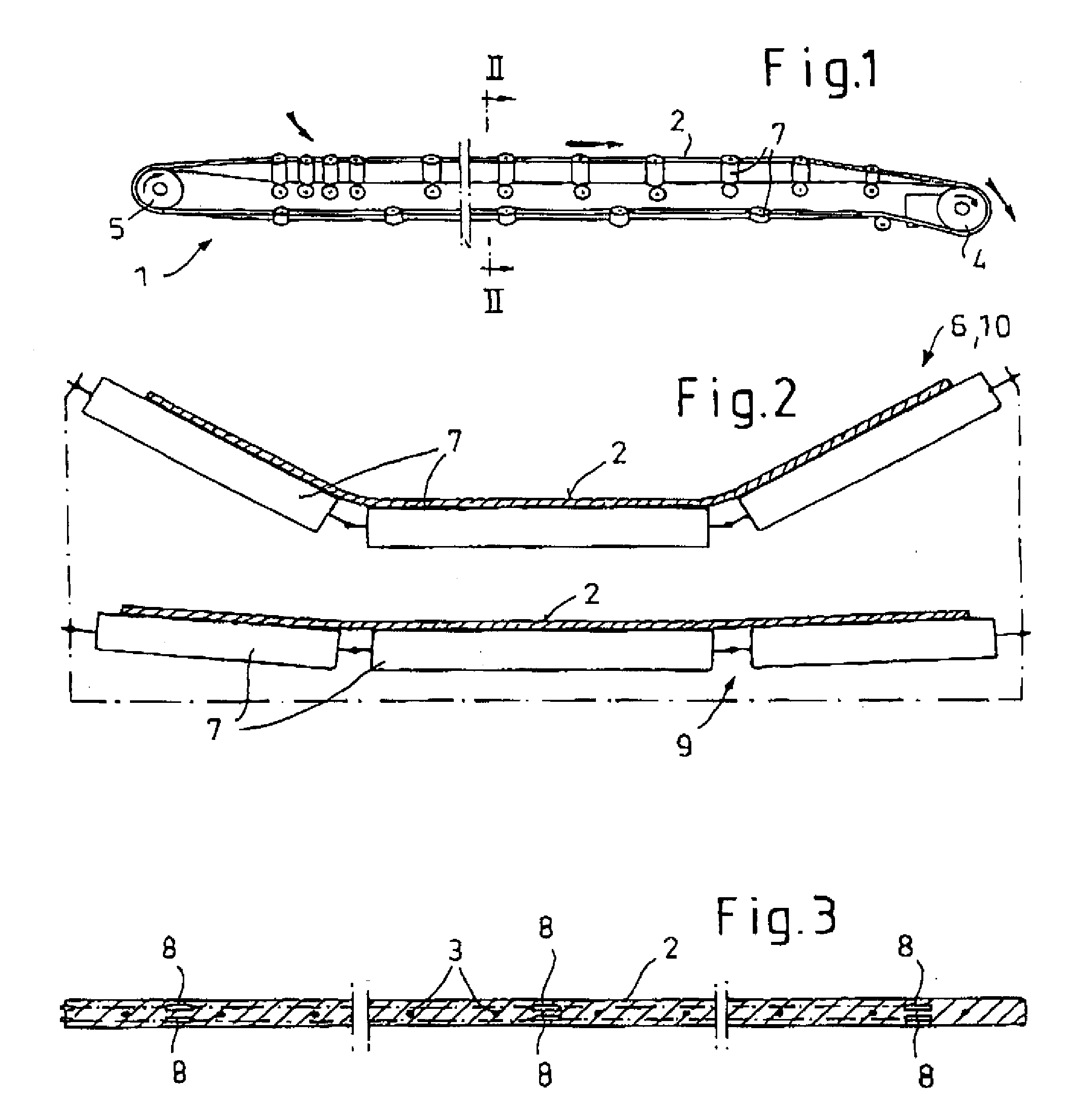

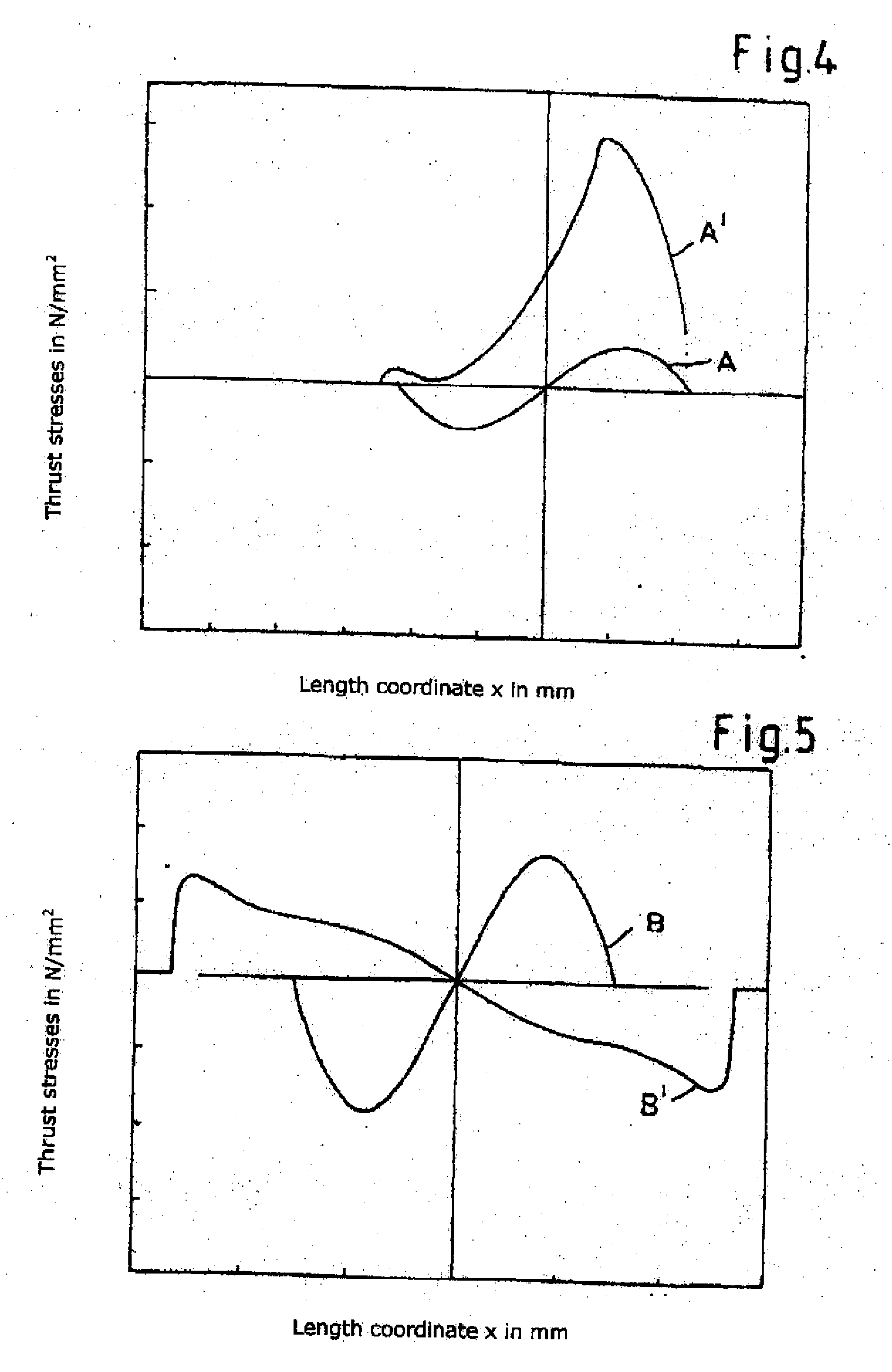

Method of monitoring belt orientation and/or belt travel of a band belt conveyor apparatus and a band belt conveyor

ActiveUS7353937B2Inexpensively monitoringThe result is accurate and reliableConveyorsControl devices for conveyorsEngineeringStress variation

Owner:ZIEGLER MANFRED DR

Apparatus and methods relating to image coding

InactiveUS7143952B2Avoid less flexibilityIncrease spaceInput/output for user-computer interactionCharacter and pattern recognitionGratingComputer science

A product has a coding pattern on its surface. The coding pattern may include symbols representing at least two different values and where each symbol comprises a raster point and at least one marking. The raster point is included in a raster that extends over the surface and the value of each symbol is indicated by the placement of the marking in relation to the raster point. The markings may each have a spatial extent that, in combination, may at least partially form the image.

Owner:ANOTO AB

High viscosity diutan gums

ActiveUS20080319186A1Increased biosynthetic productionHigh viscosity propertySugar derivativesBacteriaBiotechnologyPhysical property

The production of a diutan polysaccharide exhibiting increased viscosity properties as compared with previously produced polysaccharide of the same type of repeating units. Such an improved diutan polysaccharide is produced through the generation of a derivative of Sphingomonas sp. ATCC 53159 that harbors a multicopy broad-host-range plasmid into which genes for biosynthesis of diutan polysaccharide have been cloned. The plasmid provides the capability within the host Sphingomonas strain to produce multiple copies of genes for such polysaccharide synthesis. In such a manner, a method of not just increased production of the target diutan polysaccharide, but also production of a diutan polysaccharide of improved physical properties (of the aforementioned higher viscosity) thereof is provided. Such a diutan polysaccharide has proven particularly useful as a possible viscosifier in oilfield applications and within cement materials. The inventive methods of production of such an improved diutan polysaccharide, as well as the novel cloned genes required to produce the improved diutan within such a method, are also encompassed within this invention. Additionally, the novel engineered Sphingomonas strain including the needed DNA sequence is encompassed within this invention.

Owner:CP KELCO U S INC

Method of Monitoring Belt Orientation and/or Belt Travel of A Band Belt Conveyor Apparatus and a Band Belt Conveyor

ActiveUS20060254885A1Inexpensively monitoringThe result is accurate and reliableConveyorsControl devices for conveyorsStress variationMulti axis

A method of monitoring belt orientation and / or belt travel of a belt conveyor apparatus includes measurement of compression and / or thrust stress patterns within the belt as it passes over a support roller arrangement by measuring means embedded in the belt. The measured signal is recorded and associated with a specific support roller. The signal pattern allows conclusions to be drawn about misalignments of the belt or possible defects in the support rollers. A belt conveyor apparatus has measuring means embedded in the belt and including at least one multi-axis sensor for detecting the stress variations in the belt.

Owner:ZIEGLER MANFRED DR

Multilayer contact electrode for compound semiconductors and production method thereof

InactiveUS6531715B1Easily produceSimple in natureSolid-state devicesSemiconductor/solid-state device manufacturingContact electrodeMetal

A multilayer contact electrode for connecting a bonding wire to a p-type surface of a III / V-compound semiconductor is formed by a first metallizing step followed by a tempering step. Then, a second metallized layer of the same metal as the first metal layer is formed on the first layer but tempering of the second layer is avoided. A reliable bonding of a bonding wire to the non-tempered contact electrode is assured. The contact electrode includes a first inner metallized layer that is tempered and covered by a second nontempered metallized layer of the same metal as the first layer.

Owner:VISHAY SEMICON

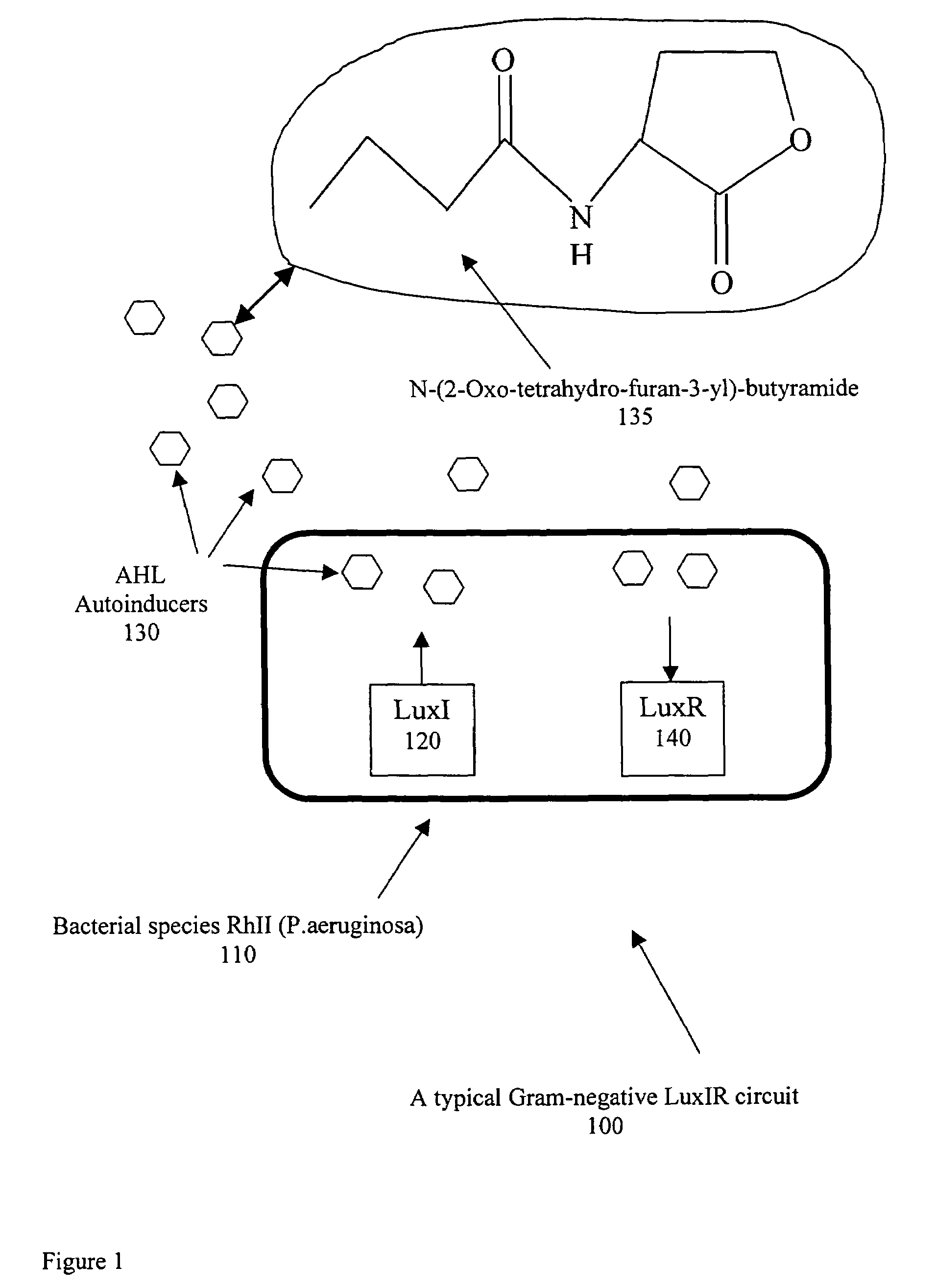

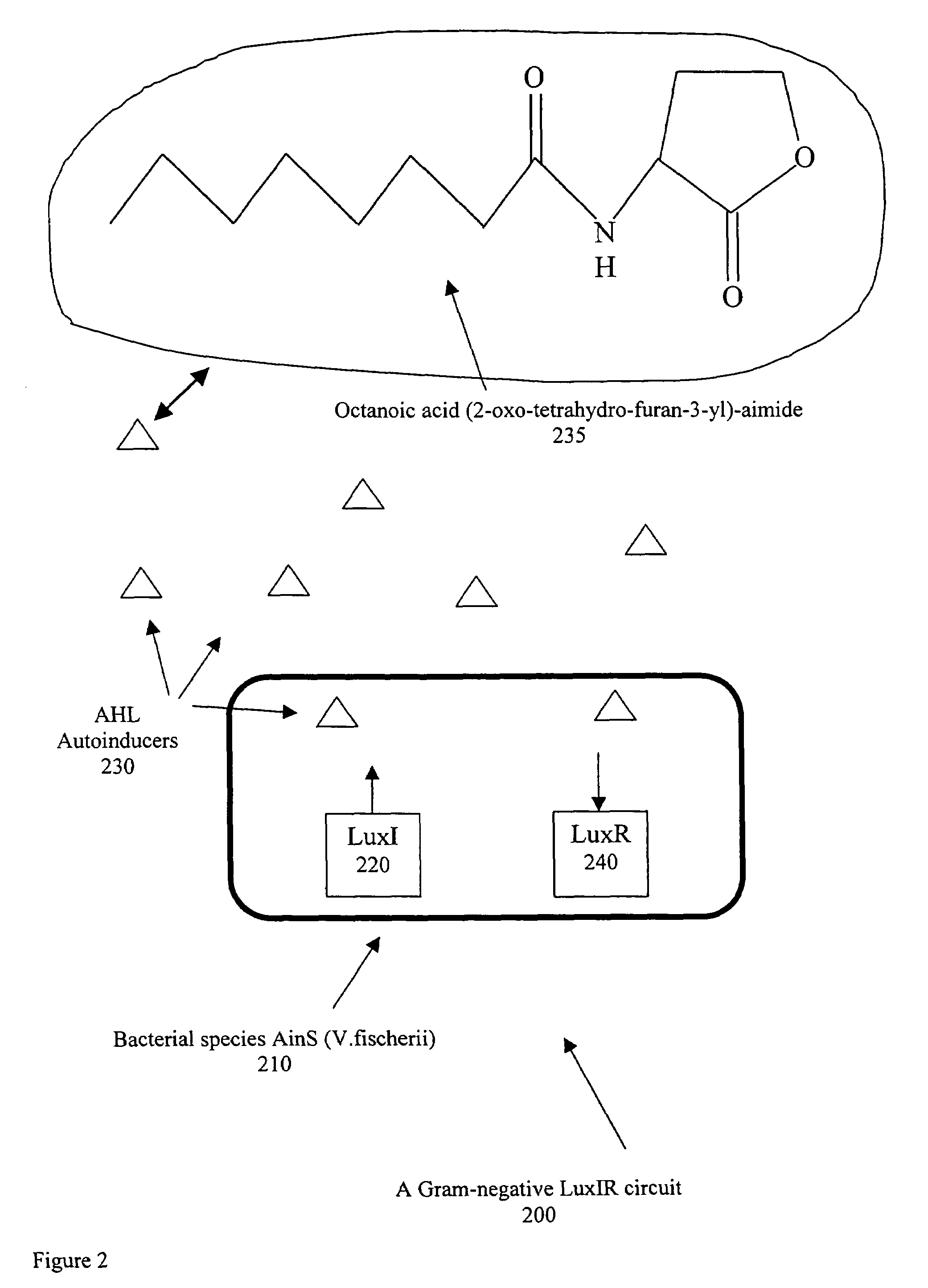

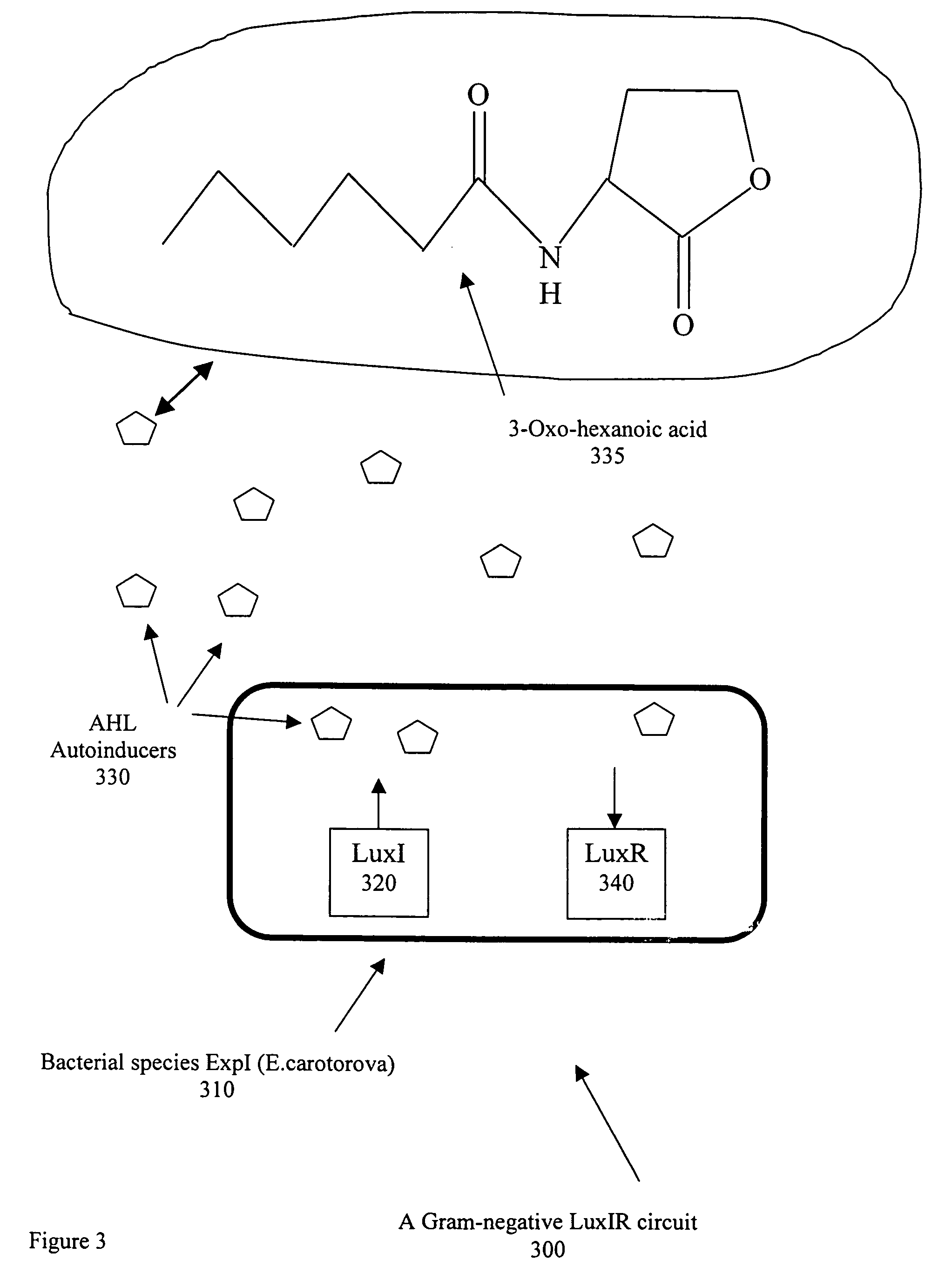

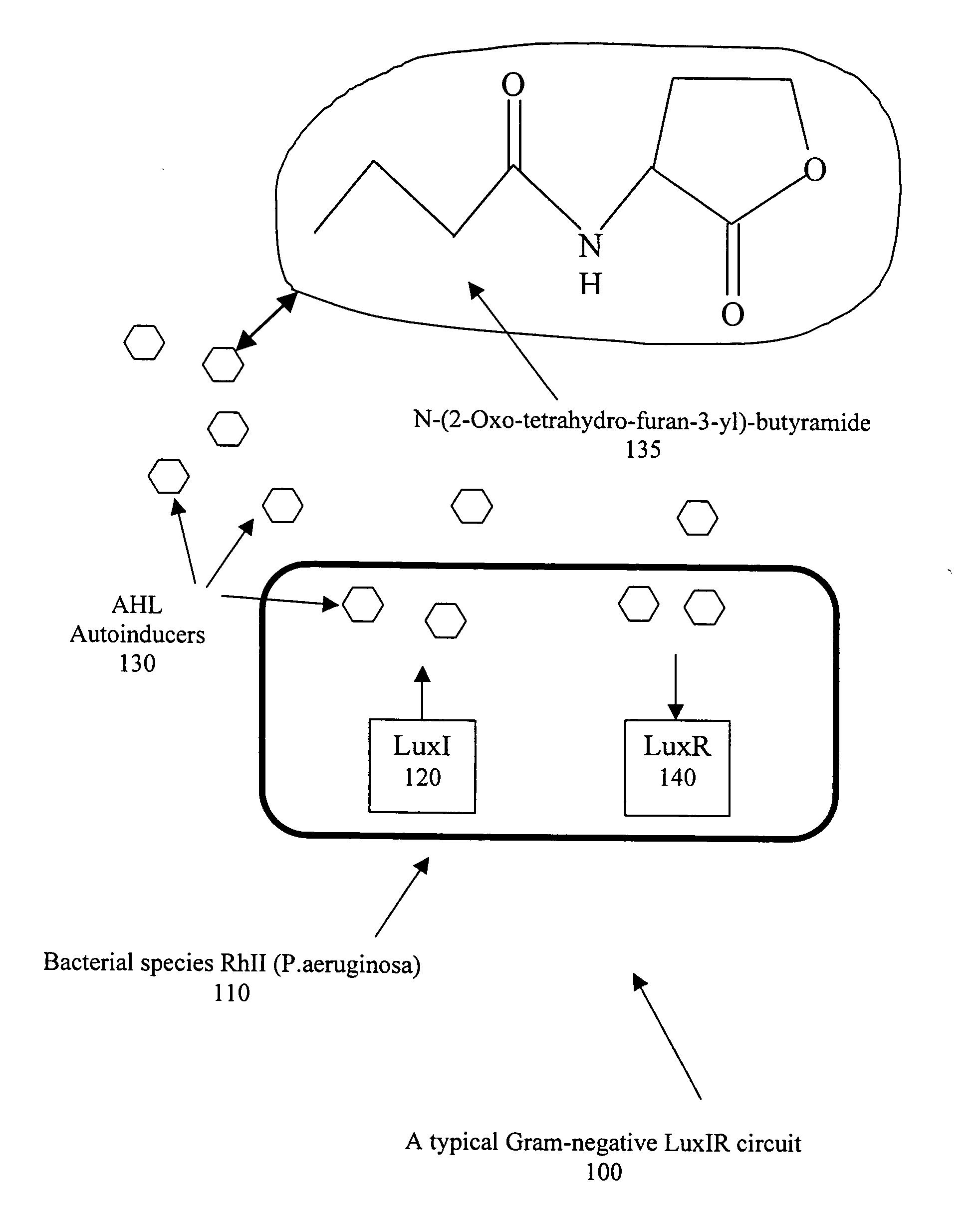

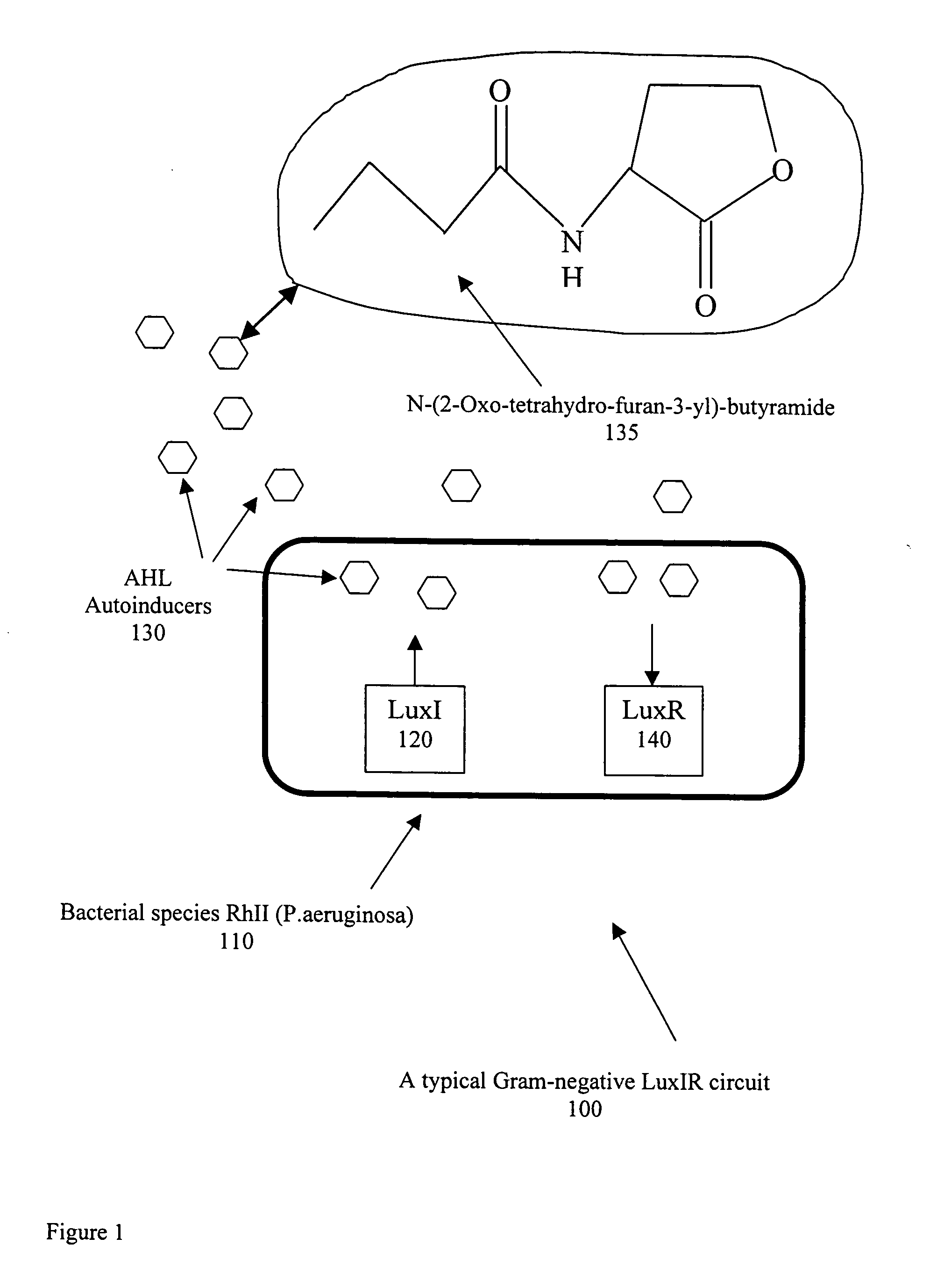

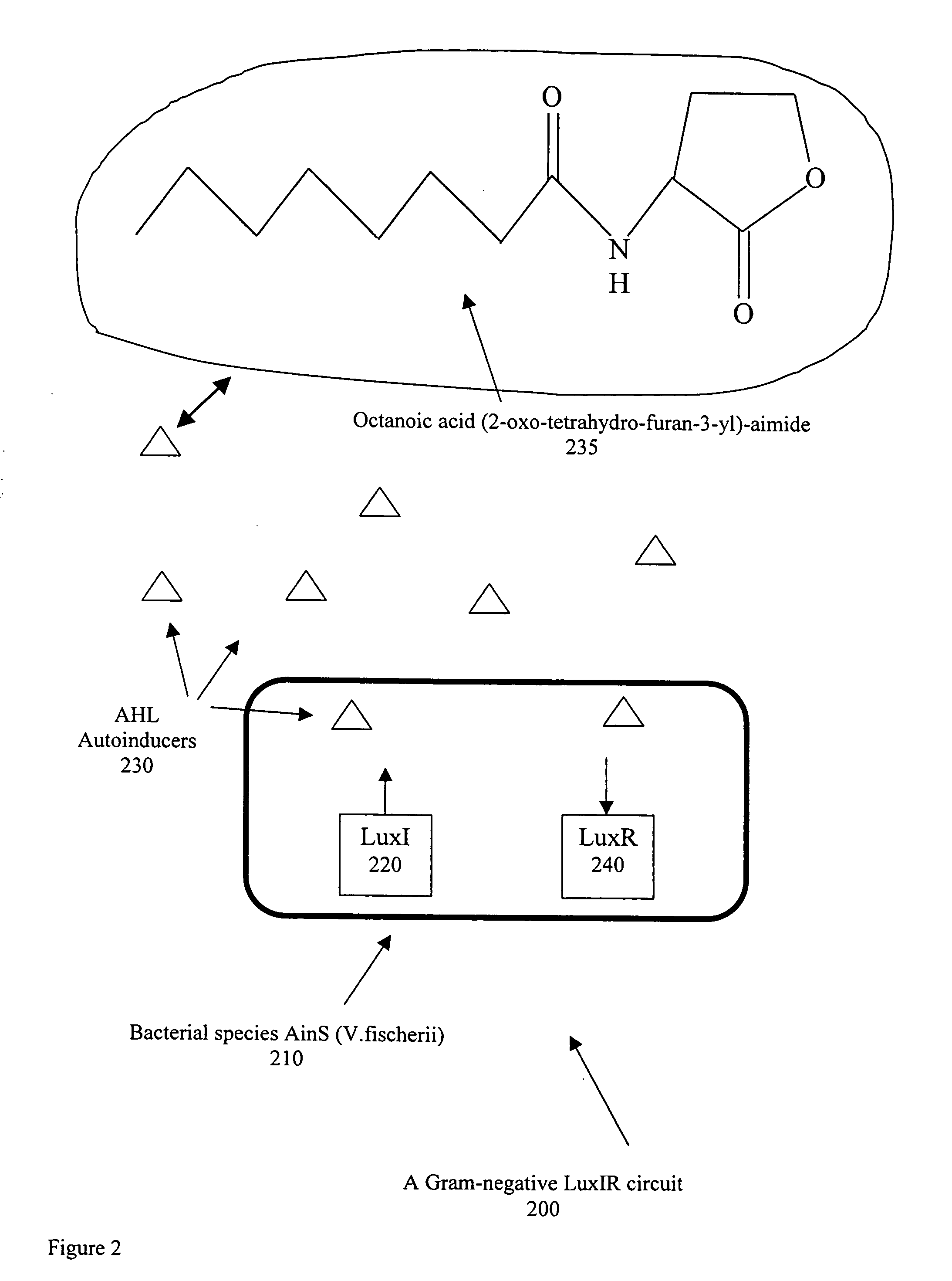

Acoustic wave biosensor for the detection and identification of characteristic signaling molecules in a biological medium

InactiveUS7651843B2Simple in naturePromotes the premature ripening of foodstuffsTransistorMicrobiological testing/measurementSignalling moleculesIntercellular space

A method of detecting and identifying bacteria, micro-organisms or plants in a liquid or gaseous medium, the bacteria, micro-organisms or plants being of the kind which produce signaling molecules in intercellular space, includes positioning a biosensor in the liquid or gaseous medium, the biosensor having a biolayer matched to specific signaling molecules to be detected whereby the biolayer is reactive thereto in a manner which varies operation of the sensor. Such variation of the operation of the biosensor is detected to thereby determine the presence and purpose of the bacteria, micro-organisms or plants in the liquid or gaseous medium.

Owner:P J EDMONSON

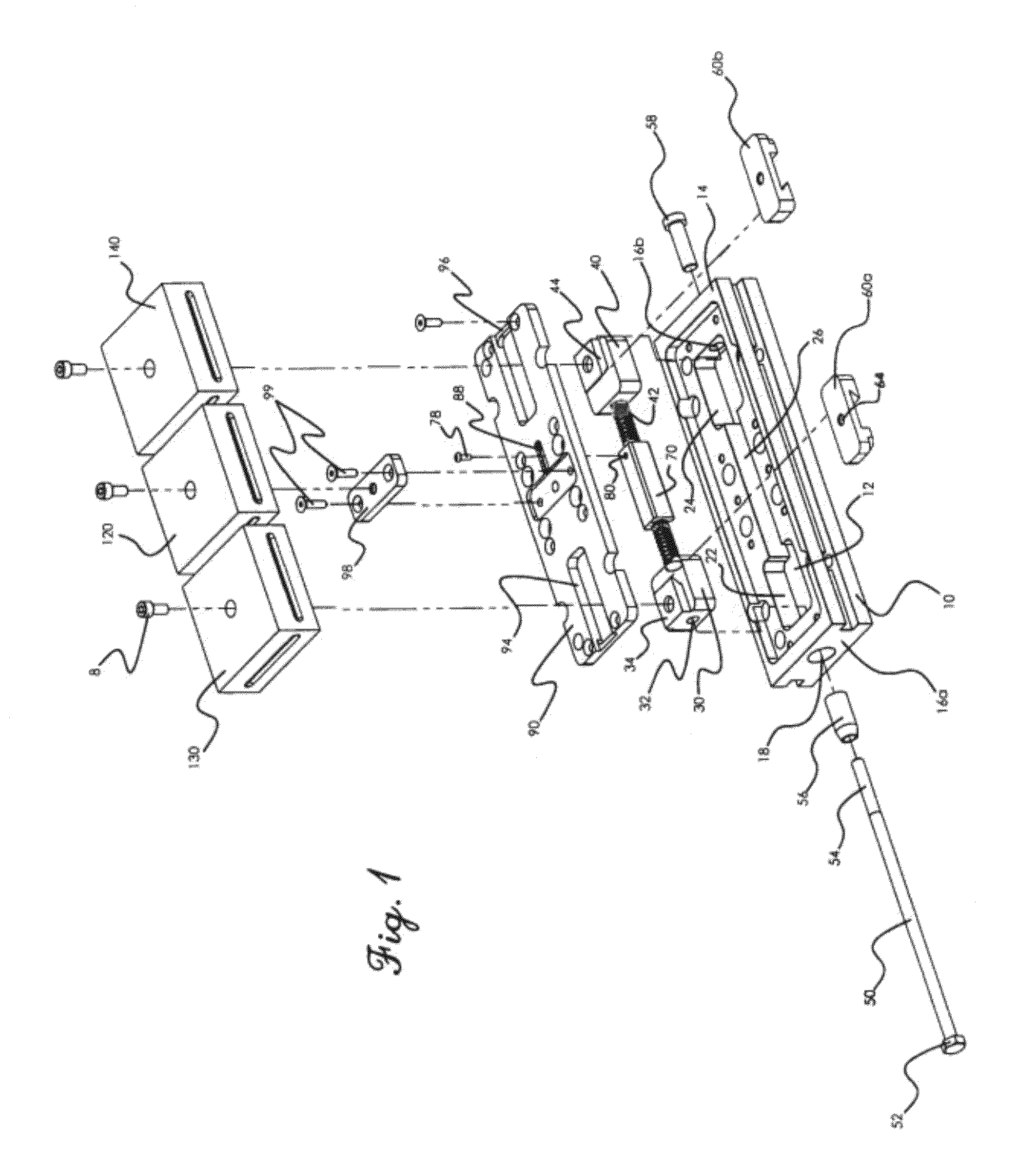

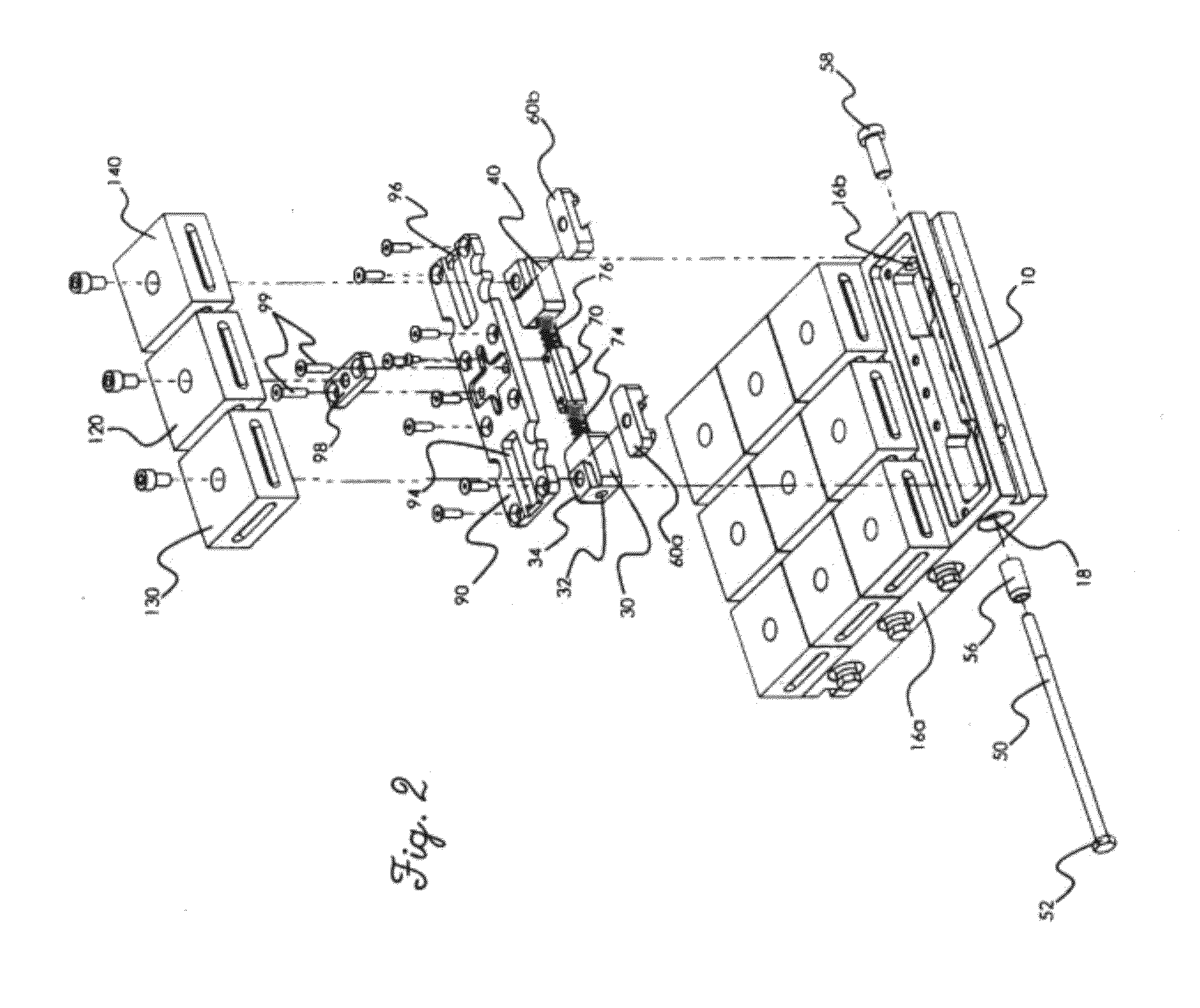

High-density fixture vise

InactiveUS8256753B2Simple design and manufactureReduce operating costsPositioning apparatusVicesHigh densityEngineering

A multi-station machine vise that is disclosed herein that utilizes soft jaws, which are symmetrical and machineable on all four sides. The jaws being identical in size and configuration makes them interchangeable / usable on any vise station, which results in reduced operating costs. The movable jaws are precisely located and fastened to the vise utilizing a jaw carrier, which incorporates a pull-down action to eliminate jaw lift. The jaw carrier includes a downwardly positioned wedge design that engages a corresponding wedge on a slide that moves the jaw carrier and the jaw. Incorporating the pull-down mechanism into the jaw carrier disposed between and slide and the jaw allows for simplifying the design and manufacture of the jaws.

Owner:HIRSH PRECISION PROD INC

System and method for sizing, inserting and securing artificial disc in intervertebral space

InactiveUS8597357B2PerformancePerforms betterSpinal implantsCoatingsIntervertebral discIntervertebral spaces

A prosthetic spinal implant having a deployable securing mechanism that is deployable into a portion of the vertebral space for affixing the implant between the vertebrae, the securing mechanism having tactile feedback means comprising a surface for transmitting tactile feedback during deployment of the securing mechanism. A spinal implant having deployable securing means that interface with the implant to prevent the deployable securing means from retracting after deployment. An implant that utilizes its resilient properties to provide the user with tactile feedback with which the user may ascertain the position of the securing mechanism. A system and tools for sizing and implanting implants with the aforementioned characteristics.

Owner:PIONEER SURGICAL TECH INC

High-density fixture vise

InactiveUS20100320666A1Simple design and manufactureReduce operating costsPositioning apparatusVicesEngineeringHigh density

A multi-station machine vise that is disclosed herein that utilizes soft jaws, which are symmetrical and machineable on all four sides. The jaws being identical in size and configuration makes them interchangeable / usable on any vise station, which results in reduced operating costs. The movable jaws are precisely located and fastened to the vise utilizing a jaw carrier, which incorporates a pull-down action to eliminate jaw lift. The jaw carrier includes a downwardly positioned wedge design that engages a corresponding wedge on a slide that moves the jaw carrier and the jaw. Incorporating the pull-down mechanism into the jaw carrier disposed between and slide and the jaw allows for simplifying the design and manufacture of the jaws.

Owner:HIRSH PRECISION PROD INC

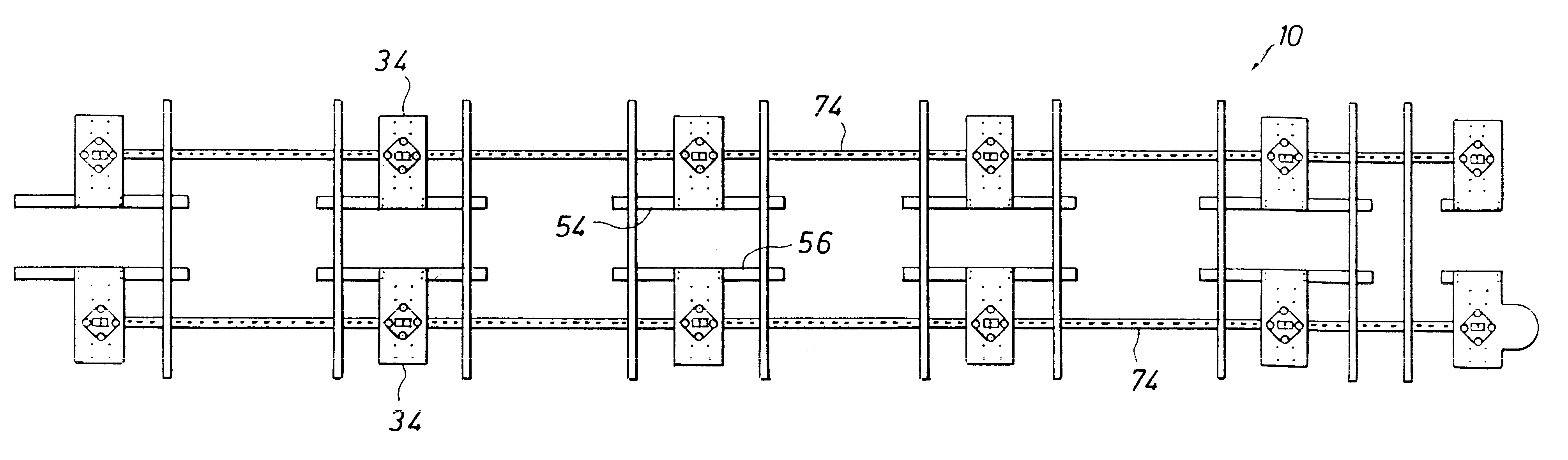

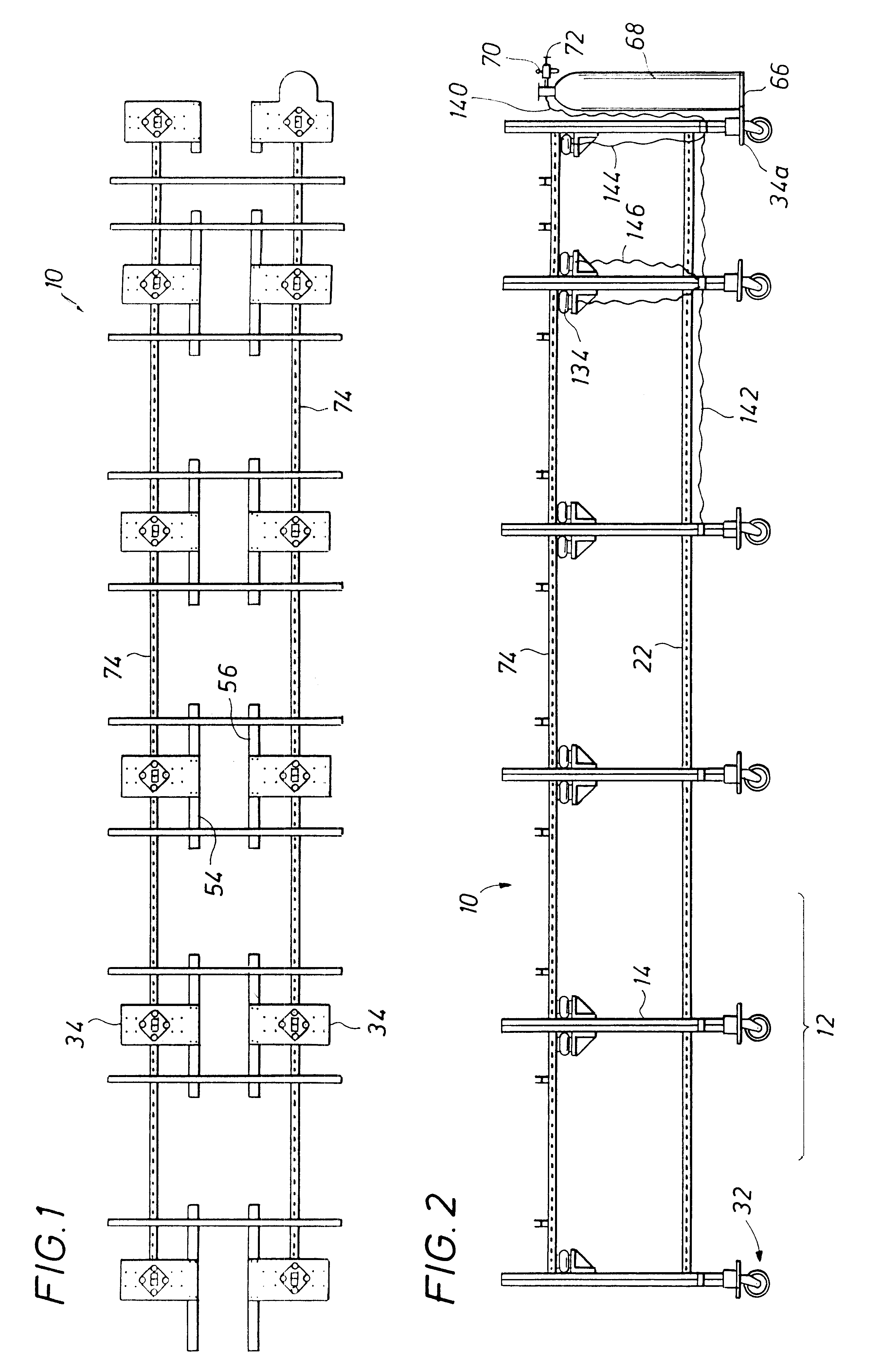

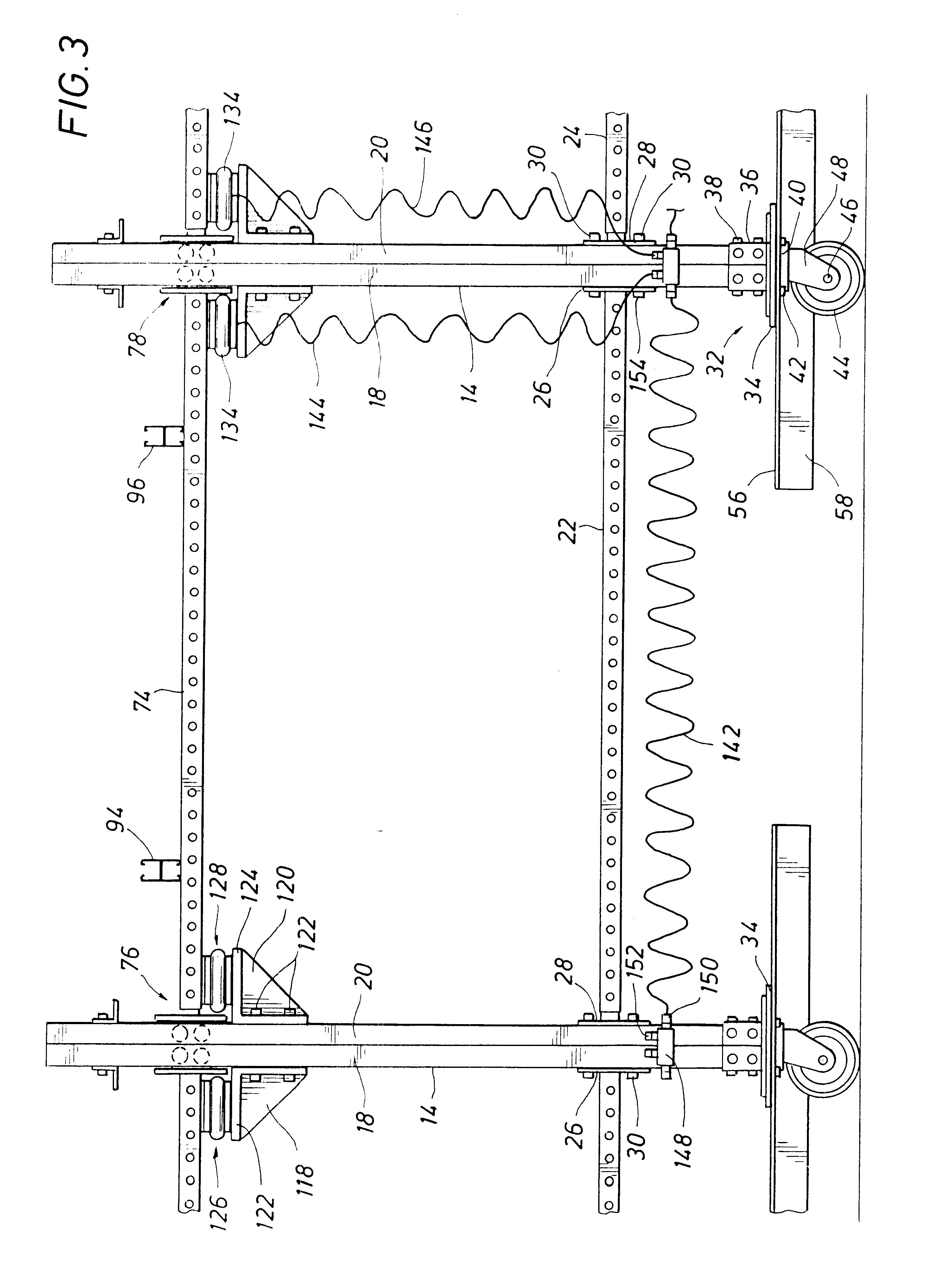

Pneumatic lift and movement system for shelving

A lifting and movement system for lifting a complete run of shelving having a plurality of shelf units and for moving the shelving along a floor surface to a desired location. First and second frame structures are defined by interconnected modular frame assemblies so as to have sufficient length to extend along the entire length of a run of shelving. Wheels such as casters are mounted to the first frame to provide for movement of the lifting system and the run of shelving along the floor surface to a desired location. A second, movable frame is in vertically movable assembly with the first frame and has shelving engaging components for lifting engagement with the run of shelving. A plurality of lift elements are supported by the first frame and provide support for the second frame and the shelving engaged thereby. A power system, which is preferably a pneumatic pressure supply is in controllable relation with each of the lift elements and is selectively actuatable for simultaneously activating each of the lift elements for simultaneous lifting or lowering of all of the modular sections of the second frame relative to the first frame to thereby provide for selective lifting or lowering the shelving.

Owner:UNIVERSAL AIRELEVATOR INC A FLORIDA

Detection of signaling molecules in a biological environment

InactiveUS20080145890A1Minimize impactSimple in natureMicrobiological testing/measurementBiological testingSignalling moleculesIntercellular space

A method of detecting and identifying bacteria, micro-organisms or plants in a liquid or gaseous medium, the bacteria, micro-organisms or plants being of the kind which produce signaling molecules in intercellular space. The method includes positioning a biosensor in the liquid or gaseous medium, the biosensor having a biolayer matched to specific signaling molecules to be detected whereby the biolayer is reactive thereto in a manner which varies operation of the sensor. Such variation of the operation of the biosensor is detected to thereby determine the presence and purpose of the bacteria, micro-organisms or plants in the liquid or gaseous medium.

Owner:P J EDMONSON

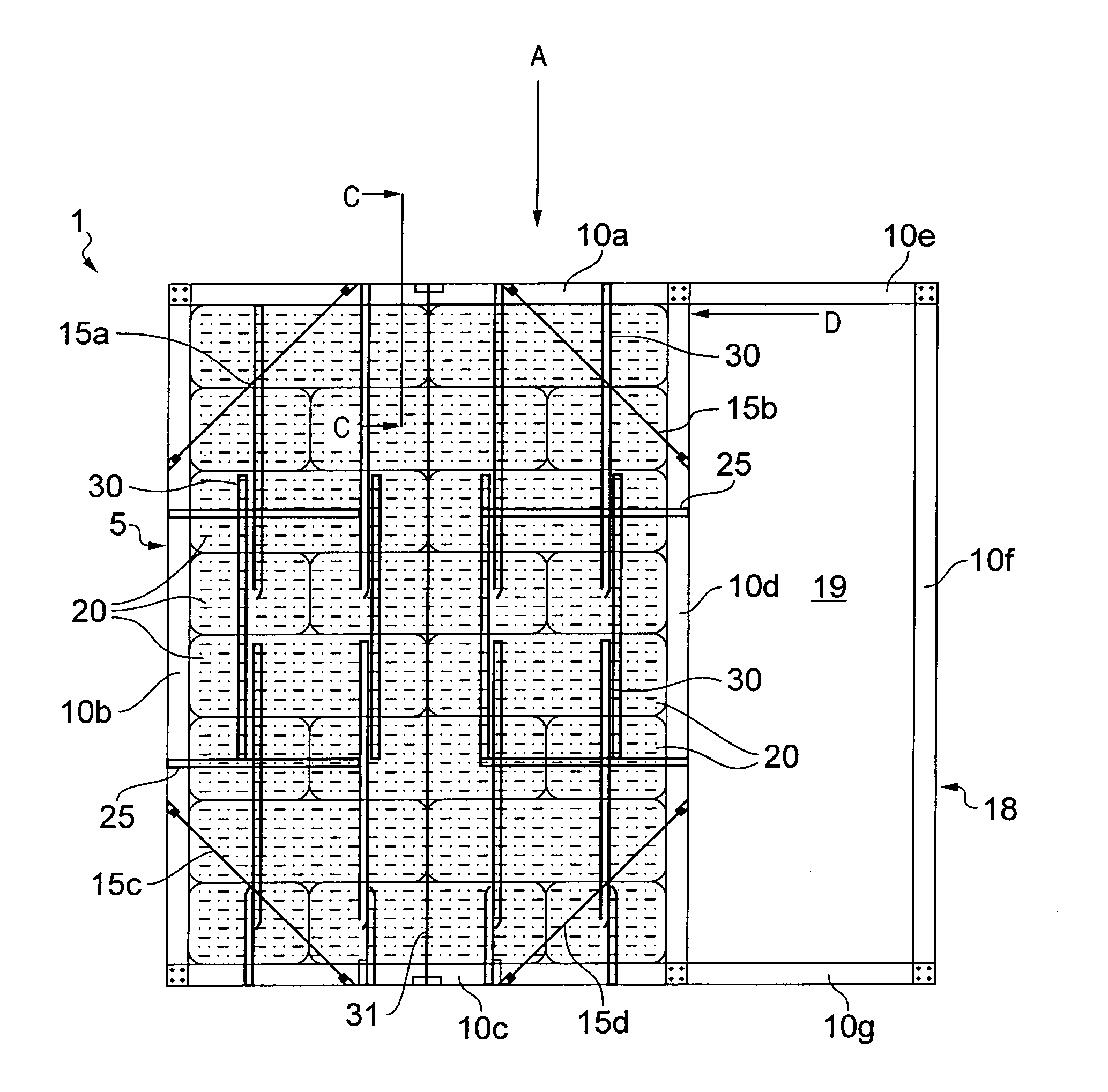

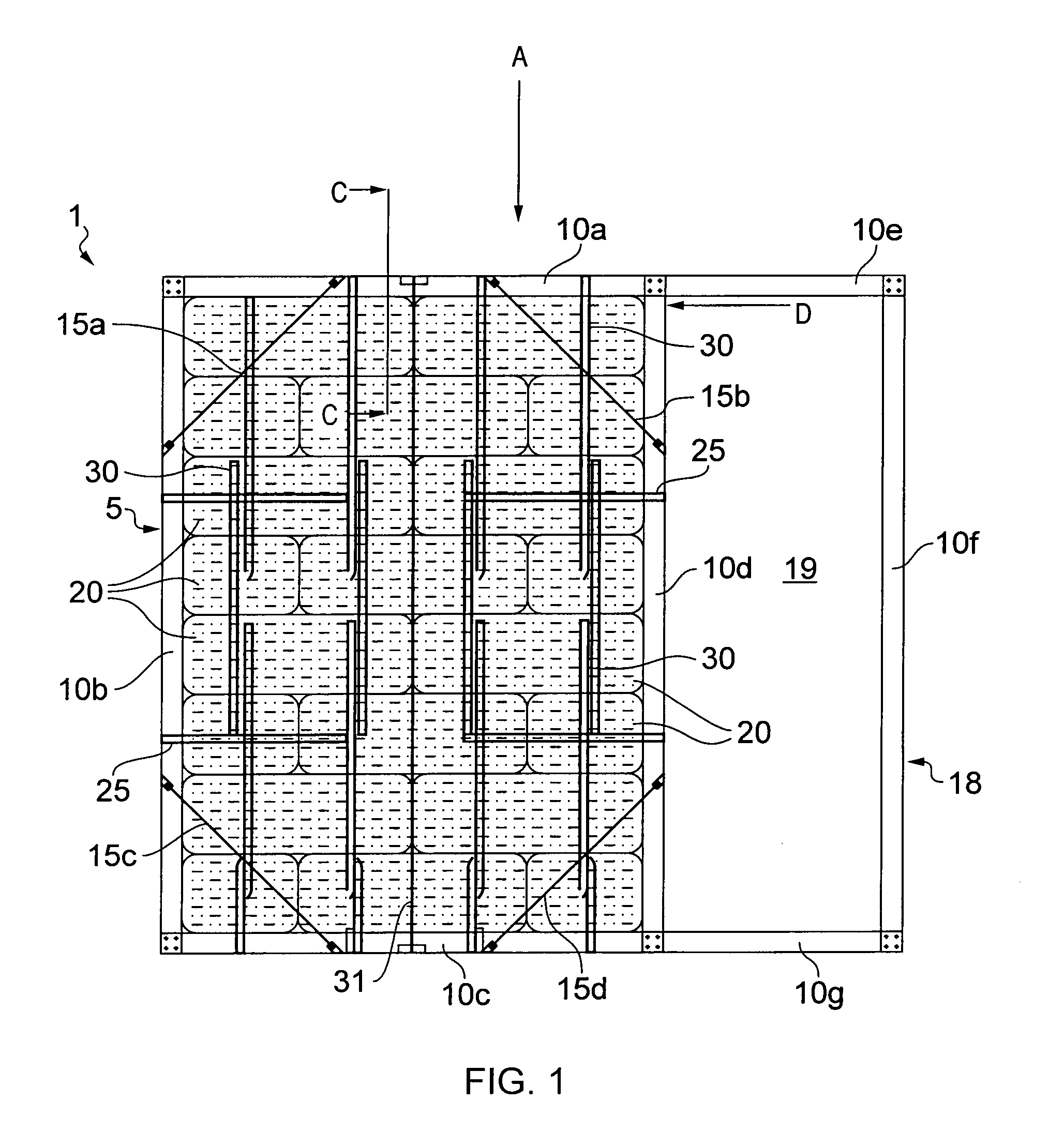

Construction panel

InactiveUS20110088338A1Reduce degradationReducing construction project durationConstruction materialTowersCelluloseBuilding construction

There is provided a construction element comprising a frame (5) and a plurality of cellulose bales (20), characterised in that the construction element further comprises at least one stabilising element (30) and in that the plurality of cellulose bales (20) is compressed. There is further provided a method of manufacture of such a construction element.

Owner:MODCELL

Systems and Apparatuses for Inserting an Implant in Intervertebral Space

ActiveUS20140236301A1PerformancePerforms betterJoint implantsSpinal implantsIntervertebral discIntervertebral space

Systems and tools for inserting and securing an implant within the intervertebral space. An intervertebral disc implant with upper and lower bearing members with an articulation interface between the members for providing relative motion therebetween. The implant may be provided with various securing members for fixing the implant within the intervertebral space. A tool may be used to insert the implant, which includes a plurality of shiftable implant engaging members that are shiftable between non-engaging and engaging configurations to alternatively release or hold the implant.

Owner:XTANT MEDICAL HLDG INC

Metal plate paint spraying method

InactiveCN109513593AEvenly distributed primerIncreasing the thicknessPretreated surfacesCoatingsLacquerCorrosion

The invention discloses a metal plate paint spraying method. The metal plate paint spraying method comprises the following steps: the surfaces of metal plates are cleaned to achieve smoothness, cleanness, no dust, no rust and no grease, and dirt and grease in scratches in the surfaces of the metal plates are removed in the scratching direction; the surface roughness of the cleaned metal plates isincreased; then, corrosion-resistance epoxy primers are sprayed to the surfaces of the metal plates; the surfaces of the metal plates are heated and dried by 15-25 min after spraying; the drying temperature is maintained within 165-175 DEG C; then, the surfaces of the dried metal plates are flatly grinded, and putty is scraped and coated in the uneven places of the surfaces; middle paint layers are sprayed to the surfaces of the metal plates after scraping of the putty; after all spraying, the metal plates are dried by 5-10 min; then, the metal plates are baked by 10-12 min through a short-wave infrared baking lamp; the metal plates are polished after total drying of the middle paint layers; and surface paint is sprayed to the surfaces of the metal plates for drying. The metal plate paintspraying method is simple and low in operation cost, and improves the mechanical performances and the glossiness of paint spraying layers.

Owner:扬州市广特机械制造有限公司

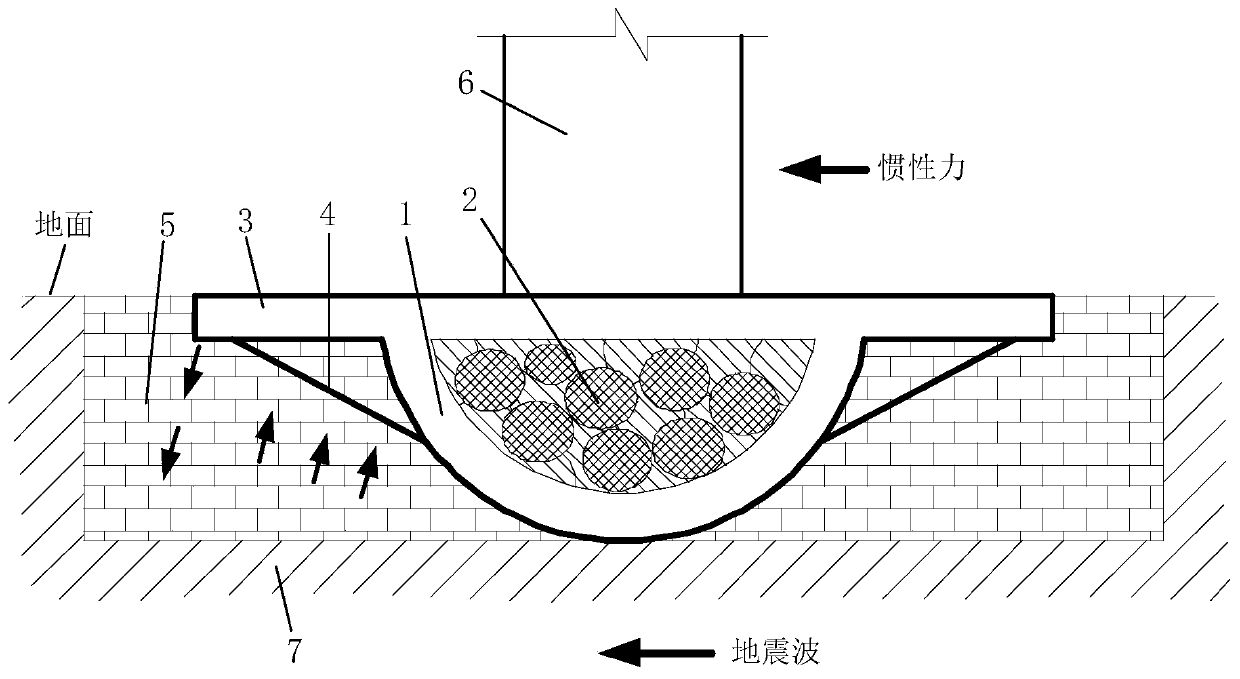

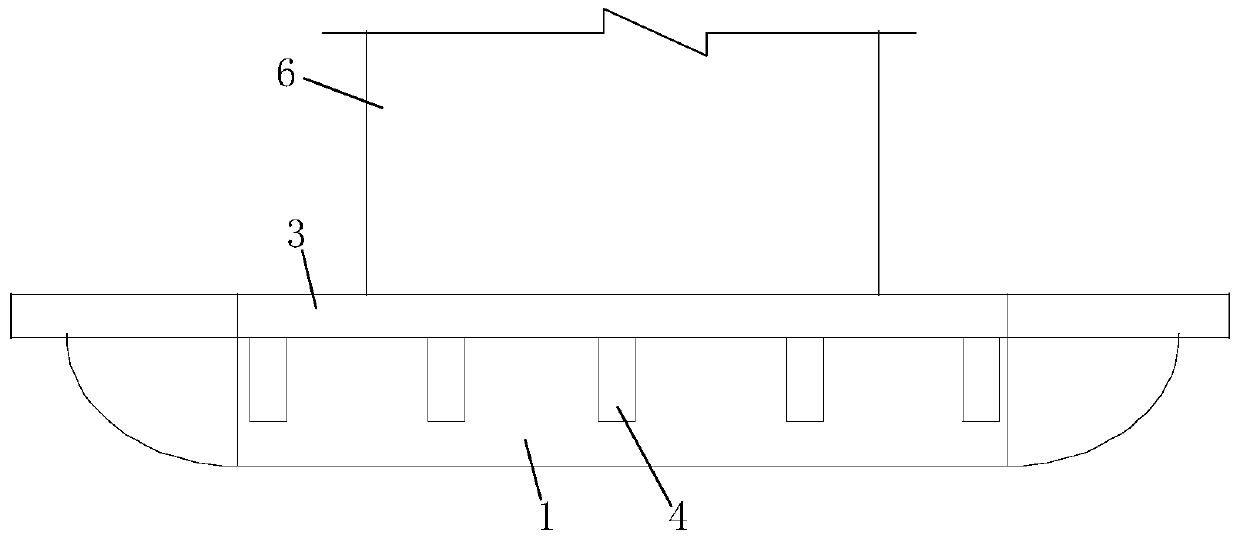

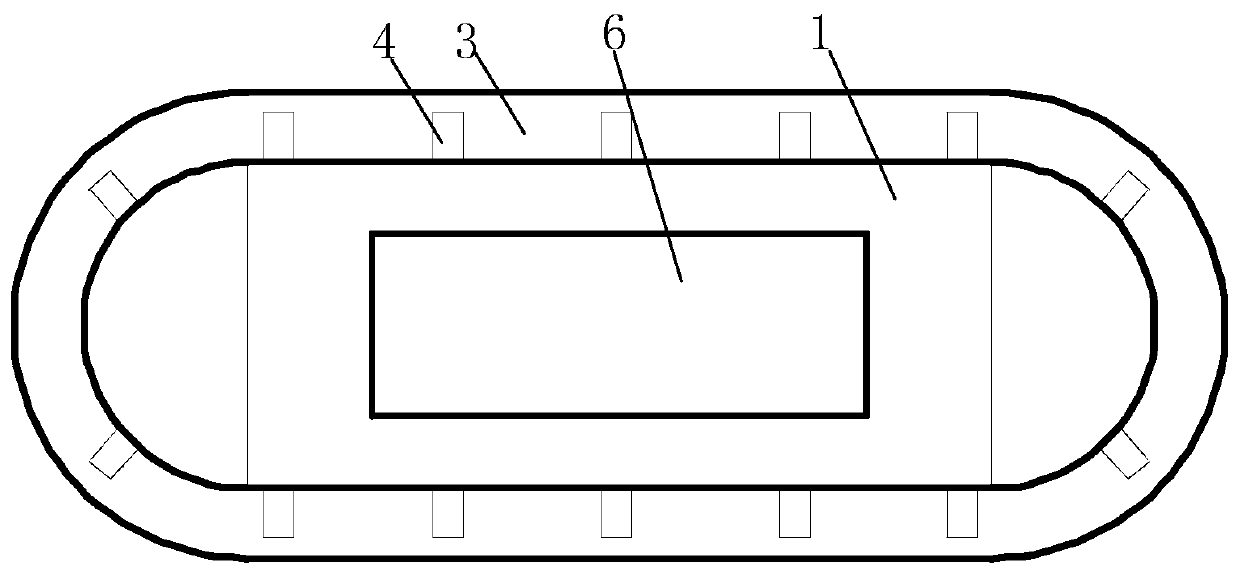

Building uncollapsed in earthquake and designed with ship shape and ballast stone principle

ActiveCN110344633AThe principle is simpleSimple structureCellarsFoundation engineeringEarthquake resistanceBallast

The present invention discloses a building uncollapsed in an earthquake and designed with a ship shape and ballast stone principle, belongs to the field of earthquake resistance of buildings and mainly solves the problem of damage and collapse of buildings in an earthquake. In the present invention, a building base is designed as a structure of a ship appearance, metal or non-metal with heavier specific gravity is used as a ballast stone structure, and a round of buffer plate is constructed on the outer edge of a ship board, so that when the earthquake occurs, the buffer plate crushes a subjacent buffer construction body and absorbs most of the impact force generated by the earthquake, so as to protect the building from being damaged during the earthquake. The angle between the bottom surface of a foundation pit, with which the building makes contact after the impact force of the earthquake is absorbed by the buffer plate, is designed to be 45 to 60 degrees. The building does not exceed the above angle under any circumstances, which can ensure the safety of personnel, equipment and the building itself.

Owner:胡松林

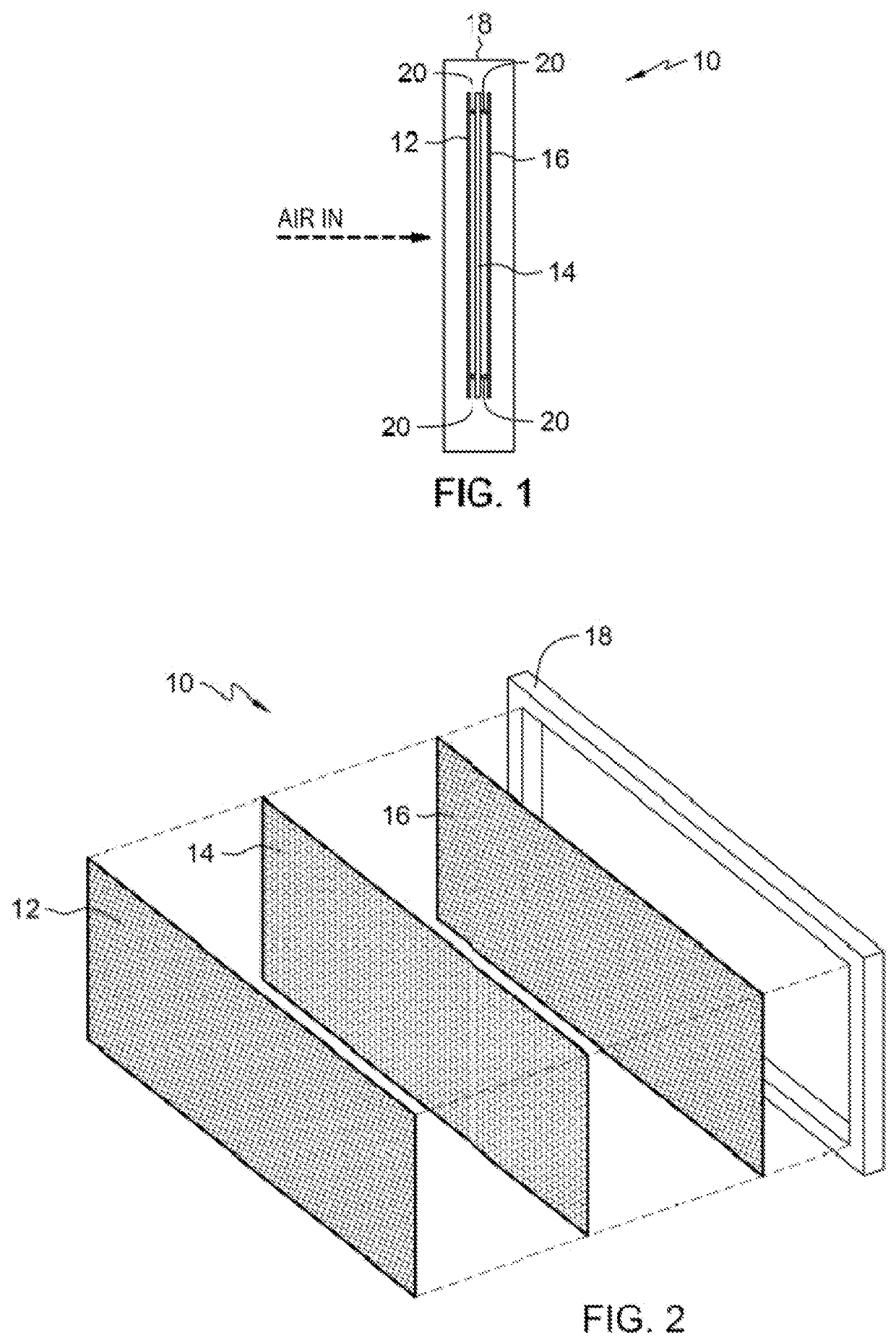

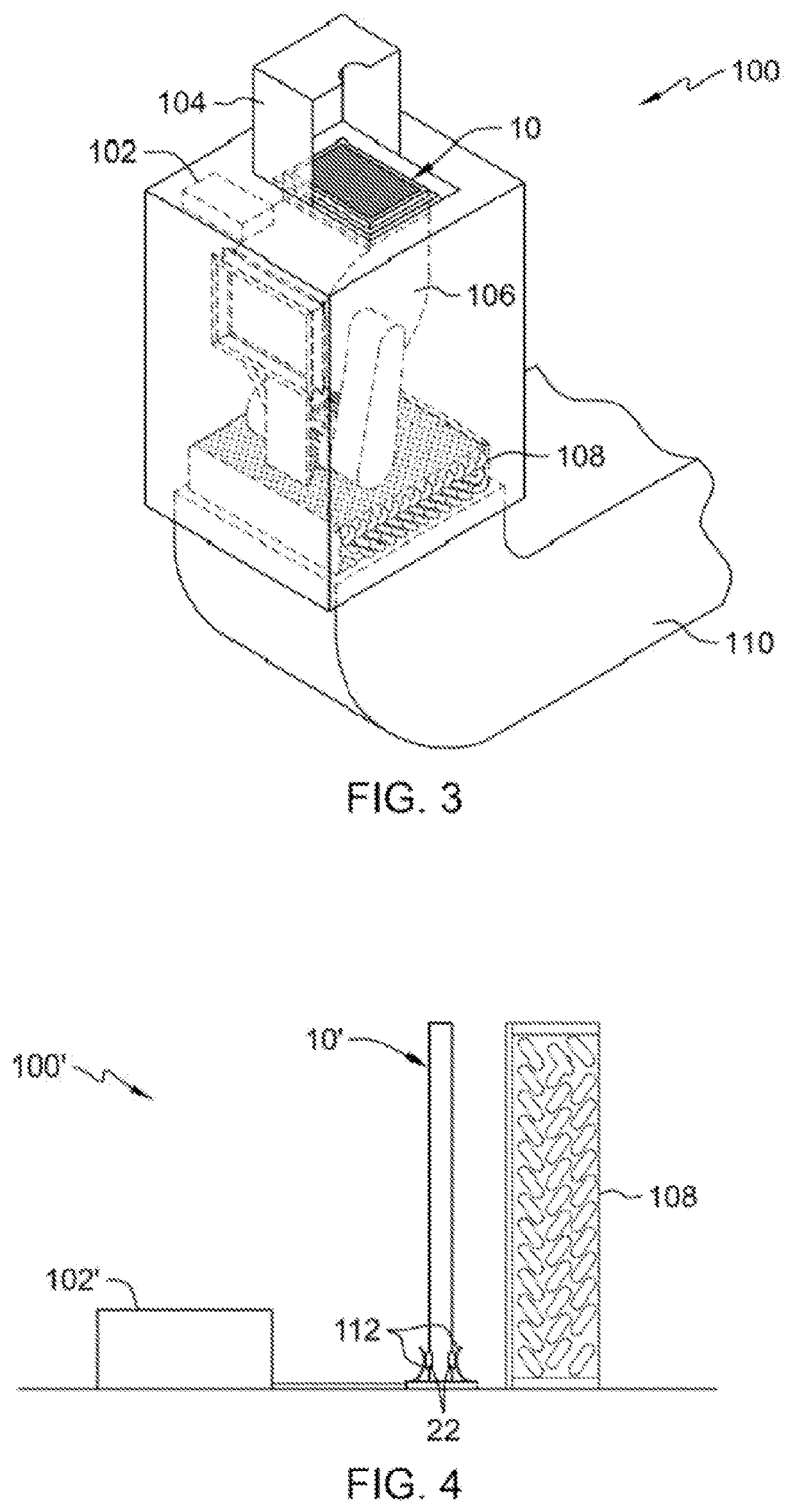

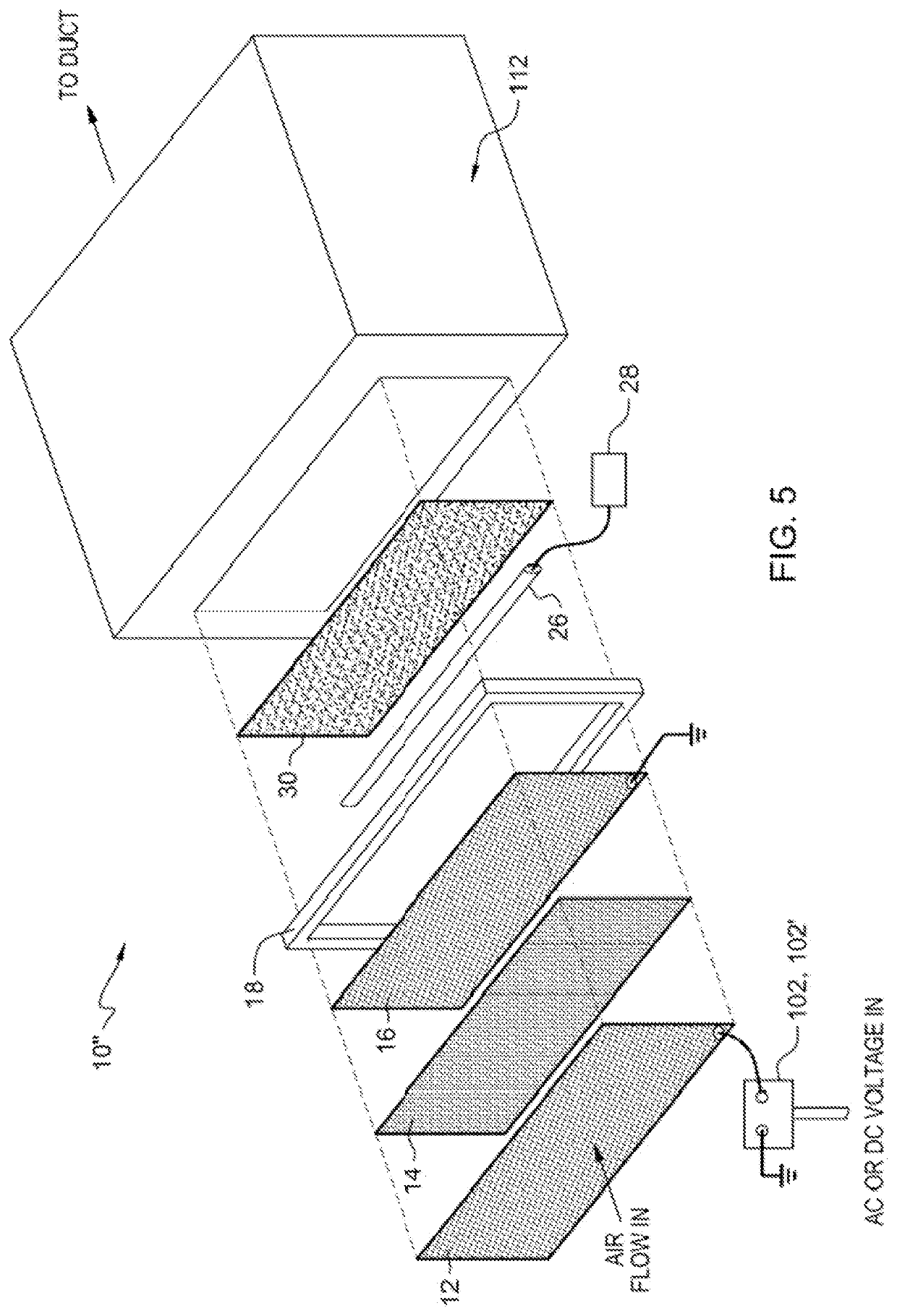

Anti-viral and antibacterial air filtration system

PendingUS20210396408A1Improve efficiencyIncrease airflowMechanical apparatusLighting and heating apparatusAir filtrationAir filter

An improved high-efficiency electrostatic air filter device implements a dust collection function and incorporates a material that captures and that is toxic to viruses / bacteria and causes viruses and bacteria to be rendered harmless by contact with this material. The device is composed of a charging section having a conductive antiviral media to charge any particles in the gas with a high electric voltage and a collecting section which contains or is composed of conductive material which has antiviral / antibacterial properties and a surface of opposite polarity or lower potential that will cause the aforementioned charged particles to adhere to the toxic material as the gas flows through or around the media. The collection section is formed with or coated by an inactivating material that inactivated pathogens when physically contacted.

Owner:SAIEVA CARL

High Viscosity Diutan Gums

ActiveUS20110282051A1Increase productionImproved viscosity propertiesSugar derivativesBacteriaBiotechnologyPhysical property

The production of a diutan polysaccharide exhibiting increased viscosity properties as compared with previously produced polysaccharide of the same type of repeating units. Such an improved diutan polysaccharide is produced through the generation of a derivative of Sphingomonas sp. ATCC 53159 that harbors a multicopy broad-host-range plasmid into which genes for biosynthesis of diutan polysaccharide have been cloned. The plasmid provides the capability within the host Sphingomonas strain to produce multiple copies of genes for such polysaccharide synthesis. In such a manner, a method of not just increased production of the target diutan polysaccharide, but also production of a diutan polysaccharide of improved physical properties (of the aforementioned higher viscosity) thereof is provided. Such a diutan polysaccharide has proven particularly useful as a possible viscosifier in oilfield applications and within cement materials. The inventive methods of production of such an improved diutan polysaccharide, as well as the novel cloned genes required to produce the improved diutan within such a method, are also encompassed within this invention. Additionally, the novel engineered Sphingomonas strain including the needed DNA sequence is encompassed within this invention.

Owner:CP KELCO U S INC

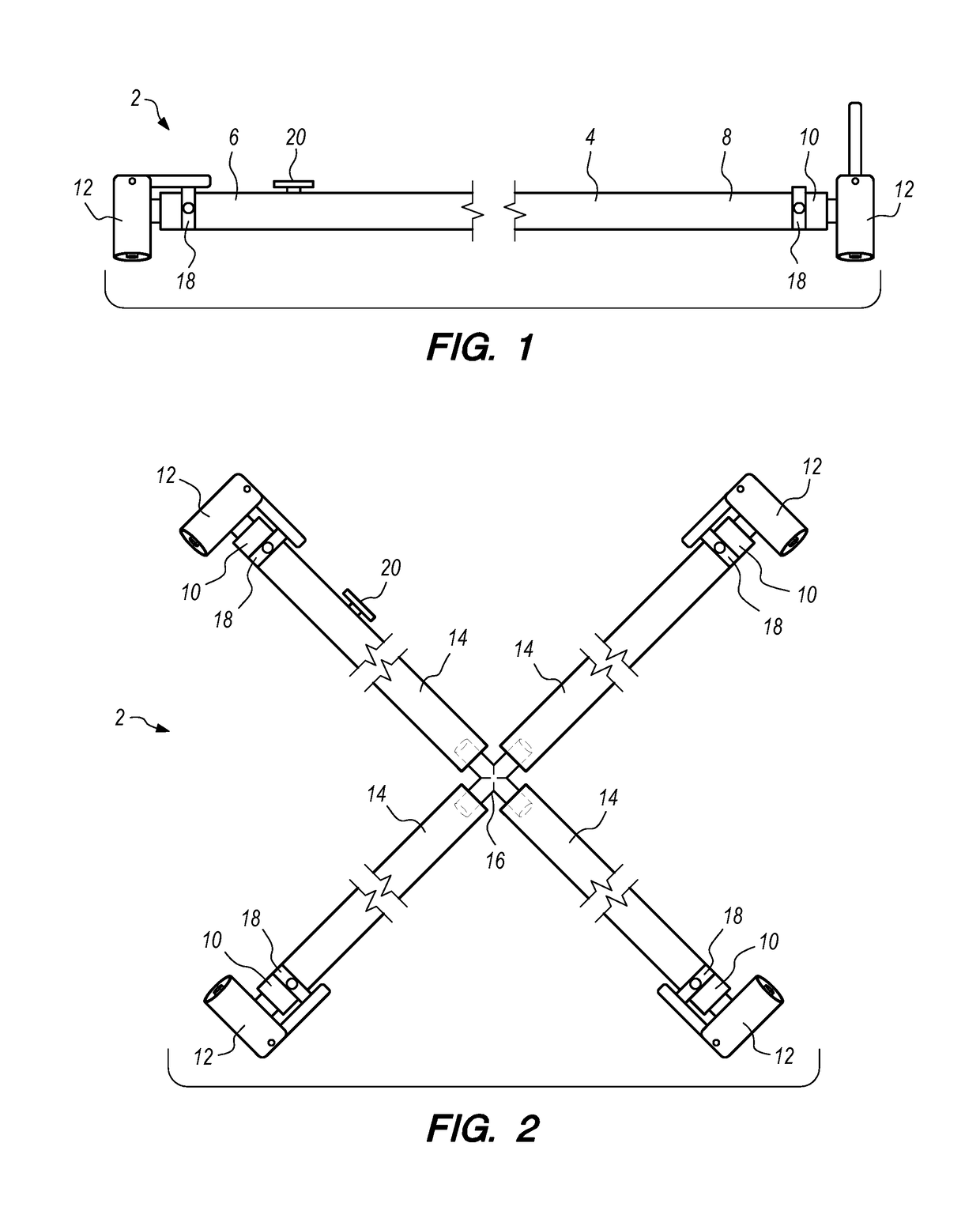

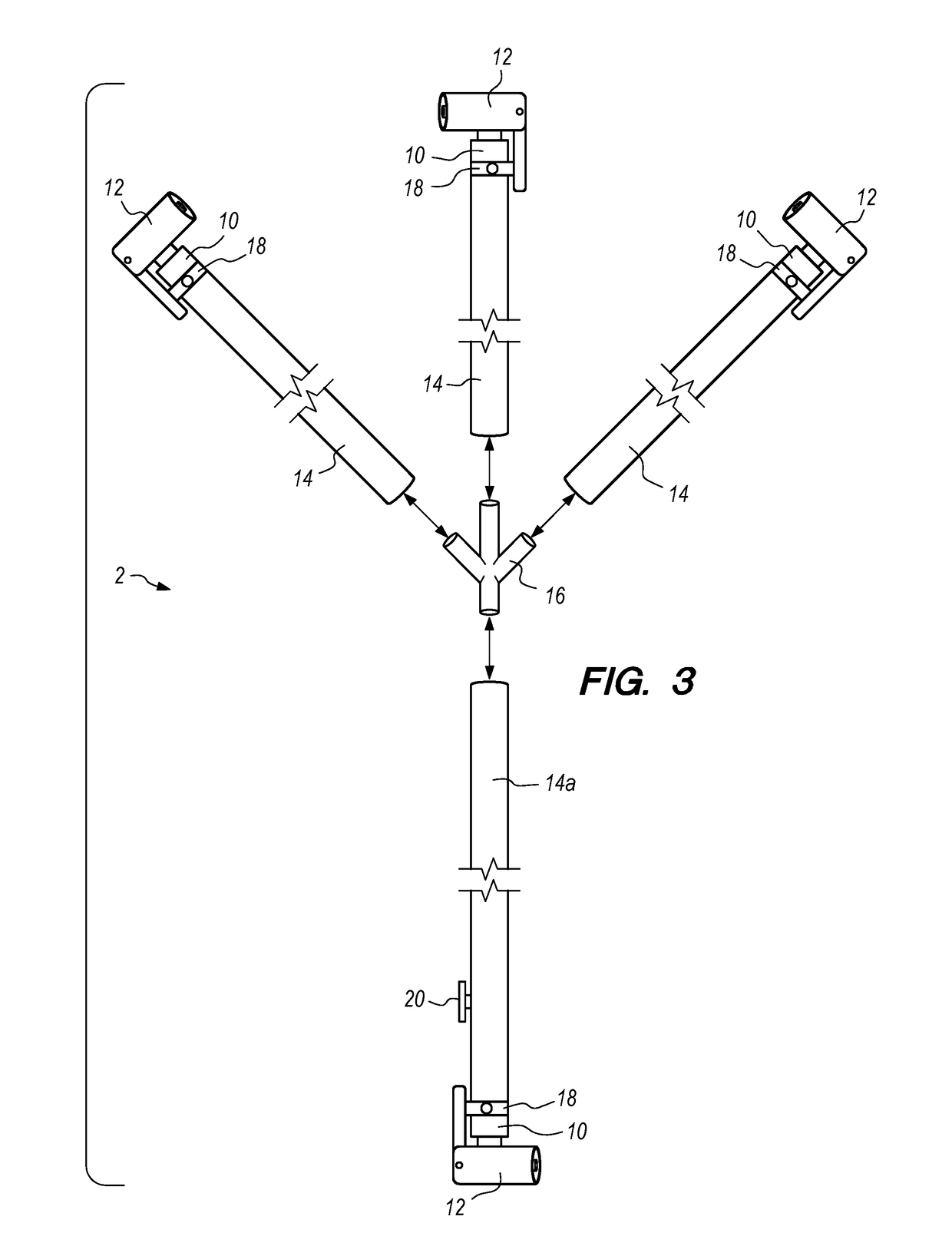

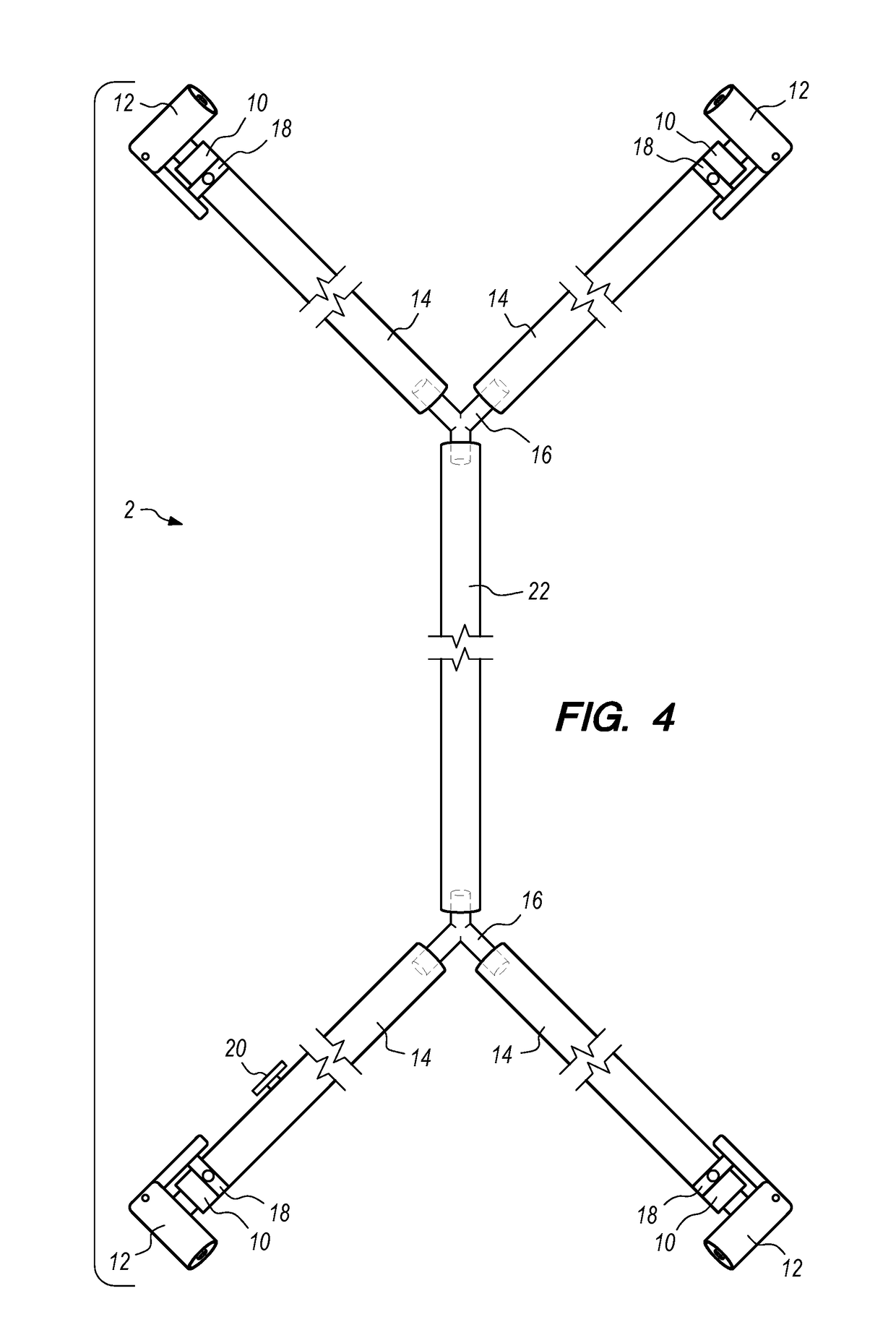

Tire Pressure Transfer Hose Assembly

InactiveUS20190077382A1Increase air pressureSimple in natureVehicle servicing/repairingHigh pressureElectrical and Electronics engineering

A hose assembly utilizing an internal lumen connecting multiple end ports, with one end port of the assembly configured to be connected to the air stem of a deflated tire and the other end port (or ports if there are more than two) are configured to be connected to the air stem of one or more additional tires of higher pressure, such that upon the opening of the end ports, air is transferred through the internal lumen from the higher pressure tire(s) until a sufficient amount of air has been input into the deflated tire to allow usage of the vehicle. Various configurations including a single, straight hose configuration or various branched configurations may be used to transfer air between tires in different situations.

Owner:NEWBURN JASON CHANCE

High pressure isolated latching safety switch device

A pressure switch is provided to arm a munition's fuze mechanism upon launch. The switch operation is based upon extreme gas pressures experienced during launch of the munition. The switch includes a piston contained in a housing. The piston translates due to launch pressures. The piston translation then causes a copper puck component to contact nearby electrical stab pins, to close a circuit. The closed circuit is then used to electrically arm the fuze mechanism.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

A kind of preparation method of metal chelate magnetic beads connected with tricarboxymethylethylenediamine

InactiveCN105126765BEasy to removeEasy to analyzeOther chemical processesAlkali metal oxides/hydroxidesEpoxyEthylenediamine

The invention relates to a preparation method of metal-chelated magnetic beads connecting tricarboxymethyl ethylenediamine. The preparation method comprises the steps: adding an alkali liquid to hydroxyl magnetic beads, and activating to obtain a mixture I containing the activated hydroxyl magnetic beads and the alkali liquid; adding dimethyl sulfoxide, epoxy chloropropane and sodium hydroxide with the concentration of 1 mol / L to the obtained mixture I, stirring for 12-14 hours at the temperature of 60 DEG C, and thus obtaining epoxy activated magnetic beads; adding a sodium bicarbonate solution and ethanediamine to the obtained epoxy activated magnetic beads, and carrying out slow oscillation for 20 hours at the temperature of 50 DEG C, to obtain processed epoxy activated magnetic beads; and adding a sodium hydroxide solution and a sodium bicarbonate solution to the obtained processed epoxy activated magnetic beads, mixing evenly, then adding bromoacetic acid, and stirring at room temperature, to prepare the metal-chelated magnetic beads connecting tricarboxymethyl ethylenediamine. The method is simple, and the prepared metal-chelated magnetic beads have strong metal binding ability and large combination capacity, and can be used for removing metal ions in solutions and biological macromolecules.

Owner:LUOYANG INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com