Two-way screw conveying device

A conveying device, bidirectional spiral technology, applied in the field of lead powder conveying device, to achieve the effects of reduced coaxiality error, reduced load, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

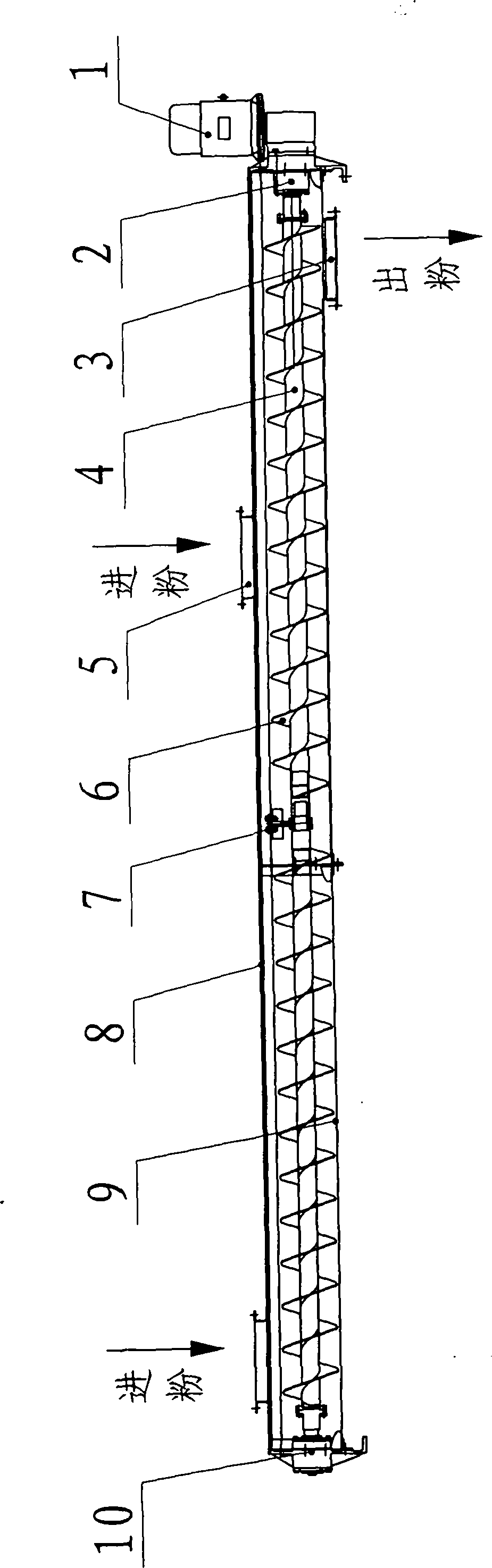

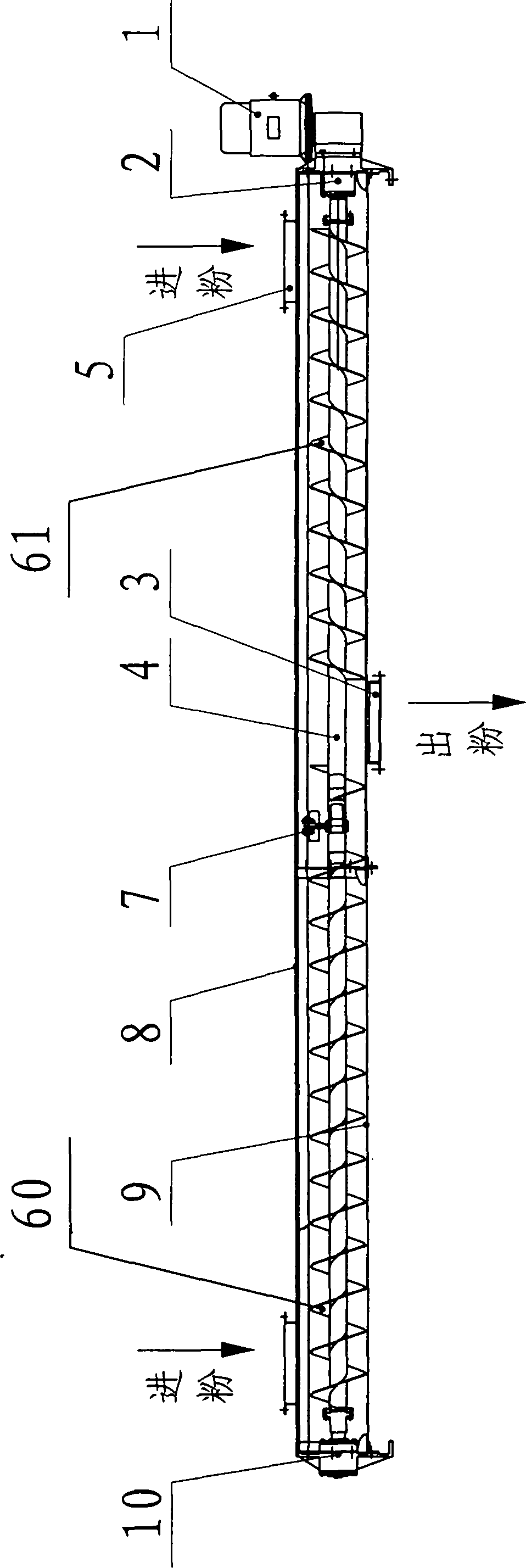

[0018] A two-way screw conveying device, including a geared motor 1, a drive assembly 2, a discharge port 3, a screw shaft 4, a feed port 5, a suspension bearing 7, a casing 9 and a driven assembly 10, the geared motor 1 is located on the machine One end of the shell 9, the driven assembly 10 is located at the other end of the casing 9, the geared motor 1 is connected to one end of the screw shaft 4 through the drive assembly 2, the other end of the screw shaft 4 is connected to the driven assembly 10, and the screw shaft 4 passes through the suspension bearing 7 is fixed, a forward helical blade 60 is provided on one section of the screw shaft 4, and a reverse helical blade 61 is provided on the other section of the helical shaft 4, and the two feed ports 5 are respectively located at the forward helical blade 60 and the reverse helical At the ends of both sides of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com