Warm-air furnace used for high temperature sterilization

A technology of high-temperature sterilization and hot air stove, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of medium and culture equipment pollution, complicated design of hot air stoves, and reduce the output of edible fungi, etc., to achieve Save the use of labor and labor, improve energy utilization, and avoid the effect of excessive heat concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

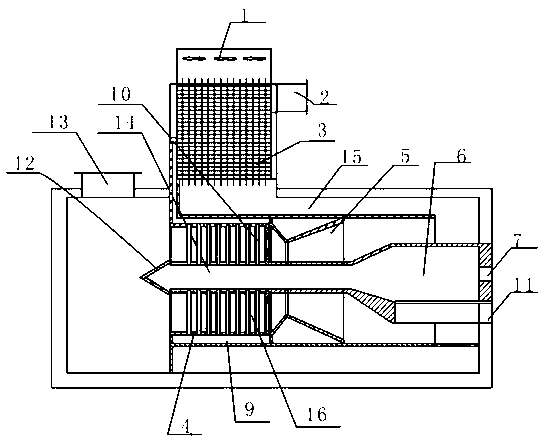

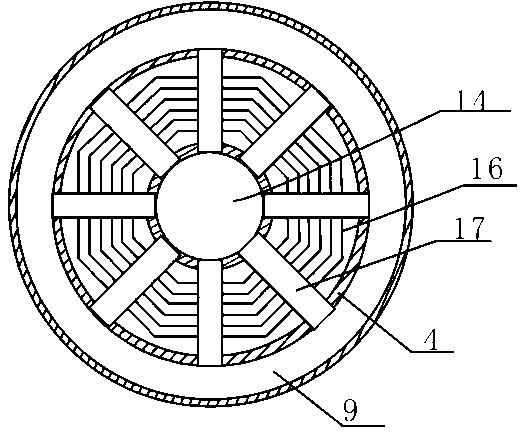

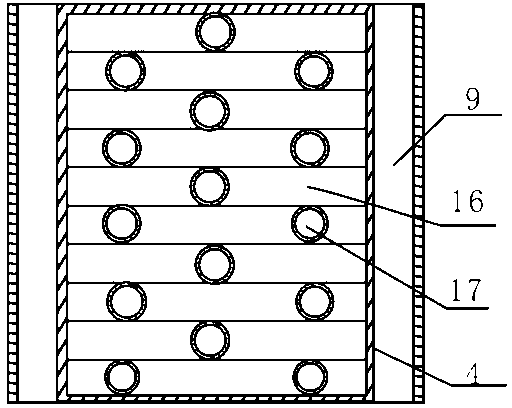

[0022] As shown in the figure, a hot air stove for high-temperature sterilization includes a boiler, a cooling fan 1, a primary heat exchanger 3 and a secondary heat exchanger 10. The boiler is composed of a furnace 6 and a heat collecting cylinder 14. The heat collecting cylinder 14 is horizontally arranged and communicated with the furnace 6, the secondary heat exchanger 10 is set outside the heat collecting cylinder 14, the secondary heat exchanger 10 includes the air cylinder 4 and the hot air pipe 17, and the air cylinder 4 is set on the circumference of the heat collecting cylinder 14 On the outside of the air cylinder 4, an air guide channel 9 is also provided, and a heat exchange channel 16 is formed between the air tube 4 and the heat collecting tube 14. The hot air pipe 17 is arranged in the heat exchange channel 16 and connects the air guide channel 9 with the heat collecting tube 14. The heat collecting cylinder 14 is connected; the primary heat exchanger 3 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com