Seawall construction method with top pipes penetrating through block stone

A construction method and pipe jacking technology, which is applied in sea area engineering, water conservancy engineering, climate change adaptation, etc., can solve problems such as scrapped seawalls, high risk coefficients, and inability to clean up rocks, and achieve the effect of reducing engineering risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] The pipe jacking construction method of the present invention crossing the rocky seawall comprises:

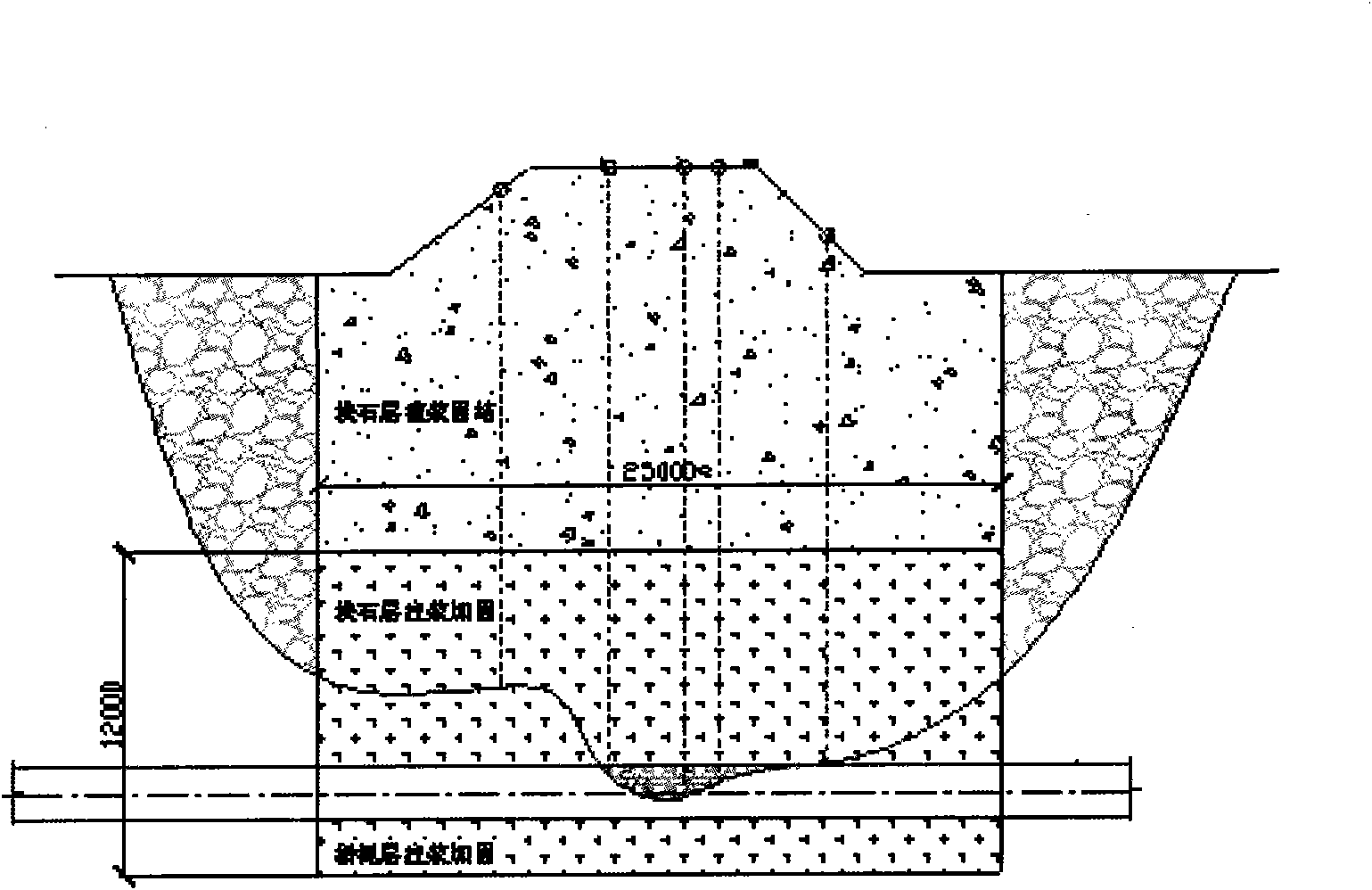

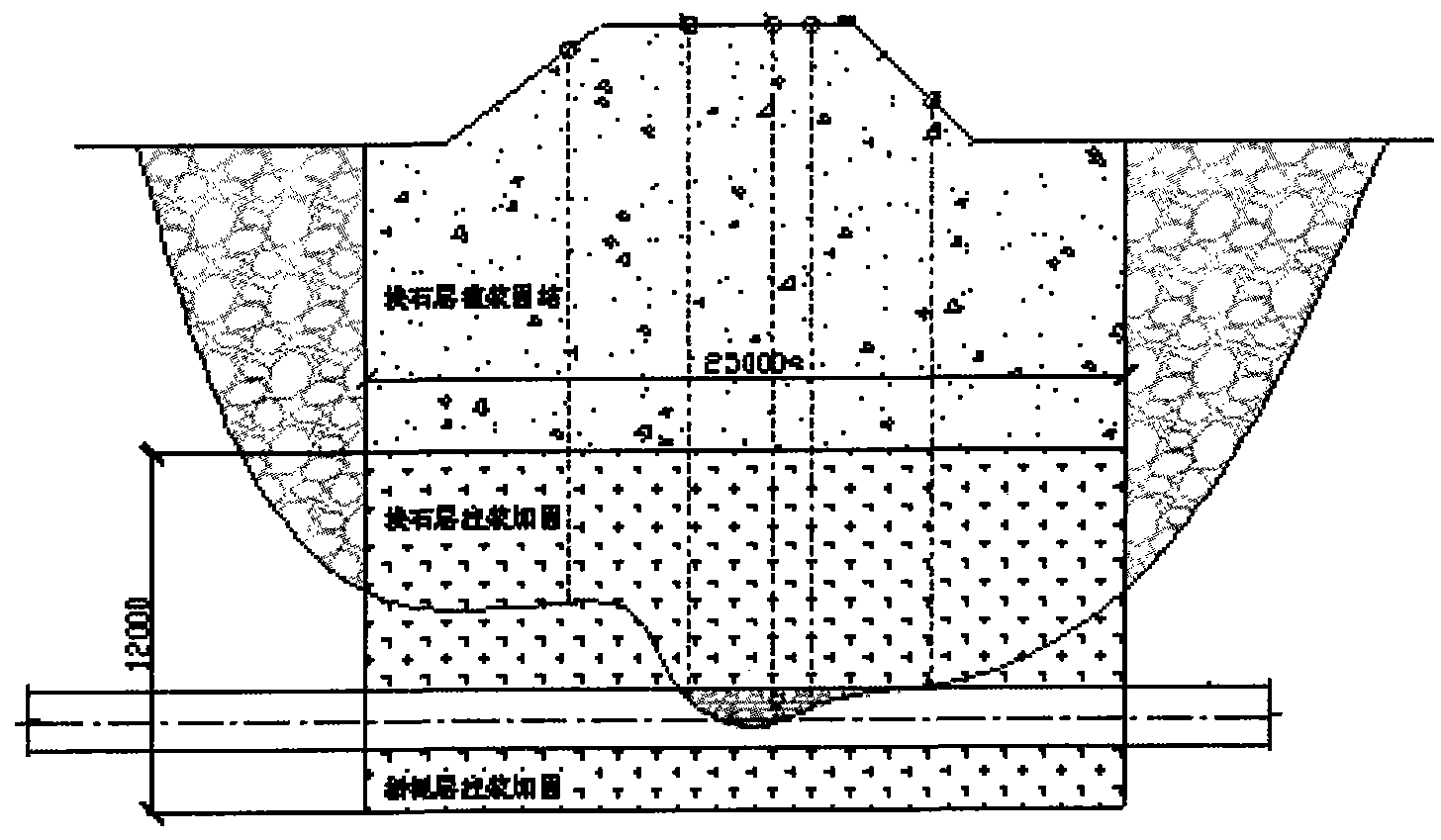

[0037] 1. Stone seawall treatment

[0038] According to the original geological data and the geological data of supplementary survey, the buried depth of the deepest layer of the Huichi seawall block is -23.47m. At present, the distance between reconnaissance points is 4m, which cannot fully and accurately reflect the situation of rocks along the pipe jacking line. Considering the uncertainty of the length and depth of pipe jacking affected by rocks on the seawall, during the reinforcement construction, the reinforcement shall be carried out from the deepest point in the current survey to both sides; according to the reinforcement drilling situation, the length and depth affected by rocks along the pipe jacking line shall be further ascertained....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com