Semi-continuous decomposition device for gas hydrates

A gas hydrate, semi-continuous technology, used in gas fuel, grain processing, petroleum industry, etc., can solve the problems of not being able to re-storage gas, reduce hydrate decomposition rate, reduce temperature, etc., and achieve continuous and compact device structure. Wide applicability, low operating pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

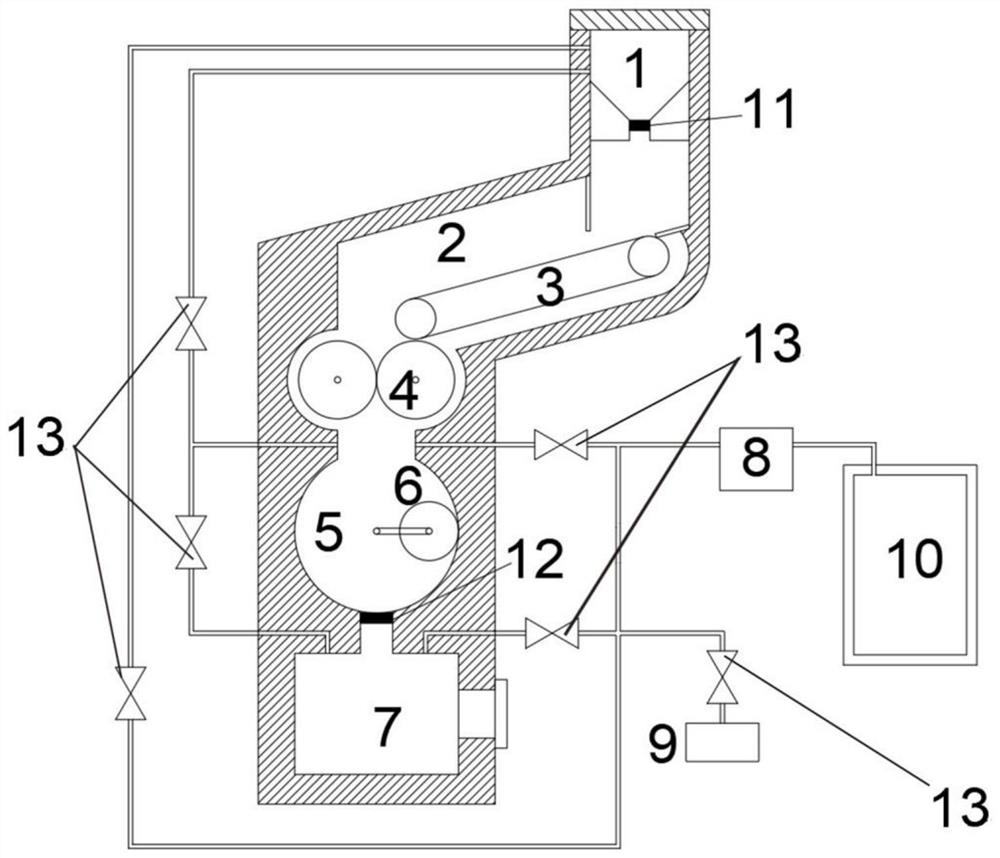

[0022] refer to figure 1 , is a gas hydrate semi-continuous decomposition device, including a feed bin 1, a pulverizing bin 2, a grinding bin 5, an ice storage bin 7, and an auxiliary system for storing gas for the device or adjusting the pressure inside the device; the feed bin 1 It is located on the upper part of the powder-making bin 2, and is used to add undecomposed hydrates into the device; one end of the powder-making bin 2 is connected to the bottom of the feed bin 1, and the other end is connected to the top of the grinding bin 5, and is used to crush massive hydrates into hydrate particles; grinding chamber 5 is provided with a grinding mechanism for grinding hydrate particles into ice powder, and the bottom of grinding chamber 5 is connected to the top of ice storage bin 7; feeding bin 1, milling bin 2, grinding bin 5, and ice storage bin 7 All are equipped with exhaust holes, and the auxiliary system includes an air storage and pressure regulating device, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com